Method for determining anisotropy coefficient of resistivity of reservoir

An anisotropic and deterministic technology, applied in the fields of electrical digital data processing, earthwork drilling and production, complex mathematical operations, etc., can solve the problem of high logging cost, inapplicability, and inability to obtain continuously changing anisotropy coefficients of reservoirs. The anisotropy coefficient of the core section can be quickly and accurately determined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of this embodiment will be described in further detail below to support the technical problem to be solved by the present invention, but it is not used as a basis for any limitation on the invention.

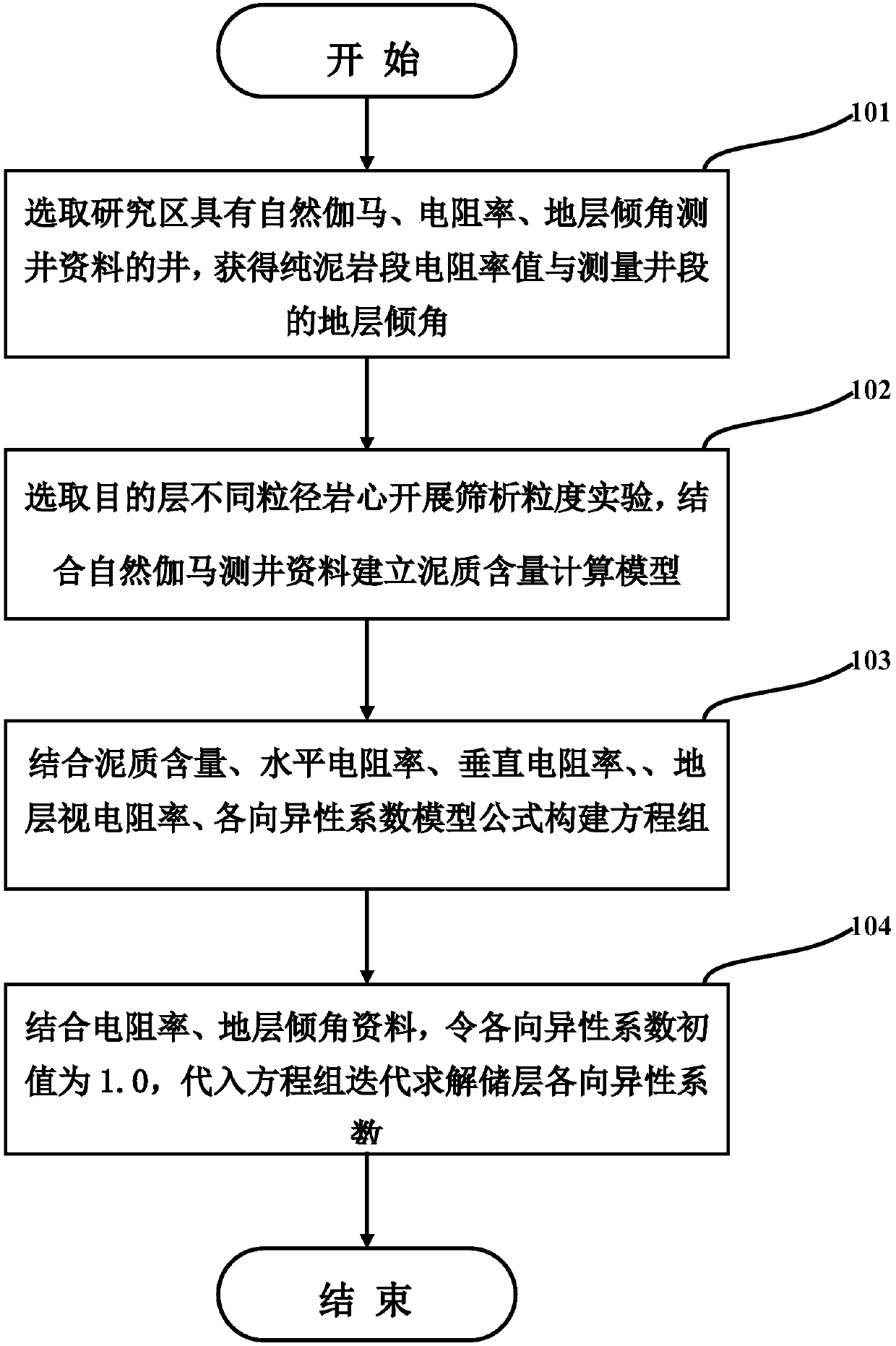

[0030] Such as figure 1 As shown, a method for interpreting a water-flooded layer in a horizontal well based on LWD provided by an embodiment of the present invention includes the following steps:

[0031] Step 101: Select the wells in the study area that have logging data of natural gamma ray, resistivity and formation dip angle, and obtain the resistivity value of the pure mudstone section and the formation dip angle of the measured well section;

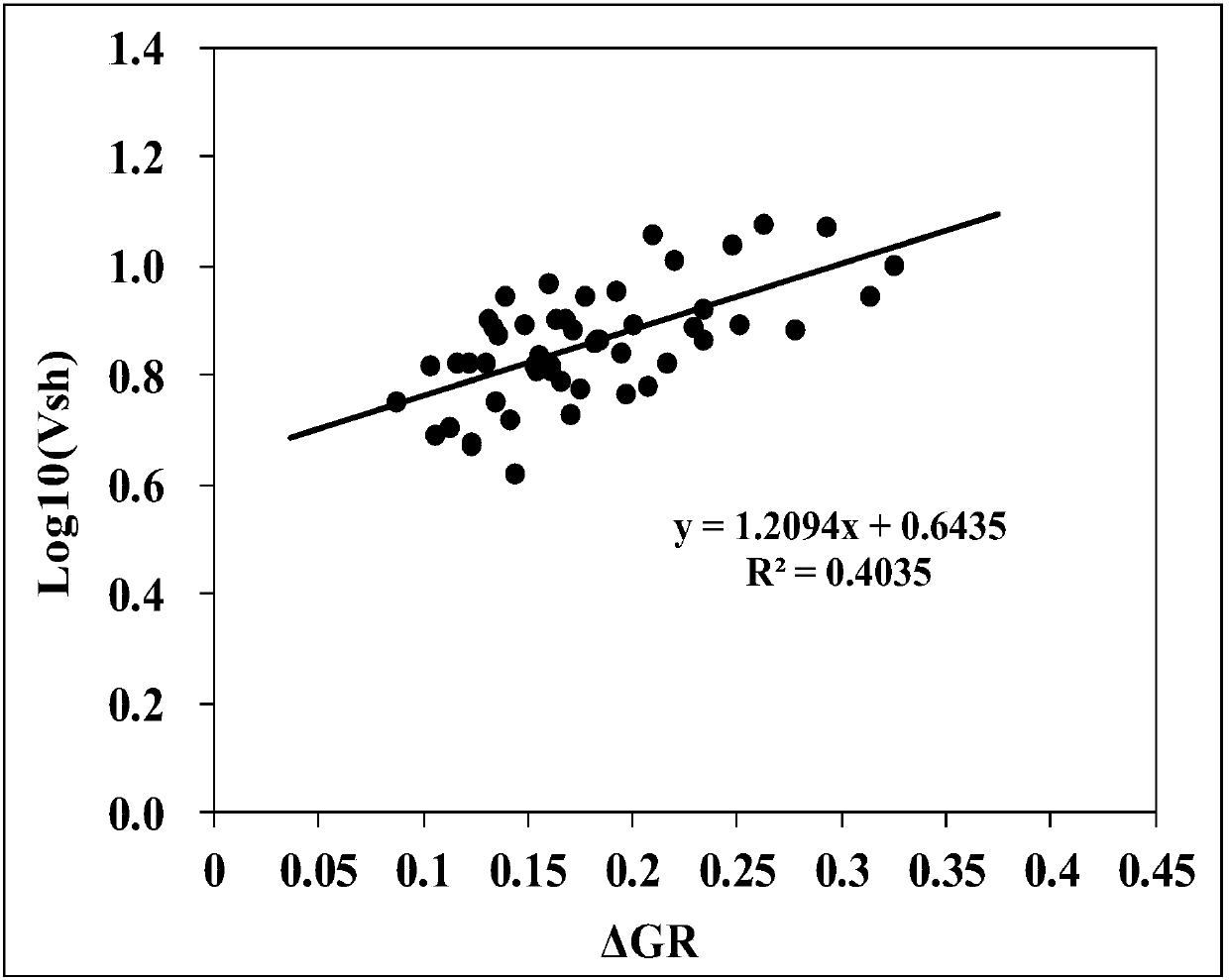

[0032] Step 102: Select cores of different particle sizes in the target layer to carry out sieving particle size experiments, and establish a calculation model for shale content in combination with natural gamma ray logging data;

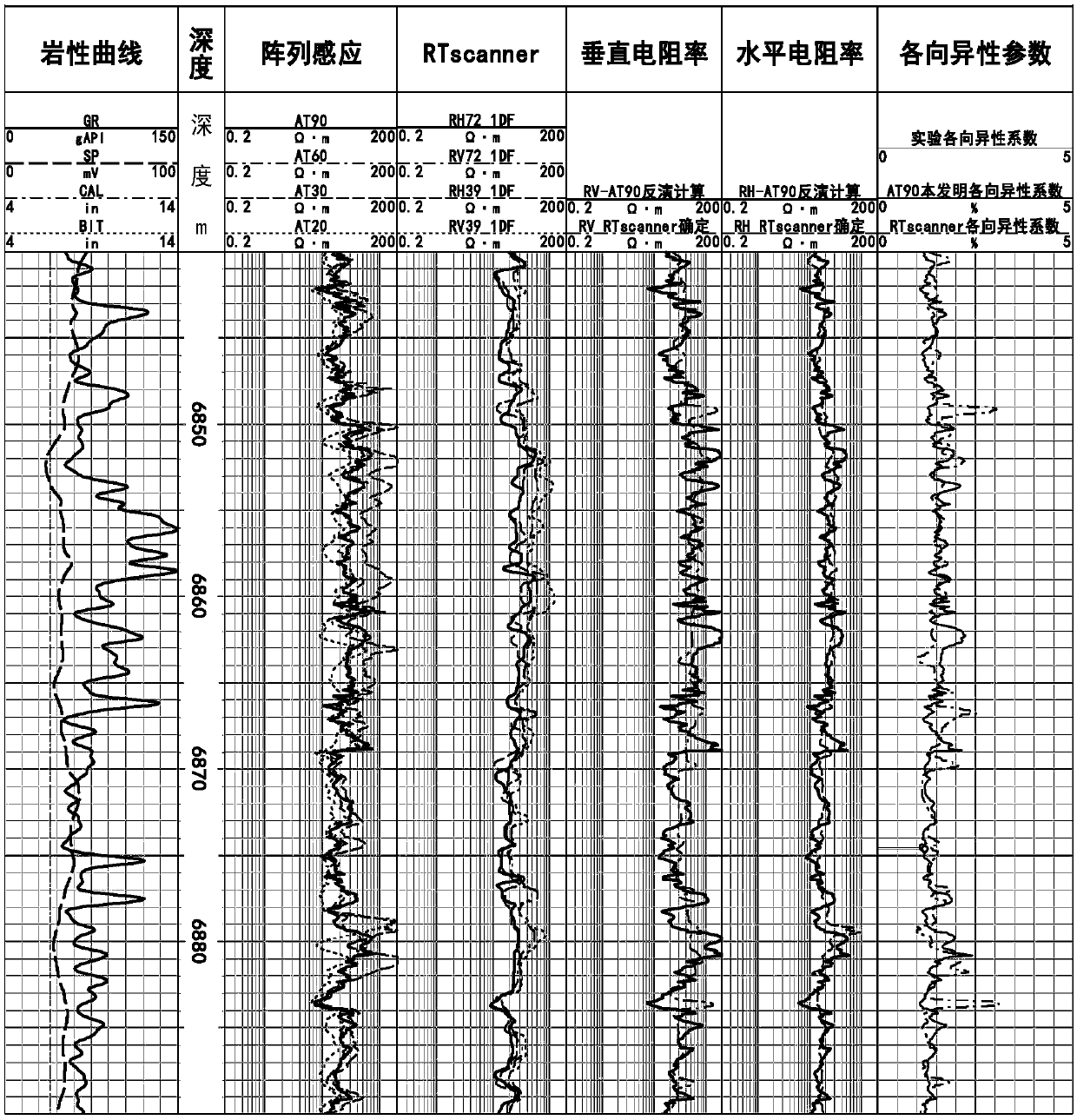

[0033] Step 103: Combining shale content, horizontal resistivity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com