Preparation method of plasma-sprayed ceramic coating for strengthening surface of water pump impeller

A surface plasma and water pump impeller technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of flow rate, head and efficiency reduction, unstable operation, affecting pump performance, etc., and reach the heat affected zone Small size, high production efficiency, and small heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Use acetone to ultrasonically clean the surface of the impeller of the water pump to remove impurities such as oil, rust, etc., and dry it immediately after cleaning to prevent rust.

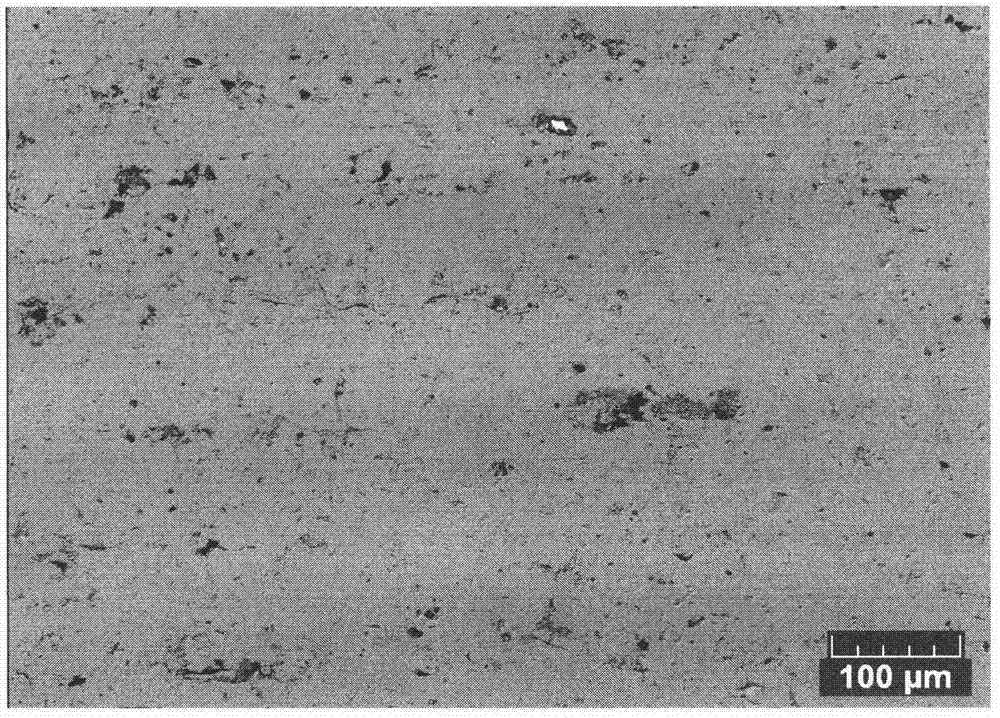

[0047] 2. Use brown corundum with a particle size of 20 mesh to roughen the surface of the water pump impeller to be sprayed to improve the bonding strength between the coating and the substrate. The surface roughness after roughening is required to be greater than Ra 7.0.

[0048] 3. Weigh 2000g of ZrO with a particle size range of 150-300 mesh 2 Ceramic powder, placed in an oven at 100°C to dry for 2 hours to maintain good fluidity of the powder during the spraying process.

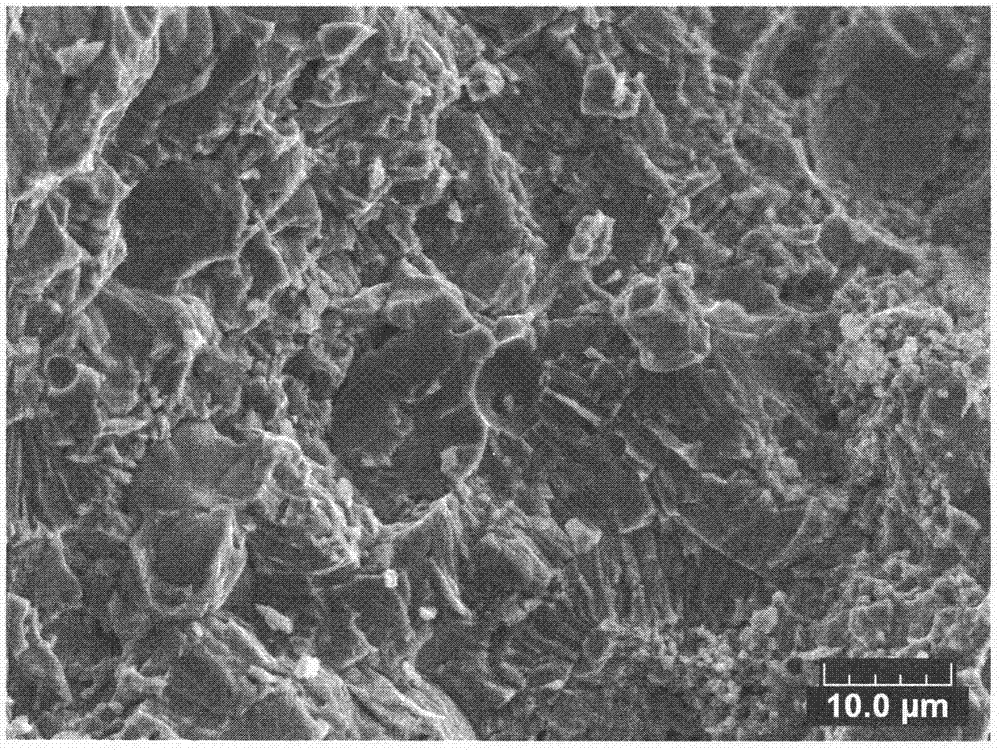

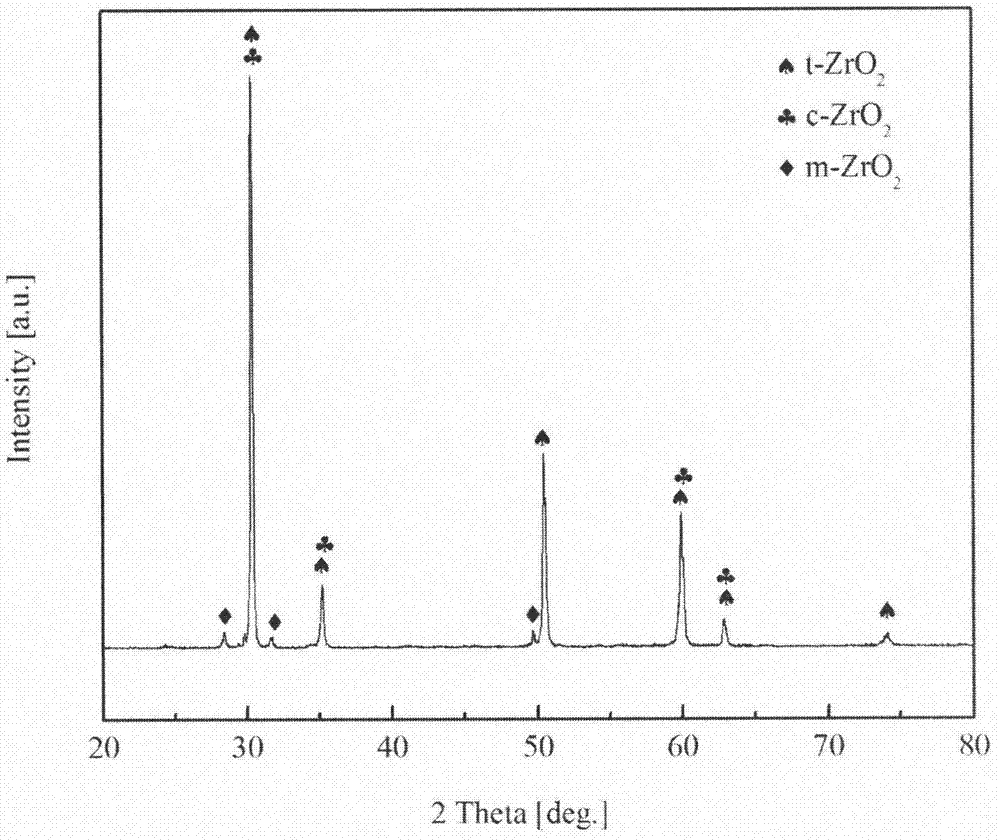

[0049] 4. Before spraying, use the plasma flame to go on the surface of the impeller substrate of the water pump, so that the substrate preheating temperature reaches about 150°C, and then use the plasma spraying process to spray ZrO on the surface of the preheated substrate 2 coating. Plasma generation gases ...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is that in step 3, 2000g of Al with a particle size range of 250-600 meshes is weighed 2 o 3 Ceramic powder; in step 4, control the powder delivery rate to be 40g / min and send it into the flame flow center, and the flow rate of the plasma generating gas Ar is 45L / min, and the H 2 The flow rate is 6L / min, the spraying power is 40kW, the spraying distance is 100mm, the translation speed of the spray gun is 300mm / s, and the spraying is repeated 5 times. Prepared on the surface of the water pump impeller with a thickness of about 240μm and a hardness of about 830HV 0.3 wear-resistant Al 2 o 3 ceramic coating. The deposition efficiency of the coating is around 50%, and the porosity is around 3%.

Embodiment 3

[0057] The difference between this embodiment and embodiment 1 is that in step 3, 2000g of TiO with a particle size range of 150-300 is weighed 2 Ceramic powder; in step 4, control the powder delivery rate to be 35g / min and send it into the flame flow center, and the flow rate of plasma generating gas Ar is 40L / min, and the H 2 The flow rate is 6L / min, the spraying power is 35kW, the spraying distance is 80mm, the translation speed of the spray gun is 300mm / s, and the spraying is repeated 5 times. Prepared on the surface of the water pump impeller with a thickness of about 250 μm and a hardness of about 750HV 0.3 Abrasion-resistant TiO 2 ceramic coating. The coating phase is mainly rutile TiO 2 , The bonding strength between the coating and the substrate can reach 31MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com