System and method of multi-element pulsed laser deposition for synthesizing composite material in batches

A technology of pulsed laser deposition and composite materials, which is applied in the field of materials science, can solve problems such as uneven growth rate, inconsistent film thickness, mask dislocation process, etc., and achieve the effects of rapid screening test, improved efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

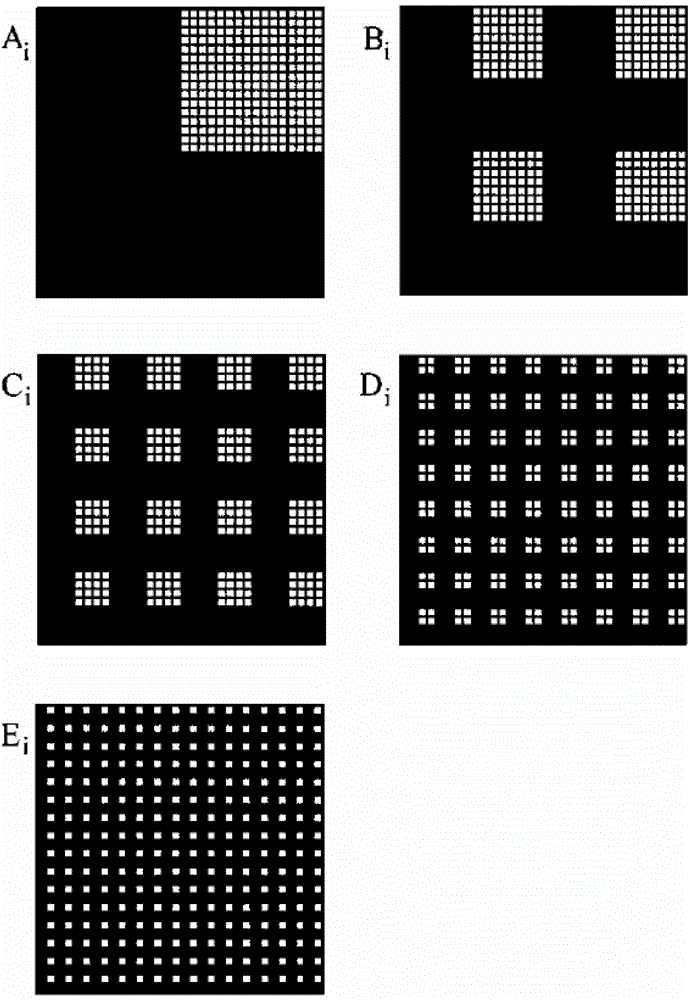

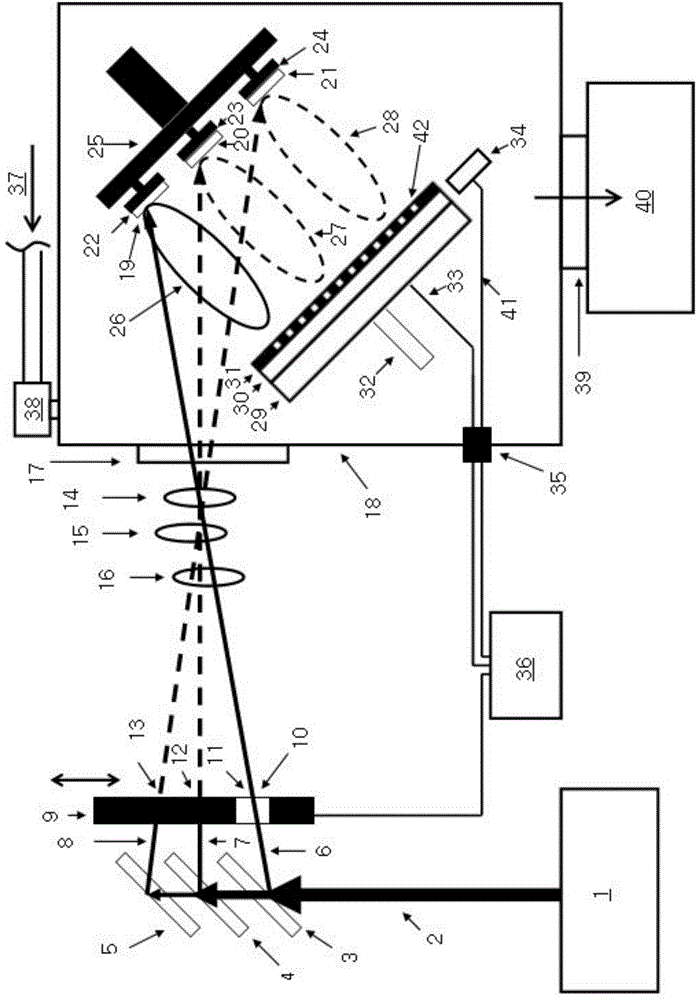

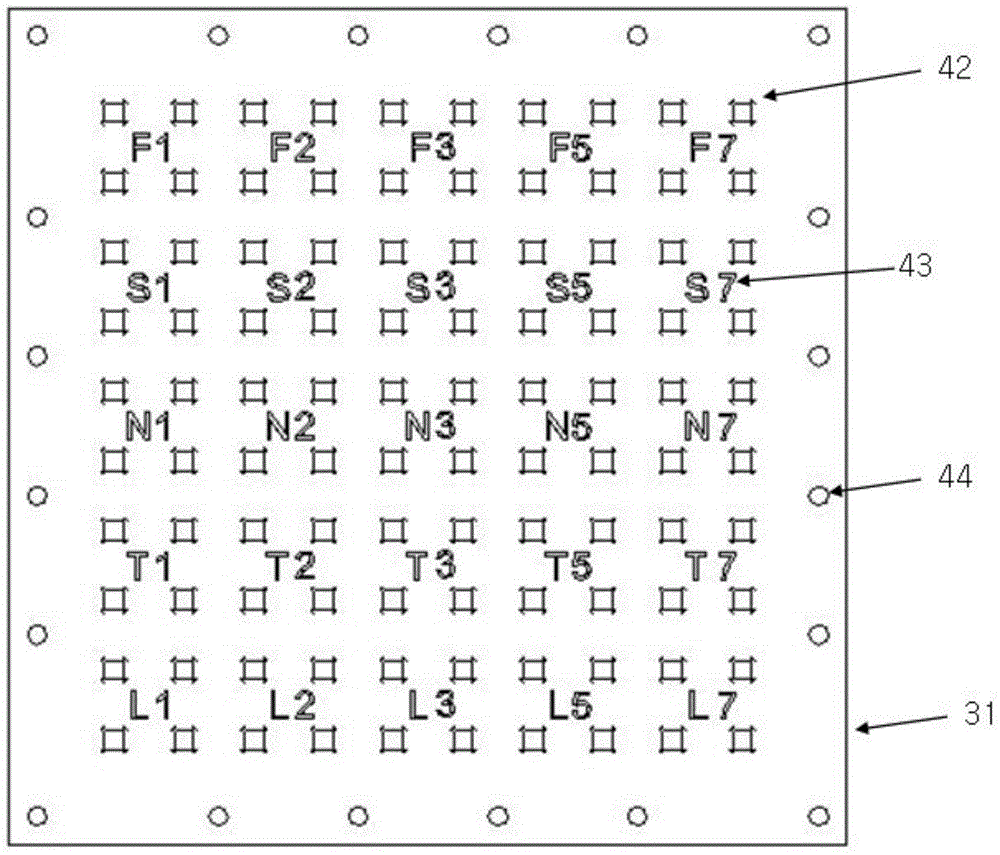

[0054] The following will combine Figure 2-Figure 4 The present invention is described in further detail with specific examples. The invention is not limited to the examples described here, since the invention likewise permits other equally effective applications.

[0055] figure 2 It is a blueprint of multi-pulsed laser deposition system. A high-energy laser 1 such as a Lambda Physik LPX 210i emits a high-energy laser beam 2 . The laser beam splitting device comprises two laser beam splitters (for example, the first beam splitter 3 has a reflectivity of 30%, a transmittance of 70%; the second beam splitter 4 has a reflectivity of 50%, a transmittance of 50%) and A mirror 5. The laser beam is split into three laser beams (first laser beam 6, second laser beam 7 and third laser beam 8). The first beamsplitter 3, the second beamsplitter 4 and the reflector 5 are arranged in series along the path of the laser beam, and the first beamsplitter 3, the second beamsplitter 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com