Degreasing method used for transparent alumina ceramic injection molding product

An alumina ceramic, injection molding technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of short degreasing cycle, long degreasing cycle, low degreasing rate, etc., achieve uniform degreasing, low defect rate, and improve degreasing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

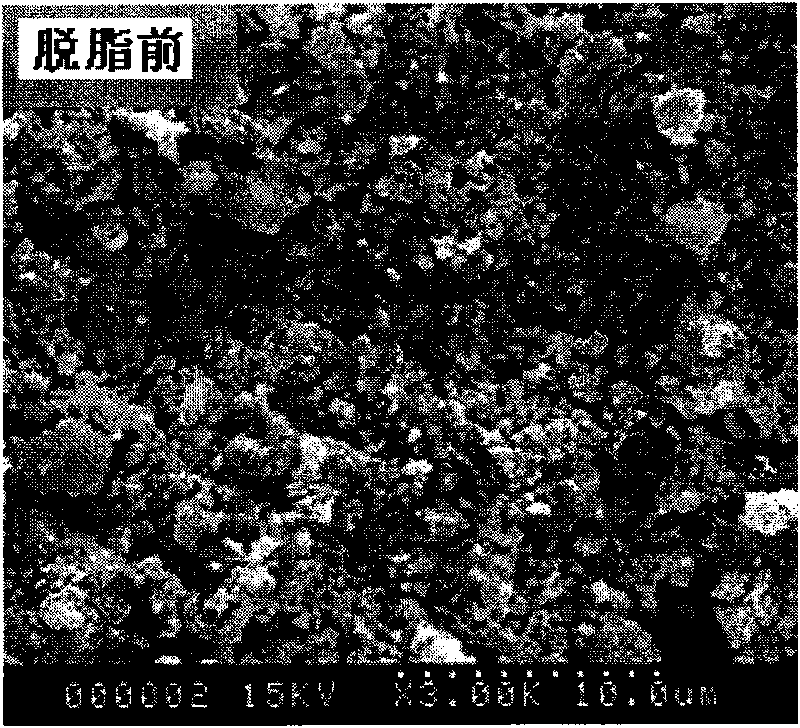

[0029] Adopt 80% alumina and 20% binder to prepare ceramic sample (transparent alumina ceramic green body of injection molding metal halide lamp tube) and weigh, wherein the weight percent component of binder is 19% poly Propylene, 80% paraffin, 1% stearic acid.

[0030] Submerge the prepared ceramic green body in the extraction solvent, wherein the ratio of the volume of the ceramic green body to the volume of the solvent is 1:60; the extraction time is 3 hours, the extraction temperature is 45°C, and the extraction solvent consists of 20% by volume Alcohol mixed with 80% n-heptane. Then, the extraction solvent was drained, and the ceramic green body was air-dried at room temperature and weighed to calculate the extraction rate.

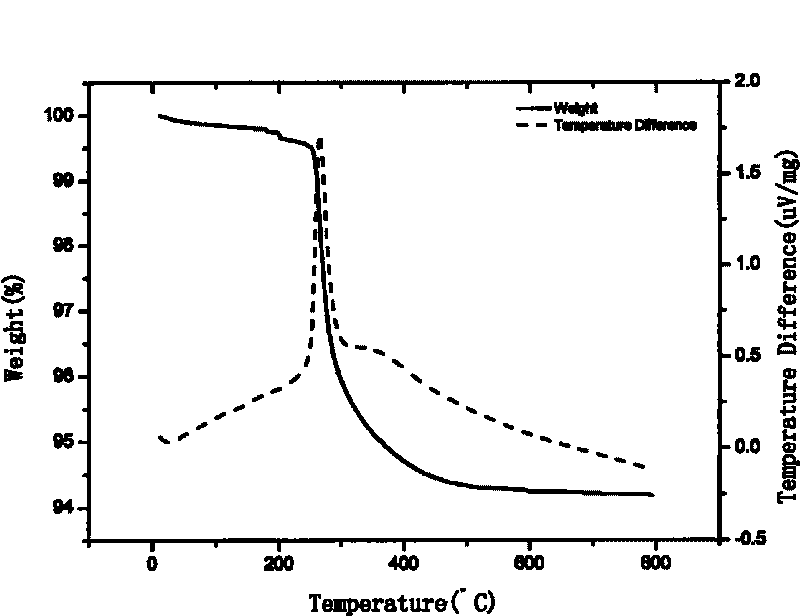

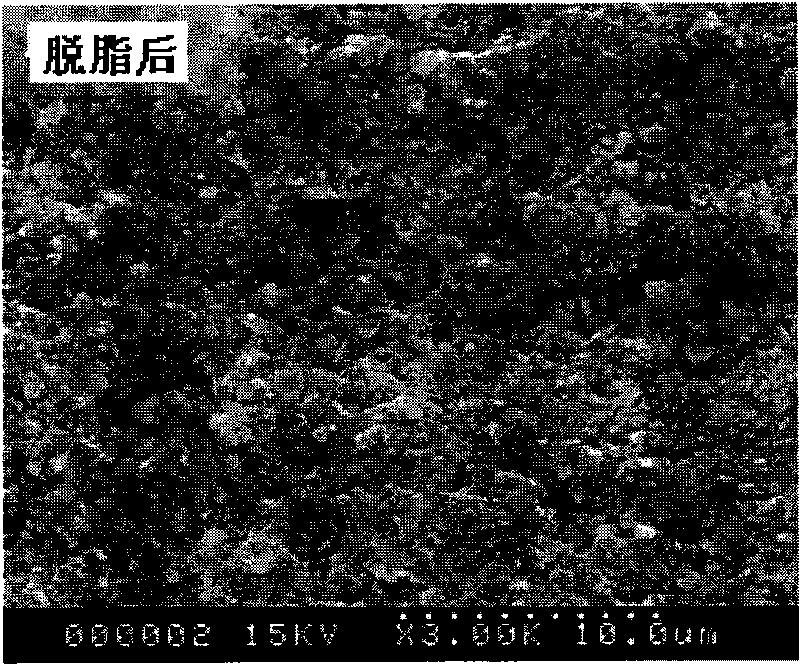

[0031] Embed the ceramic green body in alumina powder with a particle size of 20-40um, perform thermal degreasing according to the preferred temperature rise curve of thermal degreasing, weigh it, and calculate the degreasing rate.

[0032] The de...

Embodiment 2

[0037] A ceramic sample was prepared by adopting 80% of alumina and 20% of binder, wherein the components in weight percent of binder were 19% of polypropylene, 80% of paraffin, and 1% of stearic acid.

[0038] Submerge the prepared ceramic green body in the extraction solvent, wherein the ratio of the volume of the ceramic green body to the volume of the solvent is 1:80; the extraction time is 4 hours, the extraction temperature is 60°C, and the extraction solvent is composed of 20% by volume Alcohol mixed with 80% n-heptane.

[0039] After extraction, the extraction rate was measured to be 77.7%. After the extracted sample was buried in powder and thermally degreased according to the preferred thermal degreasing curve, the degreasing rate was measured to be 99.5%.

Embodiment 3

[0041] A ceramic sample was prepared by adopting 80% of alumina and 20% of binder, wherein the components in weight percent of binder were 19% of polypropylene, 80% of paraffin, and 1% of stearic acid.

[0042] Submerge the prepared ceramic green body in the extraction solvent, wherein the ratio of the volume of the ceramic green body to the solvent volume is 1:80; the extraction time is 4 hours, the extraction temperature is 60°C, and the extraction solvent is composed of 30% by volume Alcohol mixed with 70% n-heptane.

[0043] After extraction, the extraction rate was measured to be 77.5%. After the extracted sample was buried in powder and thermally degreased according to the preferred thermal degreasing curve, the degreasing rate was measured to be 99.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| skim rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com