Continuous heat treatment furnace and manufacturing method for ceramic electronic component using same

A technology for heat treatment of furnaces and workpieces, applied in capacitor manufacturing, furnace components, electrical components, etc., can solve the problems of workpiece W quality deviation, uneven degreasing results, etc., and achieve the effect of uniform heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042] - Embodiment 1 of continuous heat treatment furnace -

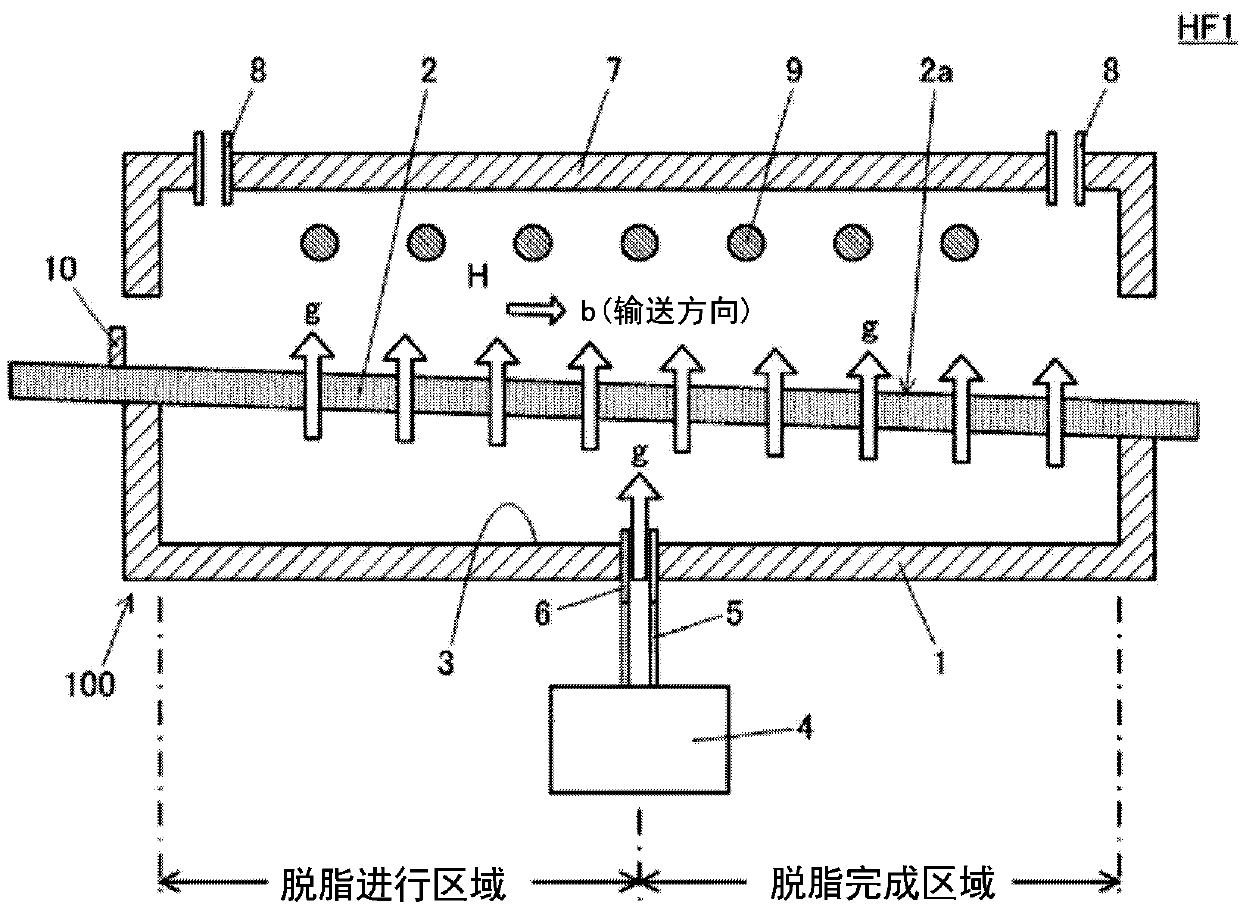

[0043] use Figure 1 ~ Figure 3 , the continuous heat treatment furnace HF1 which is Embodiment 1 of the continuous heat treatment furnace according to the present invention will be described. Continuous heat treatment furnace HF1 is a degreasing furnace for degreasing non-degreasing ceramic electronic components. Next, an embodiment of the continuous heat treatment furnace according to the present invention will be described by taking the above-mentioned degreasing furnace as a specific example.

[0044]

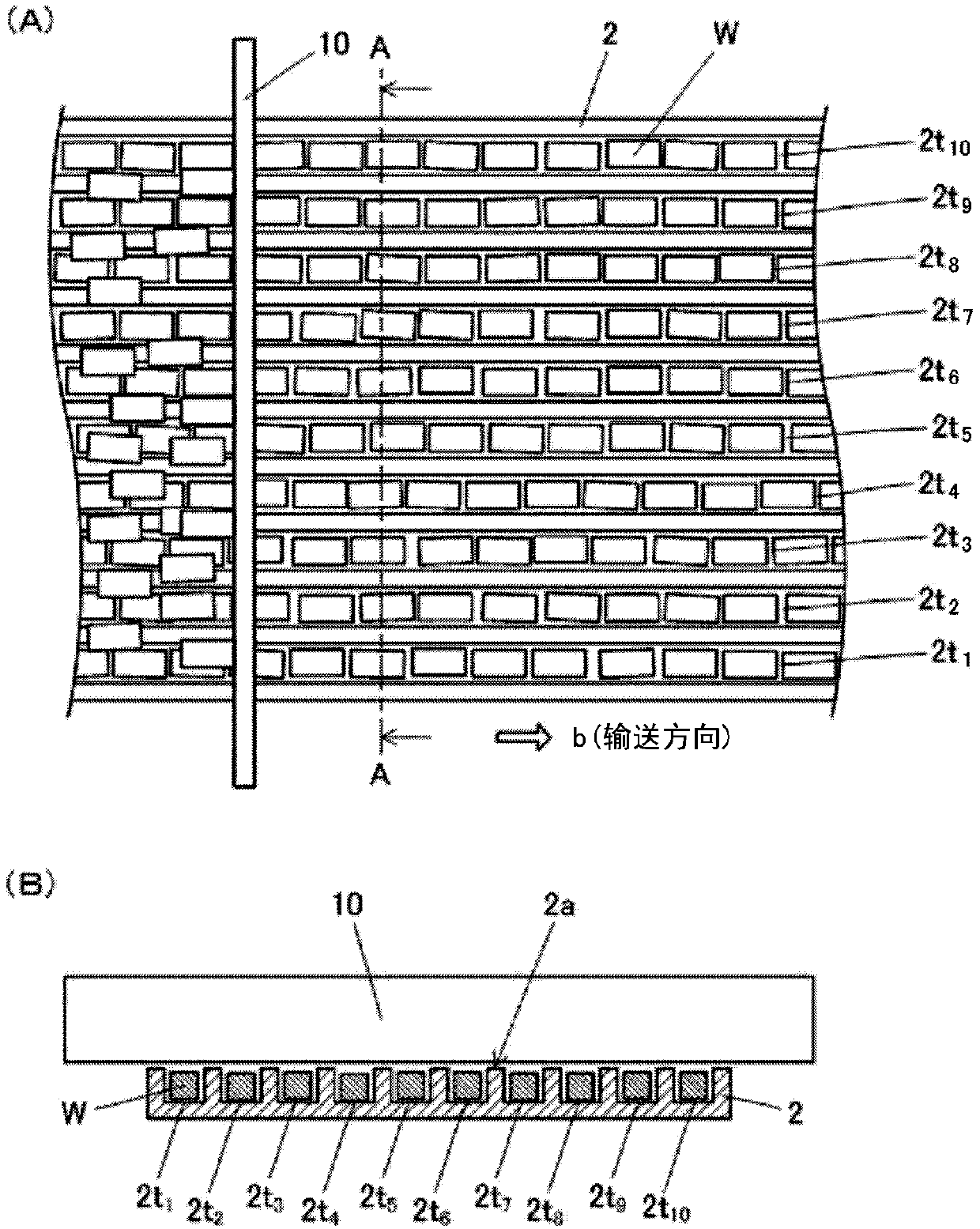

[0045] figure 1 It is a cross-sectional view schematically showing the continuous heat treatment furnace HF1. The continuous heat treatment furnace HF1 is provided with a heat treatment region H for heat-treating the workpiece along the conveyance direction b of the workpiece (not shown). The workpiece is heat-treated while being conveyed in the heat-treatment area H. As shown in FIG. The workpiece, as d...

example 2

[0067] Figure 5 is the equivalent of the porous plate 2B, which is Modification 2 of the porous plate 2 included in the workpiece conveying mechanism 100. figure 2 (B) A cross-sectional view in the direction of the arrow. In the porous plate 2B, the groove 2t formed in the upper surface 2Ba 1 ~2t 10 The cross-section perpendicular to the conveying direction b of the workpiece W is V-shaped.

[0068] In this case, as in the porous plate 2A, the workpiece W and the groove 2t 1 ~2t 10 There is a gap between the bottoms, so that it is easy to supply gas g from the bottom. Furthermore, since the area of the opening of the upper surface 2Ba becomes larger, the supplied gas g flows more easily. Therefore, the binder contained in the workpiece W can be burned more efficiently, and the heat generated by burning the binder can be dissipated more effectively.

[0069]

[0070] Image 6is the equivalent of the porous plate 2C, which is Modification 3 of the porous plate 2 in...

Embodiment approach 2

[0072] - Embodiment 2 of continuous heat treatment furnace -

[0073] use Figure 7 with Figure 8 , the continuous heat treatment furnace HF2 which is Embodiment 2 of the continuous heat treatment furnace according to the present invention will be described. The continuous heat treatment furnace HF2 is a degreasing furnace for degreasing an electronic component body constituting a ceramic electronic component, similarly to the continuous heat treatment furnace HF1.

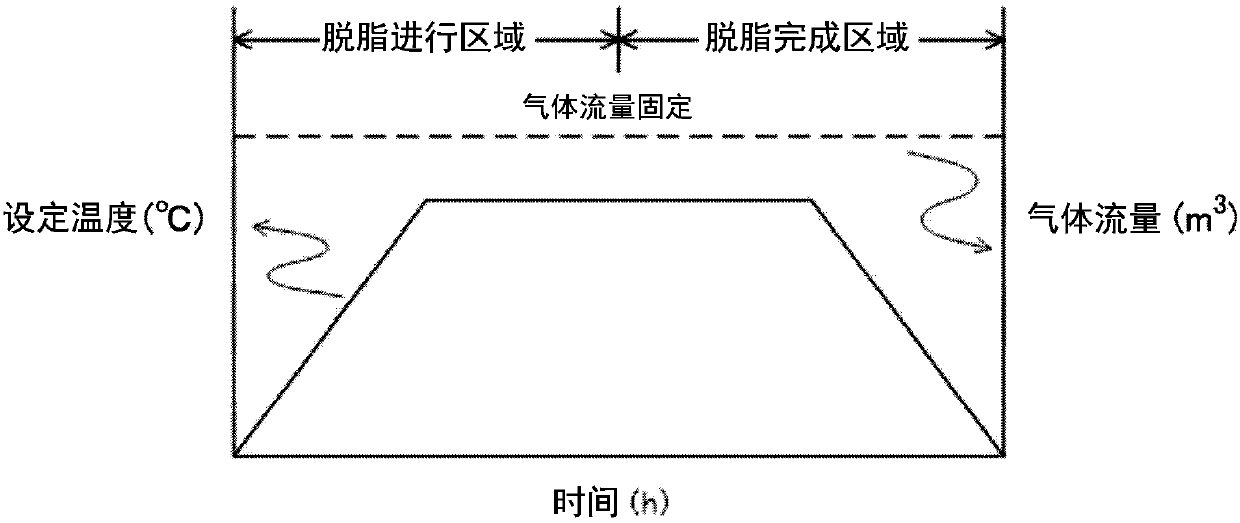

[0074] Figure 7 It is a cross-sectional view schematically showing the continuous heat treatment furnace HF2. The gas chamber of the continuous heat treatment furnace HF2 is divided into a first gas chamber 3a and a second gas chamber 3b. The air supply unit 4 communicates with the first air chamber 3a via the first pipe 5a and the first air supply port 6a, and communicates with the second air chamber 3b via the second pipe 5b and the second air supply port 6b, to Gas g is provided in each gas chamber. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com