Cement-base composite material for grouting treatment of water-rich fractured rocks and preparation process of cement-base composite material

A composite material and cement-based technology, applied in the field of material science, can solve problems such as difficult to achieve water gushing plugging, unsatisfactory grouting effect, and restrictions on the application of grouting materials, and achieve good operability, solve material uniformity, and good The effect of engineering suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] 1. Components and mass ratio: Portland cement clinker: mineralizer: 73:27, powder retarder: 1.25 parts. The mineralizer components and mass ratio are: 77 parts of quartz powder, 7.2 parts of calcium chloride, 3 parts of lithium chloride, 2.2 parts of talcum powder, 2.2 parts of hydroxypropyl methylcellulose, 2.2 parts of wollastonite powder, titanium dioxide 0.8 parts, sodium hexametaphosphate 3.6 parts, superplasticizer 1.8 parts.

[0037] 2. Preparation process: The grinding fineness of the cement-based composite material is 5502 / kg, the sieve residue of 80um negative pressure sieve is 5.5%, and the water-cement ratio is 1:1 and mixed evenly.

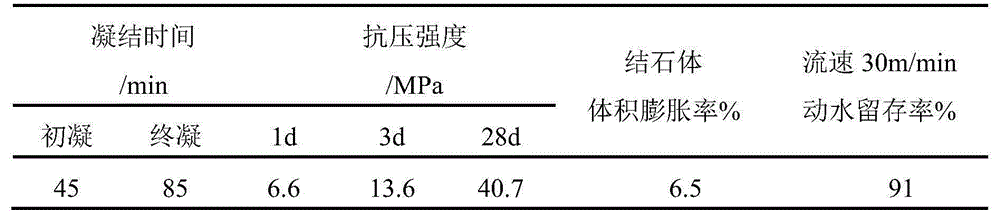

[0038] 3. The index parameters are as follows in Table 1:

[0039] Table 1

[0040]

[0041] The grouting reconstruction material prepared above was used to transform the limestone aquifer of the coal seam floor, and the long-distance pumping from the ground to the buried depth of -960 meters was realized, and the ambient ...

specific Embodiment 2

[0043] 1. Components and mass ratio: Portland cement clinker: mineralizer: 73:27, powder retarder: 1.25 parts. The mineralizer components and mass ratio are: 76 parts of quartz powder, 7.4 parts of calcium chloride, 3.6 parts of lithium chloride, 2.4 parts of talcum powder, 2.4 parts of hydroxypropyl methylcellulose, 2.6 parts of wollastonite powder, titanium dioxide 0.6 parts, sodium hexametaphosphate 3.1 parts, superplasticizer 1.9 parts.

[0044] 2. Preparation process: The grinding fineness of the cement-based composite material is 5502 / kg, the sieve residue of 80um is 5.5%, and the water-cement ratio is 1:1 and mixed evenly.

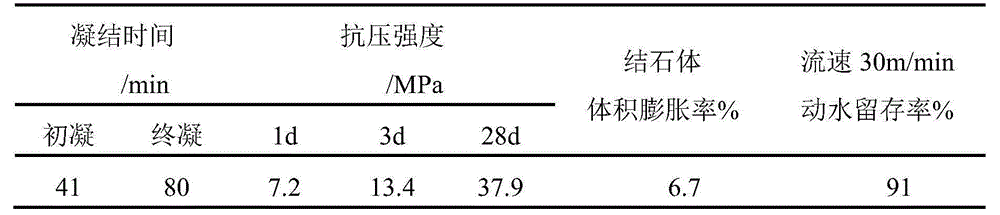

[0045] 3. The index parameters are as follows in Table 2:

[0046] Table 2

[0047]

specific Embodiment 3

[0049] 1. Component and mass ratio: Portland cement clinker: mineralizer: 70:30, powder retarder: 1.45 parts. The mineralizer components and mass ratio are: 77 parts of quartz powder, 7.2 parts of calcium chloride, 3 parts of lithium chloride, 2.2 parts of talcum powder, 2.2 parts of hydroxypropyl methylcellulose, 2.2 parts of wollastonite powder, titanium dioxide 0.8 parts, sodium hexametaphosphate 3.6 parts, superplasticizer 1.8 parts.

[0050] 2. Preparation process: The grinding fineness of the cement-based composite material is 5702 / kg, the sieve residue of 80um negative pressure sieve is 7.3%, and the water-cement ratio is 1:1 and mixed evenly.

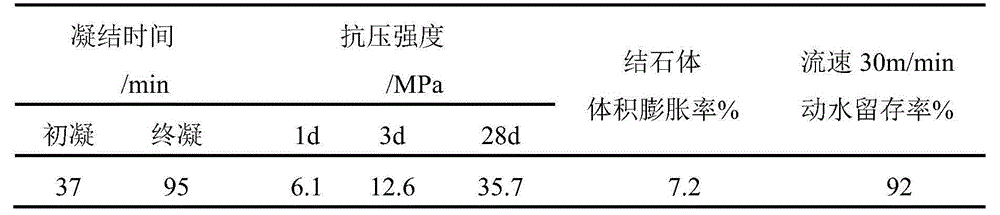

[0051] 3. The index parameters are as follows in Table 3:

[0052] table 3

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com