Laser method and laser equipment adopting robot

A robot and laser technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of increasing product production costs, product surface scratches, low production efficiency, etc., to improve production efficiency, reduce product defects, Achieve precise laser effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

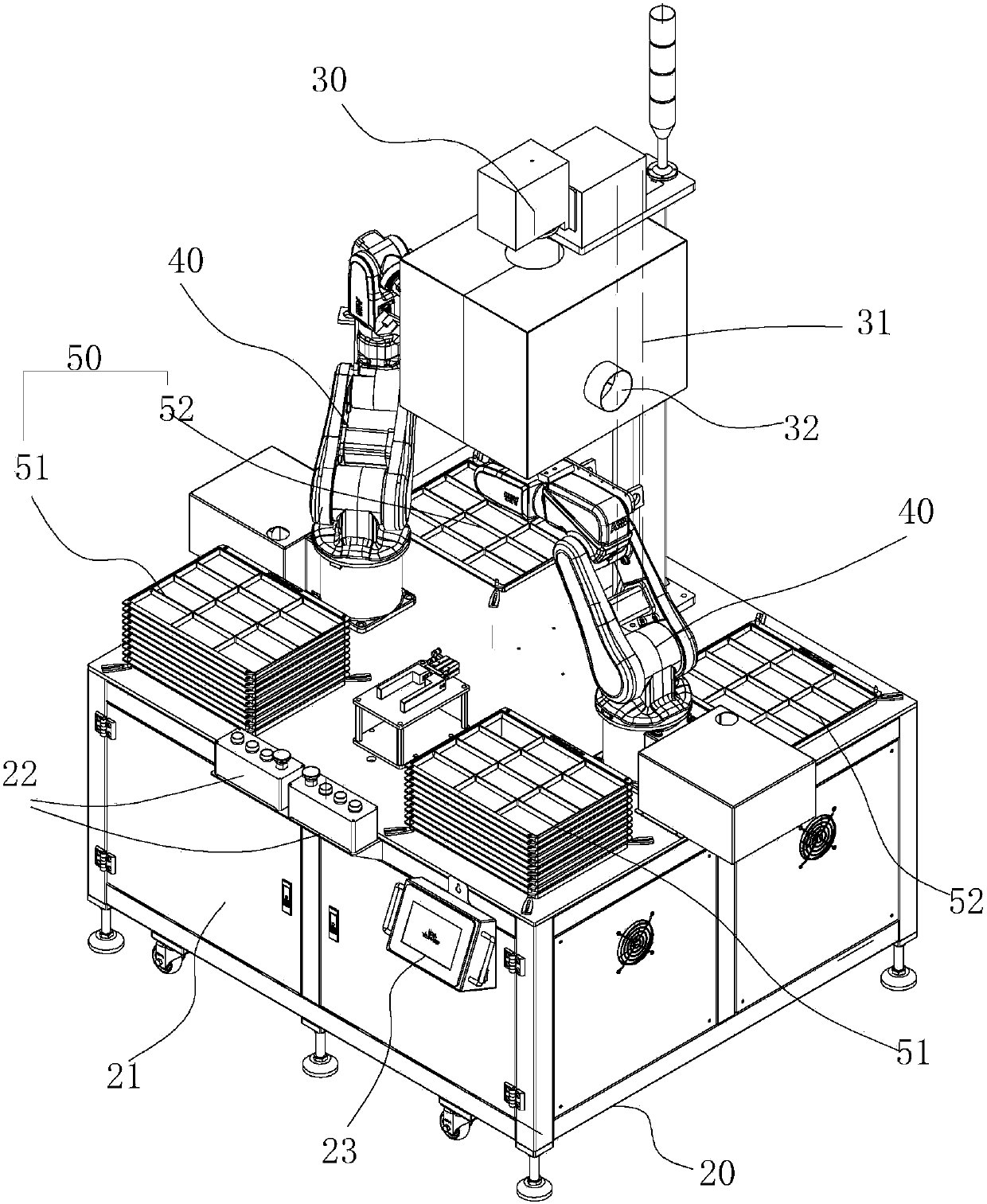

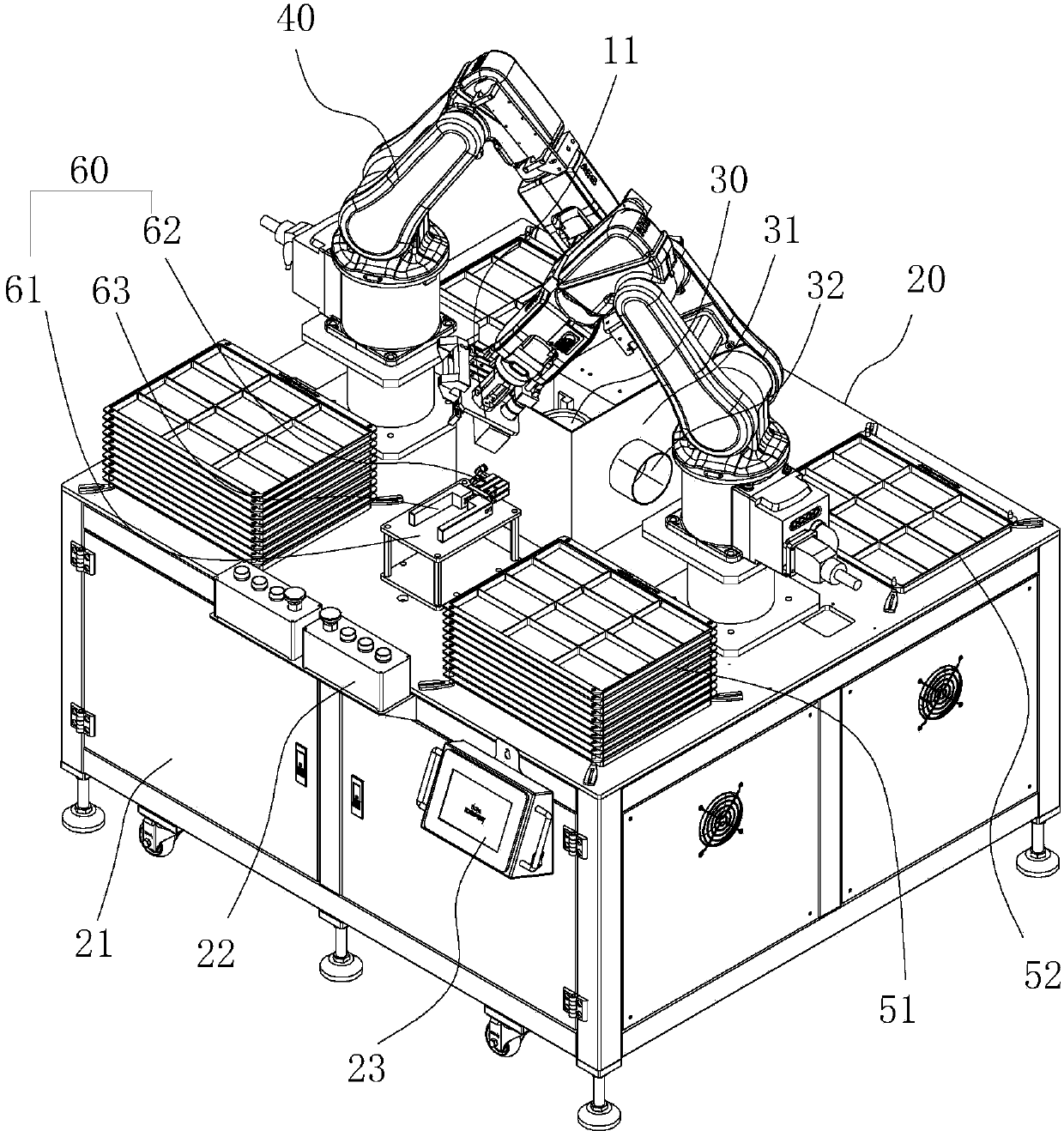

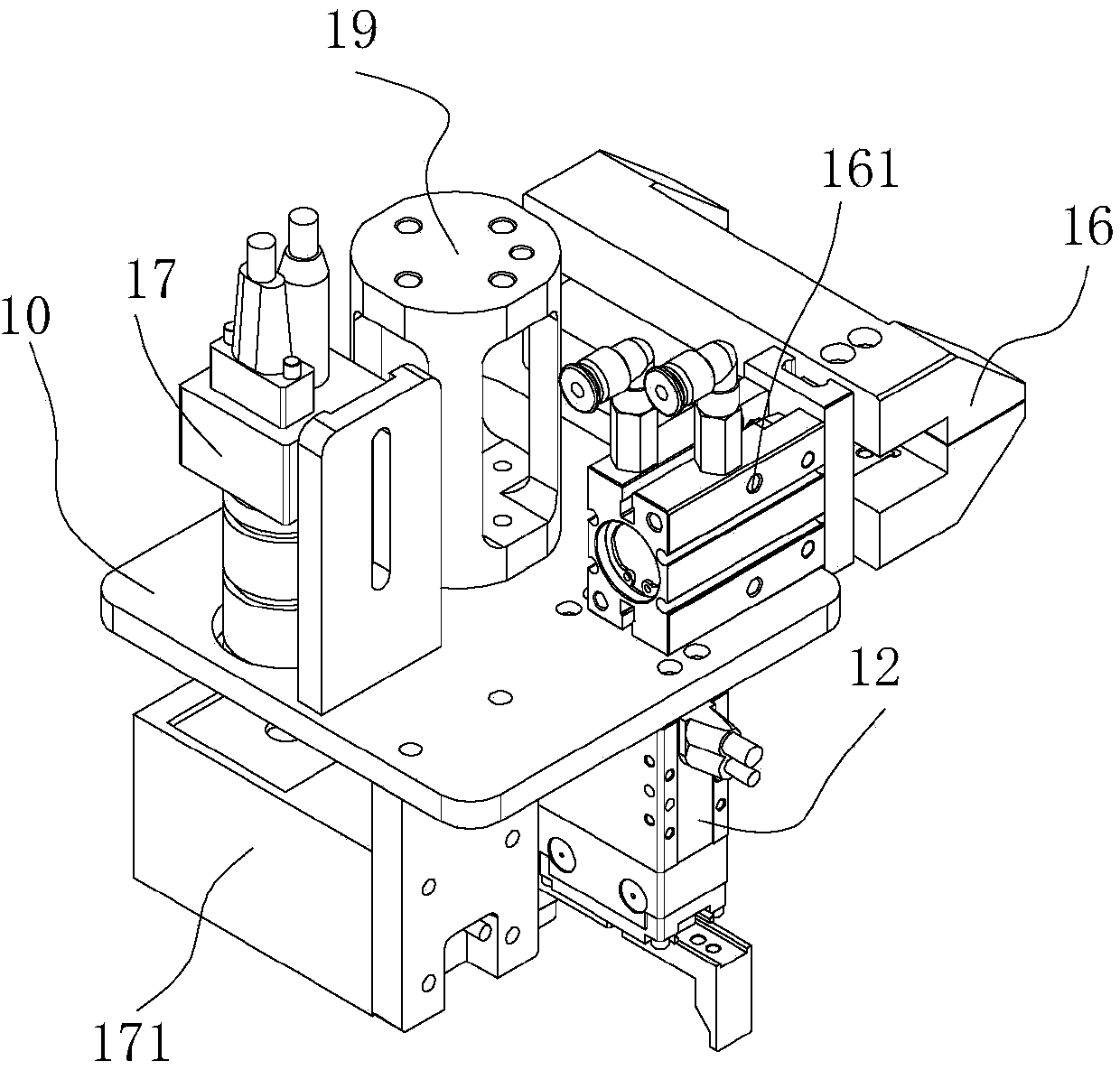

[0062] Such as figure 1 and figure 2As shown, a laser device and a laser method using a robot in the present invention include a machine base 20 and a laser machine 30 disposed on the machine base 20, and a robot 40 and a material area 50 for storing workpieces are also arranged on the machine base 20 The movable end of robot 40 is provided with the clamping structure 11 that is used for clamping workpiece to move between material area 50 and the laser area (the working area of laser machine); The clamping structure 11 is provided with the clamping portion that is used for clamping workpiece; Also Includes positioning mechanism for workpiece positioning. The material area 50 includes a loading area 51 (the workpiece to be lasere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com