Ball grinder accurate ball loading method

A technology of precise ball filling and ball milling, applied in grain processing, etc., can solve the problems of large errors and inconvenience, and achieve the effect of improving concentrate grade, reducing power consumption, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1. A copper-nickel concentrator in Yunnan, with a scale of 300 tons per day, used two grid-type ball mills with a diameter×length of 1.5×3.0 meters to conduct one-stage grinding in two series. The filling of balls in production is unreasonable, and the diameter of the balls is too large, resulting in insufficient fineness of grinding products, low sorting index, and high ball consumption. Carry out precise installation and replacement of balls in the mill of this factory, the specific procedure is as follows:

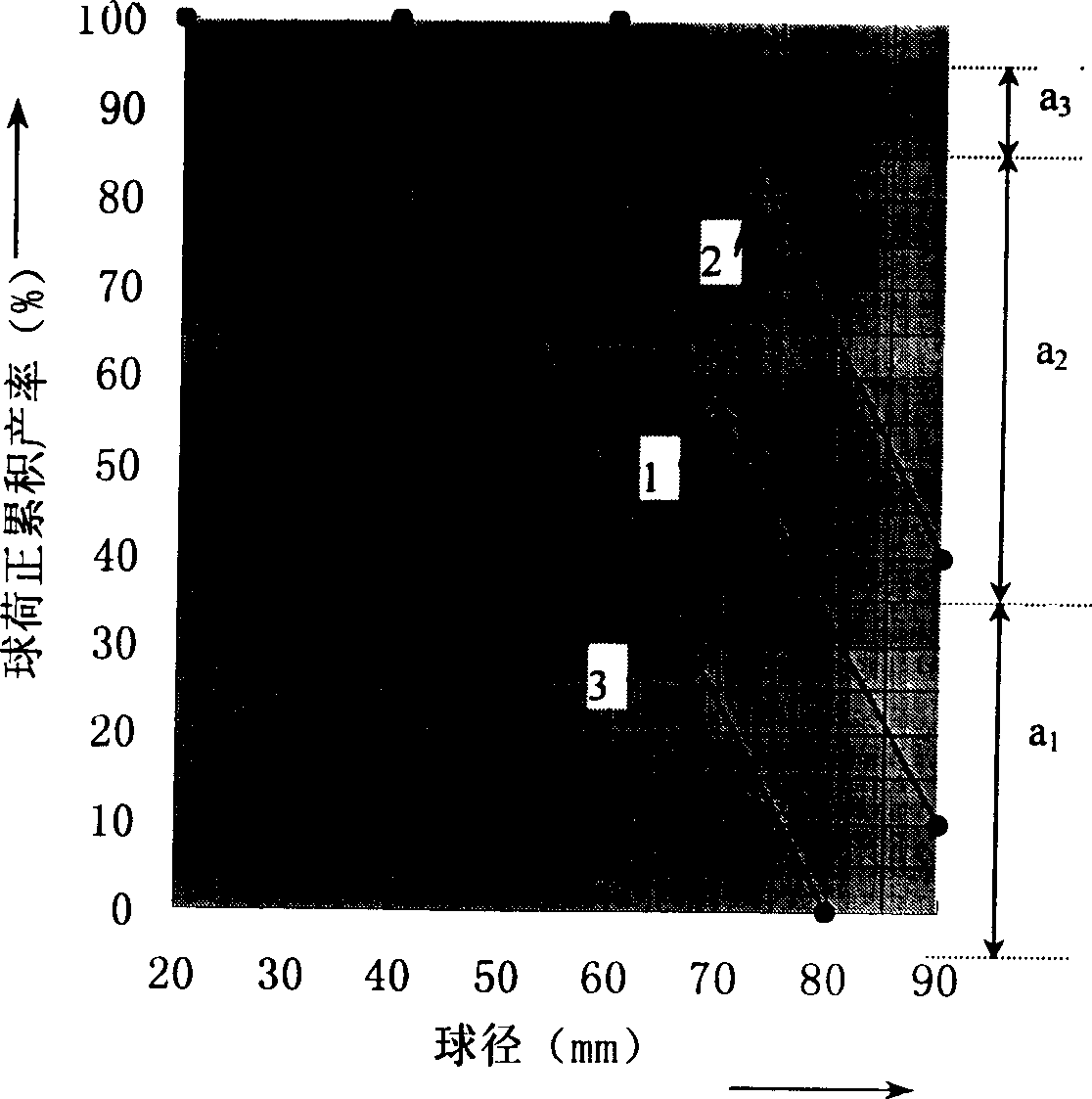

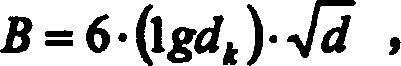

[0040] (1) Measure the uniaxial compressive strength of ore standard mechanical test piece σ=502.9kg / cm with the lump ore sample of the plant 2 , the compressive strength σ of the irregular ore block 0 =206.1kg / cm 2 , ore elastic modulus 7.36×10 5 kg / cm 2 , Poisson's ratio 0.341. The mechanical properties of the ore show that the ore is a soft ore (f=5.03), which has certain toughness and deformability. When grinding this kind of ore, both impact and...

Embodiment 2

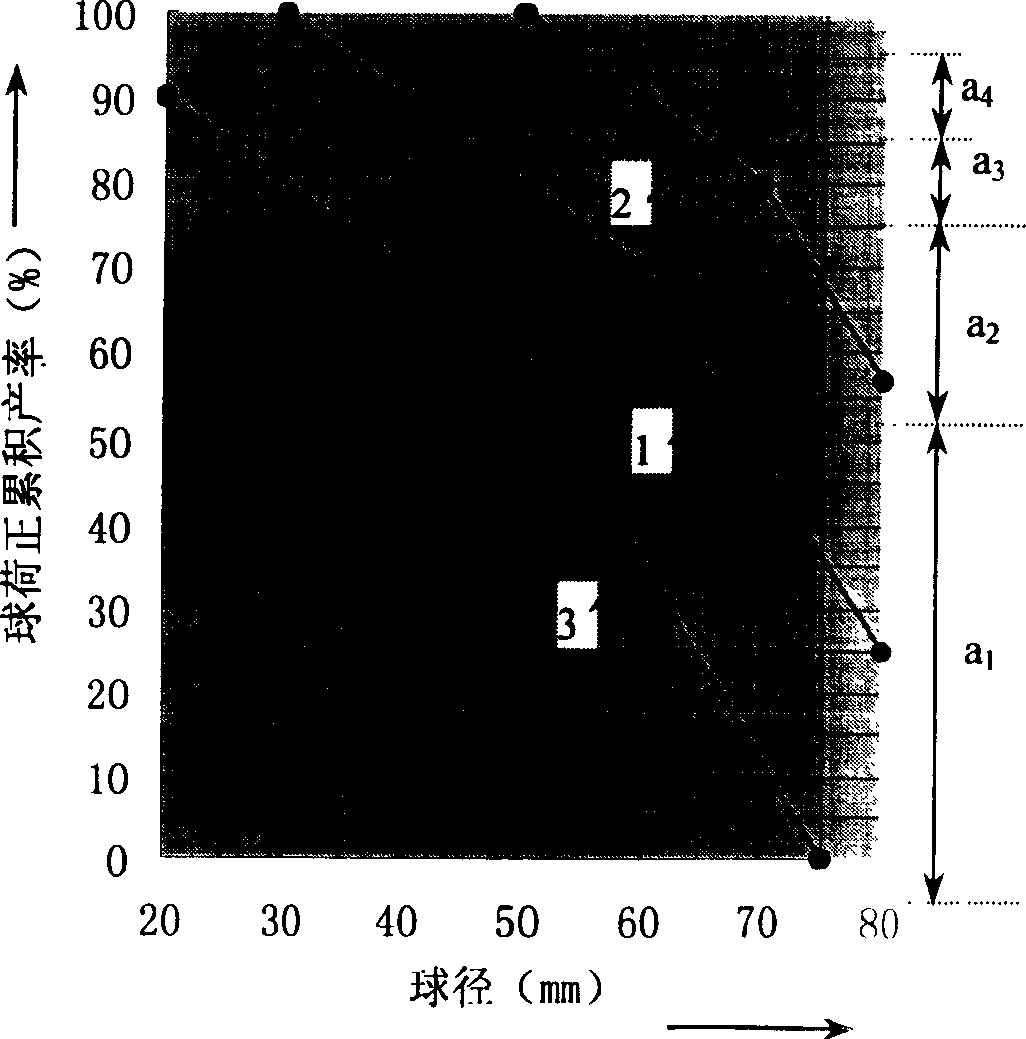

[0053] Embodiment 2. A copper beneficiation plant in Yunnan, with a scale of 3000 tons per day, adopts two large ball mills with a diameter × length of 3.6 × 4.5 meters in parallel for one-stage grinding. The filling of balls in the production is unreasonable, and the diameter of the balls is seriously too large, resulting in low mill capacity, low grinding fineness, and low sorting index. For this purpose, the factory organizes to meet production and standard problems, and adopts the method of precise loading and filling balls to improve the grinding effect. The specific procedures are as follows:

[0054] (1) Determine the mechanical properties of the ore for the ore in the plant: the uniaxial compressive strength of the standard mechanical test piece σ = 871.775kg / cm 2 , the compressive strength σ of the irregular ore block 0 =398.75kg / cm 2 , Poisson's ratio μ=0.28. The mechanical properties of the ore show that the ore is a medium-hard ore (f=8.7), with moderate brittle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com