Preparation of small-sized hydroxyl iron oxide nanorod

A nanoparticle and rod-shaped technology, which is applied in the field of rod-shaped β-FeOOH nanoparticles and its preparation, can solve the problems of low specific surface area and inability to catalyze degradation applications, and achieve the effects of simple preparation process, easy-to-control product composition, and uniform product distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of β-FeOOH nano rod, comprises the steps:

[0024] (1) Mix 40mL of deionized water and 40mL of KMnO 4 Prepare a light purple solution a with a pH of 4.0-5.0.

[0025] (2) Then weigh 0.76g of FeCl 3 ·6H 2 O was dissolved in solution a, and a dark yellow solution b with a volume of 80 ml was obtained after stirring for 1 minute and ultrasonic dispersion.

[0026] (3) Put solution b into a constant temperature drying oven, and heat-treat at 80° C. for 4 hours to obtain solution c and precipitate d.

[0027] (4) The precipitate d was collected by centrifugation, ultrasonically cleaned with deionized water and absolute ethanol, and finally dried to obtain the yellow-brown target product, namely β-FeOOH nanorods.

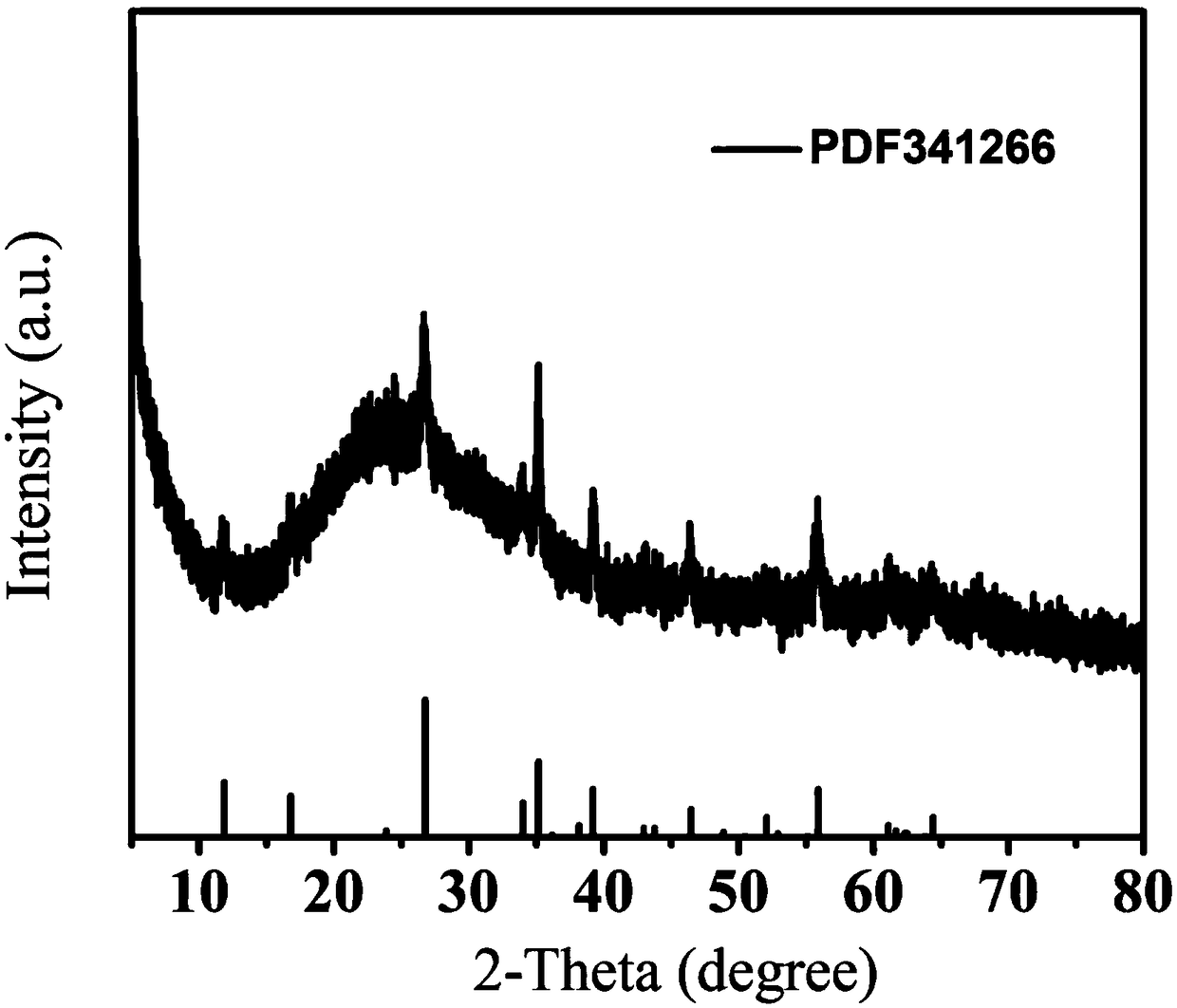

[0028] figure 1 It is the XRD spectrum pattern of the product obtained in Example 1. Compared with the standard β-FeOOH spectrum (JCPDS: 341266), the obtained product is high-purity β-FeOOH.

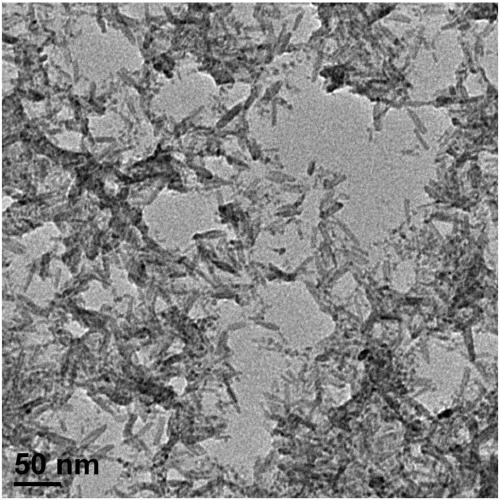

[0029] figure 2 It is the TEM picture of...

Embodiment 2

[0031] The preparation method of β-FeOOH nano rod, comprises the steps:

[0032] (1) Mix 40mL of deionized water and 40mL of 10mM KMnO 4 The purple solution a has a pH of 4.0 to 5.0.

[0033] (2) Then weigh 0.76g of FeCl 3 ·6H 2 O was dissolved in solution a, and a purple solution b with a volume of 80 ml was obtained after 3 minutes of stirring mixing and ultrasonic dispersion.

[0034] (3) Put solution b into a constant temperature drying oven, and heat-treat at 80° C. for 4 hours to obtain solution c and precipitate d.

[0035] (4) The precipitate d was collected by centrifugation, ultrasonically cleaned with deionized water and absolute ethanol, and finally dried to obtain the brown target product, namely β-FeOOH nanorods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com