Method for recycling oil-containing sludge sand

A technology of resource utilization and oil sludge sand, which is applied in the field of resource utilization of oily sludge sand, can solve problems such as polluted water, soil and air, deterioration of ecological environment, pollution, etc., and achieves huge social and economic benefits and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

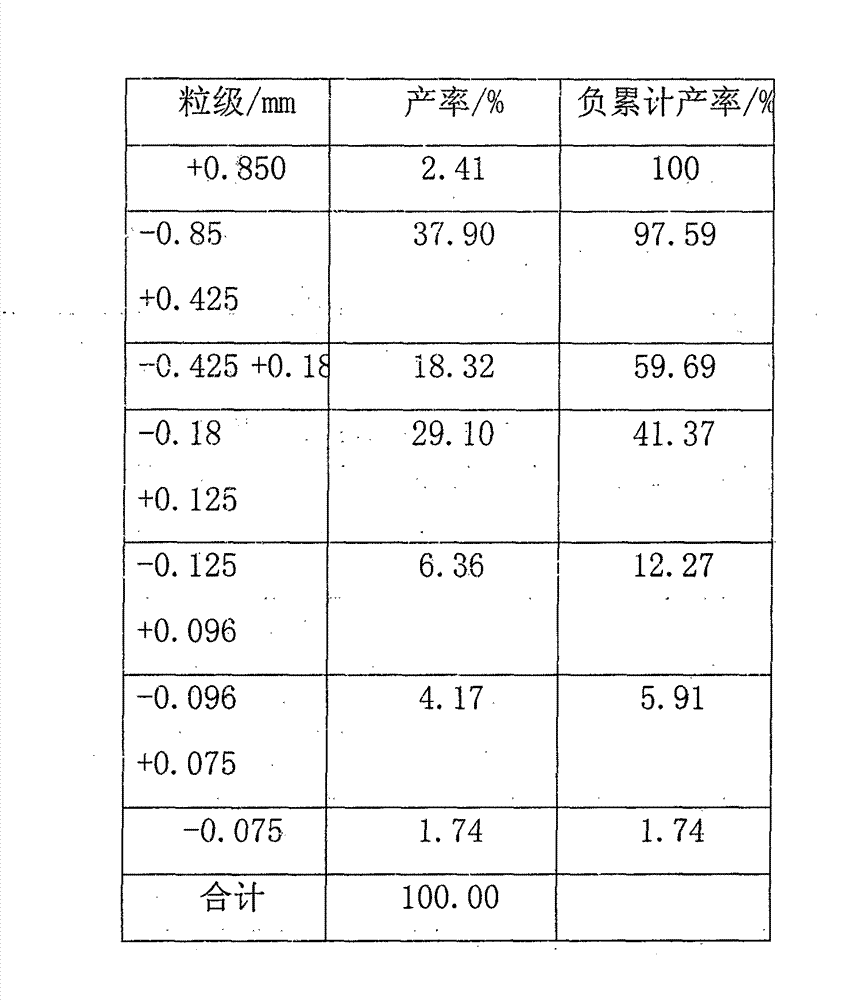

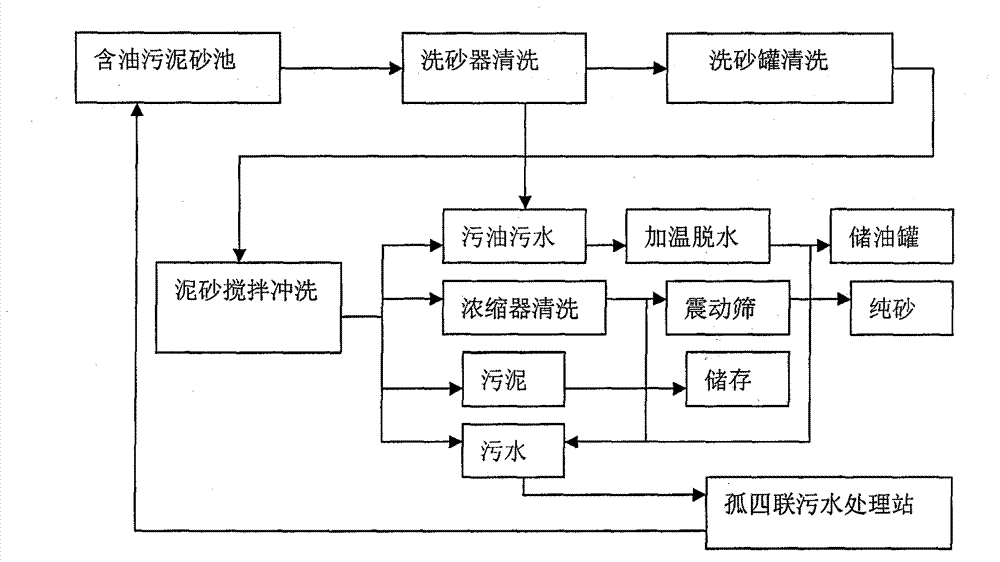

[0010] The oily sludge sand is separated from oil, water, mud and sand, and the particle size composition of the oily sludge sand is studied by the sieve analysis method. figure 1 .

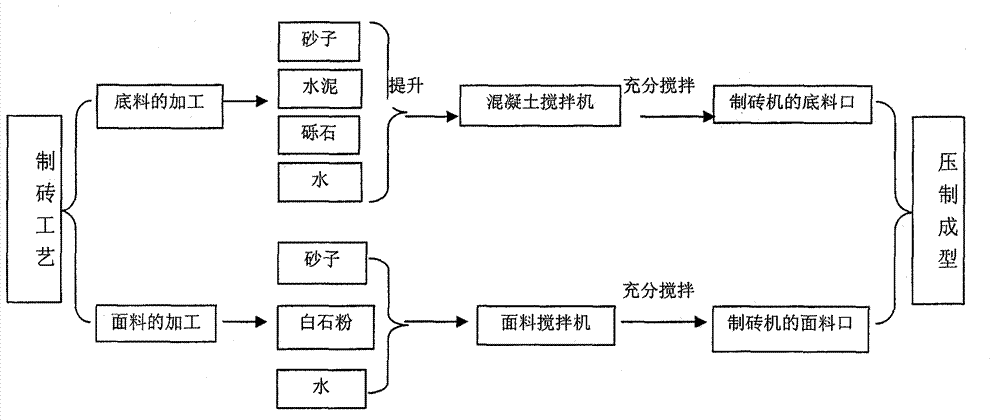

[0011] It can be seen from the sieve analysis results that the particle size distribution of oil sludge sand is mainly concentrated in 0.1-0.85mm, the yield rate is 90%, the average particle size is 0.23mm, and the mud content is 1.74%, which is suitable for making unburned bricks. After repeated tests, it was found that the separated sand was mixed with 15%-50% cement, 10%-30% gravel, 1%-10% curing agent, and 20%-50% water in the mixer to make mortar, and then used a conveyor belt Transfer to the molding machine for molding to make machine-pressed non-burning bricks. After further adding fabrics, it can be made into colored bricks of different colors. After sampling and testing, the strength level reaches MU15. Dimensional deviation, appearance, freeze-thaw, frost, lime Bursting and other indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com