Particle material grading measurement instrument and measurement method thereof

A technology for granular materials and measurement methods, applied in chemical instruments and methods, instruments, measuring devices, etc., can solve problems such as errors and mass loss, and achieve the effects of convenient use, error avoidance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

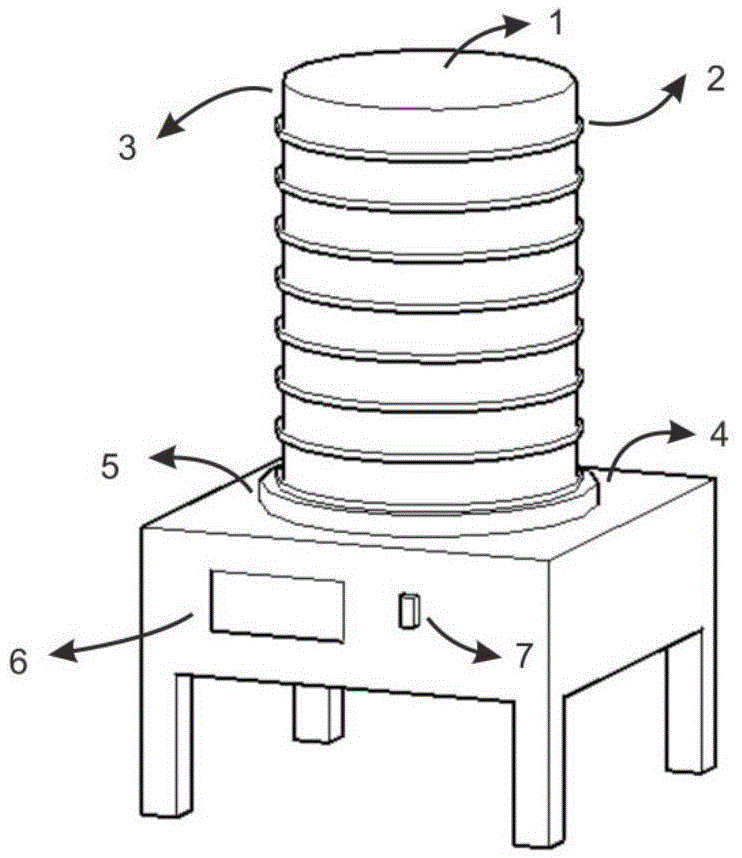

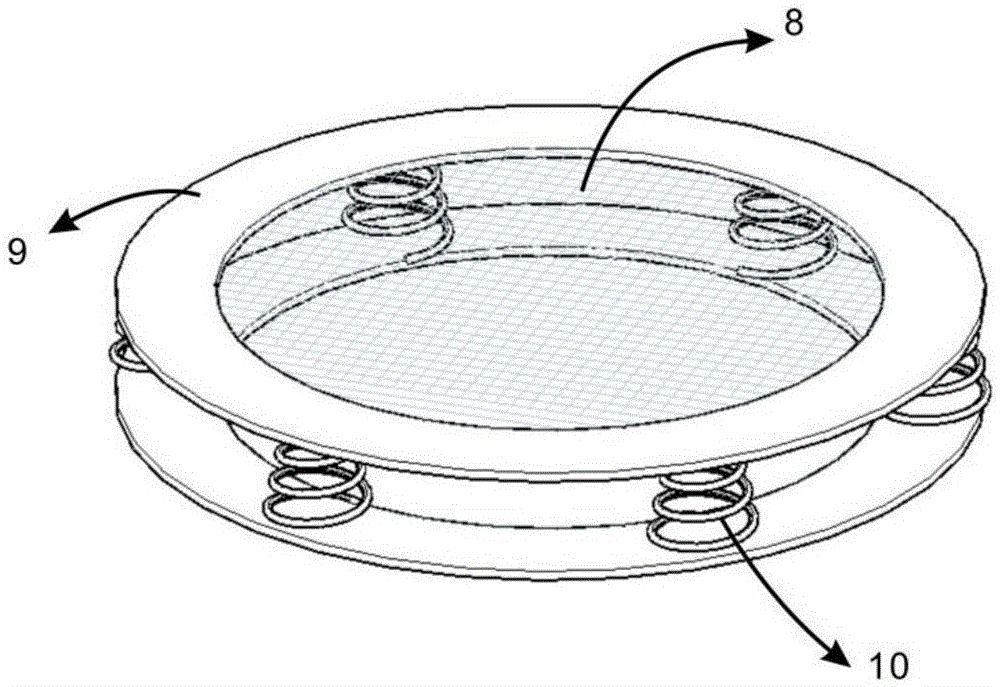

[0033] Such as Figure 1-2 As shown, a granular material gradation tester includes a machine base 4, a vibrating table 5, a sieve box 3, a sieve box cover 1, a weighing unit device 2, a micro data processor, a touchable operation screen 6 and a switch 7, The vibrating table 5 is arranged on the top surface of the machine base 4, and more than two sieve boxes 3 are stacked on the top of the vibrating table 5 from top to bottom, and the sieve box cover 1 is arranged on the top surface of the top sieve box 3; the weighing unit The device 2 is set inside the sieve box 3. The weighing unit device 2 includes: a sieve plate 8, an induction ring 9, a weighing spring 10 and a strain gauge. In the inner ring of the upper ring sheet of the induction ring 9, the sieve plate 8 of each layer of the sieve box 3 has a sieve aperture that decreases from top to bottom, and the strain gauges are arranged on the weight spring 10, each of which is 6 pieces, evenly arranged between the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com