High-strength aluminum-plate fin-type heat exchanger

A plate-fin heat exchanger, high-strength technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of incomplete installation, troublesome installation, high cost, etc., and achieve reliability in use Good, easy to make, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

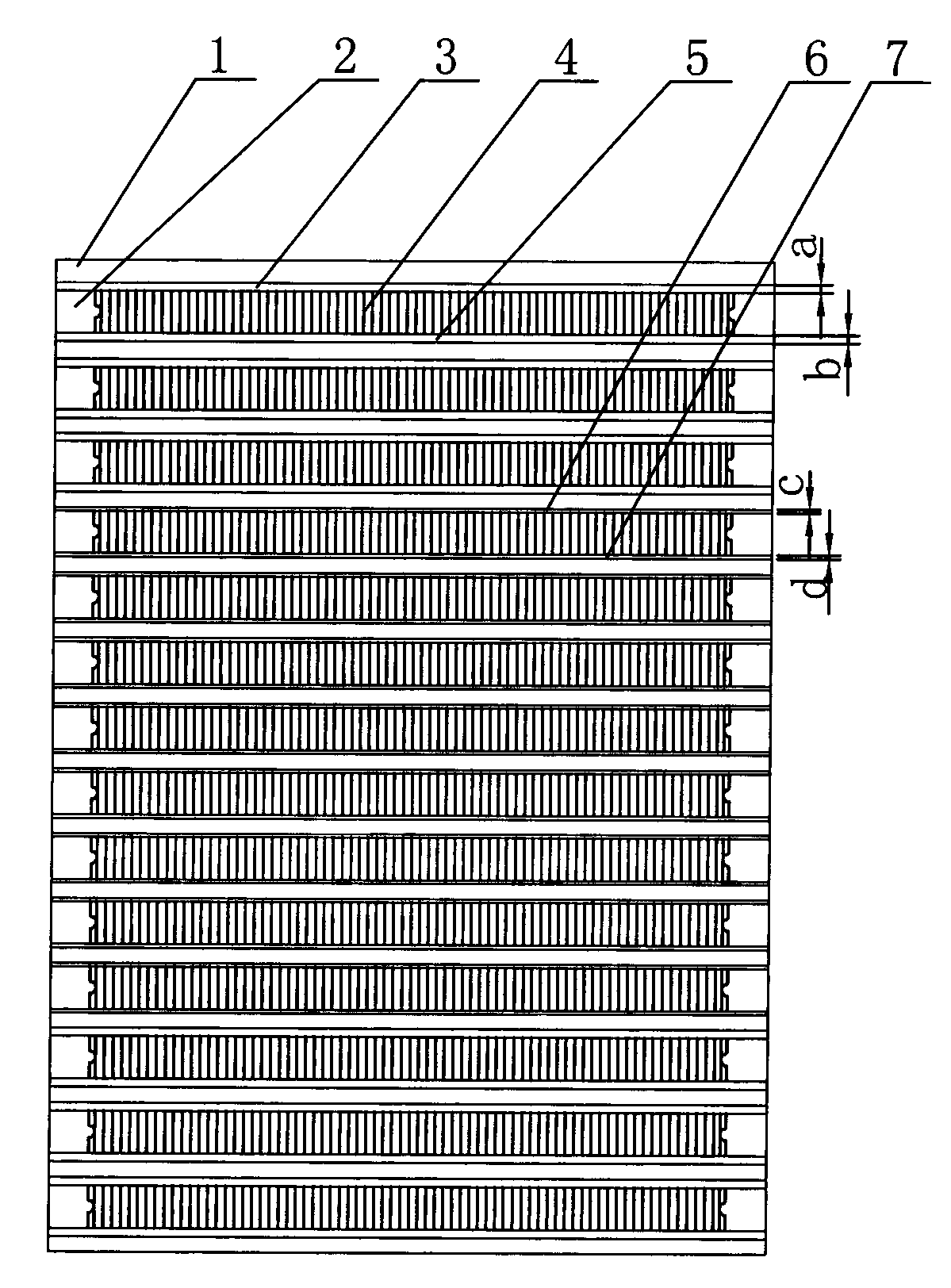

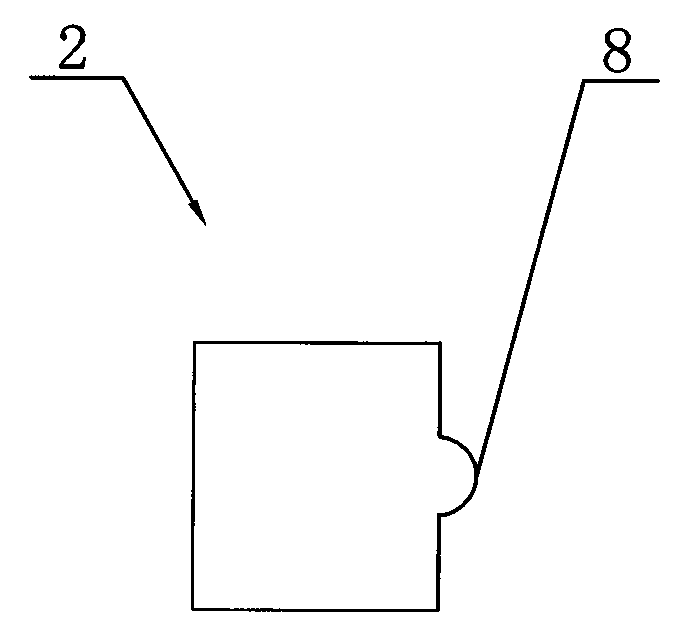

[0019] like figure 1 and figure 2 As shown, the high-strength aluminum plate-fin heat exchanger of this embodiment includes cover plates 1 installed symmetrically up and down, and a plurality of heat exchange channels are installed between the cover plates 1. The structure of the heat exchange channels is as follows: The first partition plate 3 and the second partition plate 5 are provided with uniformly arranged fins 4 between the first partition plate 3 and the second partition plate 5 , and seal strips 2 are installed at both ends of the fins 4 .

[0020] The partitions of the three heat exchange passages close to the cover plate 1 are thicker than the partitions of the remaining heat exchange passages.

[0021] The thicknesses a and b of the first separator 3 and the second separator 5 were 1.2 mm, and the thicknesses c and d of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com