Plasma synergistic resistance furnace fly ash treatment system and treatment method

A treatment system and plasma technology, which is applied in the field of fly ash treatment in an ion cooperative resistance furnace, can solve the problems of exceeding the leaching limit, high operating costs, and the inability to fundamentally eliminate heavy metal pollution in fly ash, so as to reduce oxidation and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

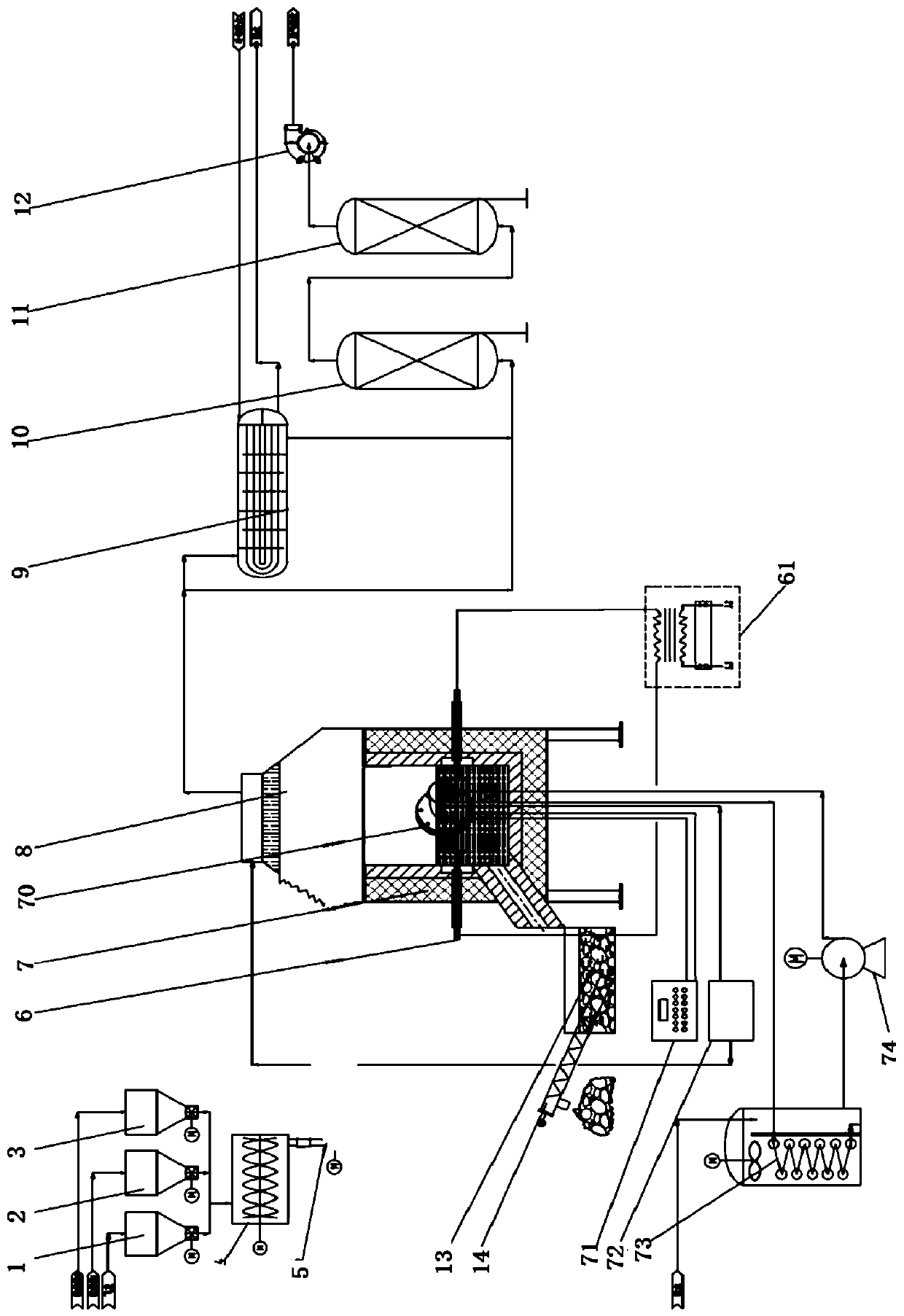

[0055] The plasma cooperative resistance furnace ash treatment system provided by the present invention includes a feeding system, a melting and solidification system and a flue gas discharge system;

[0056] Described feeding system comprises feeding funnel, the mixer 4 that is communicated with feeding funnel outlet, the spreader 5 that is connected with mixer outlet; Feeding system is made up of three feeding funnels, and each feeding funnel is communicated with mixer respectively, will Add all materials to the blender and mix. Each hopper is equipped with a rotary sealing valve, which isolates the air through the material seal generated during the feeding process, so that the entire melting process is in an oxygen-deficient process. The spreader is equipped with an automatically rotating rake, which is used to evenly spread the material on the surface of the entire molten inner liquid surface.

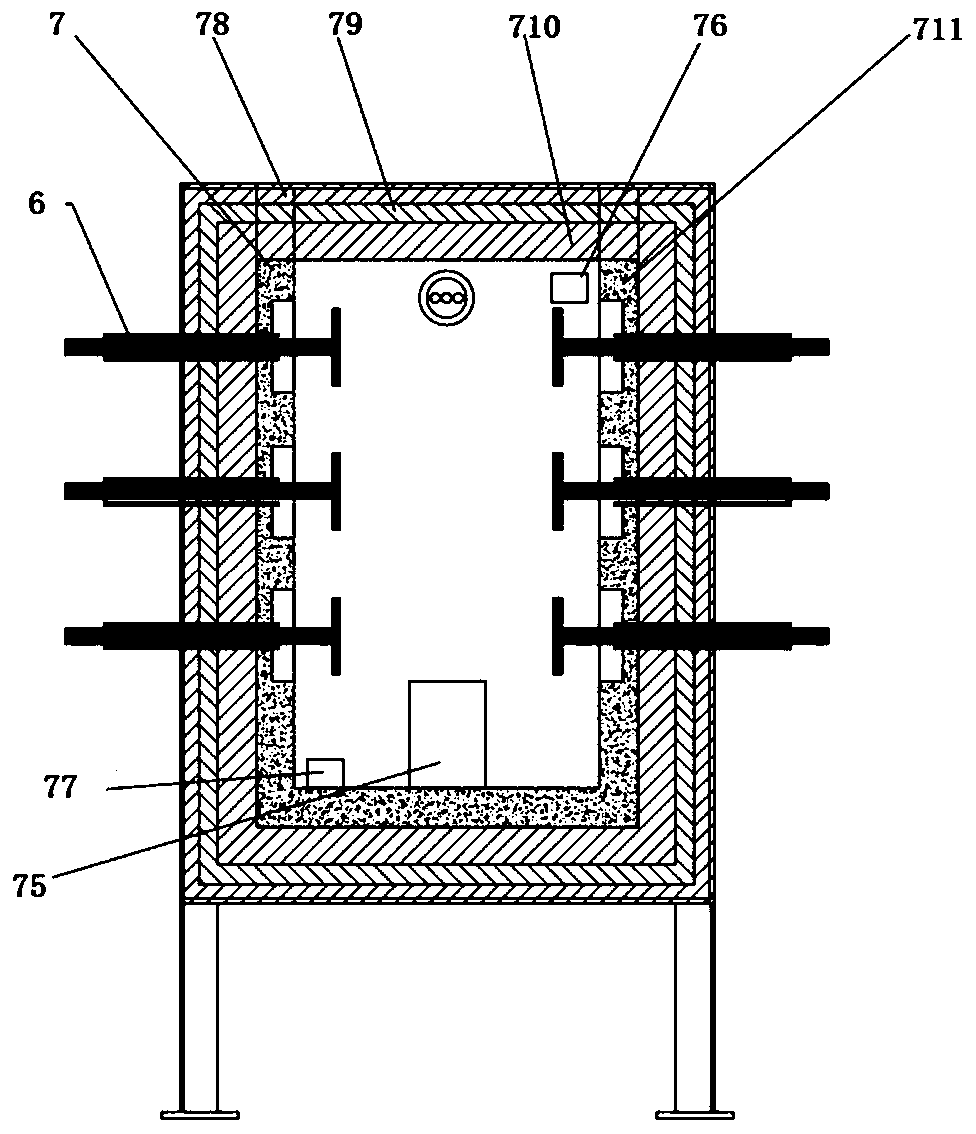

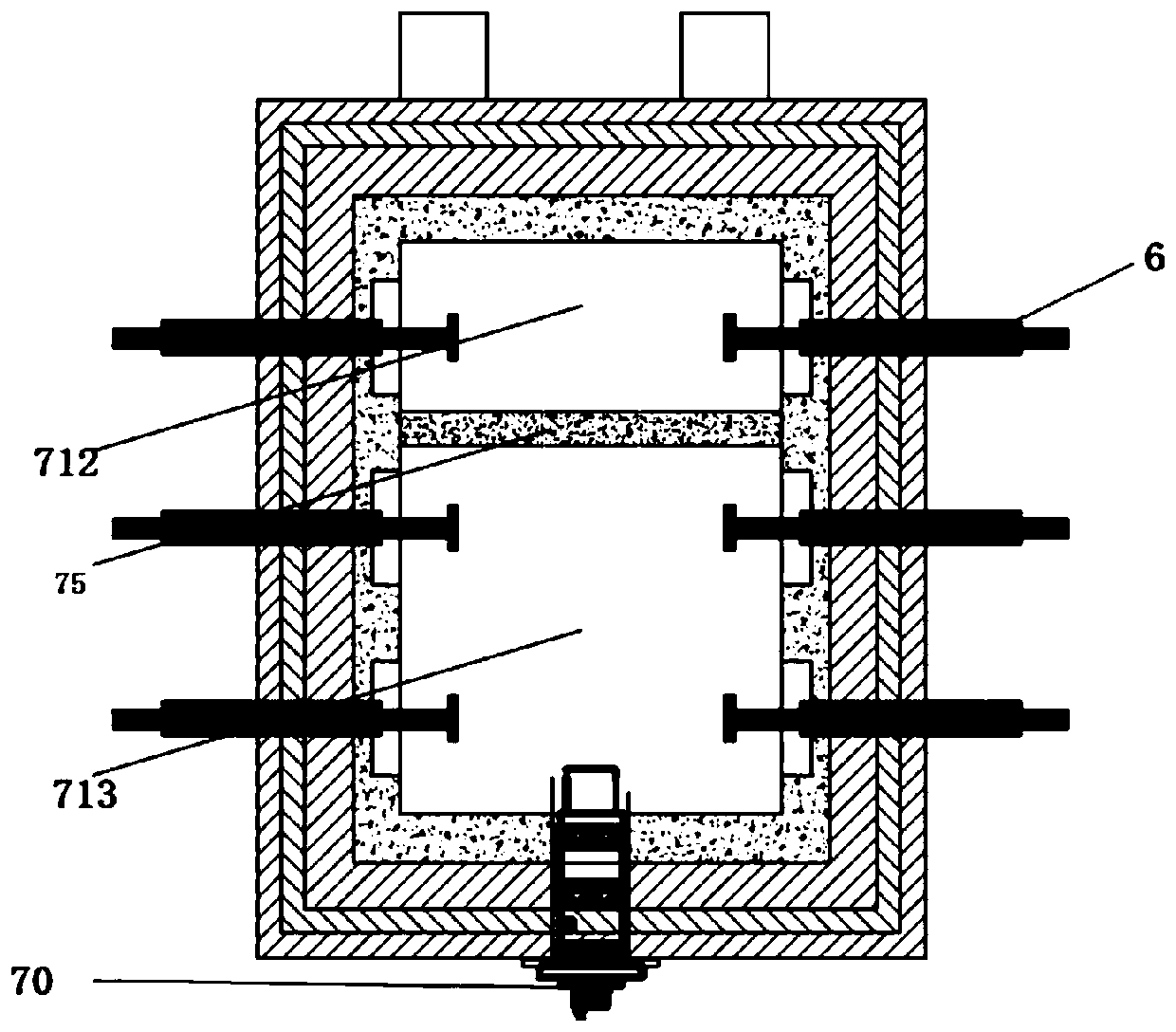

[0057] The melting and solidification system includes a melting furnace 7 for m...

Embodiment 2

[0068] This implementation is to deal with fly ash of vertical cylindrical hazardous waste. First start the water pump 74 of the plasma cooling water system, and then start the nitrogen generator 72. When the dissolved oxygen meter on the gas outlet pipeline of the melting furnace 7 is <0.1mg / L, start the plasma power supply 71. At this time, the nitrogen gas passes through the high pressure in the plasma torch 70. After the ionization, a plasma flow is generated to heat the melting furnace 7 to raise the temperature. During the heating process, the bypass cooler 9, the denitrification tower 10, the desulfurization tower 11 and the flue gas fan 12 are turned on. The water passing through the plasma torch enters the cooling tower 73 for cooling, so that the temperature of the water entering the plasma torch is <40° C., and then is pumped into the plasma torch by the water pump 74 to cool the cathode and anode of the plasma torch. After heating up to 1200°C, continuously add cu...

Embodiment 3

[0071]This embodiment is to process the fly ash of mechanical grate type medical waste. First start the water pump 74 of the plasma cooling water system, and then start the nitrogen generator 72. When the dissolved oxygen meter on the gas outlet pipeline of the melting furnace 7 is <0.1mg / L, start the plasma power supply 71. At this time, the nitrogen gas passes through the high pressure in the plasma torch 70. After the ionization, a plasma flow is generated to heat the melting furnace 7 to raise the temperature. During the heating process, the bypass cooler 9, the denitrification tower 10, the desulfurization tower 11 and the flue gas fan 12 are turned on. The water passing through the plasma torch enters the cooling tower 73 for cooling, so that the temperature of the water entering the plasma torch is <40° C., and then is pumped into the plasma torch by the water pump 74 to cool the cathode and anode of the plasma torch. After heating up to 1200°C, continuously add cullet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com