Residual stress measurement system through hole-drilling method

A measuring system and residual stress technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems such as the influence of drilling operation and drilling strain value, insufficient flexibility and convenience, and insufficient calculation system. The effect of shortened test cycle, improved adaptability and accuracy, and improved test success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

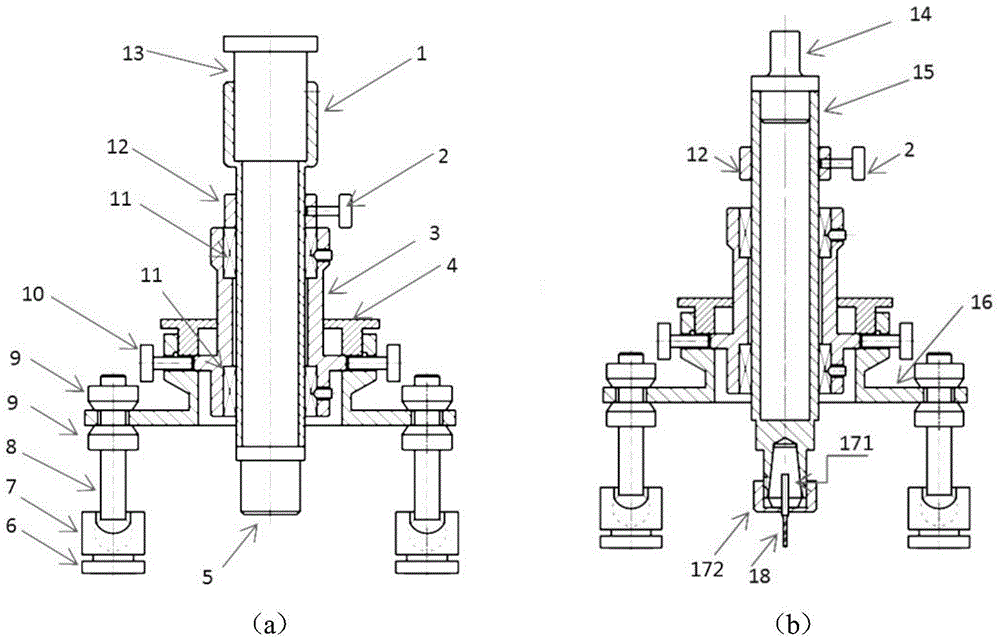

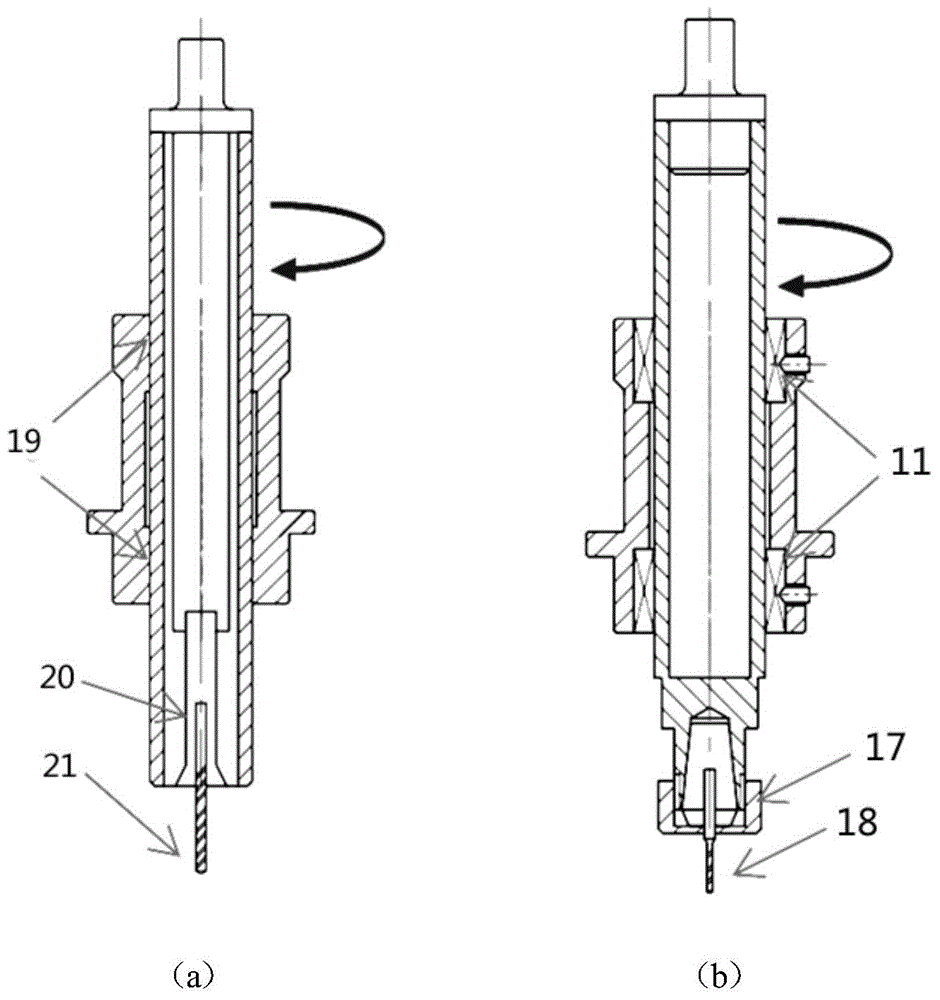

Method used

Image

Examples

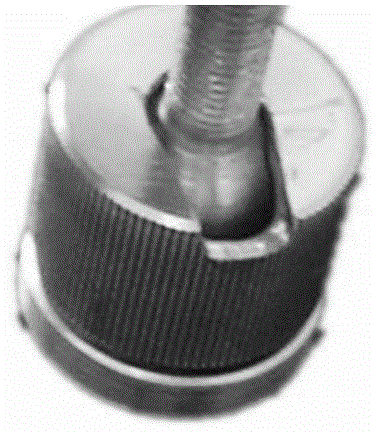

Embodiment 1

[0035] Adopt above-mentioned content of the present invention, develop such as Figure 4 (a) The KJS-HD-1 type drilling method measuring residual stress system shown in (a), including 30X tool microscope, φ22mm drill pipe, magnetic support base with guide cylinder, 0-3000rpm variable speed hand drill, 3.5″PDA handheld Type stress-strain acquisition and calculation equipment, BE120-2CA-B three-way strain rosette. The front end of the drill pipe is equipped with ER11A-3 CNC special elastic collet, NACHI high-precision variable-diameter hard drill: clamping section φ3mm, cutting tool section φ1. 5mm.

[0036] The measurement system of the present invention pastes three-way strain rosettes on the material to be measured, and the three-way strain rosettes are connected to strain gauges; Figure 4 (b) is the stress calculation interface, and the calculation adopts a two-way formula to facilitate the calculation of welding residual stress, as shown in the following formula (1):

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com