Detection system for sand blocking precision of sand prevention medium of sand prevention sieve tube for oil field

A technology of sand control screen and precision detection, which is applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of poor test effect, single application scope, inability to simulate formation sand production speed and production pressure difference, etc. Achieving a wide range of applications

Inactive Publication Date: 2016-06-08

CHINA NAT OFFSHORE OIL CORP +2

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] What the present invention is to solve is that the conventional sand control medium sand retaining accuracy detection device is a low-pressure test system, which has a single application range, and cannot accurately control the sand adding speed, cannot simulate the actual sand production speed and production pressure difference of the formation, and the test results cannot truly reflect the sand contr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

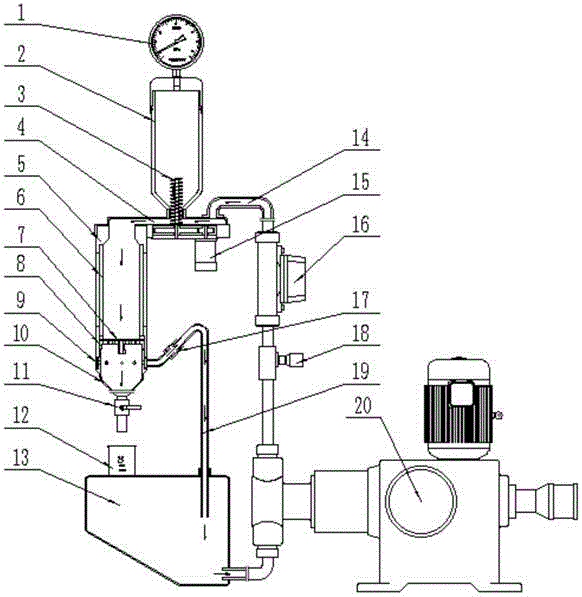

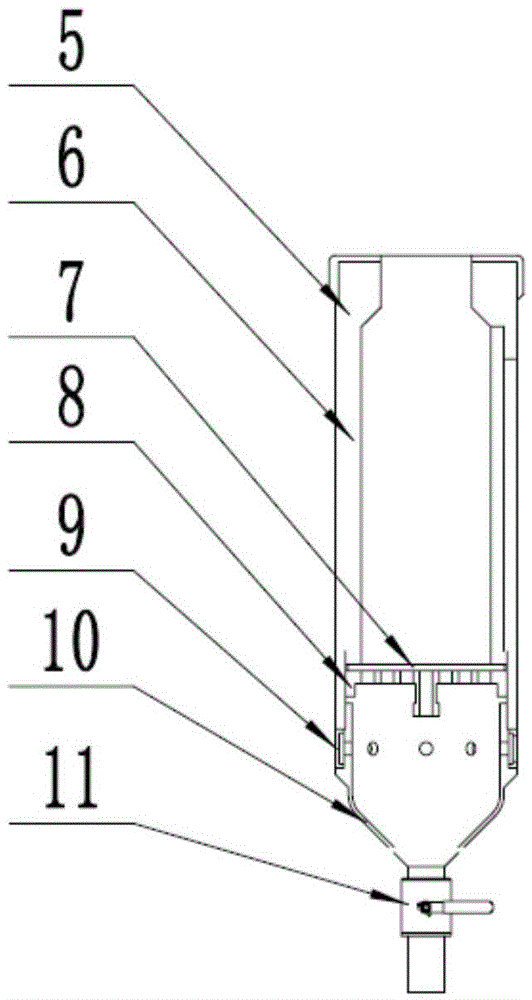

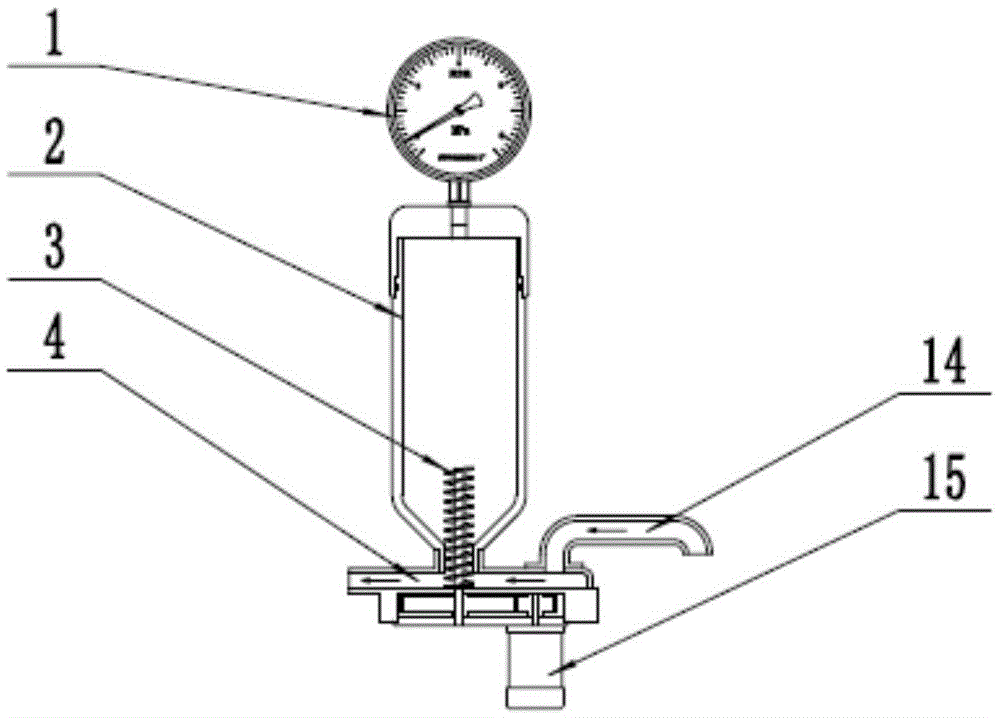

The invention belongs to the technical field of sand prevention in loose sandstone oil-gas field development and discloses a detection system for sand blocking precision of a sand prevention medium of a sand prevention sieve tube for an oil field. The detection system mainly comprises a sand adding speed control system and a main testing device. An inlet of the sand adding speed control system is connected with a plunger pump through a liquid inflow tube, a flow meter and a one-way throttle valve. The plunger pump sucks in liquid from a liquid storage tank. An outlet of the sand adding speed control system is connected with an inlet of the main testing device through a liquid flow channel of the system, and the main testing device is connected to the liquid storage tank through a liquid outflow pipe to form circulation. A sampling container is arranged below a sand sample collecting hopper, sedimentary sand can be collected to be weighed and subjected to sieve analysis, and the sand blocking precision of the sand prevention medium slice is detected according to the weighing and sieve analysis result. The sand adding speed can be precisely controlled to simulate the actual stratum sand output speed, the pressure difference of the two sides of the sand prevention medium is controlled to simulate the actual production pressure difference, the test result more similar to the actual test result is obtained, and actual production is guided to select the proper sand blocking precision.

Description

technical field [0001] The invention belongs to the technical field of sand control in the development of unconsolidated sandstone oil and gas fields, and in particular relates to a sand-retaining accuracy detection system for sand control media of sand control screens used in oil fields. Background technique [0002] At present, sand production seriously affects the exploitation of unconsolidated sandstone reservoirs, and sand control has become one of the main research topics in the exploitation of unconsolidated sandstone reservoirs. As the main sand control tool, sand control screens have been widely used, and the media that play the main role in sand control screens are called sand control media. At present, there are many types of sand control screens used in oil fields, but there are relatively few types of sand control media, which can be roughly divided into four categories: metal mesh, metal wool, gaps and particles. Different sand control media have different sand...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/08

CPCG01N15/08G01N15/0826

Inventor 孟召兰邢洪宪张亮范白涛刘春苗车争安张纪双

Owner CHINA NAT OFFSHORE OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com