Water flushing analysis method for limestone fineness for desulfurization of thermal plant

A technology of limestone powder and analysis method, applied in particle size analysis, particle and sedimentation analysis, preparation of test samples, etc., can solve the problems of large error, low sieving rate, mutual agglomeration, etc. The effect of simple requirements and analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

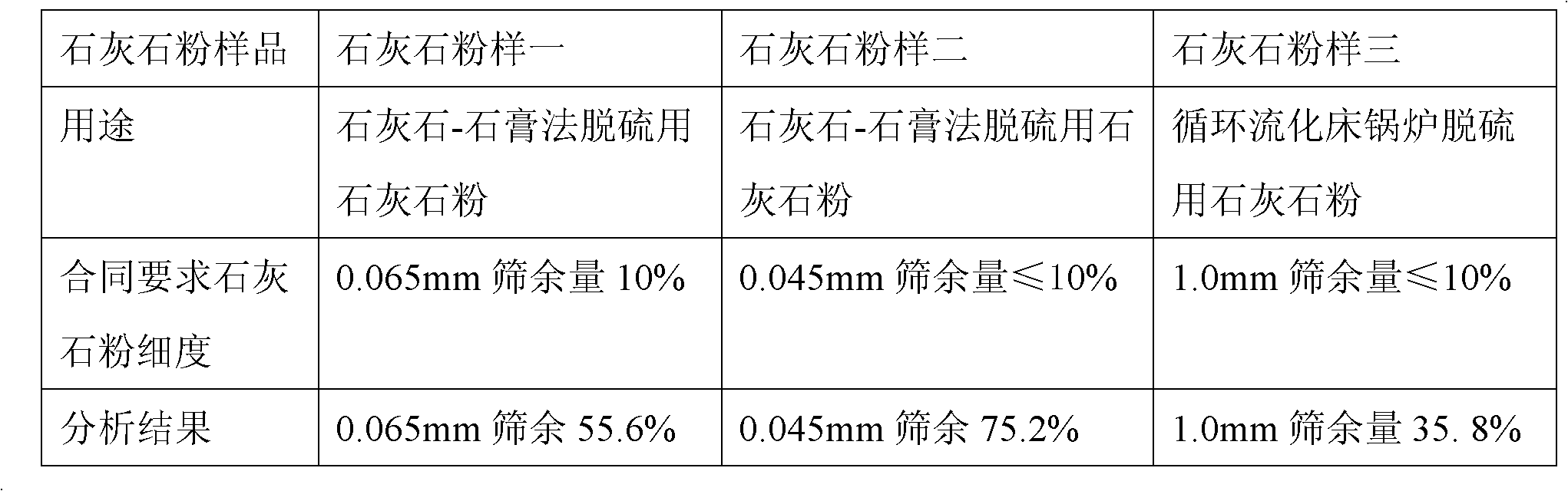

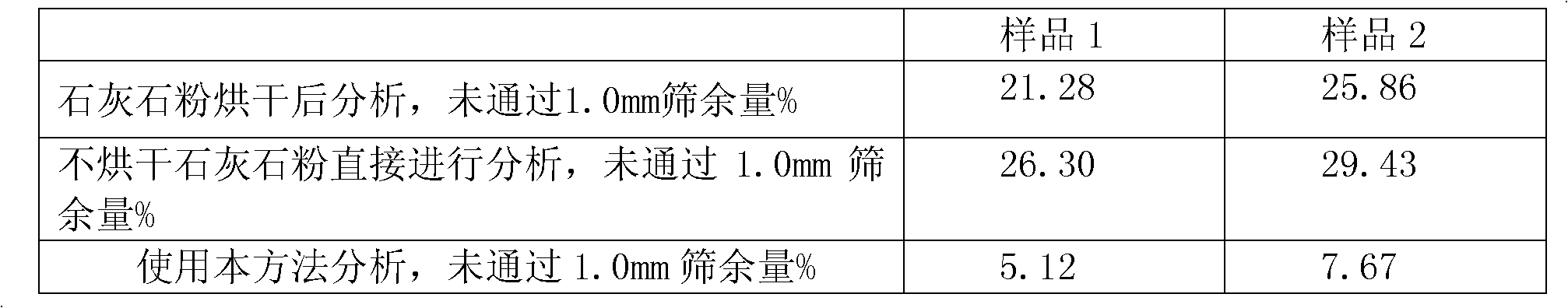

[0048] Example 1: Limestone powder used for desulfurization of a circulating fluidized bed boiler in a certain power plant in Guangxi, the contract requirement is that the 1.0mm sieve residue is not more than 10%.

[0049] Get 2 parts of limestone powder samples, sample 1, sample 2, use water flushing analysis method of the present invention and " mensuration of pulverized coal fineness " analysis method comparative analysis test:

[0050] ① After drying sample 1 and sample 2 at 100°C, weigh 25.0g (accurate to 0.01g) respectively, and carry out the fineness of limestone powder according to the analysis method of "Determination of Coal Fineness" (DL / T567.5-95). degree analysis. The analysis results are shown in Table 7.

[0051] Table 7: Analysis results of 1.0mm sieve residue of limestone powder after drying using the determination method "Determination of Coal Fineness"

[0052]

[0053]② Without drying the limestone powder, directly weigh sample 1 and sample 2, and anal...

Embodiment 2

[0061] Example 2: A 300MW unit thermal power plant in Guangxi adopts limestone-gypsum wet desulfurization, and the contract requirement for limestone powder is that the balance not passing through a 0.065mm sieve (250 mesh) is ≤10%.

[0062] Take 3 samples of limestone powder, namely sample 1, sample 2, and sample 3, and analyze them according to the steps of ①②③ in Example 1:

[0063] ① After drying sample 1, sample 2 and sample 3 at 100°C, weigh 25.0g (accurate to 0.01g) respectively, and carry out according to the analysis method of "Determination of Fineness of Coal Powder" (DL / T567.5-95) Limestone powder fineness analysis. The analysis results are shown in Table 10.

[0064] Table 10: Analysis results of 0.065mm sieve residue of limestone powder after drying using the determination method "Determination of Coal Fineness"

[0065]

[0066] ② Without drying the limestone powder, directly weigh sample 1, sample 2, and sample 3, and analyze the fineness of limestone powd...

Embodiment 3

[0073] Example 3: A 300MW unit thermal power plant in Guangxi adopts limestone-gypsum wet desulfurization, and the contract requirement for limestone powder is that the balance of failing to pass through a 0.045mm sieve (325 mesh) is ≤ 10%.

[0074] Get 3 parts of limestone powder, which are sample 1, sample 2, and sample 3 respectively, and analyze according to the steps of ①②③ in Example 1:

[0075] ① After drying sample 1, sample 2 and sample 3 at 100°C, weigh 25.0g (accurate to 0.01g) respectively, and carry out according to the analysis method of "Determination of Fineness of Coal Powder" (DL / T567.5-95) Limestone powder fineness analysis. The analysis results are shown in Table 13.

[0076] Table 13: Analysis results of 0.045mm sieve residue of limestone powder after drying using the method "Determination of Coal Fineness"

[0077]

[0078] ② Without drying the limestone powder, directly weigh sample 1, sample 2, and sample 3, and analyze the fineness of limestone po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com