Preparation of bismuth membrane electrode

A bismuth film electrode and glassy carbon electrode technology, applied in the field of electrodes, can solve the problems of poor selectivity of glassy carbon electrodes, and achieve the effects of high sensitivity, short test process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After polishing the glassy carbon electrode, sweep cyclic voltammetry (about 20 times) in 0.5M sulfuric acid solution until the electrode reaches a stable state, and then dry it for later use.

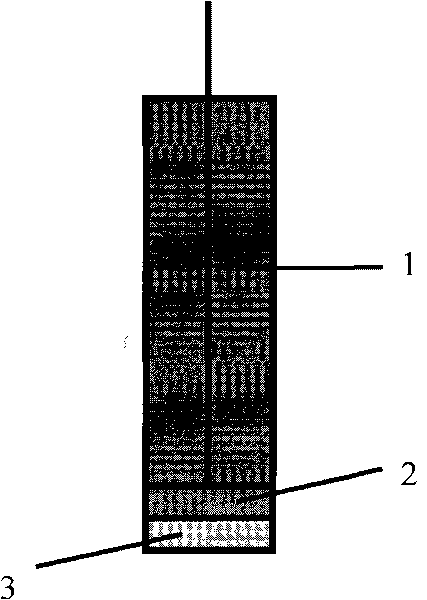

[0016] 1% by weight of Nafion (diluted with superior pure anhydrous ethanolamine weight ratio) and ionophore with a molar concentration of 2mmol / L (using chromatographically pure tetrahydrofuran as solvent) were calculated as 1:1 ultrasonic Mix well for 30 minutes, then drop 3 μL onto the surface of the spare glassy carbon electrode above, dry at room temperature, and finally blow with hot air for 1 min to harden, cool to room temperature and place it in a Bi solution containing 1000 μg / L (III) In the acetic acid-sodium acetate buffer solution of pH 4.5, the Ag / AgCl electrode is used as the reference electrode, the platinum electrode is used as the counter electrode, and the bismuth film electrode is used as the working electrode, and a potential of -1.2V is applied under the con...

Embodiment 2

[0019] Using the electrode prepared by the present invention to measure lead in seawater is an example.

[0020] Seawater pretreatment: first filter with a filter membrane with a diameter of 0.45 μm, then place the filtrate under a high-pressure mercury lamp for digestion for 50 minutes, and then adjust the pH to 4.5 with 0.1M acetate buffer.

[0021] Measurement process:

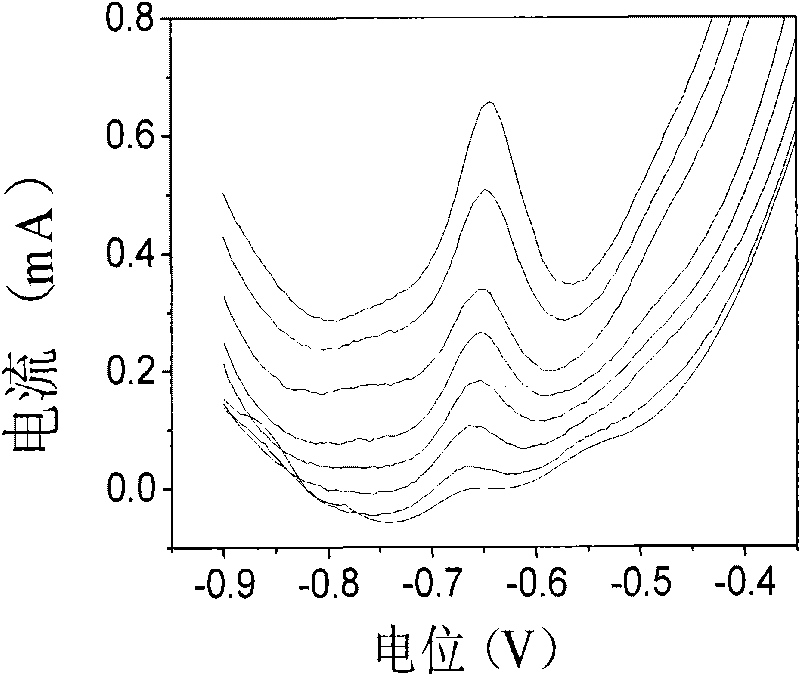

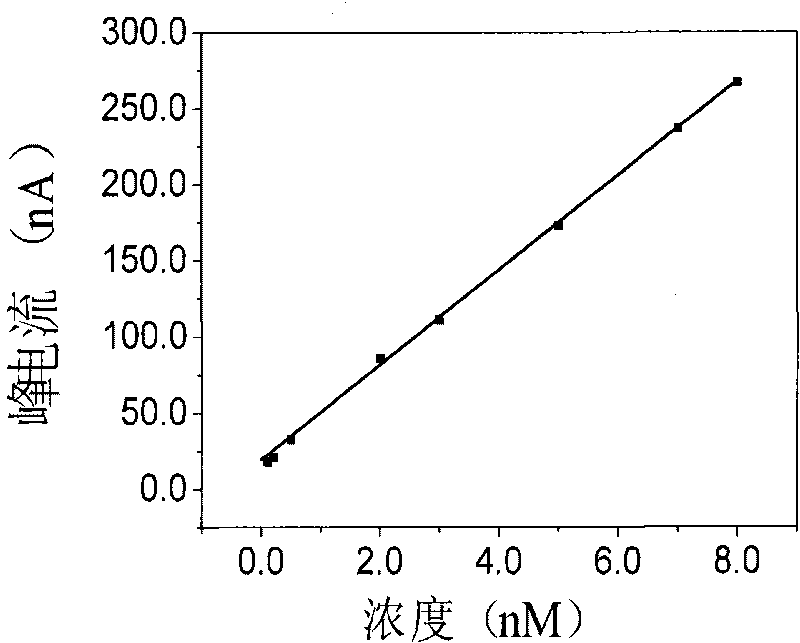

[0022] 1) Take the bismuth film electrode prepared in Example 1 as the working electrode, insert it into the pretreated seawater containing 1000 μg / L Bi(III), and enrich it with a potential of -1.2V for 180s under the condition of stirring so that Both bismuth and lead are deposited on the electrode surface. The Ag / AgCl electrode (inner filled with 3M KCl) is used as the reference electrode, and the platinum electrode is used as the counter electrode, and then the potential remains unchanged for 15s, and then the differential pulse voltammetry is used to scan forward from -1.0V to -0.3V, during this proce...

Embodiment 3

[0028] The electrode prepared by the invention is used to measure the concentration of lead in a solution with tin present.

[0029] When measuring lead ions using a bismuth film electrode, the elution peak of tin present in the solution often overlaps with lead, which interferes with the measurement of lead. Adopt electrode of the present invention and existing bismuth film electrode to measure the concentration (referring to Table 1) of the solution lead of identical concentration lead and tin (molar concentration is 5nM),

[0030] Table 1

[0031]

[0032] As can be seen from Table 1, on the existing bismuth film electrode, when only lead exists, its stripping peak current is 33.06nA, but when lead and tin two kinds of ions exist in solution simultaneously, peak current is then 11.04nA, reduces nearly two-thirds, indicating that tin seriously interferes with the determination of lead. And under the same situation, on the electrode of the present invention, the strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com