Method and apparatus for real-time detecting mixing gas component content by thermal conductivity detector

A thermal conductivity detector and mixed gas technology, applied in the direction of thermal conductivity of materials, etc., can solve the problems of complex testing process, and achieve the effect of wide range of gases and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

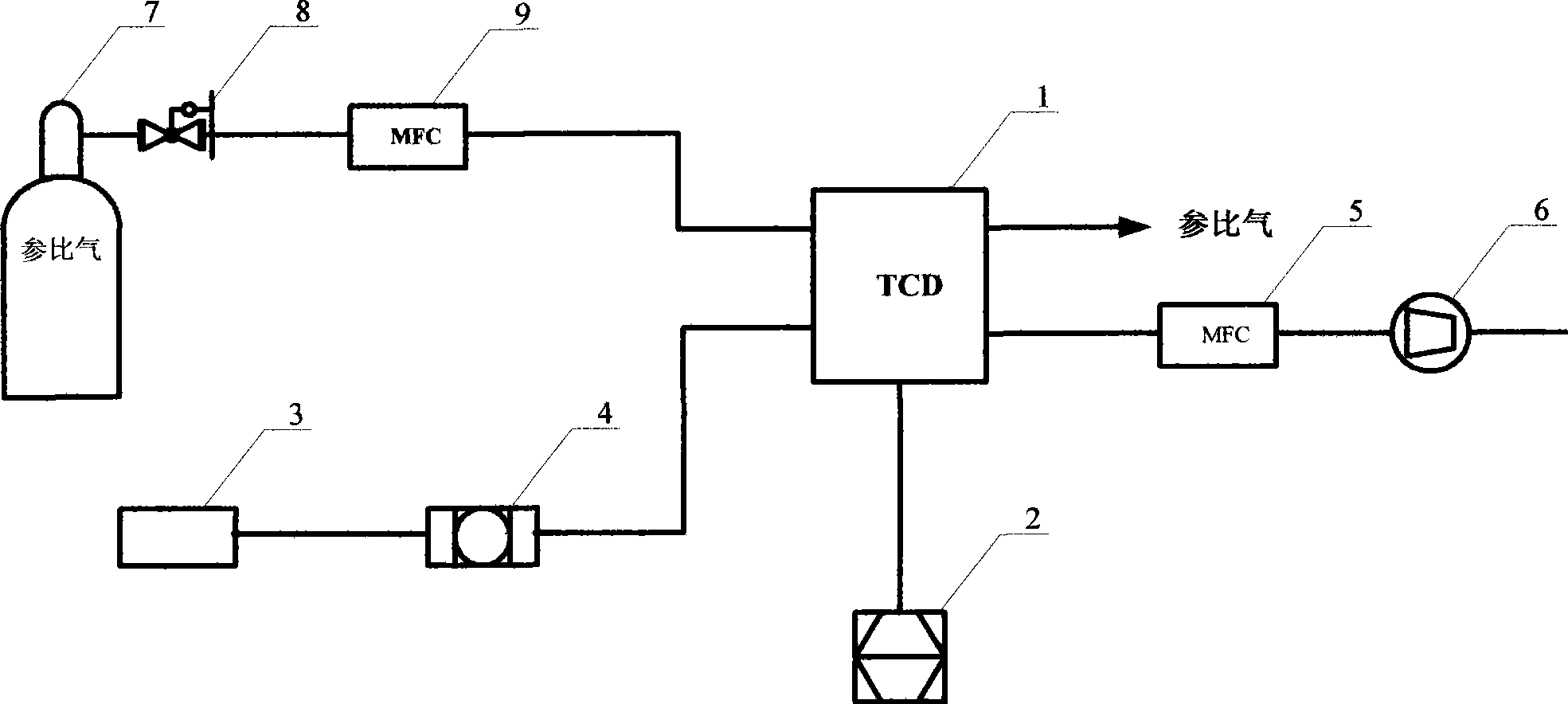

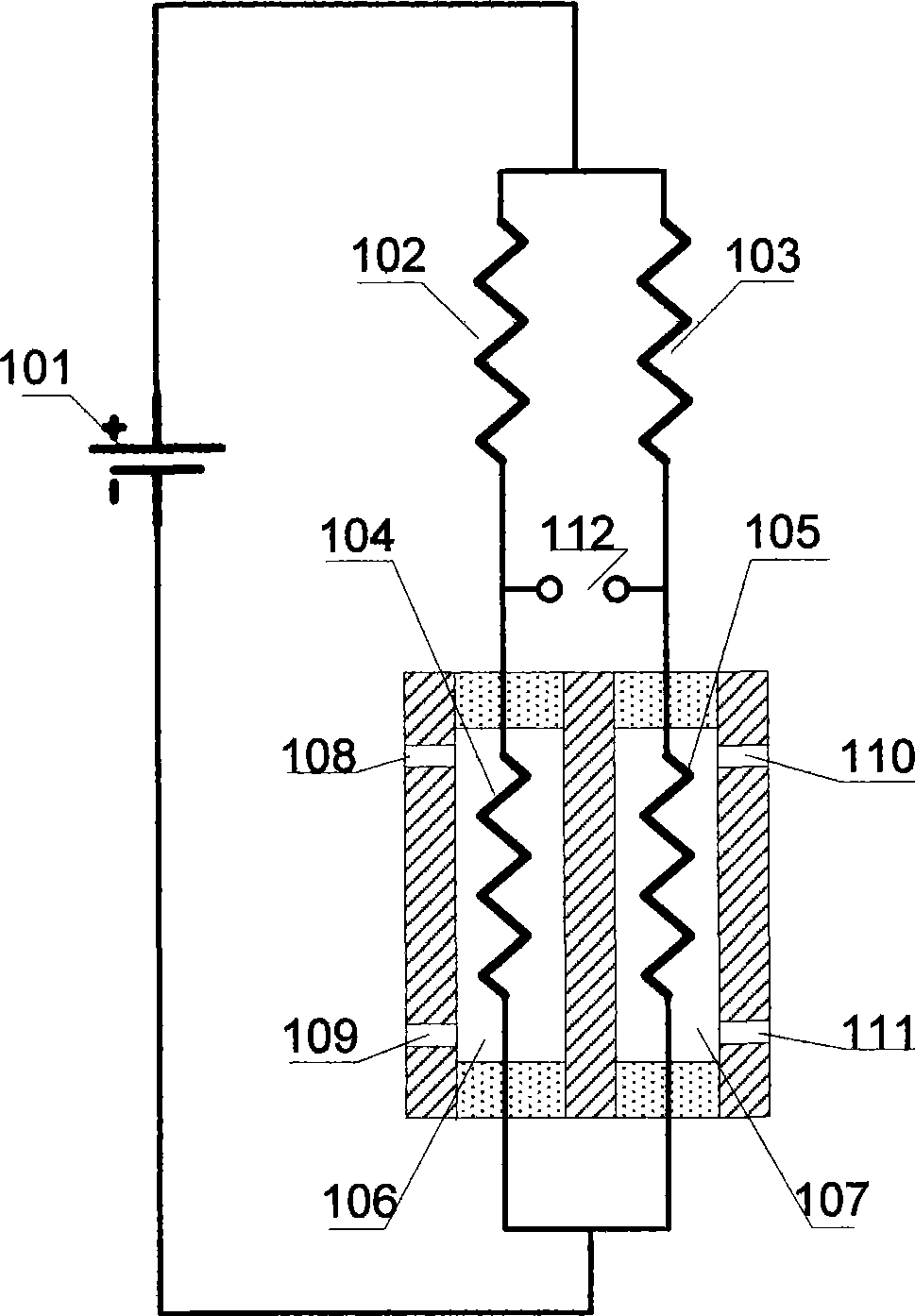

Method used

Image

Examples

Embodiment

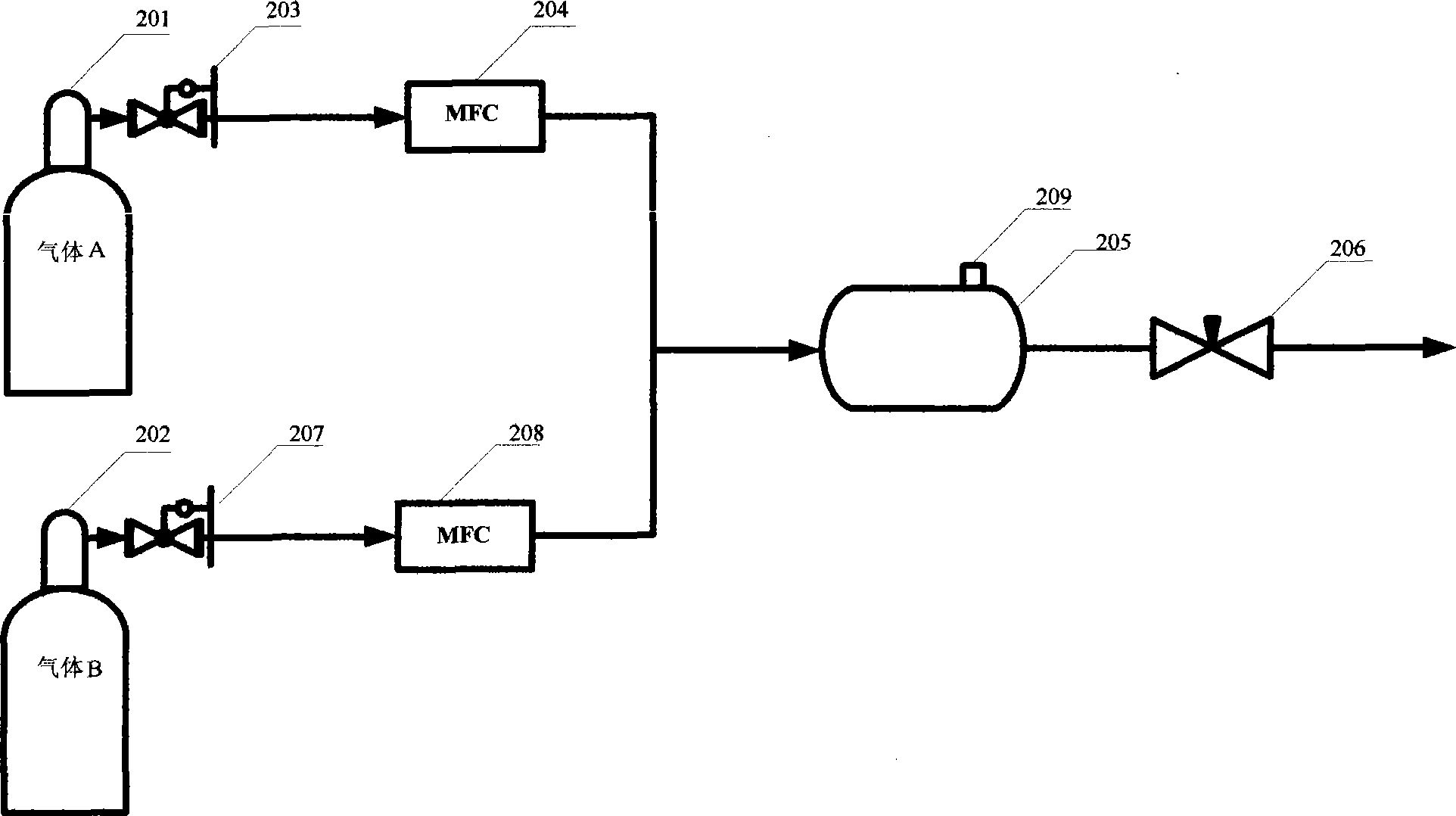

[0033] Embodiment: the test of helium concentration in a certain fluidized bed reactor

[0034] Application background: Study the gas flow law in the fluidized bed reactor by using the concentration change law of the tracer gas helium in the bed layer.

[0035] Such as image 3 As shown, a certain fluidized bed reactor is composed of the following parts: fluidization gas (air used here) inlet 301, bellows 302, gas distribution plate 303, fluidized bed body 304, helium distributor 305, gas Filter 306, gas outlet 313. Bed 312 contains solid particles having an average particle size of 60 microns. The gas distribution plate 303 is a sintered porous metal plate. The helium gas distributor 305 is a stainless steel pipe with a diameter of 6 mm, and the part inserted into the reactor is drilled with 5 holes with a diameter of 0.5 mm for introducing helium into the fluidized bed. The filter 306 is a sintered metal tube, which is used to discharge the gas in the fluidized bed while...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com