Treatment method of oil palm seed core-shell material for manufacturing handicraft articles

A treatment method and seed core technology, applied in decorative art, special decorative structures, etc., can solve the problems of restricting the development of oil palm industry, waste of oil palm seeds, and no commercial value, so as to meet individual needs, high utilization rate, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Obtaining oil palm seed core shell materials

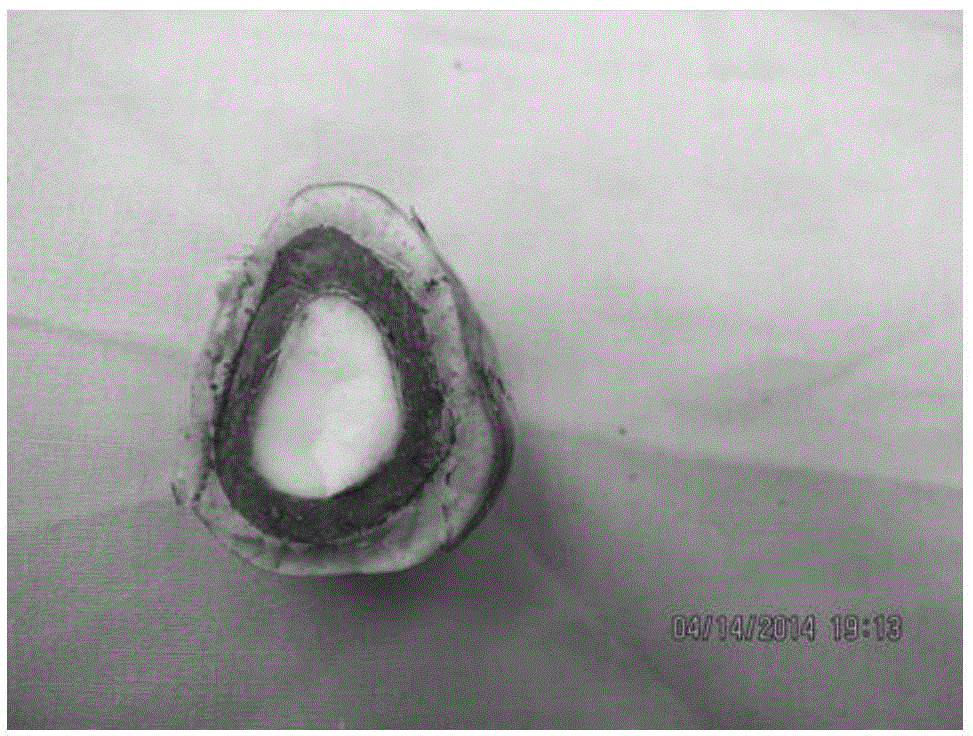

[0048] The thick-shell type oil palm tree (the thickness of the seed core and shell is about 1.3-3.7 mm) is selected as the seeding mother tree, and the mature oil palm ears are collected from the seeding mother tree (the oil palm ears grow many fruits and the fruit twist rate is high Up to 2000 grains / string, the seed core shell is dark brown and the core is milky white. figure 1 ); The collected oil palm ears are retorted and pulped to obtain a thick-shell oil palm seed ( image 3 ), and classified according to its size and shape.

[0049] 2. Oil palm seed carbonization and dehydration treatment

[0050] Take 80% mass percent concentrated sulfuric acid solution to carbonize and dehydrate the selected oil palm seeds twice, 2 minutes each time. After taking it out, wash off the residual concentrated sulfuric acid with water, and then wipe the surface of the oil palm seed core shell with sandpaper or gauze. . After the fresh o...

Embodiment 2

[0058] 1. Obtaining oil palm seed core shell materials

[0059] The thick-shell type oil palm tree (the thickness of the seed core shell is about 1.3-3.7 mm) is selected as the selection mother tree, and then the immature oil palm ears are collected from the selection mother tree (the oil palm ears grow a lot of fruits, the twist rate is Up to 2000 grains / string, the seed core shell is apricot or light apricot color, figure 2 ); The collected oil palm ears are retorted and pulped to obtain thick-shell oil palm seeds with apricot or light apricot color, complete fibers and clear stripes ( Figure 8 ), and classified according to its size and shape.

[0060] 2. Oil palm seed carbonization and dehydration treatment

[0061] Take a 90% mass percentage of concentrated nitric acid solution to carbonize and dehydrate the selected oil palm seeds for 3 minutes each time. After taking it out, wash off the residual concentrated nitric acid with water, and then wipe the surface of the oil palm ...

Embodiment 3

[0069] 1. Obtaining oil palm seed core shell materials

[0070] Directly collect discarded stale thick-shell oil palm seeds on the ground near the thick-shell oil palm tree (the thickness of the seed core shell is about 1.3-3.7 mm) (the surface of the seed's core shell is darker and grayish-brown, fiber The damage is not bright and the stripes are not clear); the thick shell oil palm seeds will be collected ( Figure 13 ), and classified according to its size and shape.

[0071] 2. Oil palm seed carbonization and dehydration treatment

[0072] Take a 90% mass percent concentrated sulfuric acid solution to carbonize and dehydrate the selected oil palm seeds twice for 2 minutes each. After taking it out, wash off the residual concentrated sulfuric acid with water, and then wipe the surface of the oil palm seed core shell with sandpaper or gauze. . After the stale oil palm seeds are carbonized and dehydrated, the surface of the core shell is bright and charcoal, with many remaining ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com