Process for producing high calorific value water-coal slurry by utilizing coal or coal gangue and coal gasification process adopting process

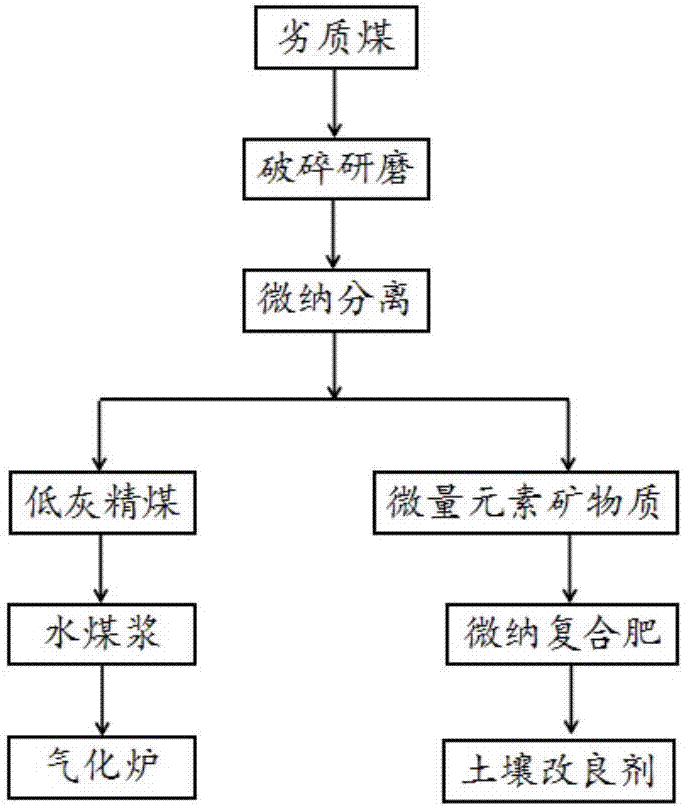

A technology of coal-water slurry and coal gangue, applied in the field of coal gasification process, can solve the problems of limited effect, high transportation cost, difficult absorption, etc., and achieve the effect of increasing profit space and stable and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

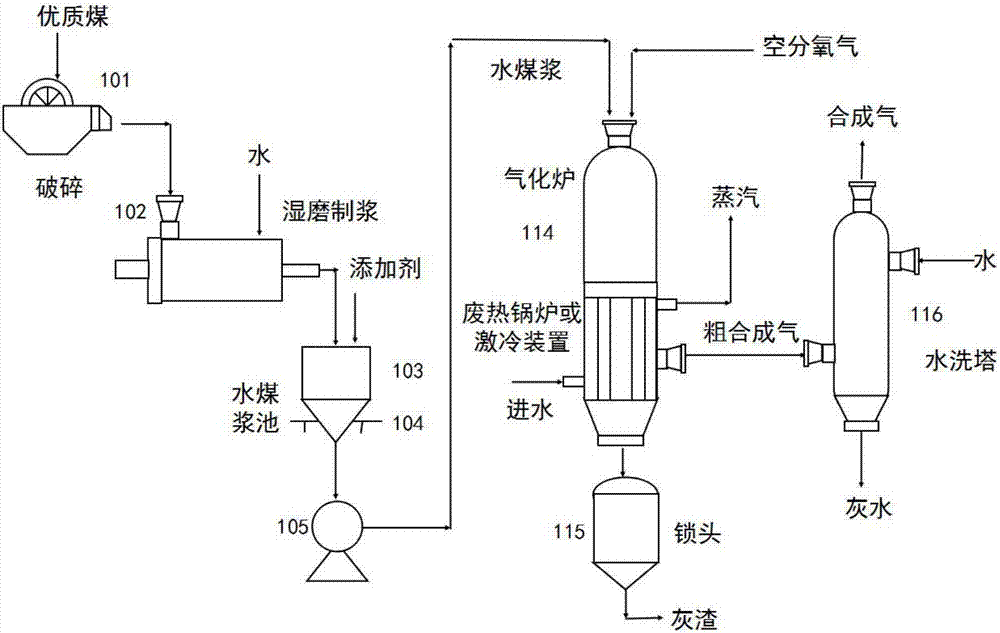

[0036] The low-quality coal used is peat with a mineral content of 30wt%, which is transported to the crusher for preliminary crushing, and then introduced into a wet mill for grinding to a particle size of less than 50 microns, adding water and additives for wet grinding and pulping . The prepared coal water slurry is stored in the coal water slurry storage tank, and the addition amount of the coal water slurry is controlled by the coal water slurry weighing instrument. The coal-water slurry is delivered to the micro-nano separation equipment at a pumping pressure of 0.3 MPa through the coal-water slurry feed pump and the coal-water slurry delivery pipeline.

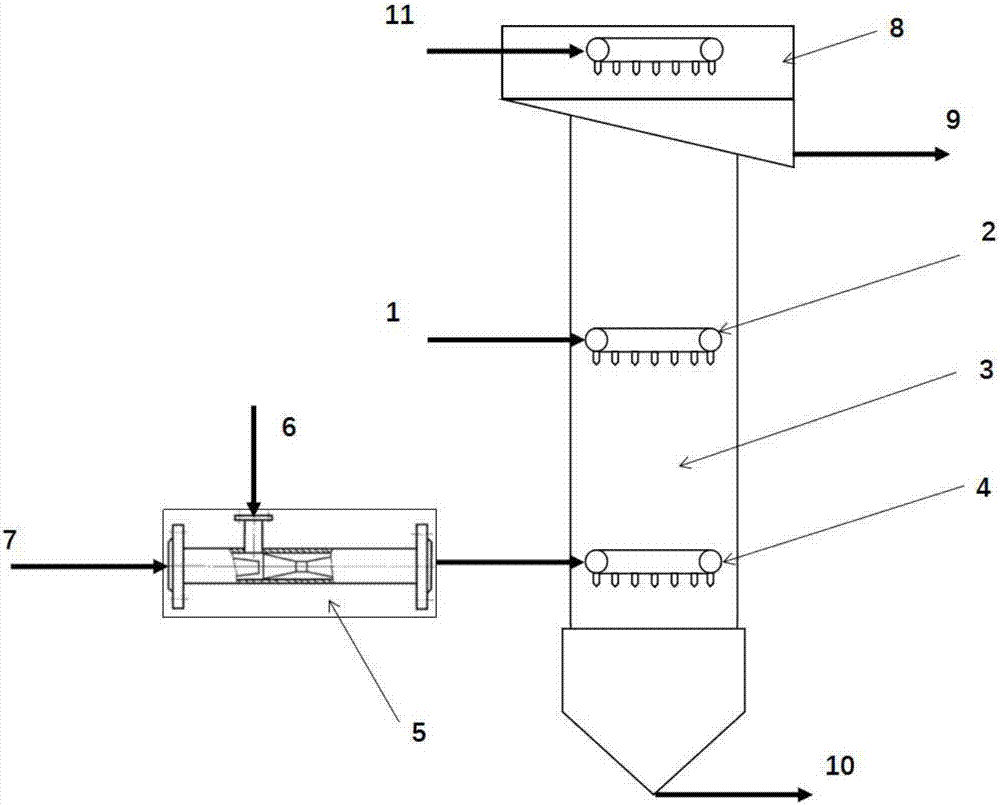

[0037] The separation principle of the micro-nano separation equipment is based on the difference of particle surface properties and the principle of particle interference and sedimentation in the fluidized fluid, using a composite force field to separate hydrocarbon combustible material particles from mineral impurity ...

Embodiment 2

[0040] The low-quality coal used is lignite with a mineral content of 20wt%, which is transported to a crusher for primary crushing, and then introduced into a wet mill for grinding to a particle size of less than 450 microns, and then added with water and additives for wet grinding and pulping. The prepared coal water slurry is stored in the coal water slurry storage tank, and the addition amount of the coal water slurry is controlled by the coal water slurry weighing instrument. The coal-water slurry is delivered to the micro-nano separation equipment at a pumping pressure of 0.3 MPa through the coal-water slurry feed pump and the coal-water slurry delivery pipeline.

[0041] still use as figure 2 The equipment and method of operation shown. The diameter of the bubbles used for micro-nano separation is less than 200 microns. After the hydrocarbon combustible material particles are separated from the foam, some conventional additives can be added to prepare a suspension-st...

Embodiment 3

[0043] The coal gangue used is washed coal with a mineral content of 40wt%, which is transported to a crusher for preliminary crushing, then introduced into a wet mill and ground to a particle size of less than 100 microns, and then added with water and additives for wet mill adjustment pulp. The prepared coal water slurry is stored in the coal water slurry storage tank, and the addition amount of the coal water slurry is controlled by the coal water slurry weighing instrument. The coal-water slurry is delivered to the micro-nano separation equipment at a pumping pressure of 0.3 MPa through the coal-water slurry feed pump and the coal-water slurry delivery pipeline.

[0044] still use as figure 2 The equipment and method of operation shown. The diameter of the bubbles used for micro-nano separation is less than 80 microns. After the hydrocarbon combustible material particles are separated from the foam, some conventional additives can be added to prepare a suspension-stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com