A kind of wet particle size analysis vibrating sleeve sieve and its application

A technology of particle size analysis and sieve set, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of large screen loss, long classification time, large classification error, etc., and achieve low dust in the operating environment, wide application range, The effect of small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

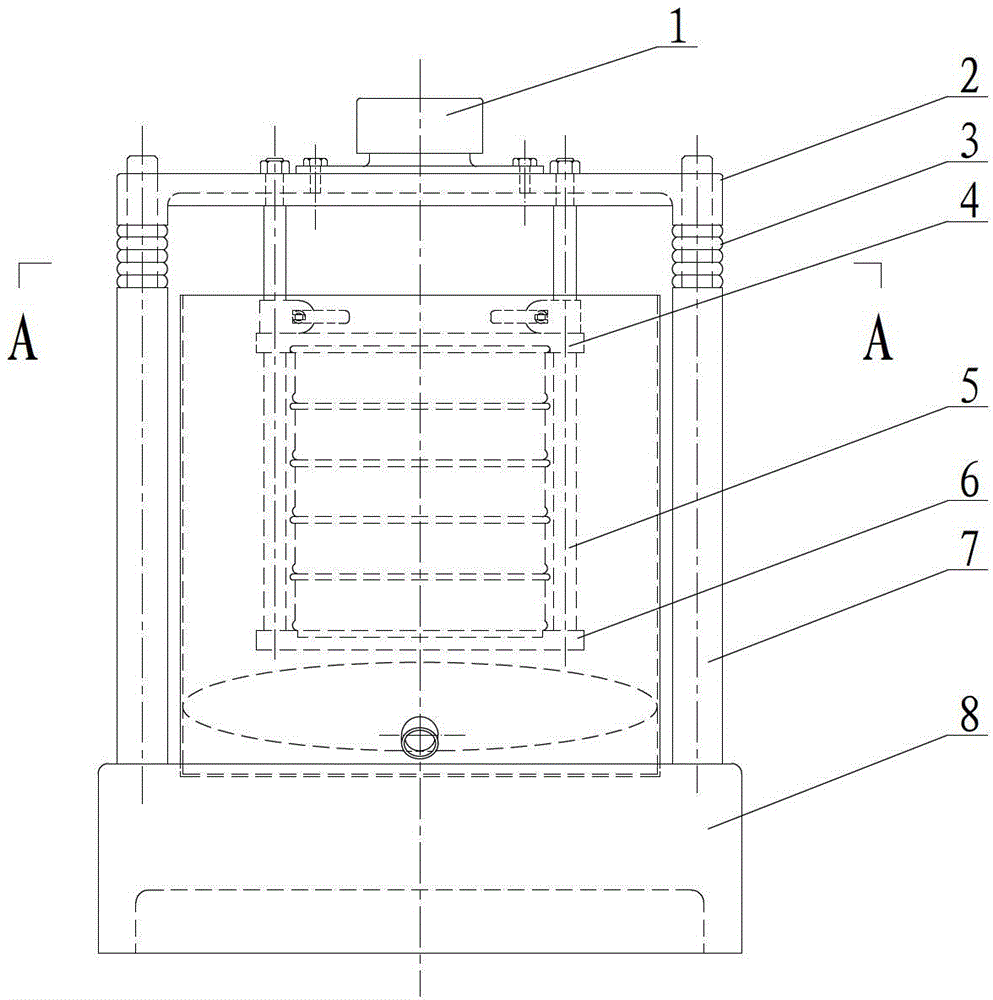

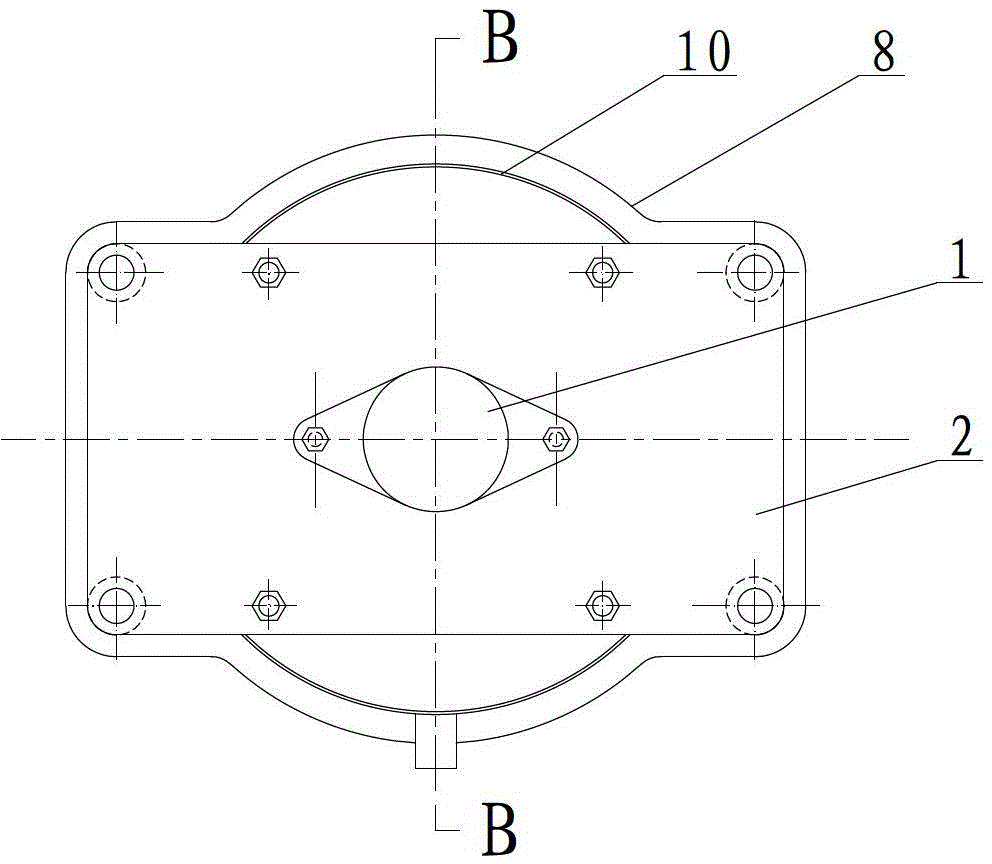

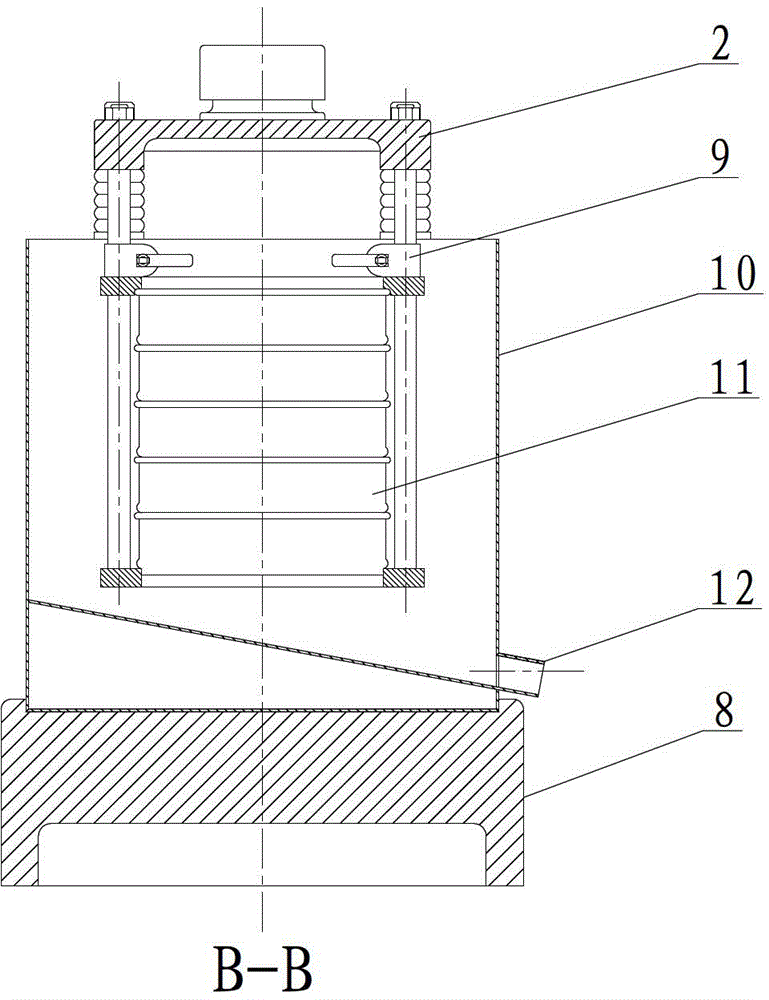

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a vibrating sieve for wet particle size analysis consists of an electromagnetic vibrator 1, a vibrating plate 2, a rubber spring 3, a standard sieve upper pressure plate 4, a standard sieve hanger 5, a standard sieve hanger chassis 6, and a vibrating plate Pillar 7, base 8, pressure plate clamp 9 on the standard cover sieve, water tank 10, standard cover sieve 11 and water outlet 12 constitute.

[0029] Dimensions of a vibrating sieve for wet particle size analysis: length 510mm, width 420mm, height 676mm; water tank diameter 190mm, height 380mm; vibrator model: CZ10, vibration force 10kg, vibration direction vertical up and down, amplitude about 2mm, vibration frequency 3000 times / min, voltage 220V; the vibrator 1 is fixed on the vibrating plate 2, and the vibrating plate 2 is sleeved on the vibrating plate pillar 7 through four holes and supported on the rubber spring 3. The vibrator 1 generates high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com