Device and method for measuring mechanical properties of rocks

A measuring device and technology of rock mechanics, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test material strength, etc., can solve the problems of complex operation, large economic consumption, and long experiment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

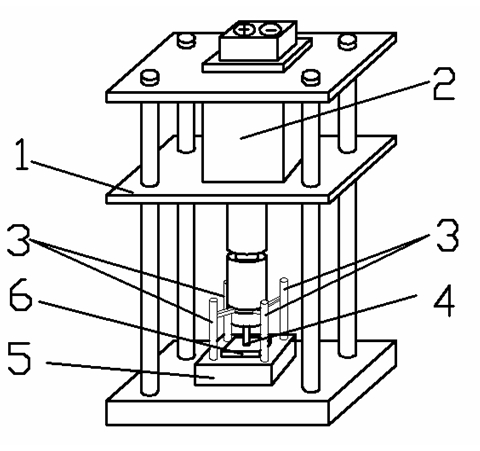

Image

Examples

Embodiment 1

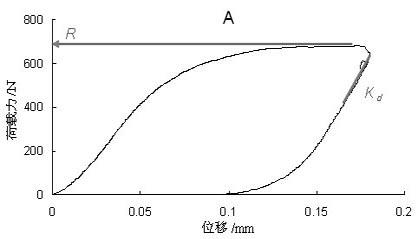

[0050] 1) This example is to measure the elastic modulus of sandstone. First, calibrate the system stiffness of indenters with different flat head diameters. Aluminum alloy material (Al7049) is used as the calibration material. The mechanical parameters are: E=71.4GPa, v=0.33, elastic yield limit σ y =655MPa, don’t calibrate the system stiffness when the drill diameter is 0.5, 1, 2mm

[0051] 2) Since the particles of sandstone are relatively coarse, a flat-bottomed cylindrical indenter with a diameter of 2m is selected.

[0052] 3) Take 3 groups of sandstone samples, with 5 as a group, the thickness of the rock samples is about 10mm, and the diameter is about 40mm. Different rock samples are distinguished by numbers, which represent different sampling locations. The upper and lower parts are machine ground to be smooth and smooth. Different groups of rock samples are distinguished by numbers, which represent different sampling locations.

[0053] 4) Put the rock sample on t...

Embodiment 2

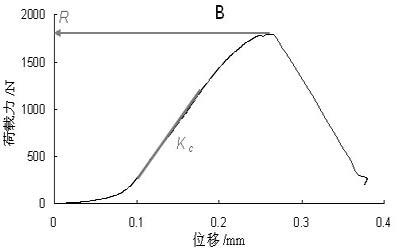

[0057] 1) This example is to measure the elastic modulus of limestone, as example 1, at first calibrate the system stiffness of indenters with different flat head diameters with known mechanical properties materials such as aluminum alloy.

[0058] 2) Since the particles of limestone are relatively coarse, a flat-bottomed cylindrical indenter with a diameter of 0.5m is selected.

[0059] 3) Take 3 groups of limestone samples, 5 as a group, the thickness of the rock samples is about 10mm, and the diameter is about 40mm. Different rock samples are distinguished by numbers, which represent different sampling locations. The upper and lower parts are machine ground to be smooth and smooth. Different groups of rock samples are distinguished by numbers, which represent different sampling locations.

[0060] 4) Put the rock sample on the sample fixing platform, start the DC motor to start loading, the loading rate is represented by displacement, and the displacement measurement syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com