Garbage three-phase separation treatment process

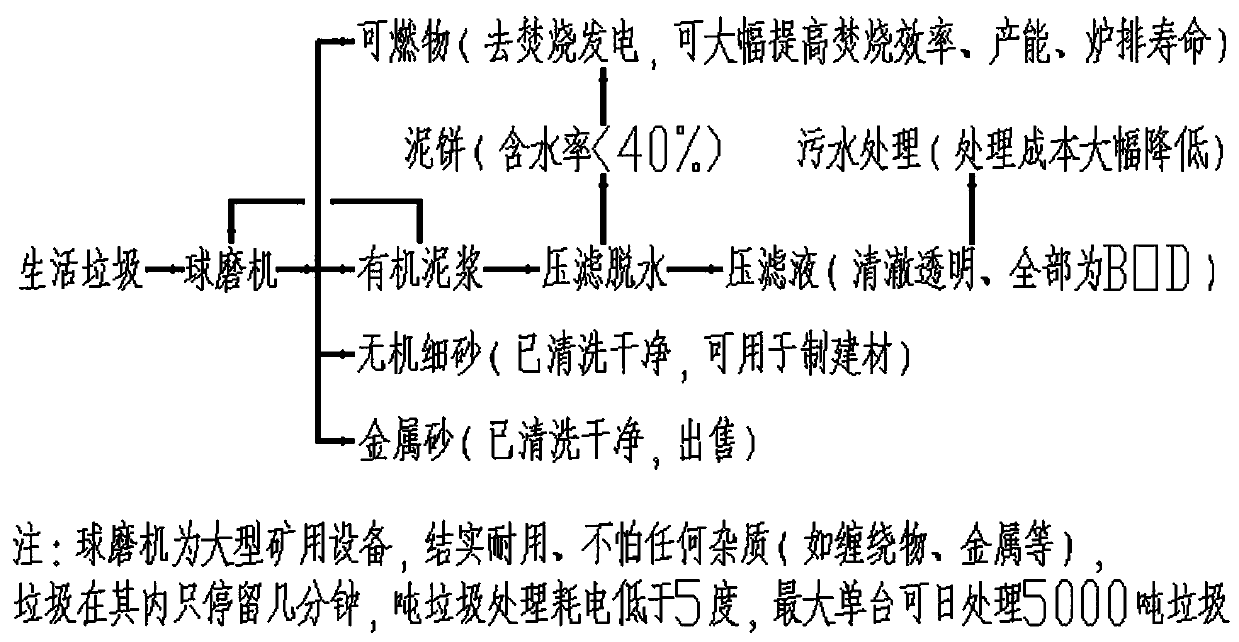

A three-phase separation and treatment technology, applied in the field of garbage disposal, can solve the problem of inability to separate garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

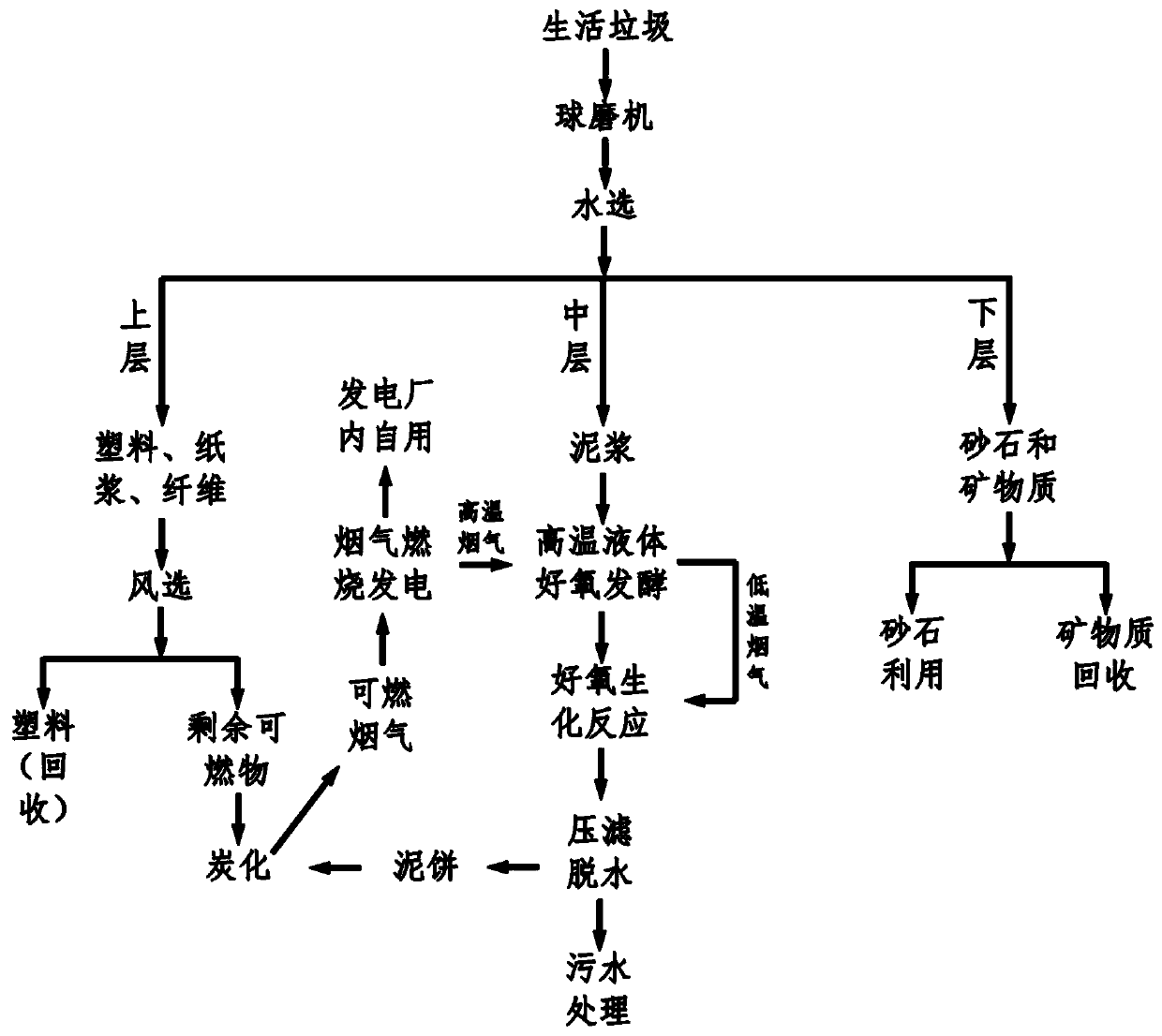

[0037] Embodiment 2. On the basis of Embodiment 1, the upper layer of combustible materials separated from garbage water is closed and carbonized, and a large amount of combustible gas is produced in the carbonized water. The combustible gas is burned to generate hot air at about 800 degrees, which is used to dry mud Cake and combustible garbage, the remaining waste heat is passed into the mud furnace to heat the mud, the heat in the flue gas is transferred to the mud, and the temperature of the mud rises to about 100 degrees for ultra-high temperature liquid aerobic composting.

Embodiment 3

[0038] Embodiment 3, on the basis of Embodiment 1 or 2, after waste gas passes through ultra-high temperature liquid aerobic composting, waste heat is utilized through a waste heat generator, and the waste heat generator adopts a Rankine generator;

[0039] After the waste heat is utilized, the temperature of the exhaust gas is reduced to about 35 degrees, and the activated sludge aeration pipe is used for washing and condensation to remove harmful substances in the exhaust gas and reduce the temperature of the exhaust gas;

[0040] The internal suspension filler is a biofilm filler, a spherical composite filler, and the material is PE, which increases the area of microbial attachment, increases the concentration of sludge in the biochemical reactor, and improves the efficiency of biochemical treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com