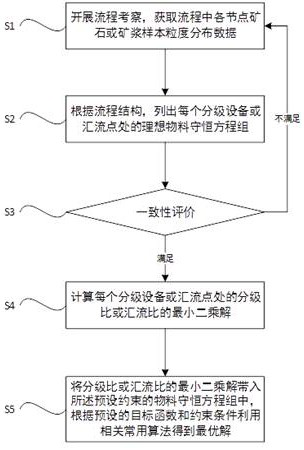

Calculation method for inspecting particle size distribution data consistency correction in ore crushing or grinding process

A technology of particle size distribution and calculation method, applied in computing, complex mathematical operations, data processing applications, etc., can solve the problems of difficult to maintain consistency of process inspection data, unstable operation of process, complex process, etc. Universality, clear and concise steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

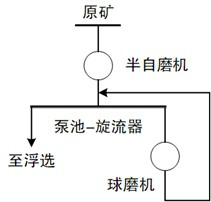

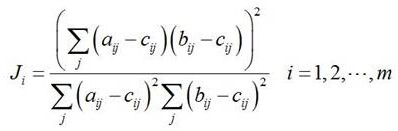

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described below in conjunction with examples, as will be described herein, as described in the embodiments of the invention, not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0040] Process inspection process unstable operation and inspection processes of sampling, drying, screening various aspects of the process will introduce errors, resulting study data flow is difficult to maintain consistency.

[0041]Mass balance principle is the process of industrial design, modeling, control and optimization of the basic principles. It requires input from the total macroscopic whole process, dynamic mass balance of the total output of material from the input and output requirements of the micro-material production facilities to meet the dynamic mass balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com