Method for comprehensive recovery of valuable metals in brown iron type laterite-nickel ores

A technology of laterite nickel ore and valuable metals, applied in chemical instruments and methods, improvement of process efficiency, filtration and screening, etc., can solve problems such as harsh process conditions, low comprehensive recycling rate of valuable metals, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

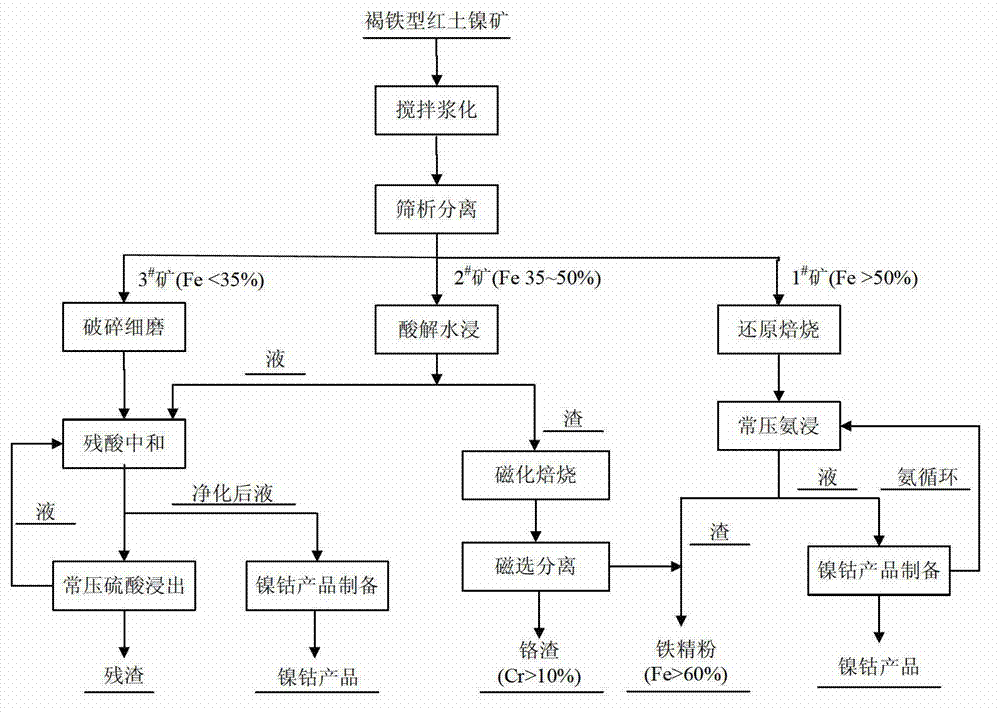

[0042] See attached figure 1 . The raw ore was stirred and pulped for 48 hours with a slurry concentration of 35%, and then sieved with 30 mesh and 150 mesh screens respectively. The obtained 1# ore was reduced and roasted in a CO atmosphere at 750°C for 0.5 hours, and the calcination was carried out in an ammonium bicarbonate solution. Atmospheric pressure leaching, the leaching slag contains 62% iron, and the ammonia in the leaching solution is recovered after the nickel-cobalt product preparation process and returned to the normal pressure ammonia leaching process; the obtained 2# ore is mixed with 98% concentrated sulfuric acid 200kg / t-mine Acid hydrolysis, water immersion after acid hydrolysis, leaching slag mixed with 8% lignite, magnetized and roasted at 700°C for 1 hour, magnetic separation of calcined sand under a magnetic field of 150MT to obtain iron powder containing 60% iron and chromium containing 10% Chromium slag, the leaching solution is incorporated into the...

Embodiment 2

[0044] The raw ore was stirred and pulped for 20 hours, the concentration of the pulp was 25%, and then sieved with 50 mesh and 120 mesh screens respectively. The obtained 1# ore was reduced and roasted with coal at 700 ° C for 1 hour, and the calcined sand was placed in an ammonium bicarbonate solution under normal pressure. After leaching, the leaching slag contains 61% iron, and the ammonia in the leaching solution is recovered after the nickel-cobalt product preparation process and returned to the normal pressure ammonia leaching process; the obtained 2# ore is mixed with 98% concentrated sulfuric acid 220kg / t-ore acid hydrolysis After acidolysis, water immersion is carried out, and the leaching slag is mixed with 10% lignite and magnetized and roasted at 750°C for 0.5h. The calcined sand is magnetically separated under a magnetic field of 120MT to obtain iron powder containing 61% iron and chromium containing 10.2%. slag, and the leachate is incorporated into the 3# ore tr...

Embodiment 3

[0046] The raw ore was stirred and pulped for 8 hours with a slurry concentration of 15%, and then sieved and analyzed by 60-mesh and 120-mesh screens respectively. The obtained 1# ore was reduced and roasted with coal at 850°C for 1.5 hours, and the calcined sand was often mixed with ammonium bicarbonate solution. Pressure leaching, the leaching slag contains 60% iron, and the ammonia in the leaching solution is recovered after the nickel-cobalt product preparation process and returned to the normal pressure ammonia leaching process; the obtained 2# ore is mixed with 98% concentrated sulfuric acid 250kg / t-mineral acid After acidolysis, water immersion is carried out, and the leaching slag is mixed with 9% lignite and magnetized and roasted at 730°C for 0.5h. The calcined sand is magnetically separated under a magnetic field of 160MT to obtain iron fine powder containing 61% iron and 10.0% chromium. Chromium slag, the leaching solution is incorporated into the 3# ore treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com