Micro-tensile bonding strength testing fixture for dental bonding agent

A technology for bonding strength and testing fixtures, used in measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve the problems of unsuitable bonding strength testing of dental adhesives, complex structures, etc., and achieve bonding strength testing. Accurate results, extended functionality, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below through specific examples. The following examples are further illustrations of the present invention, but do not limit the scope of the present invention.

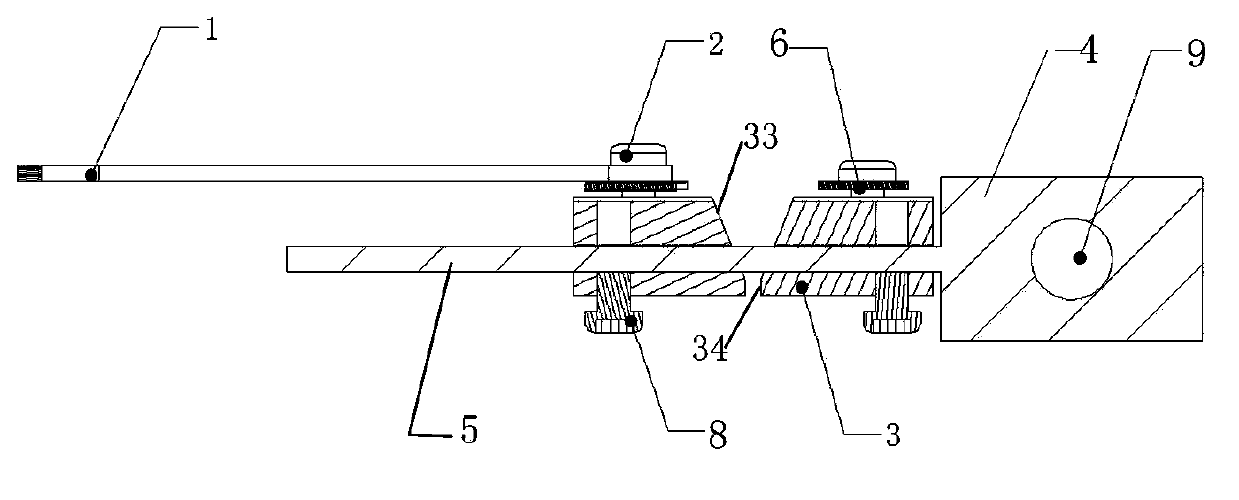

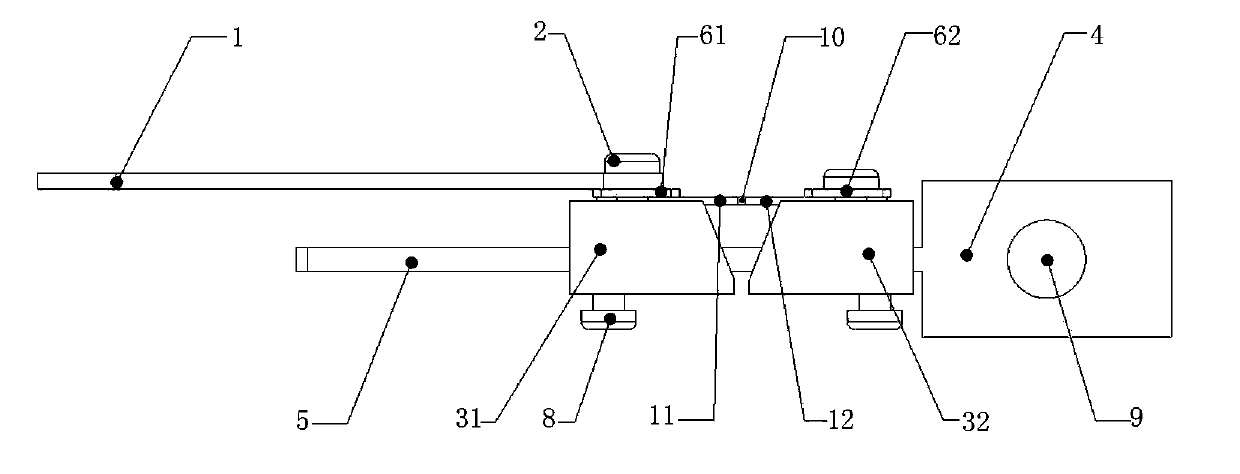

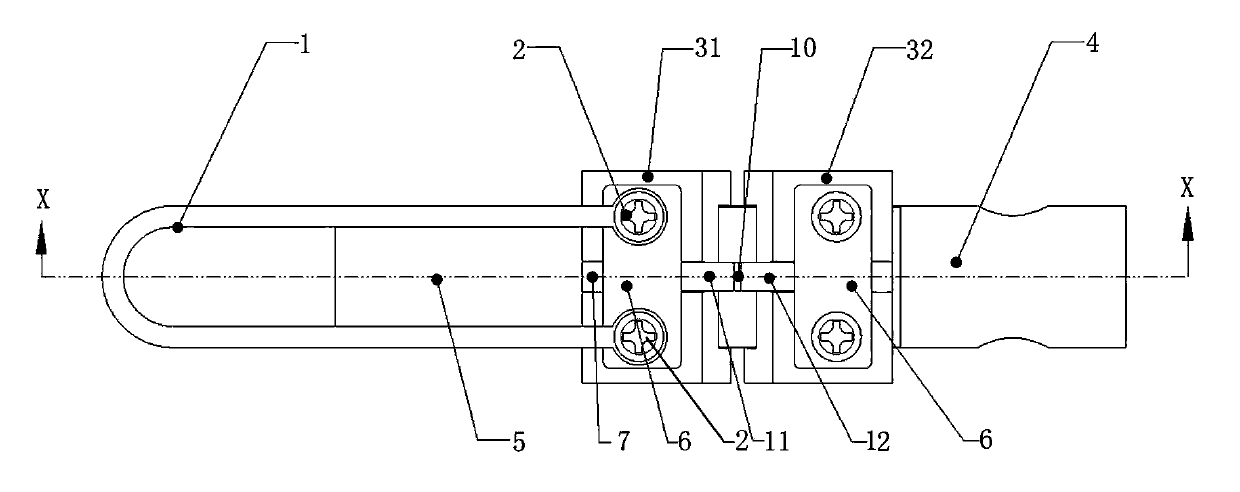

[0023] A jig for testing the micro-tensile bonding strength of dental adhesives. The front part of the connecting shaft 4 is a guide rod 5, and the side of the rear part is provided with a pin hole 9; in the working state, the upper slider 31 is fixedly connected with the pull rod 1, Simultaneously, it is slidably connected with the guide rod 5; the lower slider 32 is fixedly connected with the guide rod;

[0024] The working surfaces of the upper and lower sliders are located on the same horizontal plane, and the center line of the working surfaces of the upper and lower sliders is provided with a sample limiting groove 7 .

[0025] The pull rod is a U-shaped structure; the pull rod is fixedly connected with the upper slider through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com