Method for preparing slurry titanium dioxide by hydrothermal method

A technology of titanium dioxide and hydrothermal method, applied in chemical instruments and methods, titanium dioxide, fibrous fillers, etc., can solve the problems of low extraction rate, reduced weather resistance of titanium dioxide slurry, etc. The effect of weather resistance, high storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

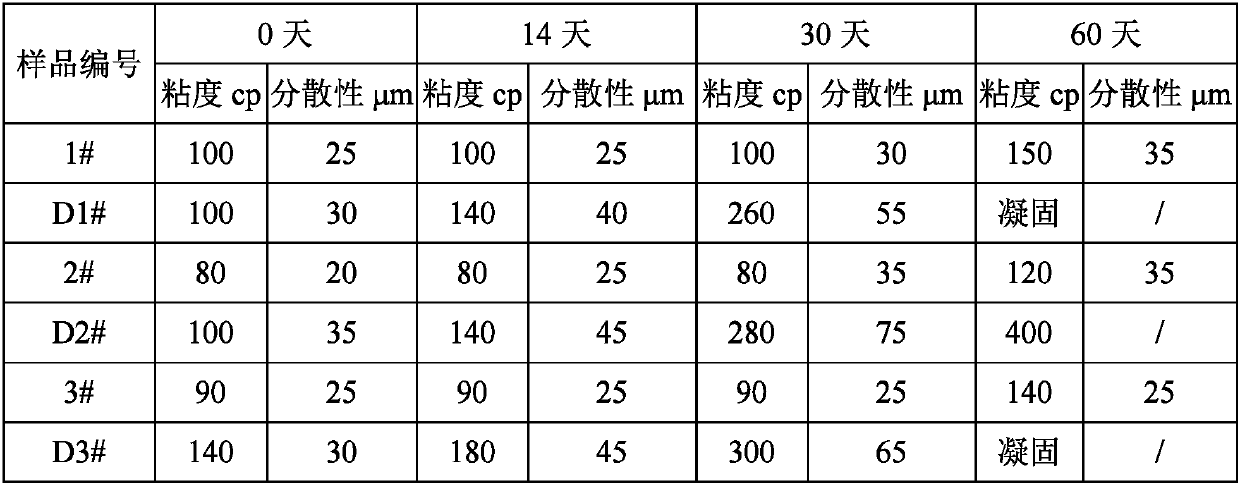

Examples

Embodiment 1

[0029] Select the chlorination method base material with a particle size D50 of 0.285 μm and a particle size distribution of 1.48 to make a 300 g / L slurry, raise the temperature to 90 ° C, adjust the pH to 10.5 with sodium hydroxide solution; add 3.5 wt % silicate solution (as SiO 2 meter), the addition time is 15min; the pH of the slurry is adjusted to 5 with dilute sulfuric acid, and the adjustment time is 100min; the hydrothermal reaction is carried out at a temperature of 150°C, and the reaction time is 3h; the temperature is lowered to 60-70°C, and 2.4wt% chloride is added Aluminum solution (as Al 2 o 3 meter), add sodium hydroxide solution at the same time, keep the slurry pH as 7.5, add time 60min, homogenize 30min; Wash the slurry through a 325-mesh sieve until the conductivity of the filter cake is 70-100 μs / cm, and the solid content of the filter cake is >65%; perform beating and dispersion, add 1.0 wt% polycarboxylate sodium salt dispersant, and the solid content ...

Embodiment 2

[0031] Select a sulfuric acid base material with a particle size D50 of 0.325 μm and a particle size distribution of 1.47 to make a 4S0g / L slurry, raise the temperature to 85°C, adjust the pH to 9 with sodium hydroxide solution; add 3.0wt% silicate solution (as SiO 2 meter), the addition time is 25min; the pH of the slurry is adjusted to 6.5 with dilute sulfuric acid, and the adjustment time is 80min; the hydrothermal reaction is carried out at a temperature of 175°C, and the reaction time is 6h; the temperature is lowered to 60-70°C, and 1.0wt% aluminum sulfate is added solution (as Al 2 o 3 meter), add dilute sodium hydroxide solution at the same time, keep the slurry pH as 6, add time 40min, homogenize 30min; adjust pH to 7 with sodium hydroxide solution, carry out hydrothermal reaction at temperature 150 ℃, reaction time is 6h; wash the slurry through a 325-mesh sieve until the conductivity of the filter cake is 70-100 μs / cm, and the solid content of the filter cake is >...

Embodiment 3

[0033] Select the chlorination method base material with a particle size D50 of 0.370 μm and a particle size distribution of 1.44 to make a 350g / L slurry, raise the temperature to 70°C, adjust the pH to 10 with sodium hydroxide solution; add 2.6wt% silicate solution (as SiO 2 meter), the addition time is 30min; the pH of the slurry is adjusted to 8 with dilute sulfuric acid, and the adjustment time is 160min; the hydrothermal reaction is carried out at a temperature of 180°C, and the reaction time is 2h; the temperature is lowered to 60-70°C, and 4.8wt% aluminum metabolite is added Sodium acid solution (as Al 2 o 3 meter), add dilute sulfuric acid solution at the same time, keep the slurry pH as 9, add time 130min, homogenize 30min; The slurry is washed through a 325-mesh sieve until the conductivity of the filter cake is 70-100 μs / cm, and the solid content of the filter cake is > 65%; beating and dispersing is performed, and 3.0 wt% polycarboxylate sodium salt dispersant is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com