Preparation method of photo-thermal seawater desalination film based on tea and photo-thermal seawater desalination film

A photothermal and tea powder technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of membrane material durability, complicated preparation, and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a tea-based photothermal seawater desalination membrane is characterized in that the method comprises the following steps:

[0022] (1) Grinding the tea into tea powder after drying;

[0023] (2) dispersing the tea powder into a solvent to obtain a dispersion;

[0024] (3) The dispersion liquid is vacuum filtered onto the filter membrane to obtain a photothermal seawater desalination membrane.

[0025] Wherein, the tea can be tea leaves and / or tea dregs after brewing tea leaves; from an economic point of view, tea dregs after brewing tea leaves are preferred.

[0026] In the embodiment of the present invention, for the convenience of experiments, the tea residues are obtained by brewing tea leaves by the inventor himself, for example, by brewing, extracting and drying the tea leaves for 3-5 times. In industry, tea dregs can be obtained in large quantities at low cost, for example, by purchasing discarded tea dregs when tea beverage companies pro...

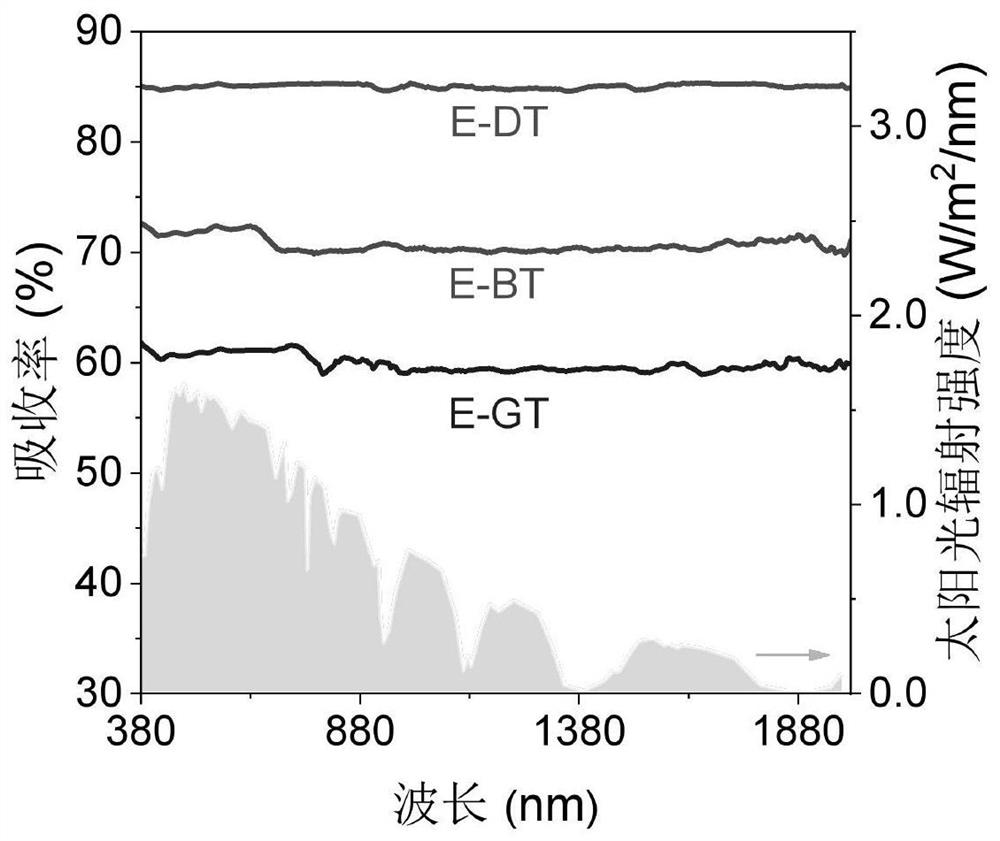

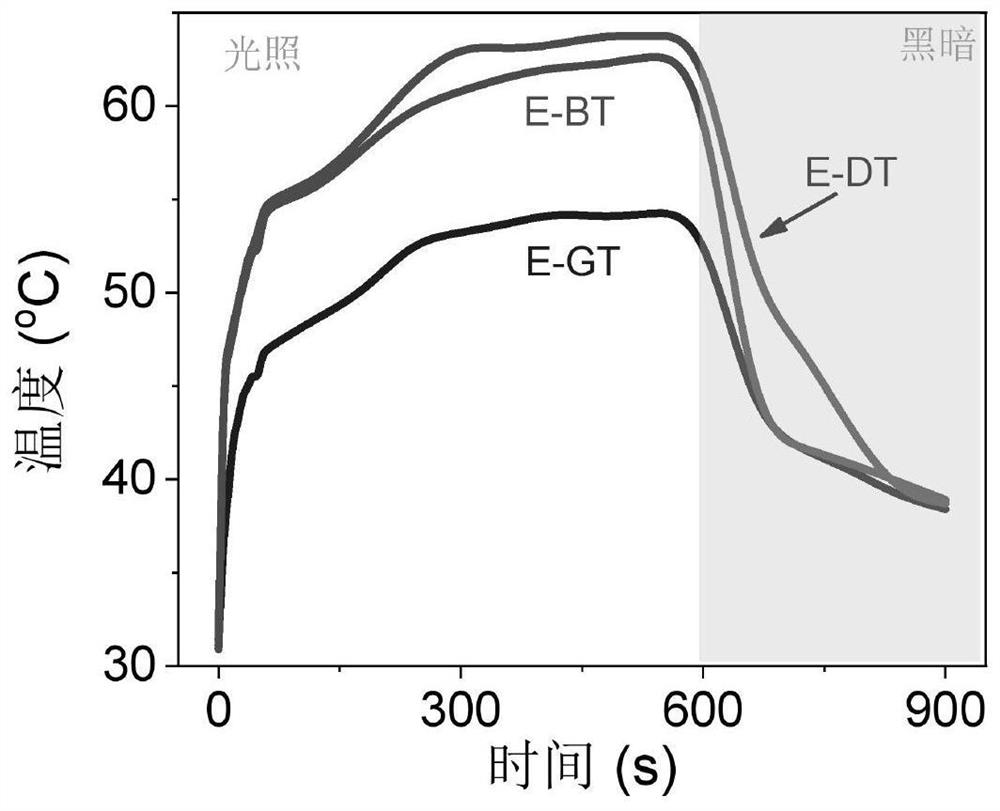

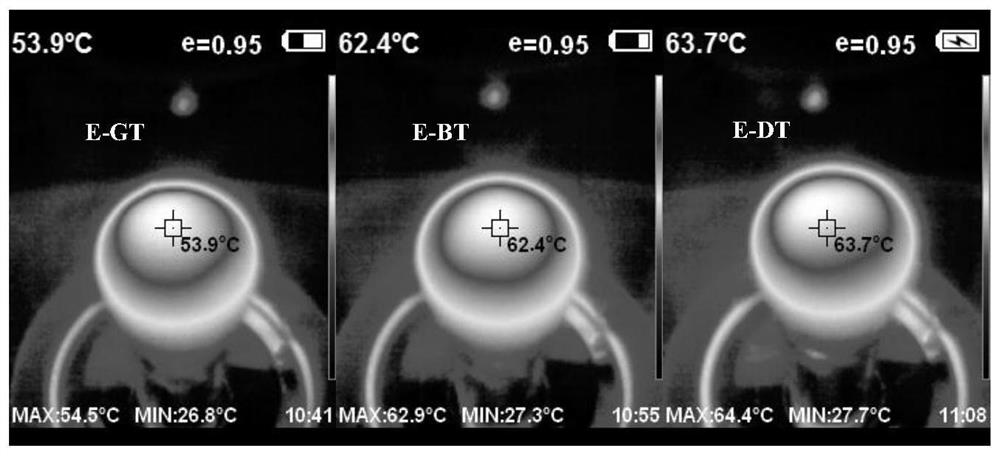

Embodiment 1

[0035] (1) Brewing and extracting black tea leaves for 5 times and drying;

[0036] (2) Put the dried black tea residue on a ball mill, and work at a speed of 500 rpm for 10 minutes to obtain black tea residue tea powder with an average particle size of 1.2 μm;

[0037] (3) Disperse 10 mg of black tea grounds powder into 20 g of distilled water to obtain a dispersion;

[0038] (4) Vacuum filter the dispersion liquid onto a polytetrafluoroethylene filter membrane for 30 minutes to obtain a photothermal seawater desalination membrane with a thickness of 5 mm, which is named E-BT.

Embodiment 2

[0040] (1) Green tea leaves are brewed and extracted 5 times and dried;

[0041] (2) Place the dried green tea dregs on a ball mill and work at a speed of 800 rpm for 30 minutes to obtain green tea dregs tea powder with an average particle size of 0.6 μm;

[0042] (3) Disperse 6 mg of green tea residue powder in 20 g of tetrahydrofuran to obtain a dispersion;

[0043] (4) Vacuum filter the dispersion onto the mixed cellulose ester membrane for 70 minutes to obtain a photothermal seawater desalination membrane with a thickness of 2.2 mm, which is named E-GT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com