Patents

Literature

69results about How to "High assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

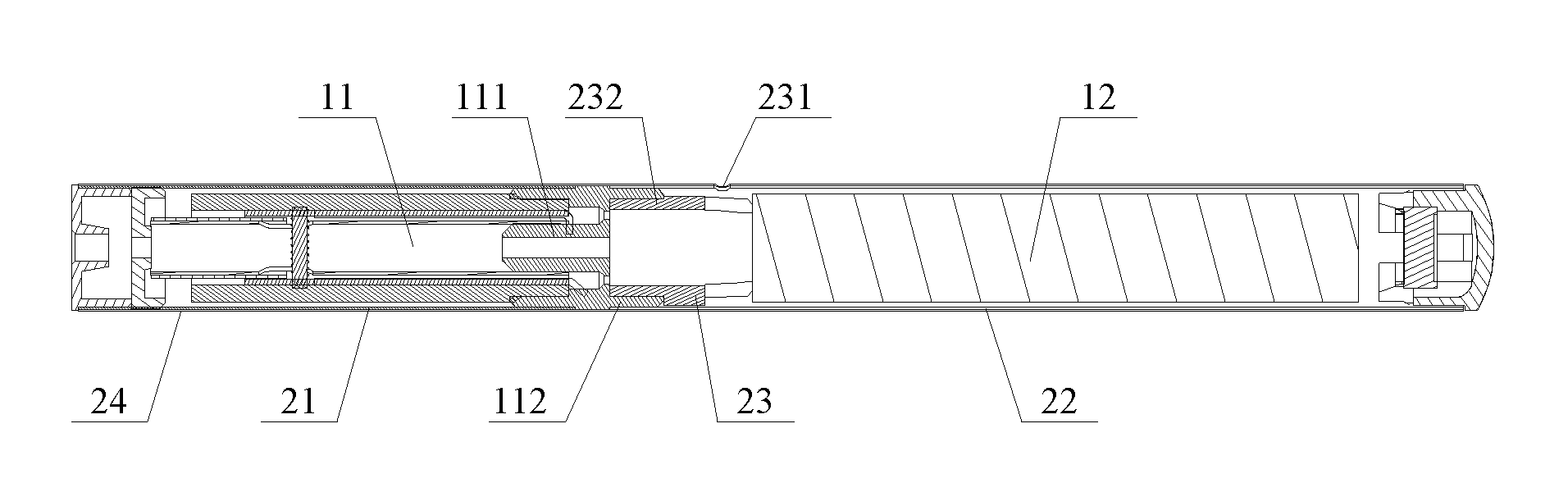

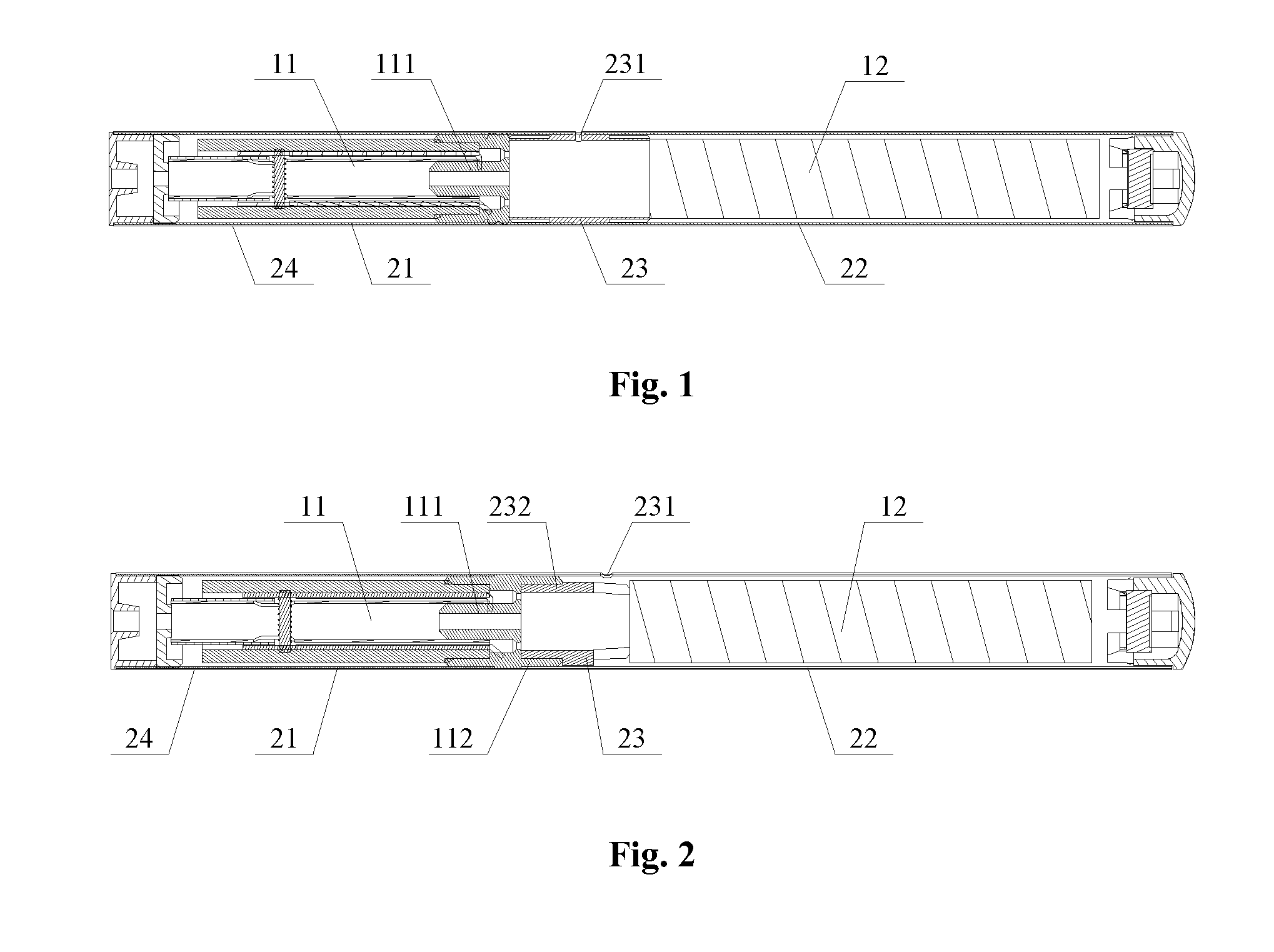

Electronic cigarette

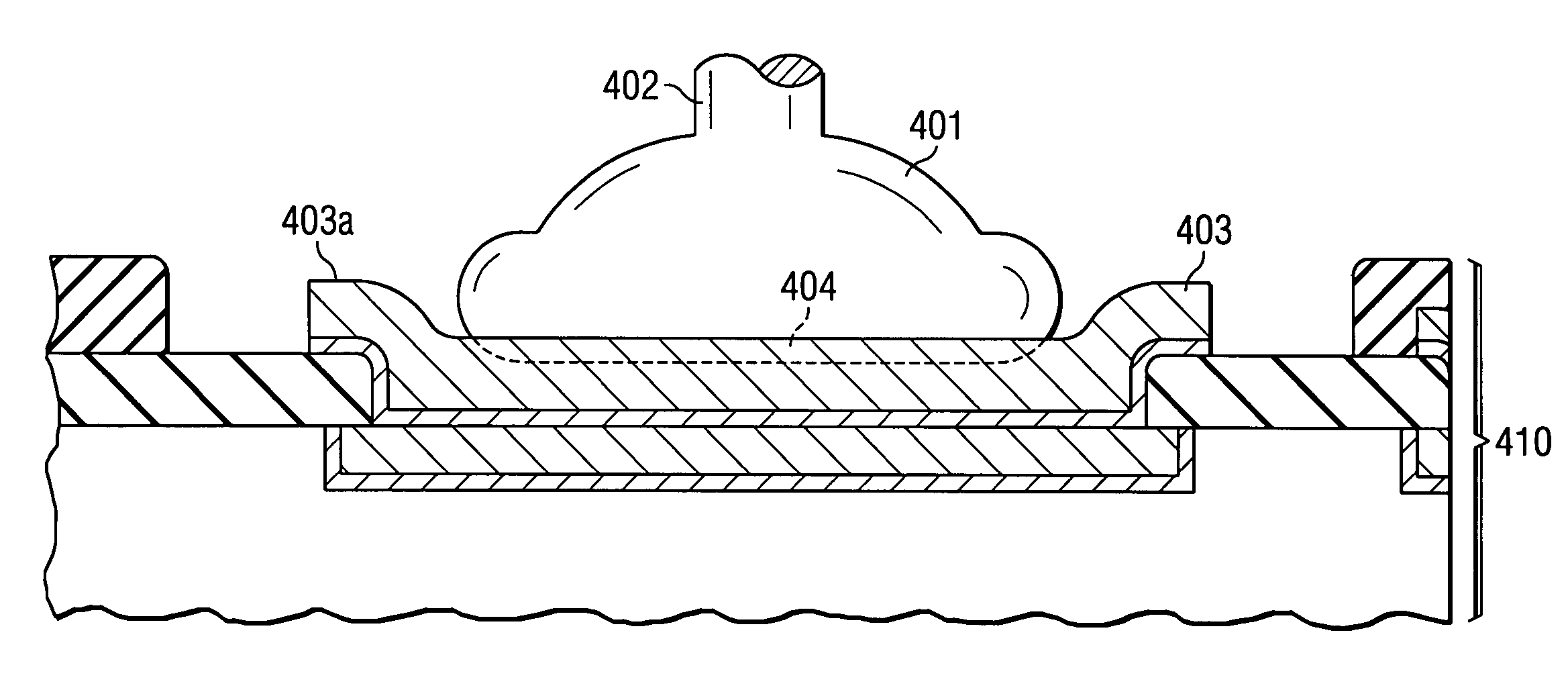

InactiveUS20160242463A1Prevent oil leakageAssembly structure is stable and reliableTobacco devicesCell component detailsElectrical batteryEngineering

An electronic cigarette, in which an atomizer assembly protective cartridge is provided outside of the atomizer assembly, and a battery assembly protective cartridge is provided outside of the battery assembly. An atomizing seat fitted with the holder is provided at an inner end of the atomizer assembly. At least a coating layer is provided outside of the atomizer assembly protective cartridge, the holder and the battery assembly protective cartridge, and enables connection between the atomizer assembly protective cartridge, the holder and the battery assembly protective cartridge. In the overall process of assembling the electronic cigarette, since there is no pushing or squeezing action between the atomizer assembly and the battery assembly, it is possible to effectively avoid oil leakage caused by an inclination and a deformation of the atomizing seat under uneven force is effectively avoided.

Owner:HUIZHOU KIMREE TECH

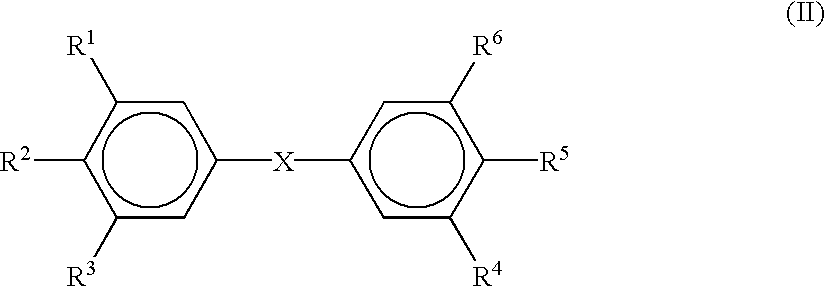

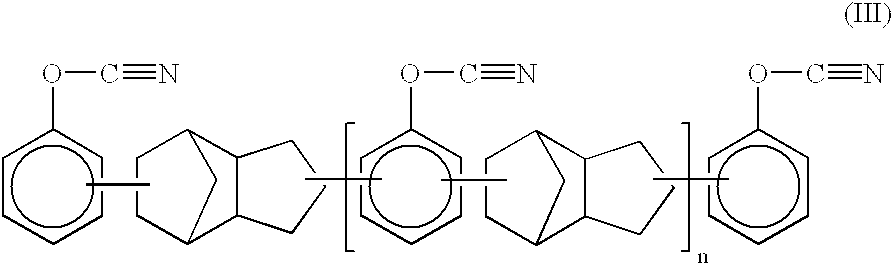

Flowable compositions and use in filling vias and plated through-holes

InactiveUS6090474AEfficient use ofImprove routing densityPrinted circuit aspectsElectrical connection printed elementsEngineeringPrinted circuit board

A printed circuit board or card having plated through-holes is provided wherein plated through-holes are filled with a photocured polymerized composition. Also, a method for fabricating these printed circuit boards or cards is provided. Also provided are compositions and methods of providing carrier films coated with the compositions for use in filling vias or plated through-holes.

Owner:IBM CORP

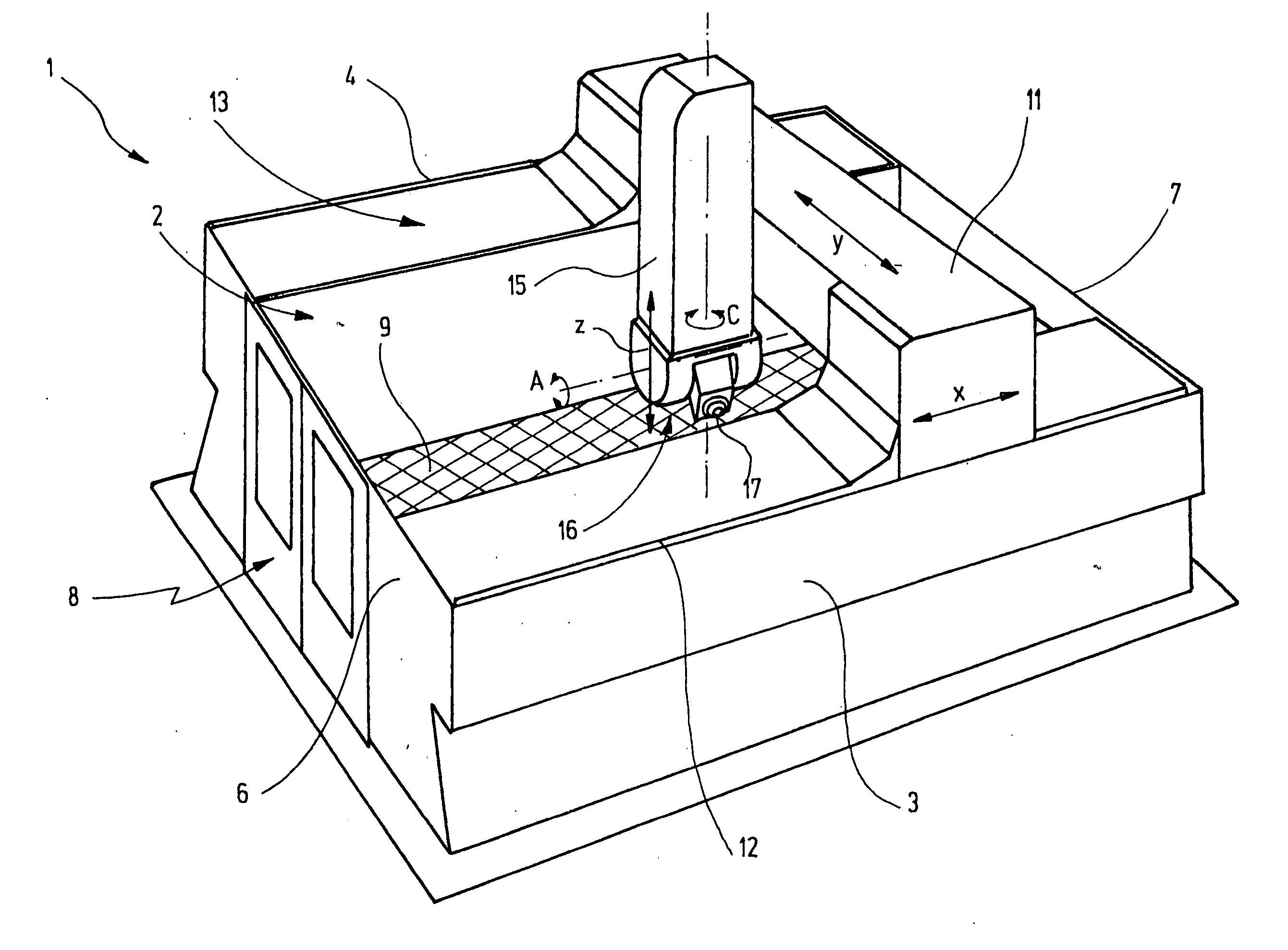

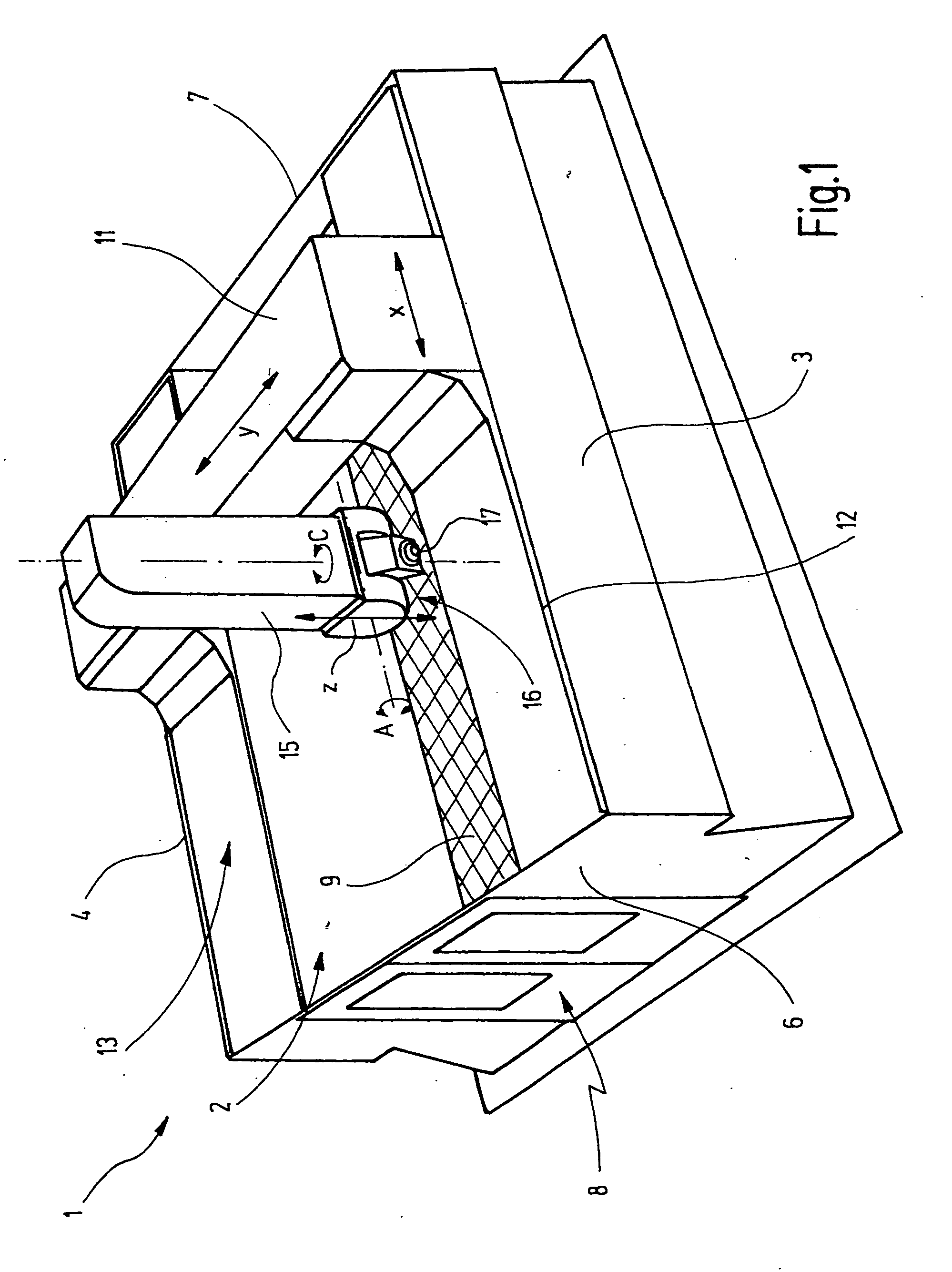

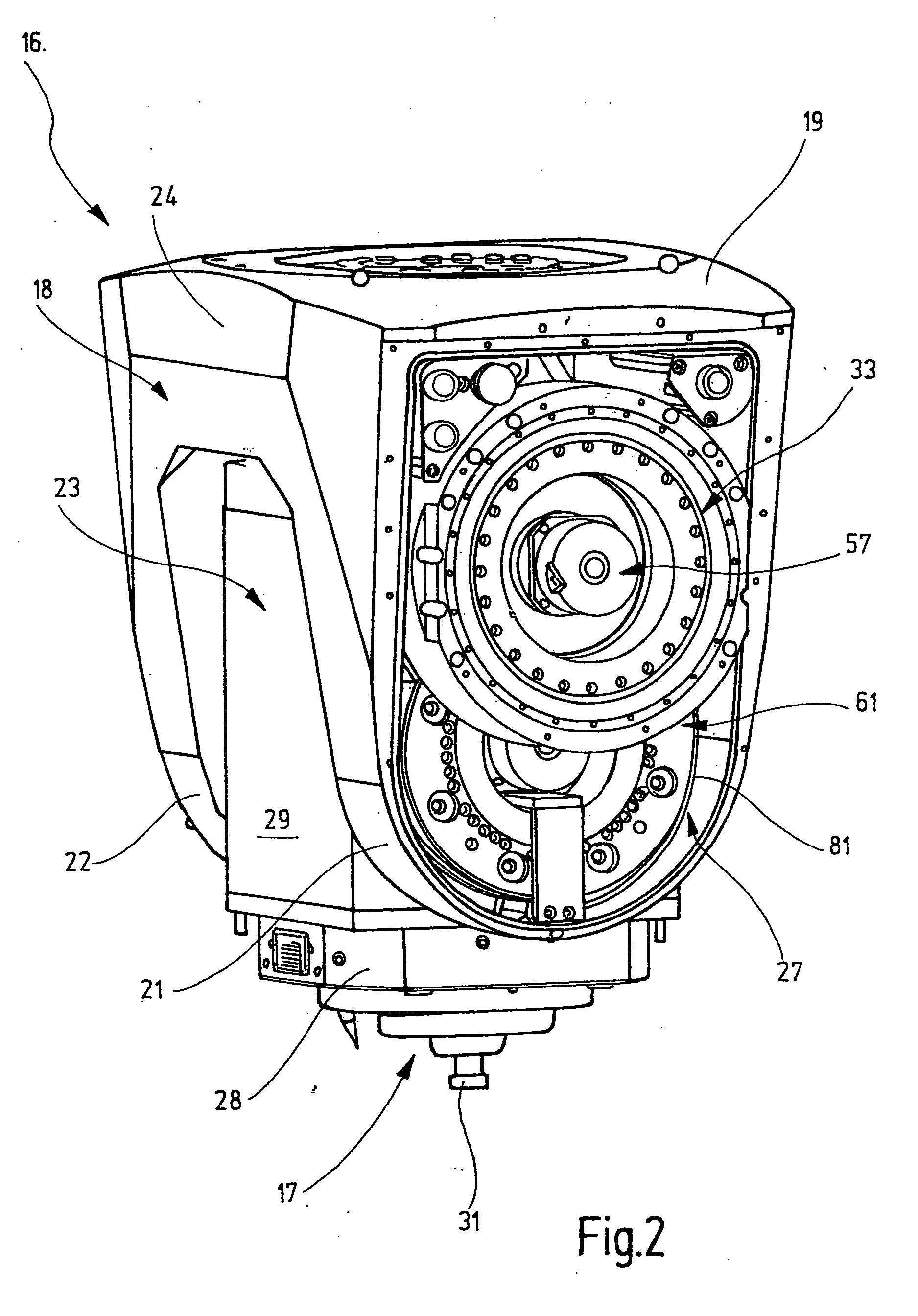

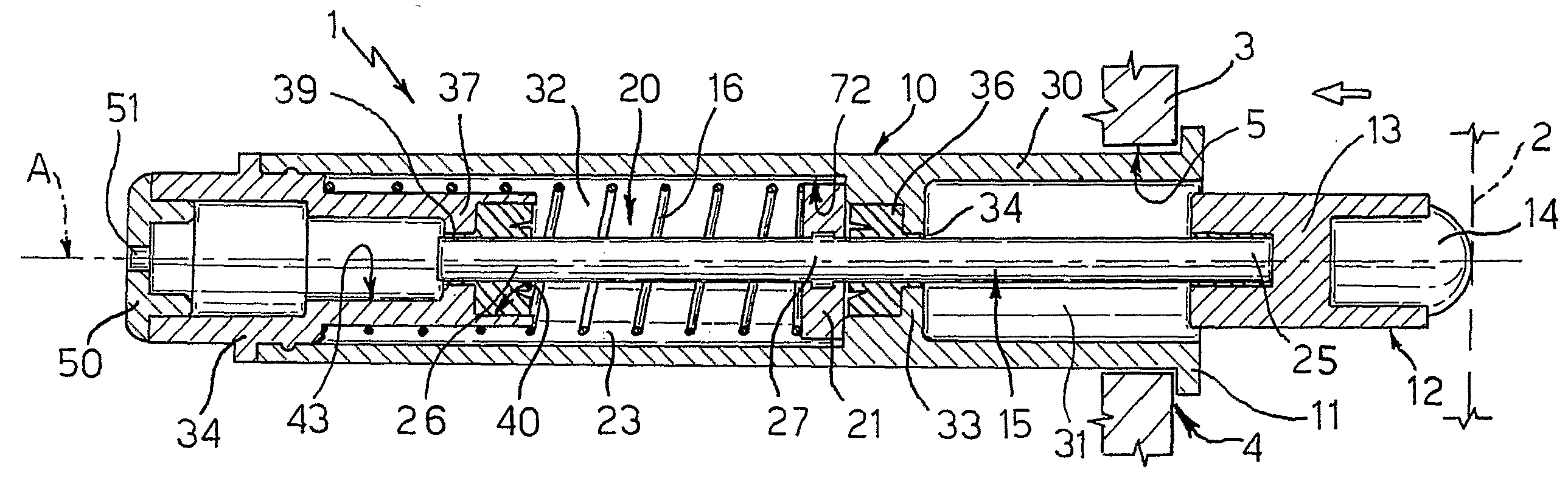

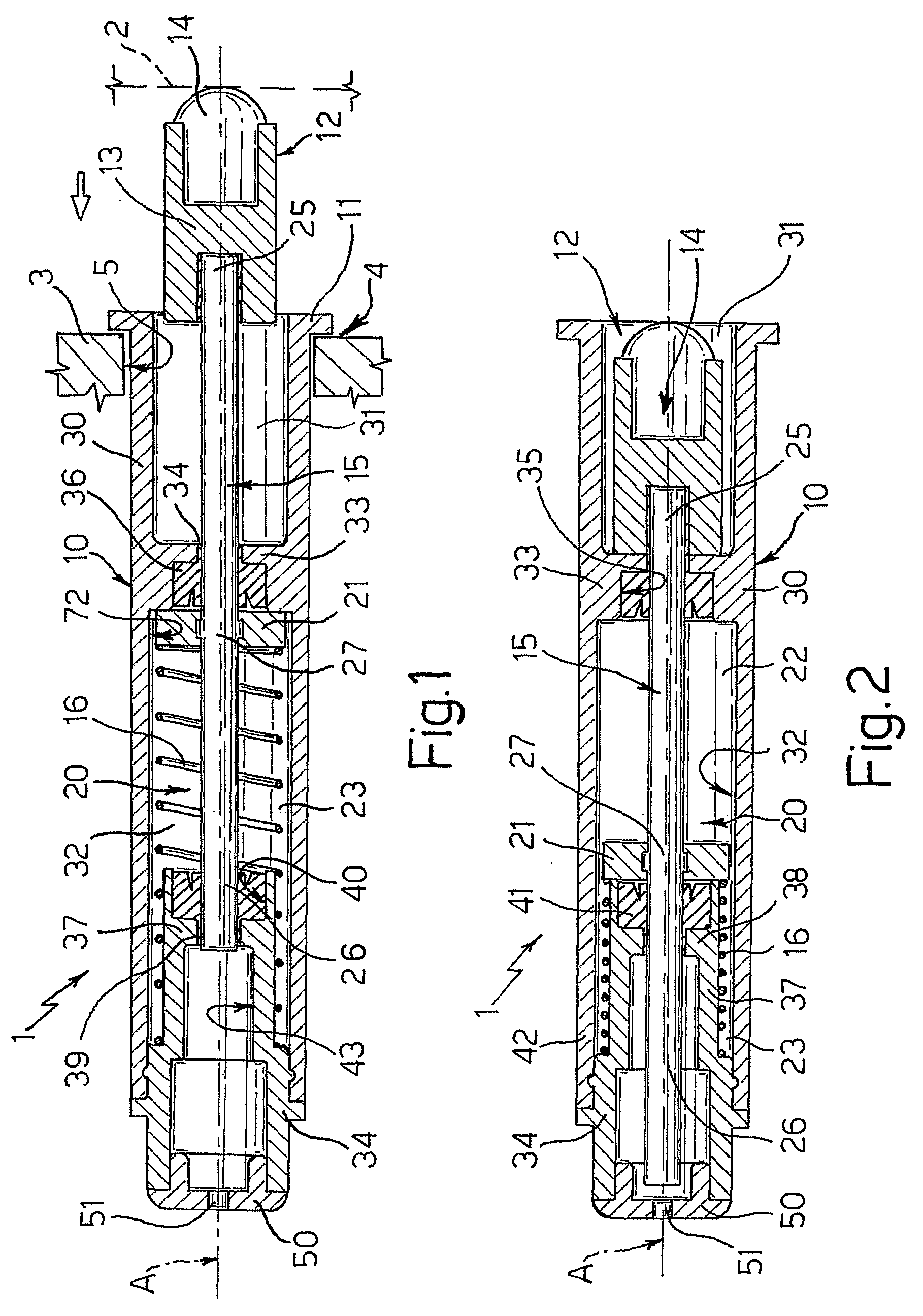

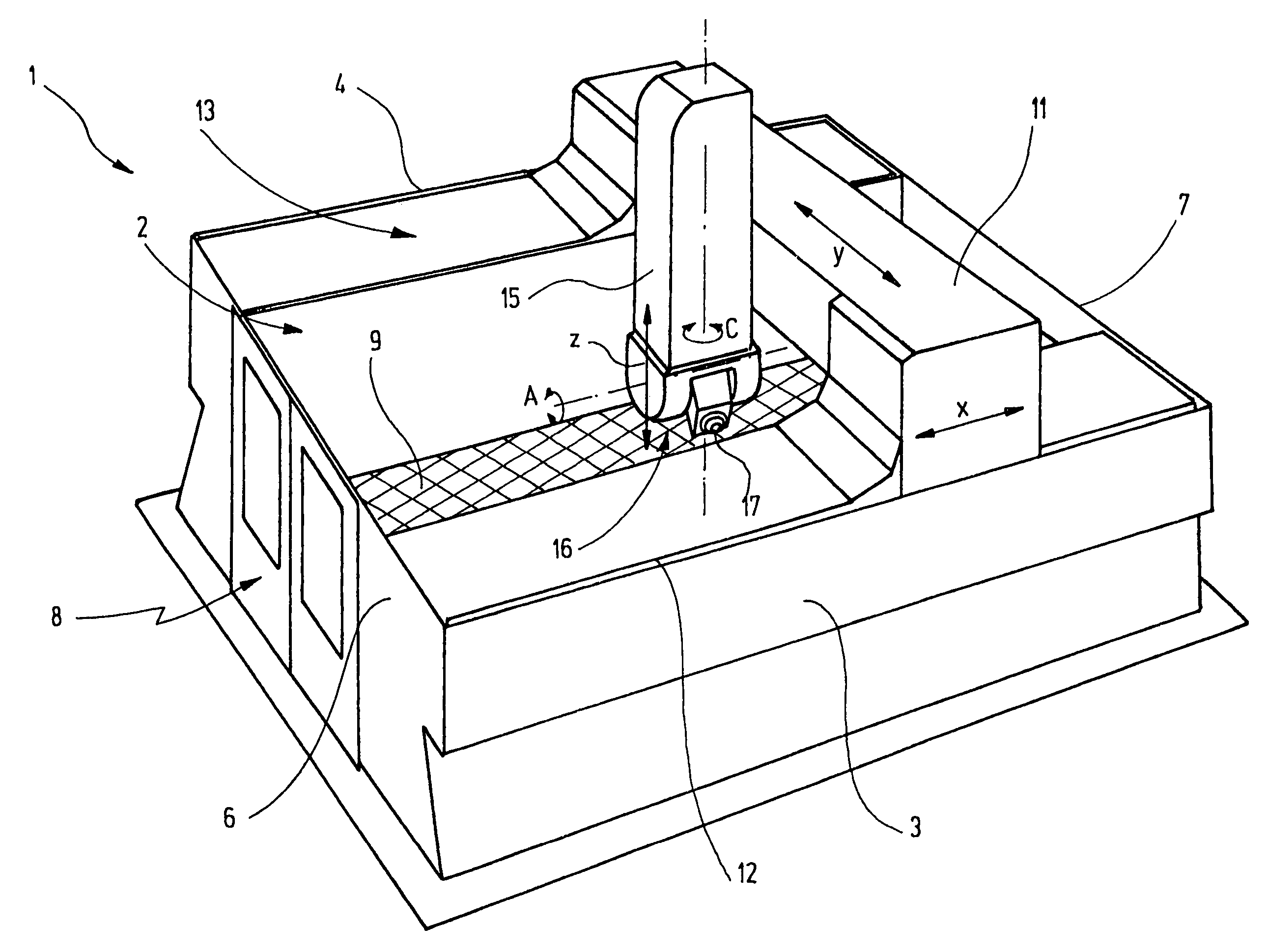

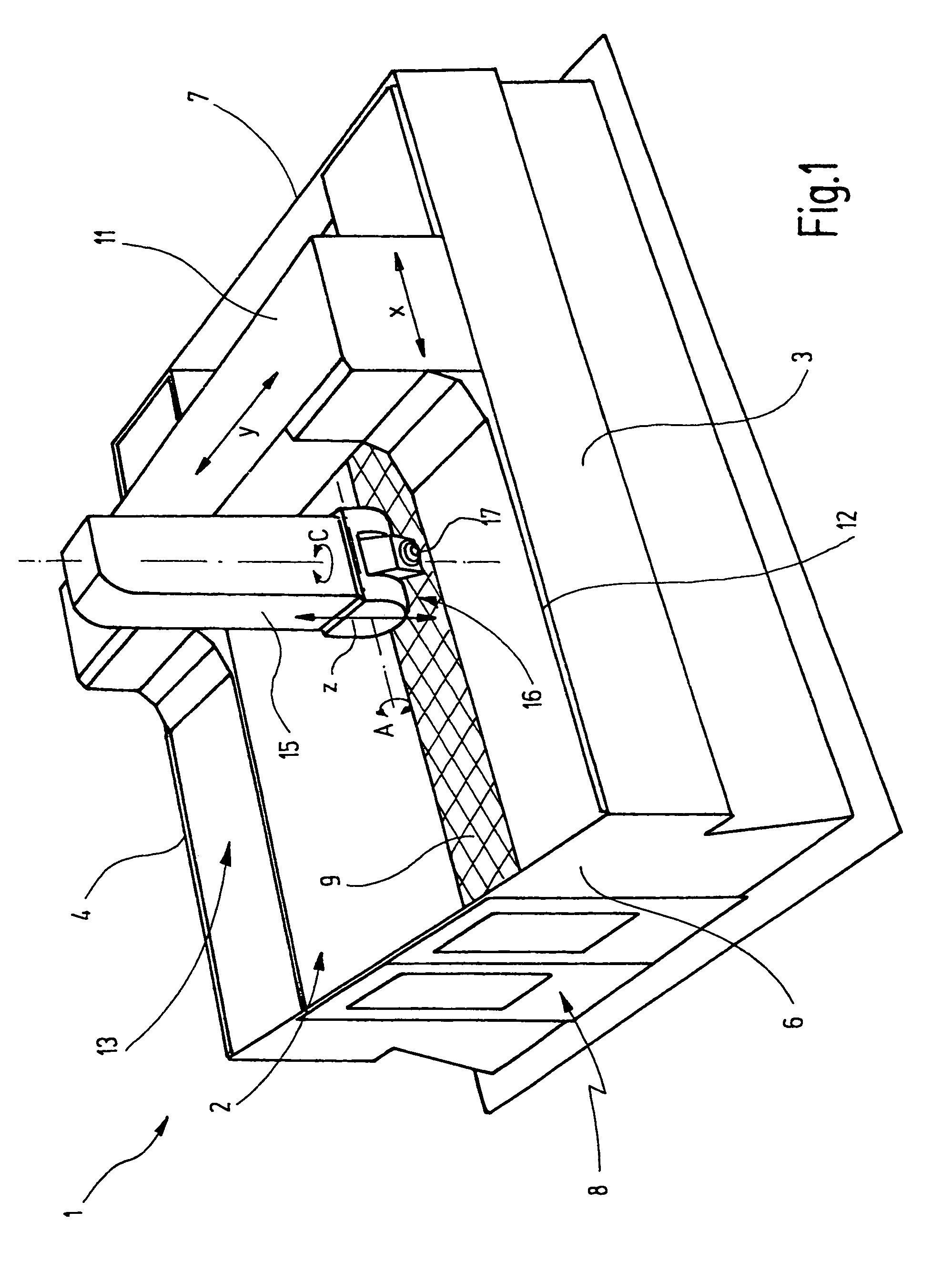

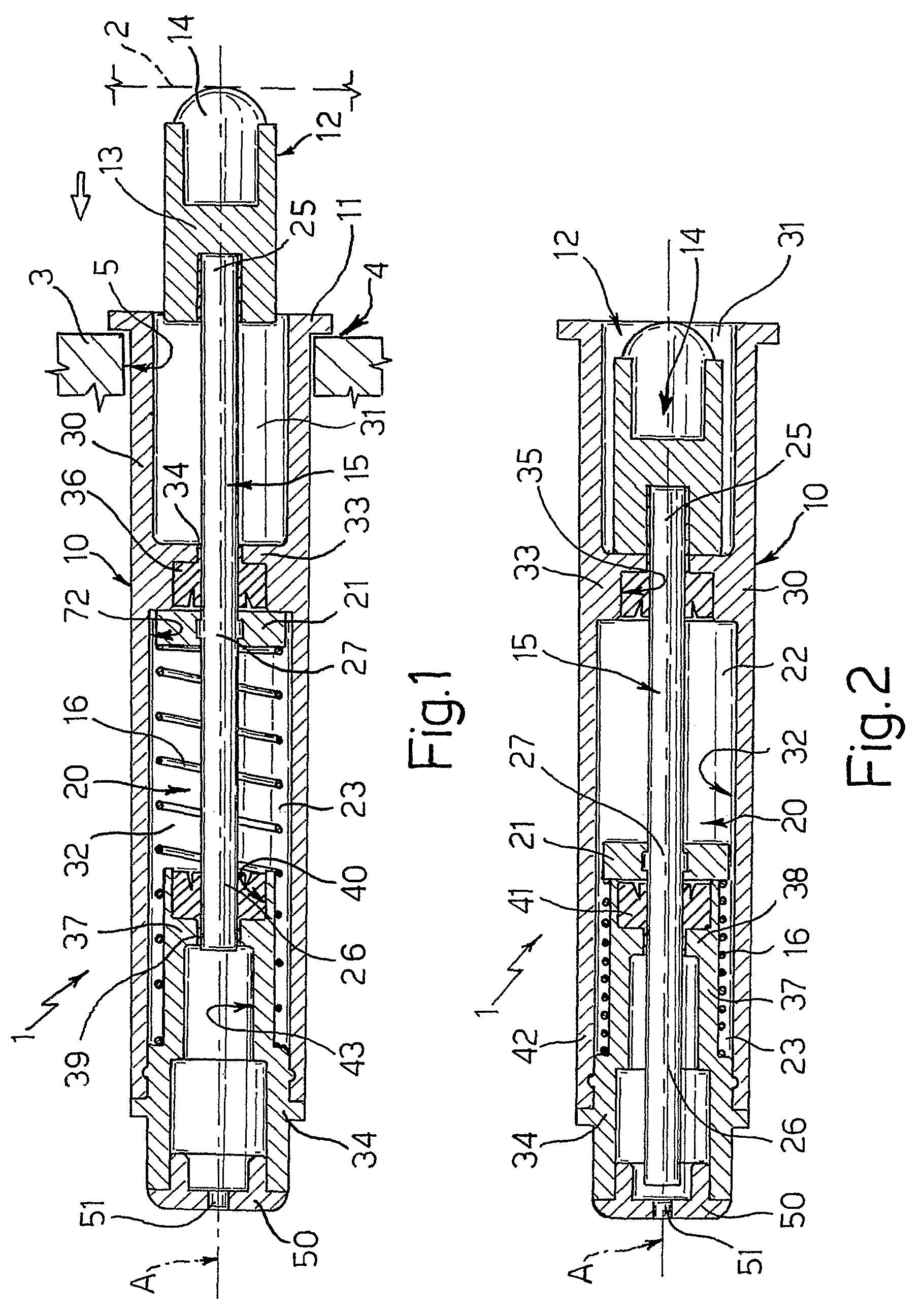

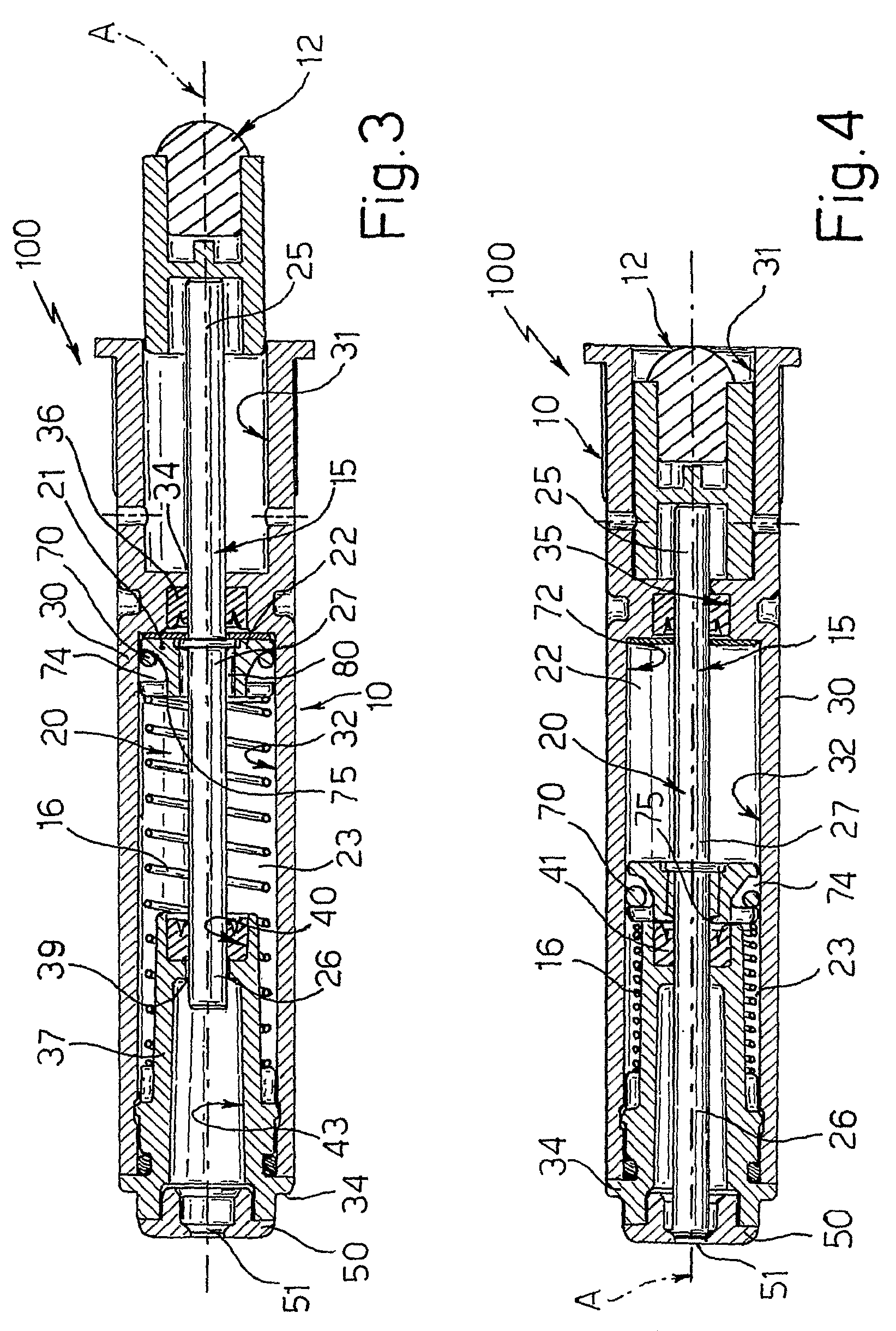

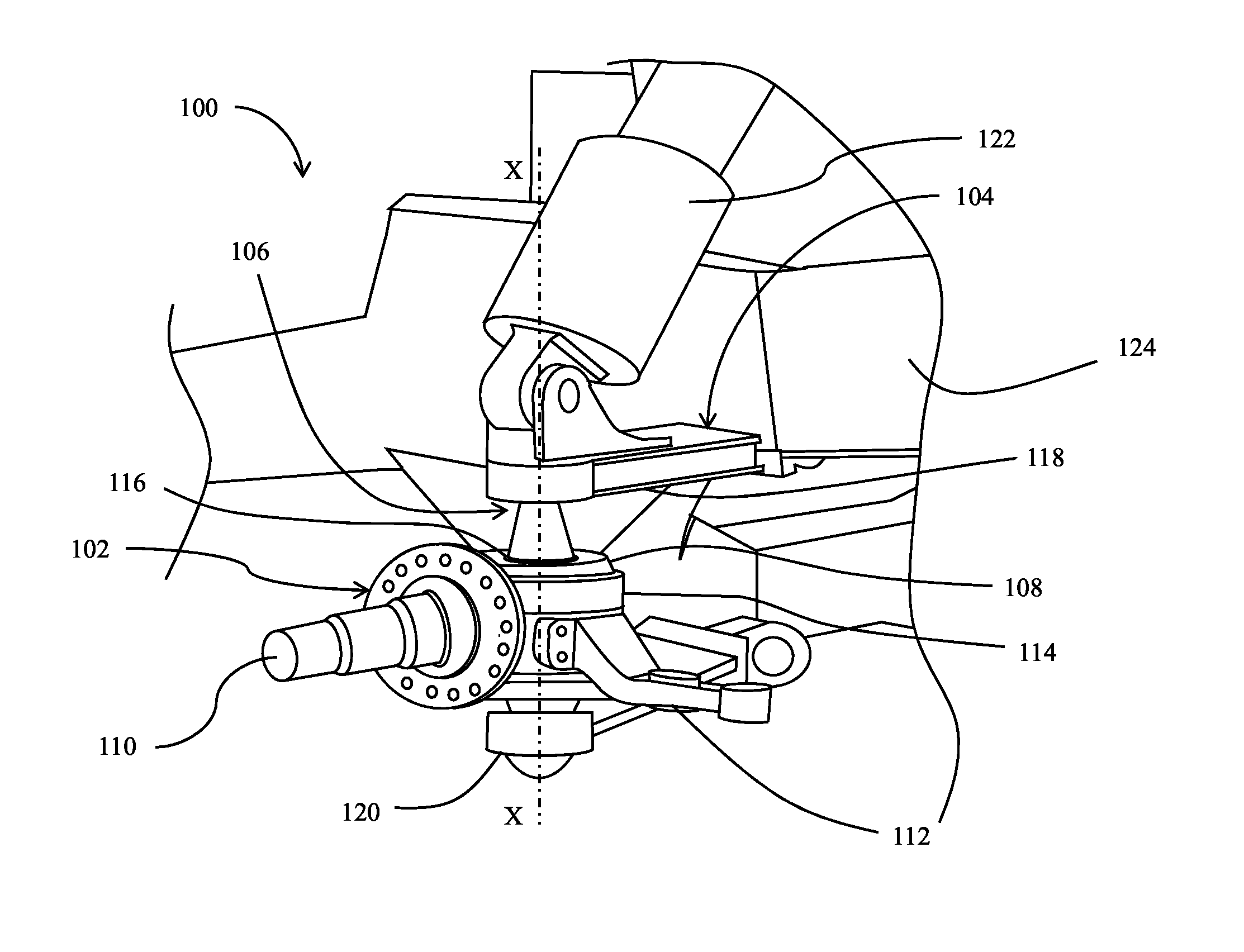

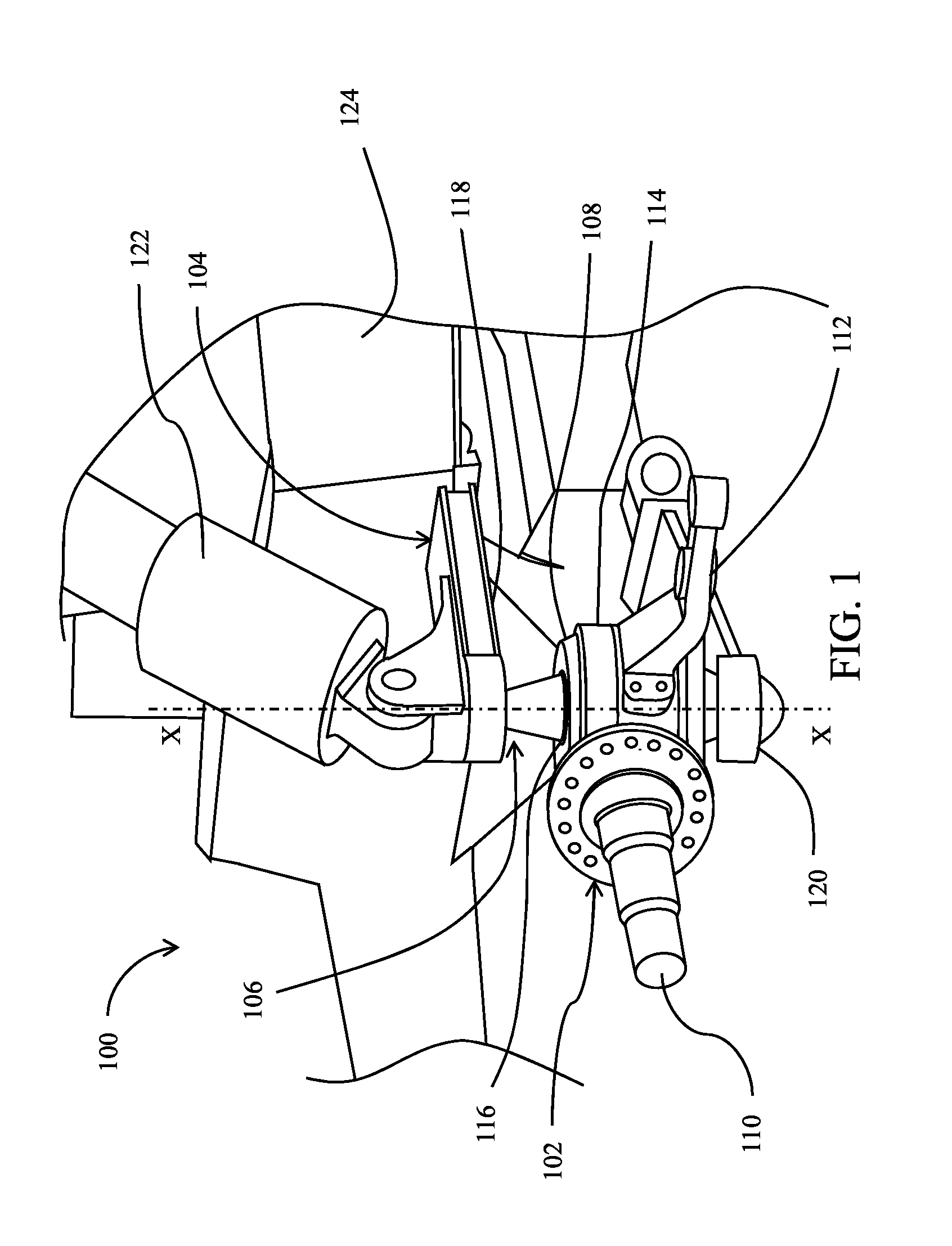

Mobile milling head with torque motor drive

InactiveUS20070059116A1Improve surface qualityPrecise positioningMachine tool componentsWorkpiecesDynamic stiffnessGear drive

A milling head (16) for a milling machine (1) arranged for machining large-size workpieces comprises a fork 18, which is rotatably arranged around a first axis (C) and demonstrates a pair of fork arms (21, 22), which are separated from one another, a spindle device (23), which is arranged between the fork arms and rotatable around a second axis A, a first torque motor (42), which is coupled to the fork 18 for directly driving and controlling of the rotation of the fork around the first axis (C), and a second torque motor (57) for driving and controlling the rotation of the spindle around the second axis (A), said second torque motor being coupled to the spindle device (23) by means of a one-stage toothed gearing (61), which is mechanically clamped free of backlash. The configuration according to the invention is arranged to achieve high torque with high dynamic stiffness and small interference contour of the milling head (16).

Owner:FA F ZIMMERMANN

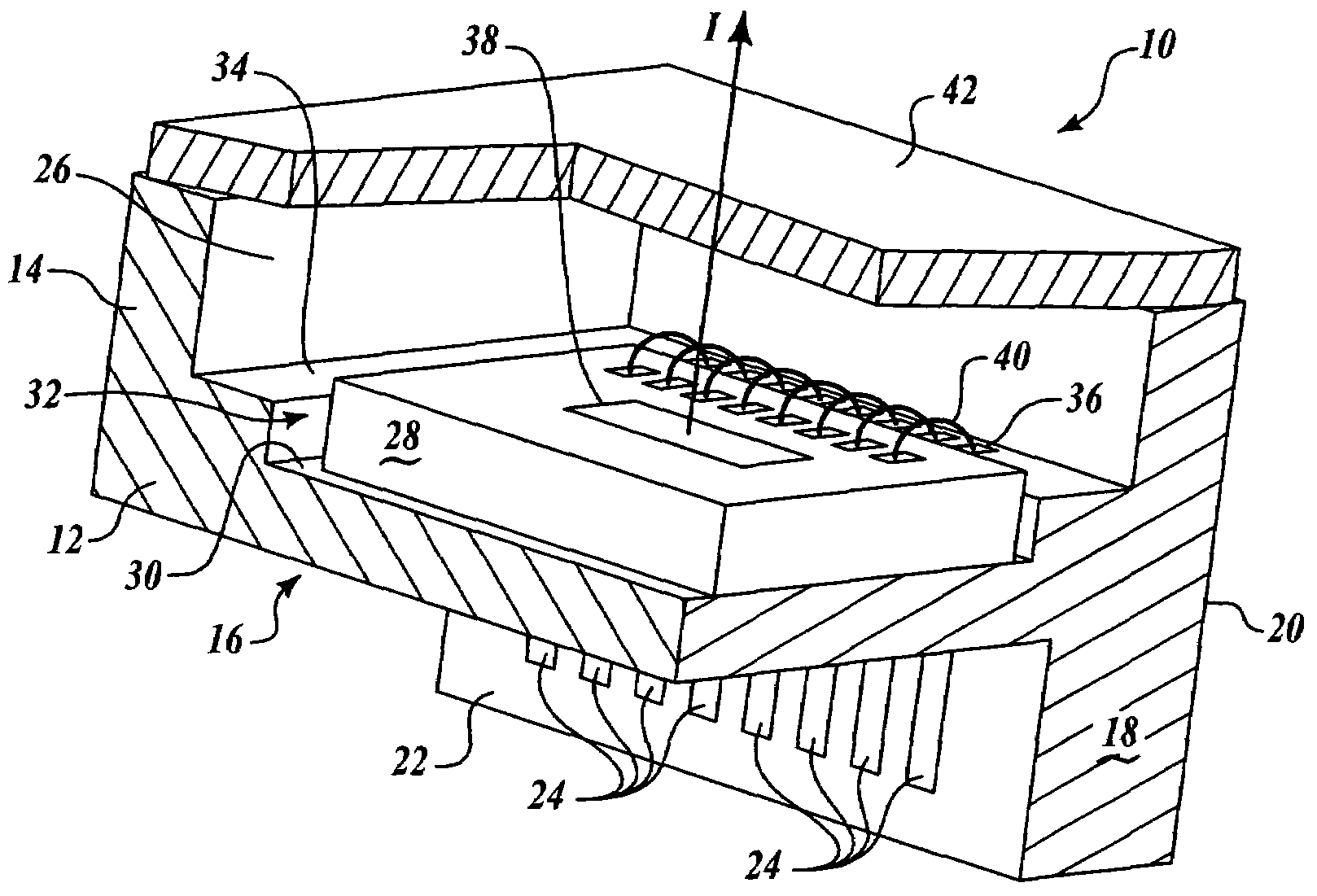

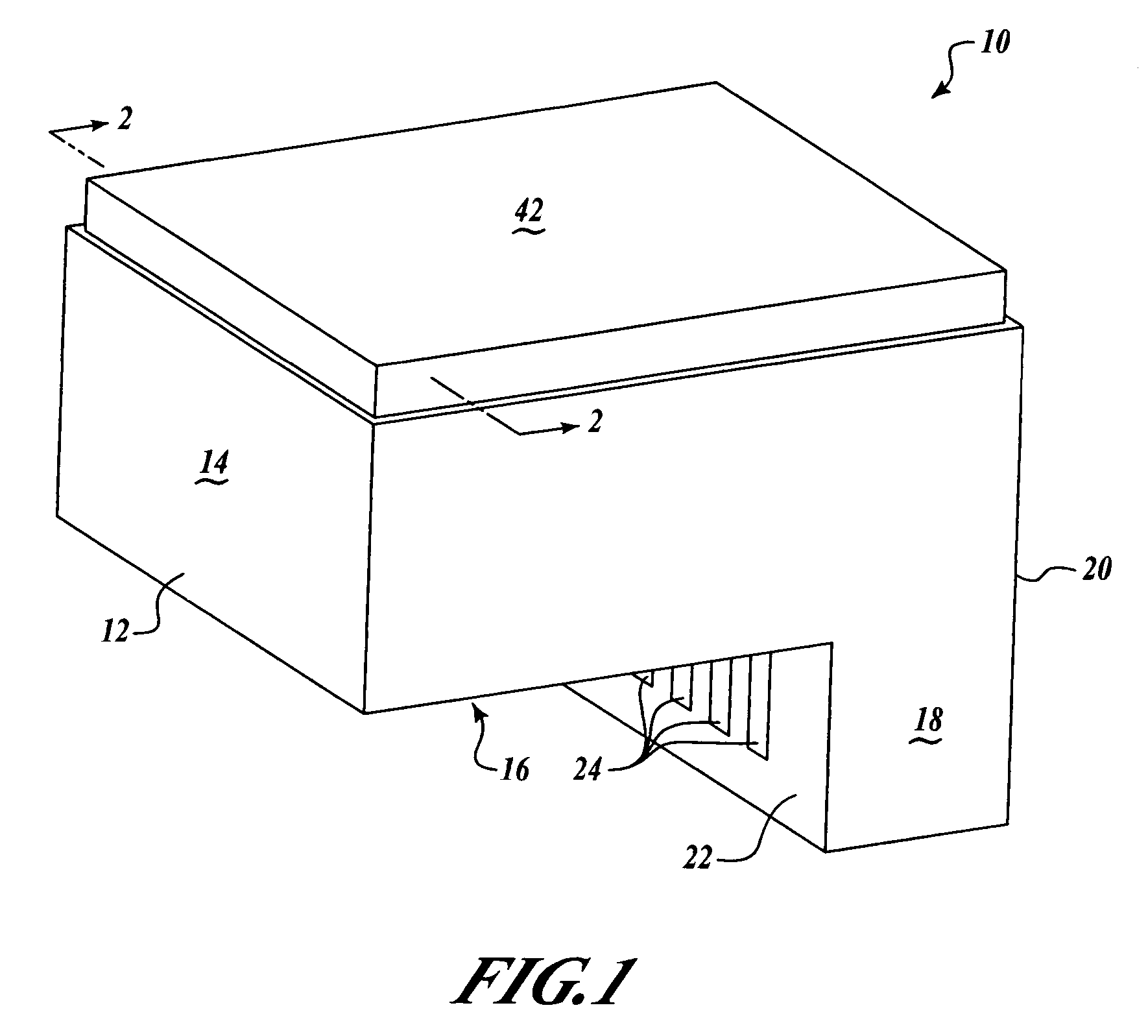

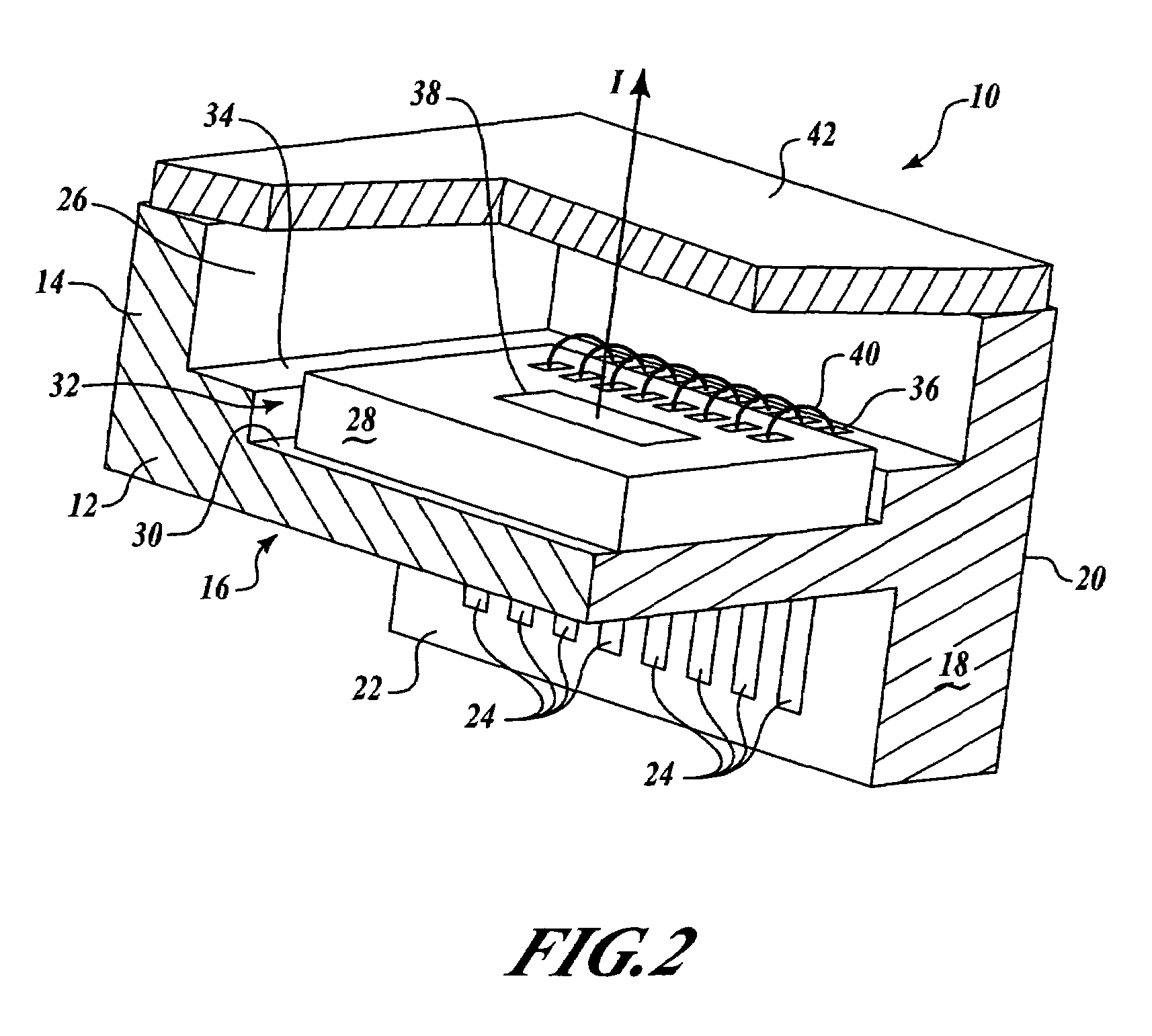

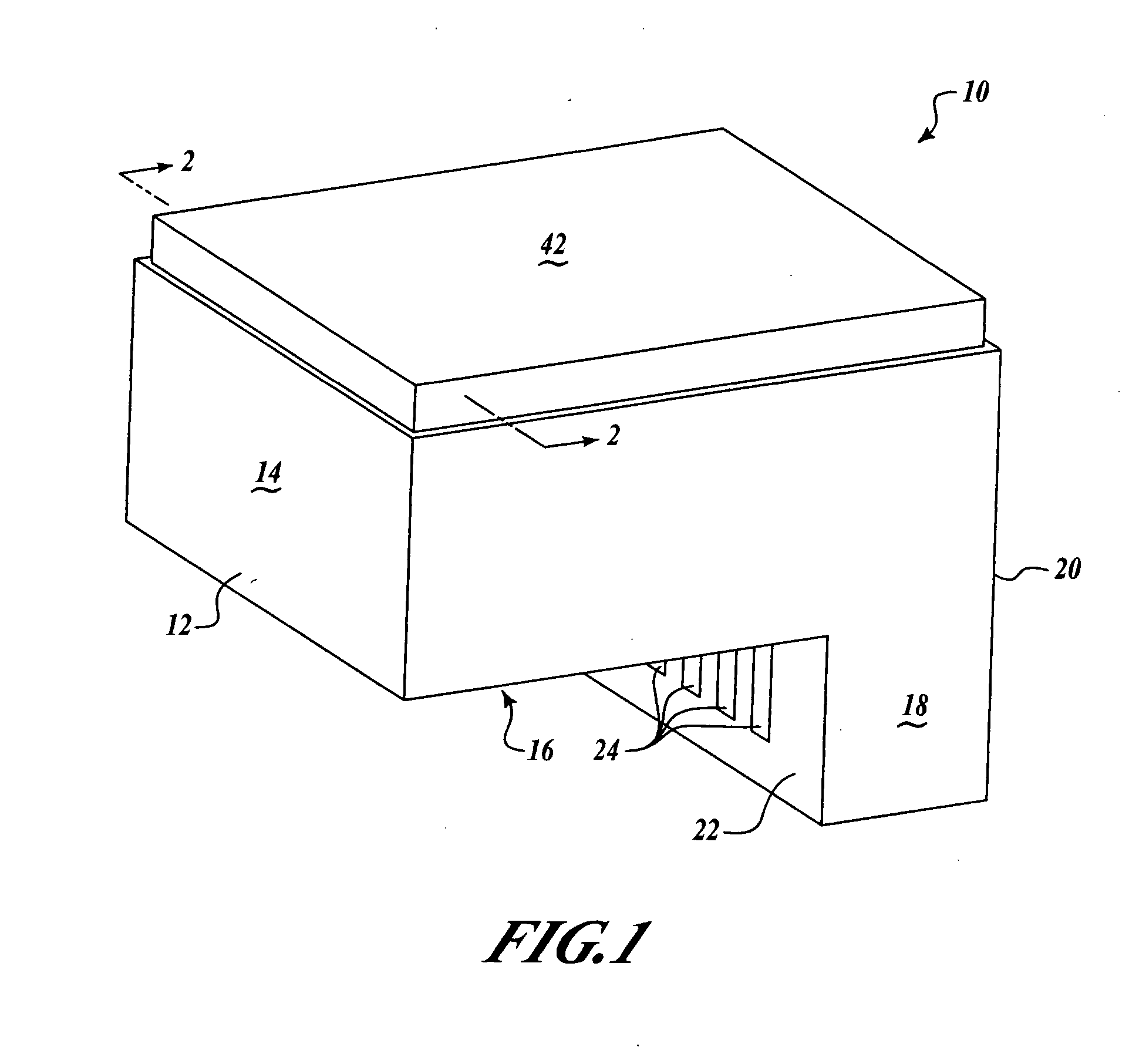

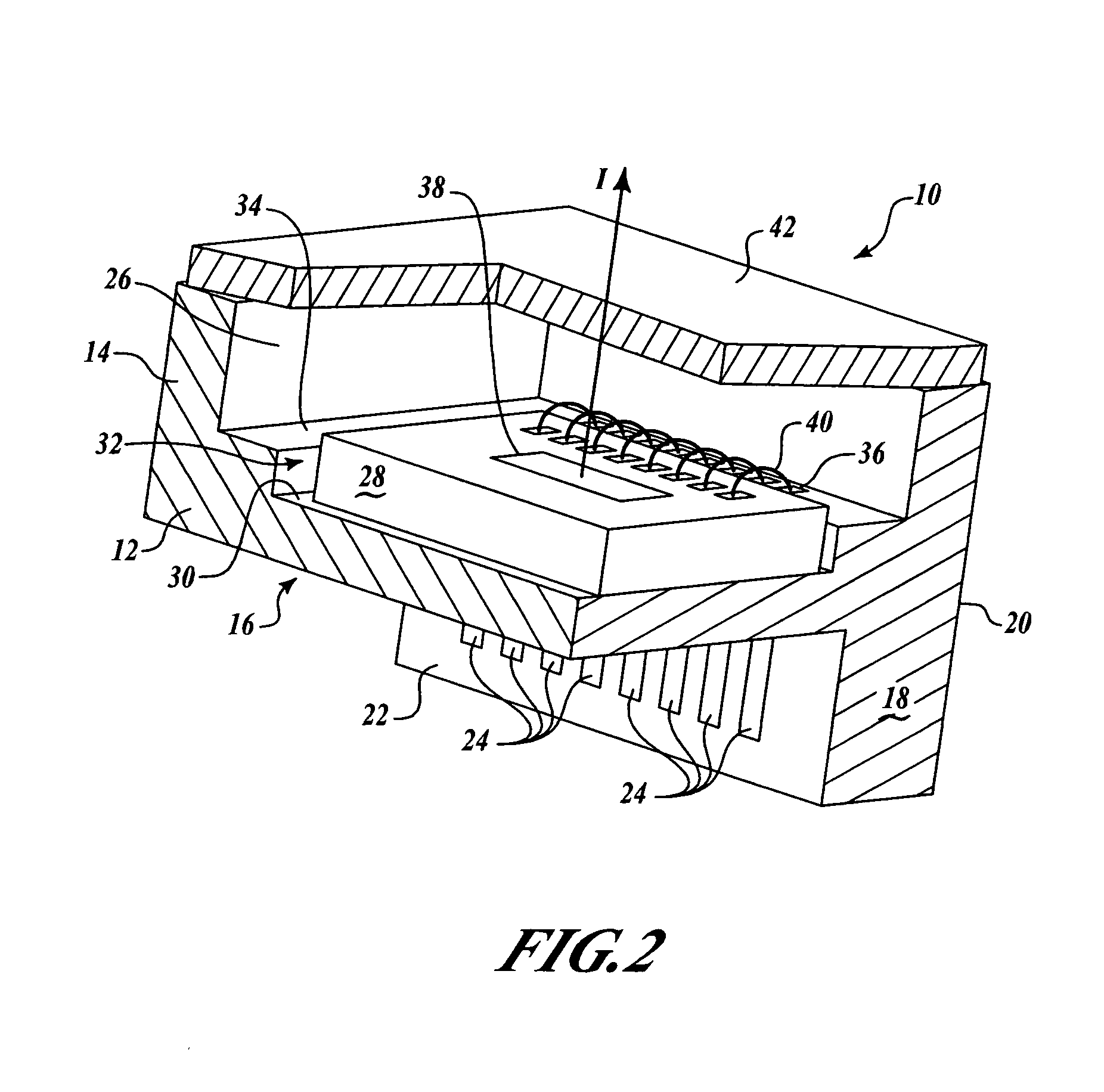

Miniature package for translation of sensor sense axis

InactiveUS7467552B2Small sizeHigh assemblySolid-state devicesSpeed/acceleration/shock instrument detailsPrinted circuit boardSystem level

A ceramic L-shaped or T-shaped packaging apparatus for a Micro Electro-Mechanical System (MEMS) inertial sensor die that translates the sensor sense axis perpendicular to the normal input plane for direct attachment to a system-level printed circuit board (PCB).

Owner:HONEYWELL INT INC

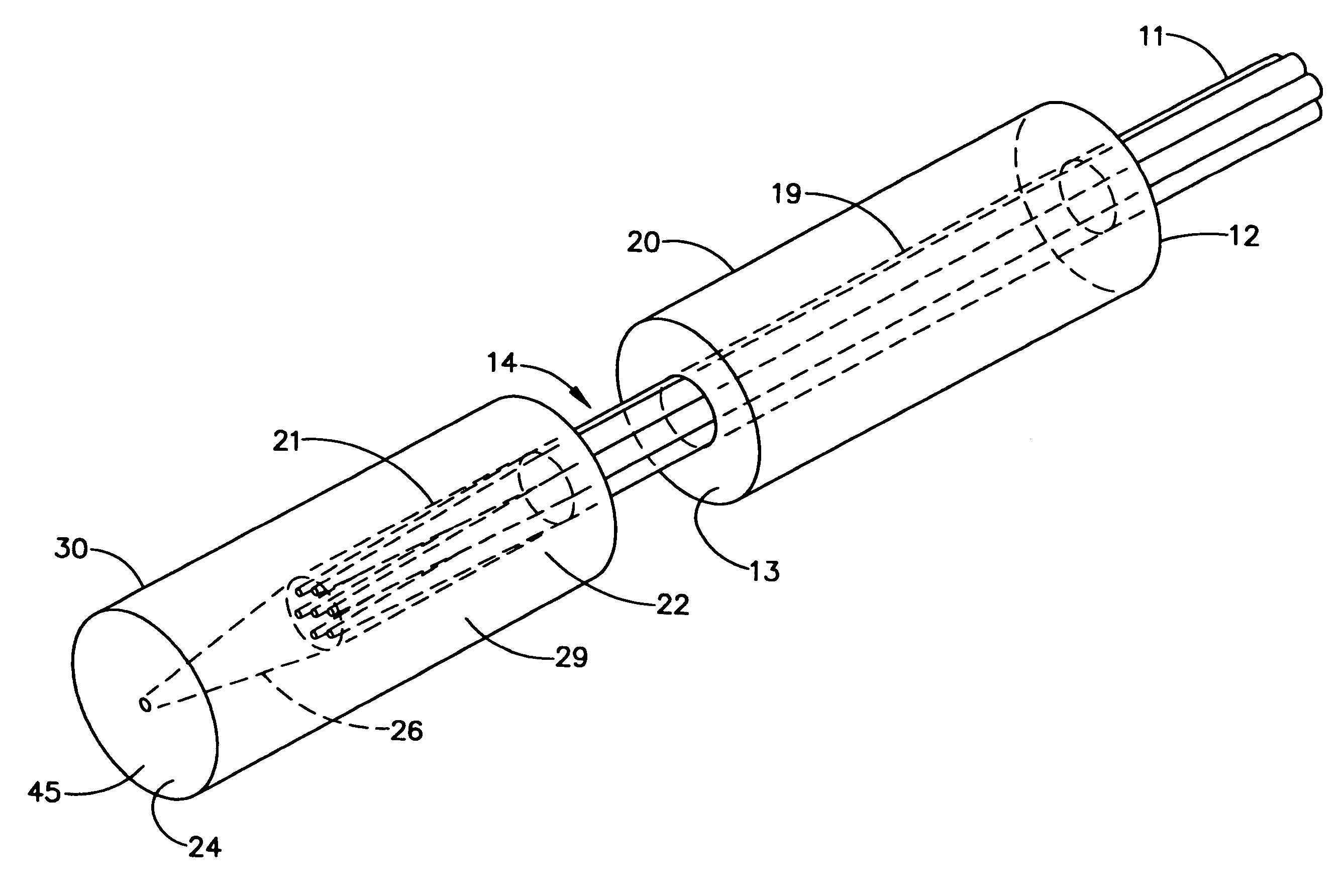

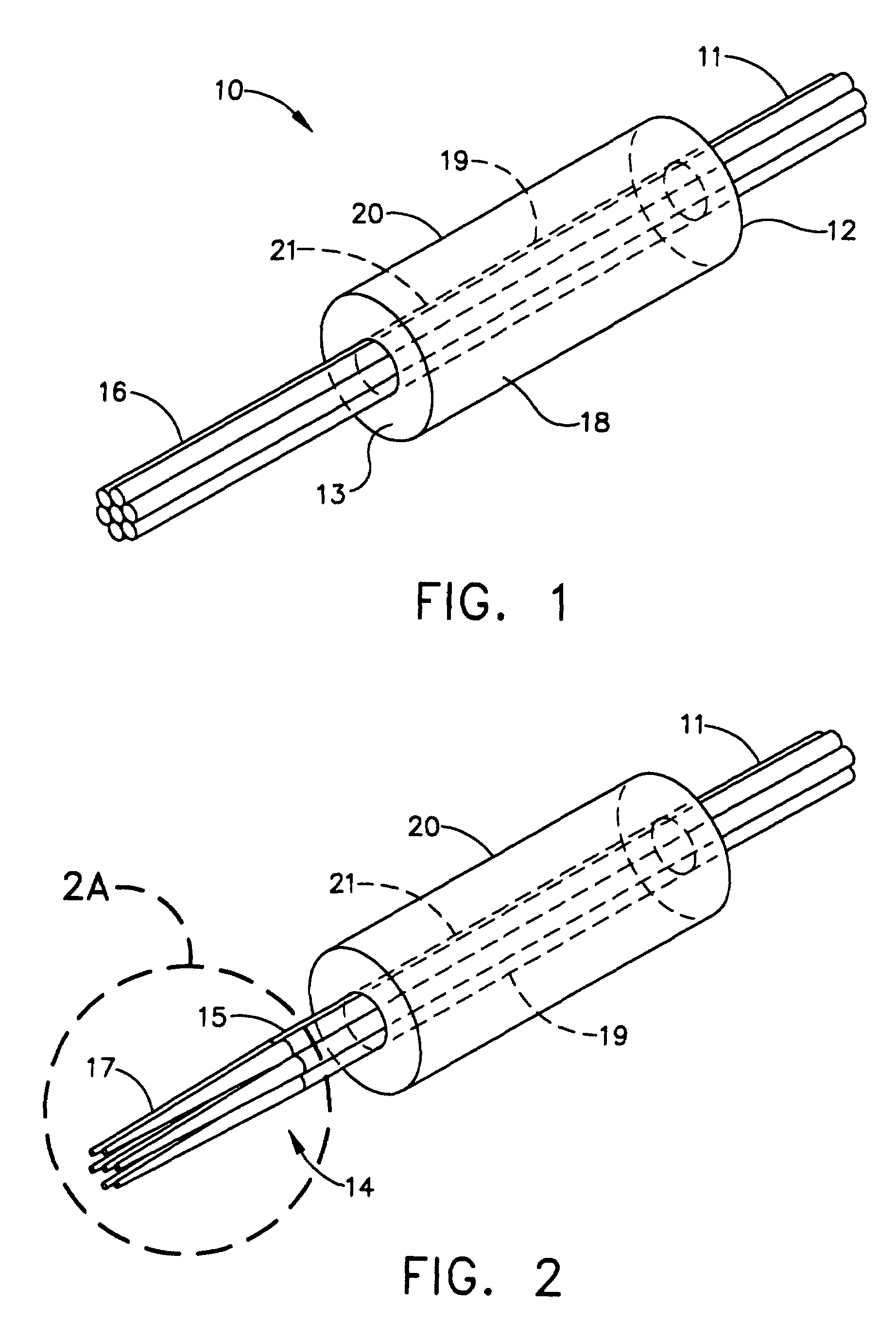

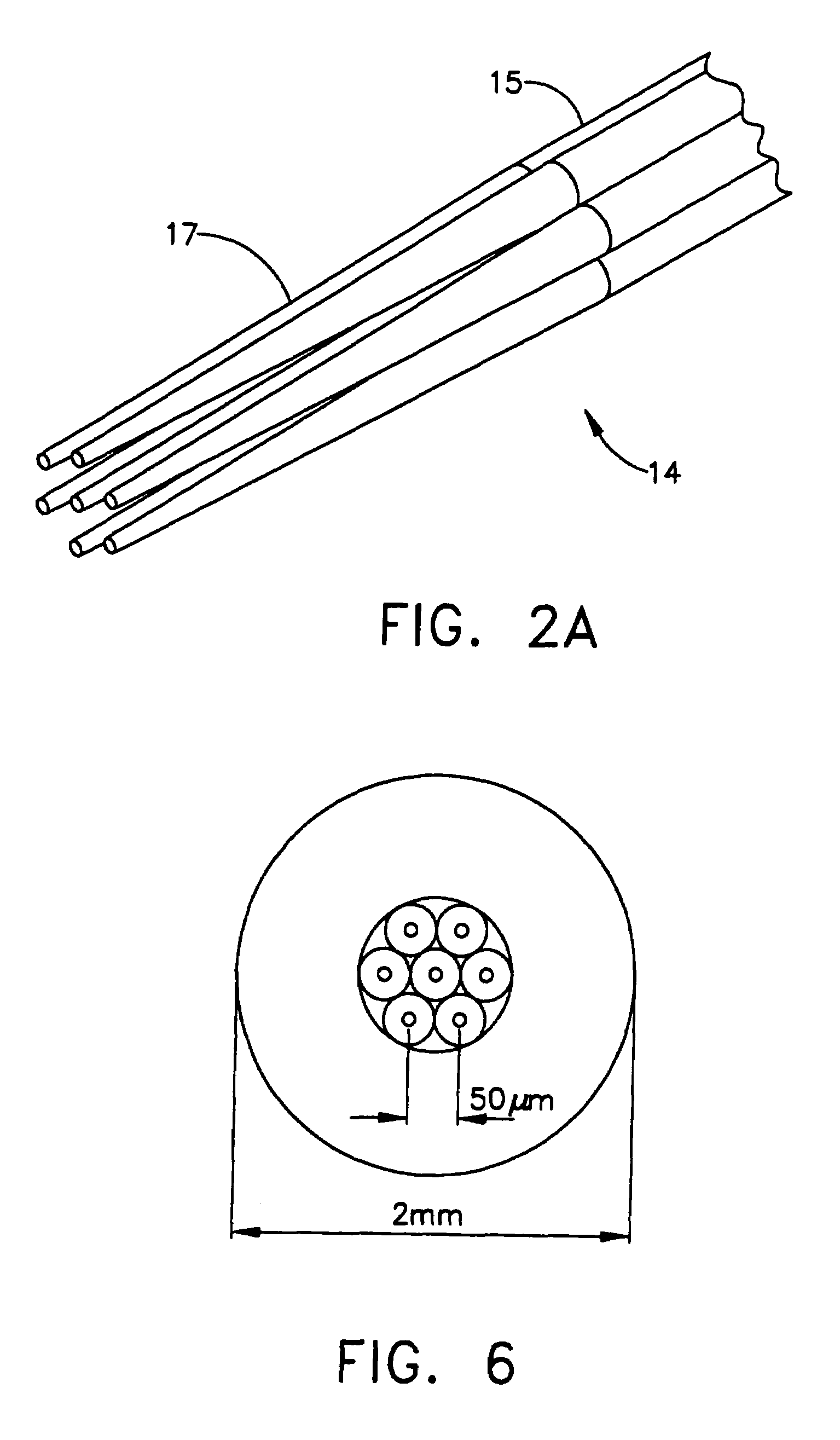

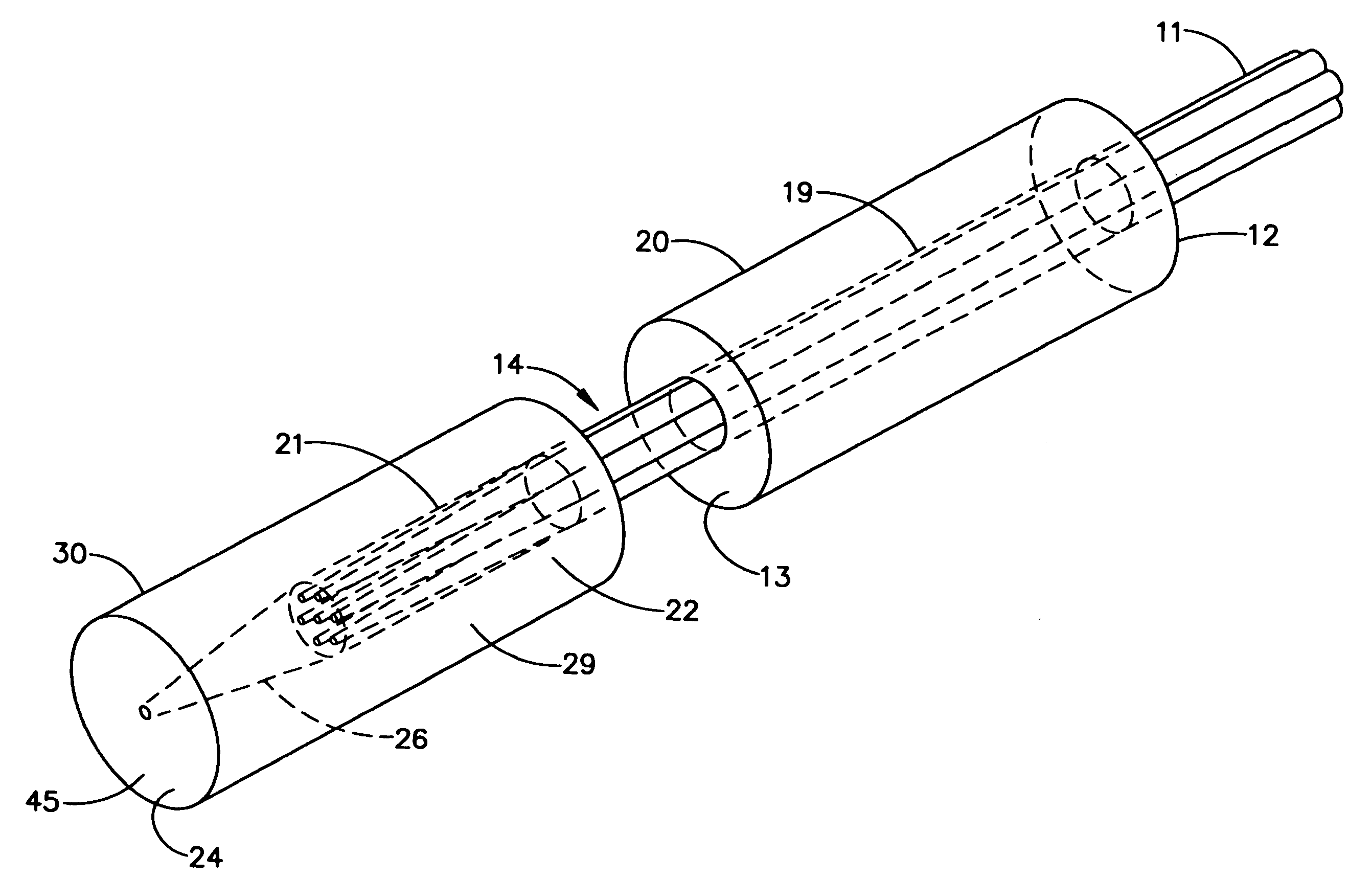

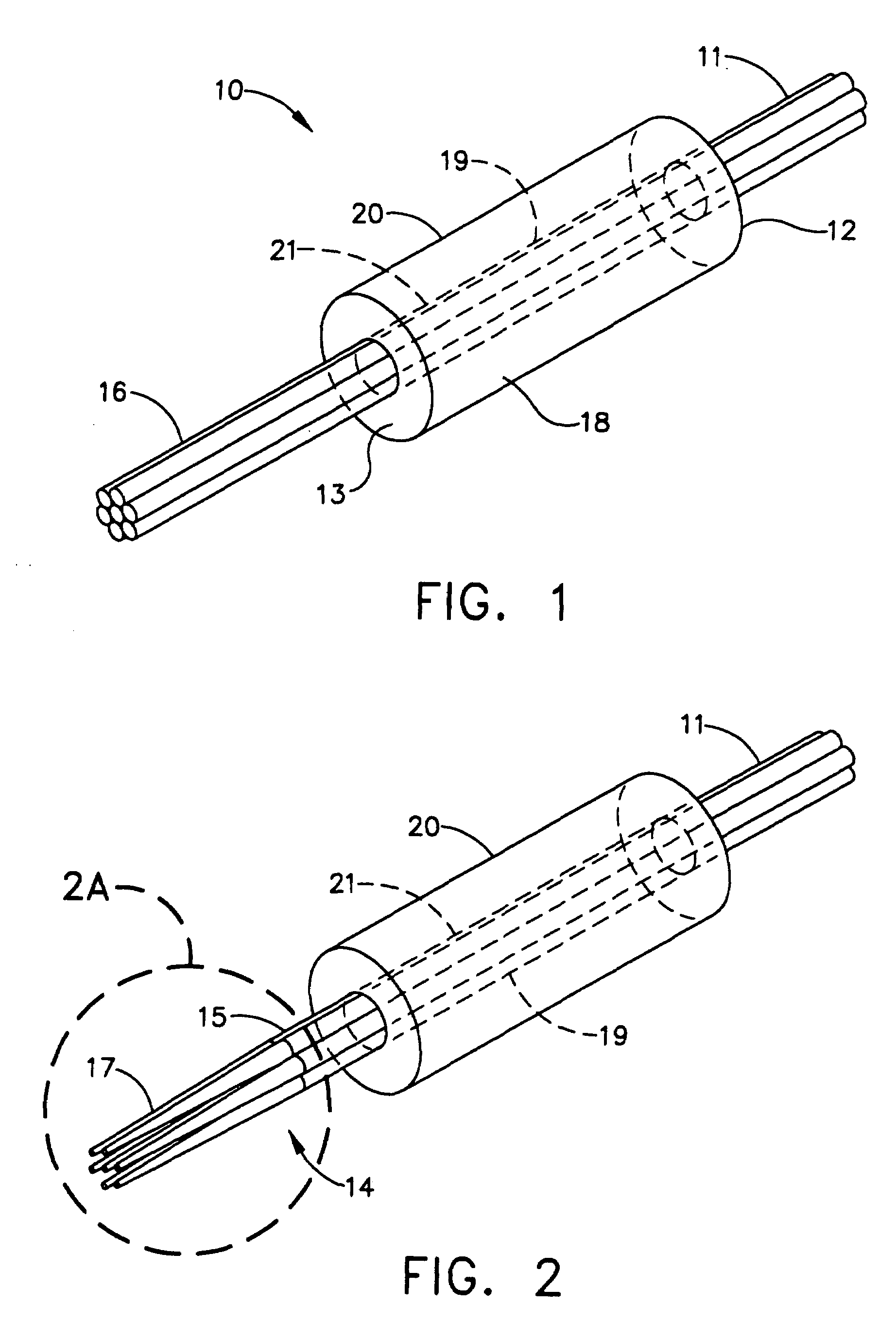

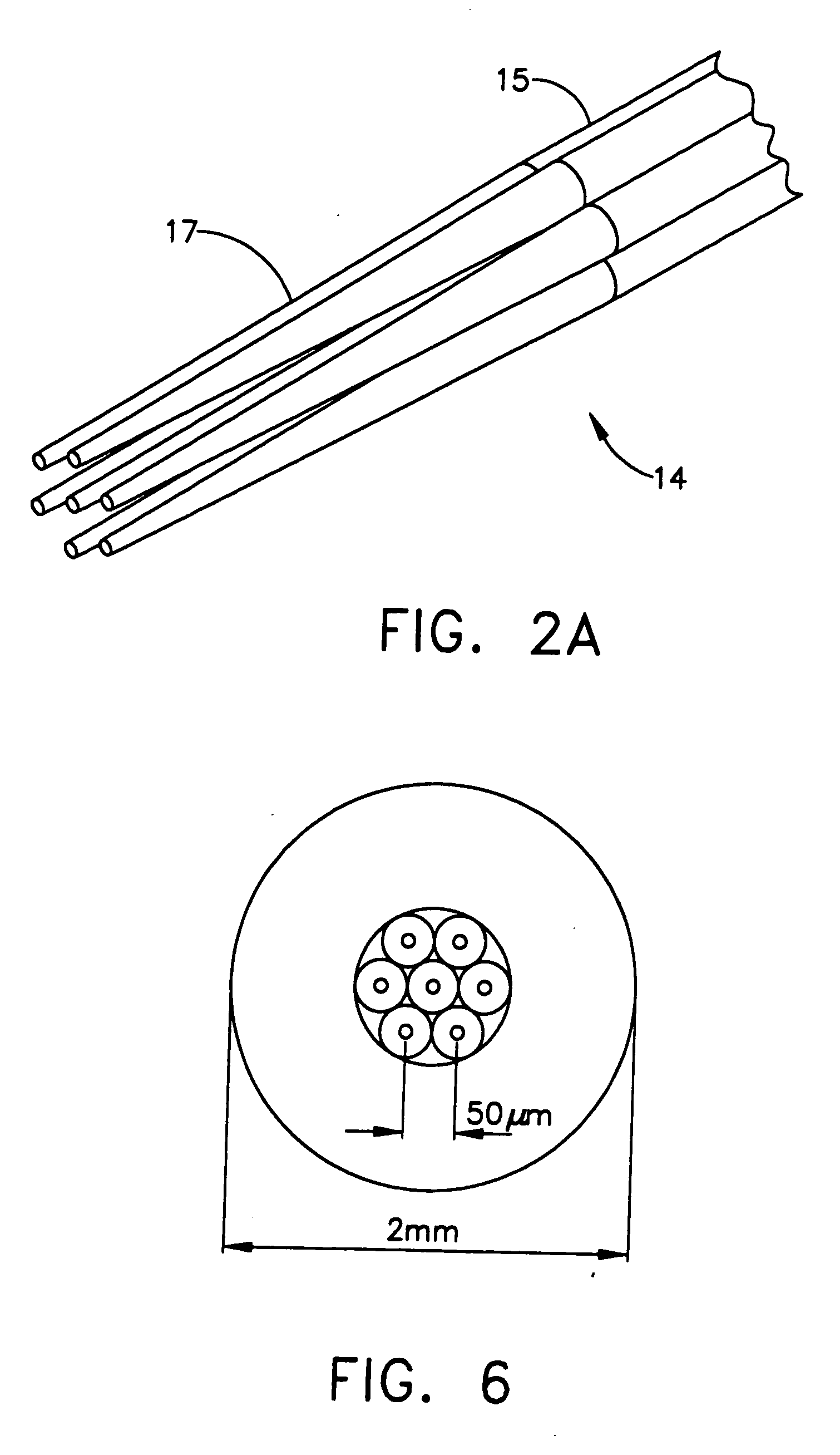

Fiber bundle termination with reduced fiber-to-fiber pitch

InactiveUS7419308B2Reduced fiber-to-fiber pitchHigh assemblyGlass making apparatusCoupling light guidesFiber bundleOptoelectronics

A method of fabrication of a fiber bundle termination with reduced fiber-to-fiber pitch which includes reducing the outside diameter of fibers in the fiber bundle by etching and provides means for preventing breakage of the etched fibers during etching and assembly. A high yield fabrication and assembly process is described.

Owner:THE BOEING CO

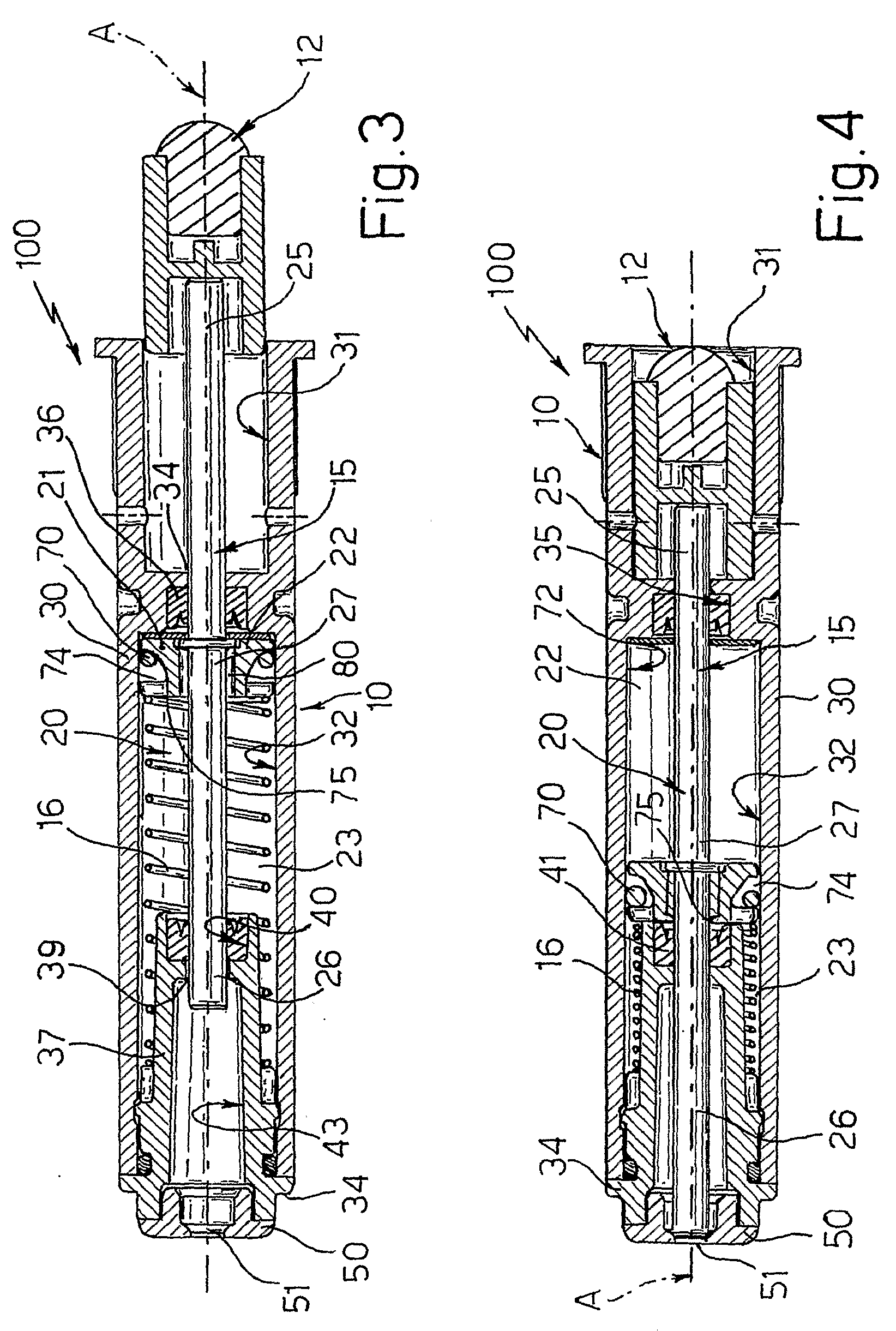

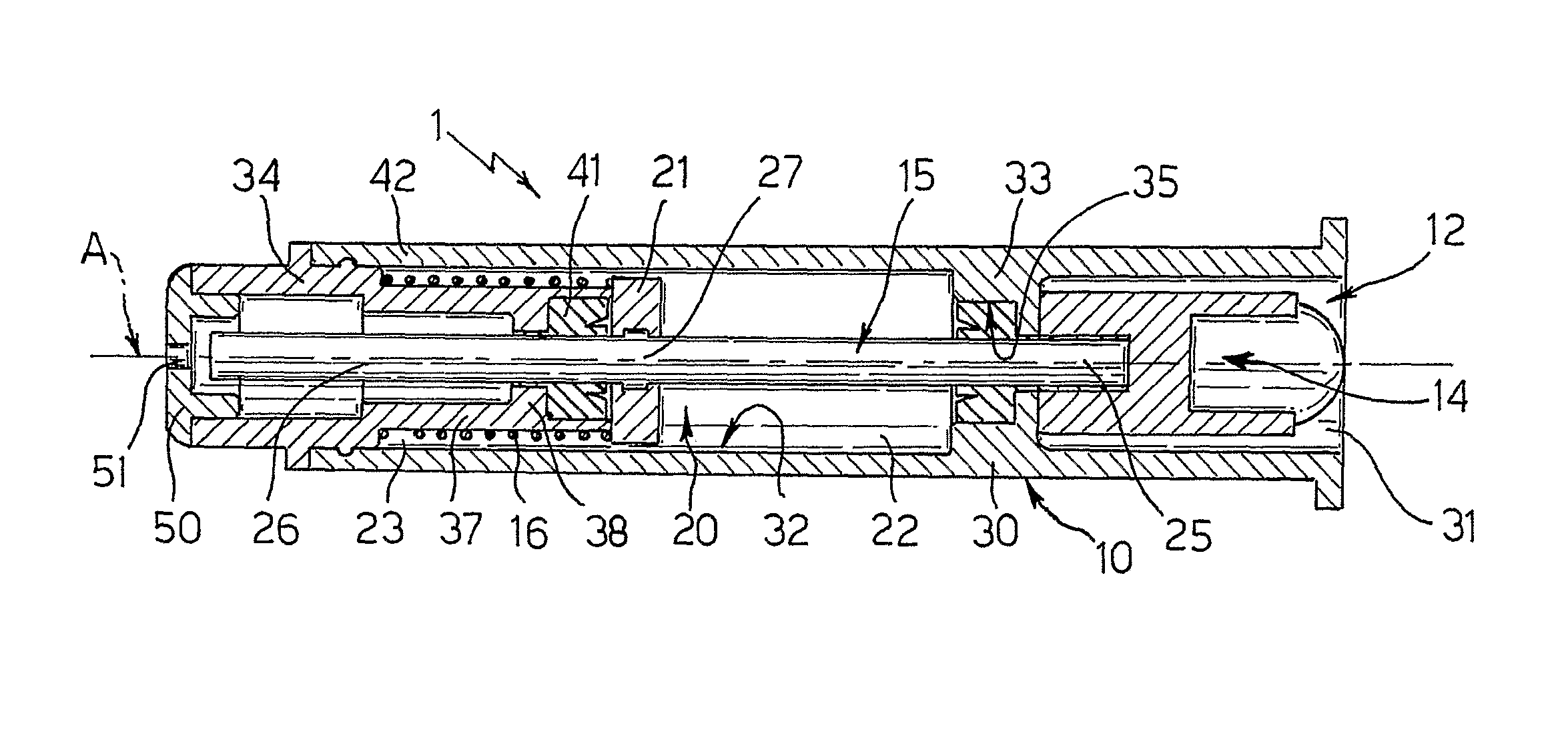

Decelerating stop device for a movable member, in particular a furniture door or drawer, fittable to a stop surface of the movable member

InactiveUS20090119873A1Small dimensionReduce manufacturing costSpringsBuilding braking devicesViscous liquidStops device

A decelerating device intended to intercept an end-of-stroke part of a closing path of a mobile member, such as a furniture drawer or door, including: a body fastenable in use to an abutting surface for the mobile member and internally defining a sealed chamber filled in use with a viscous fluid; a pushrod at least in part overhanging from the body and being adapted to cooperate in use with the mobile member, the pushrod being integral with a stem slidingly accommodated in the body against the bias of elastic means between an extracted position of the pushrod and a retracted position; and a piston accommodated in the sealed chamber so as to divide it into two portions hydraulically connected to each other and mechanically connected to the stem; wherein the stem presents a first end integrally connected to the pushrod and a second end opposite to the first, both slidingly accommodated in the body outside the sealed chamber and fluid-tightly towards the sealed chamber itself; the piston is provided with a mobile sealing member to choke the hydraulic communication between the two portions of the sealed chamber only during the stroke of the stem towards the retracted position.

Owner:ITW IND COMPONENTS SRL

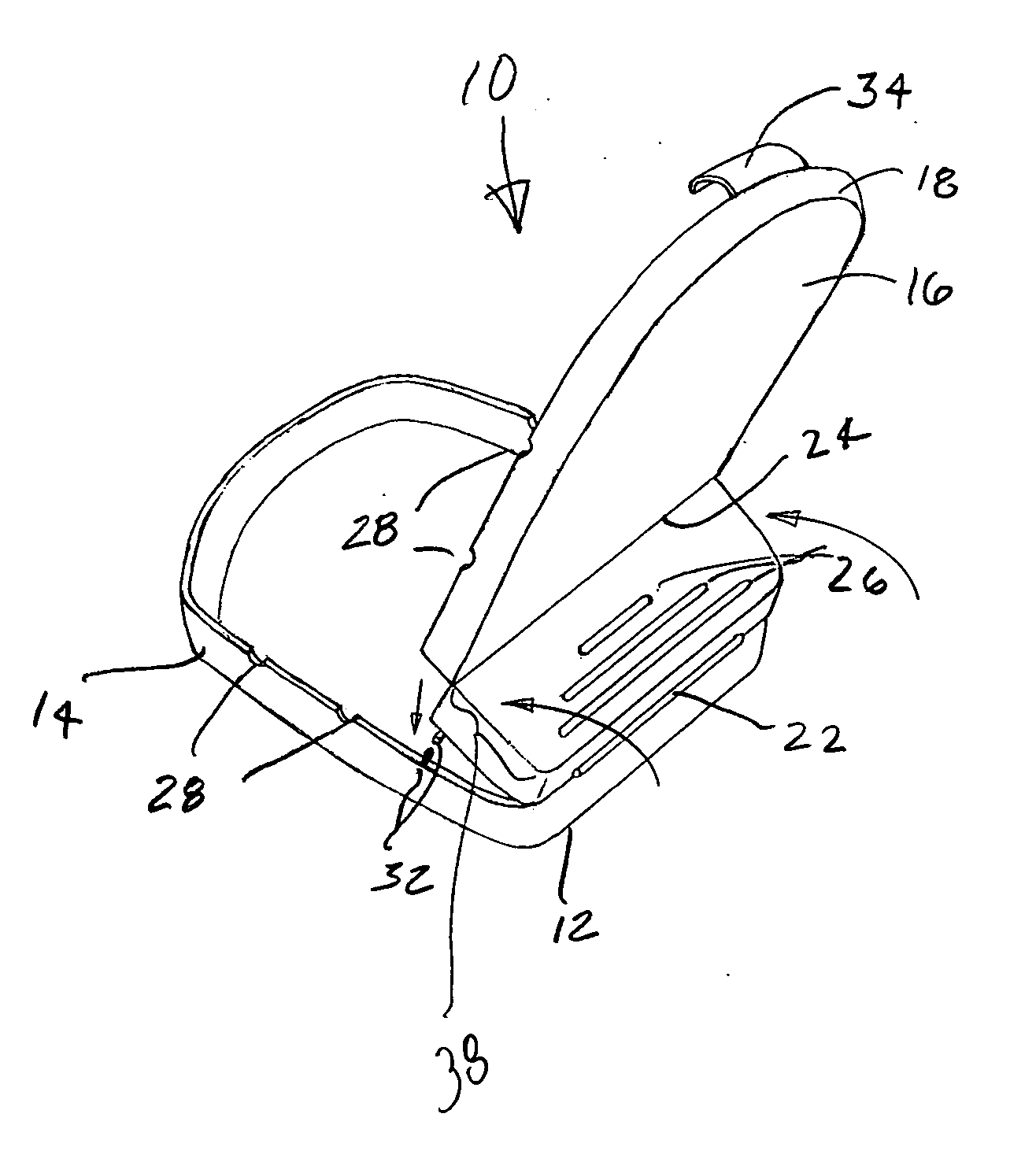

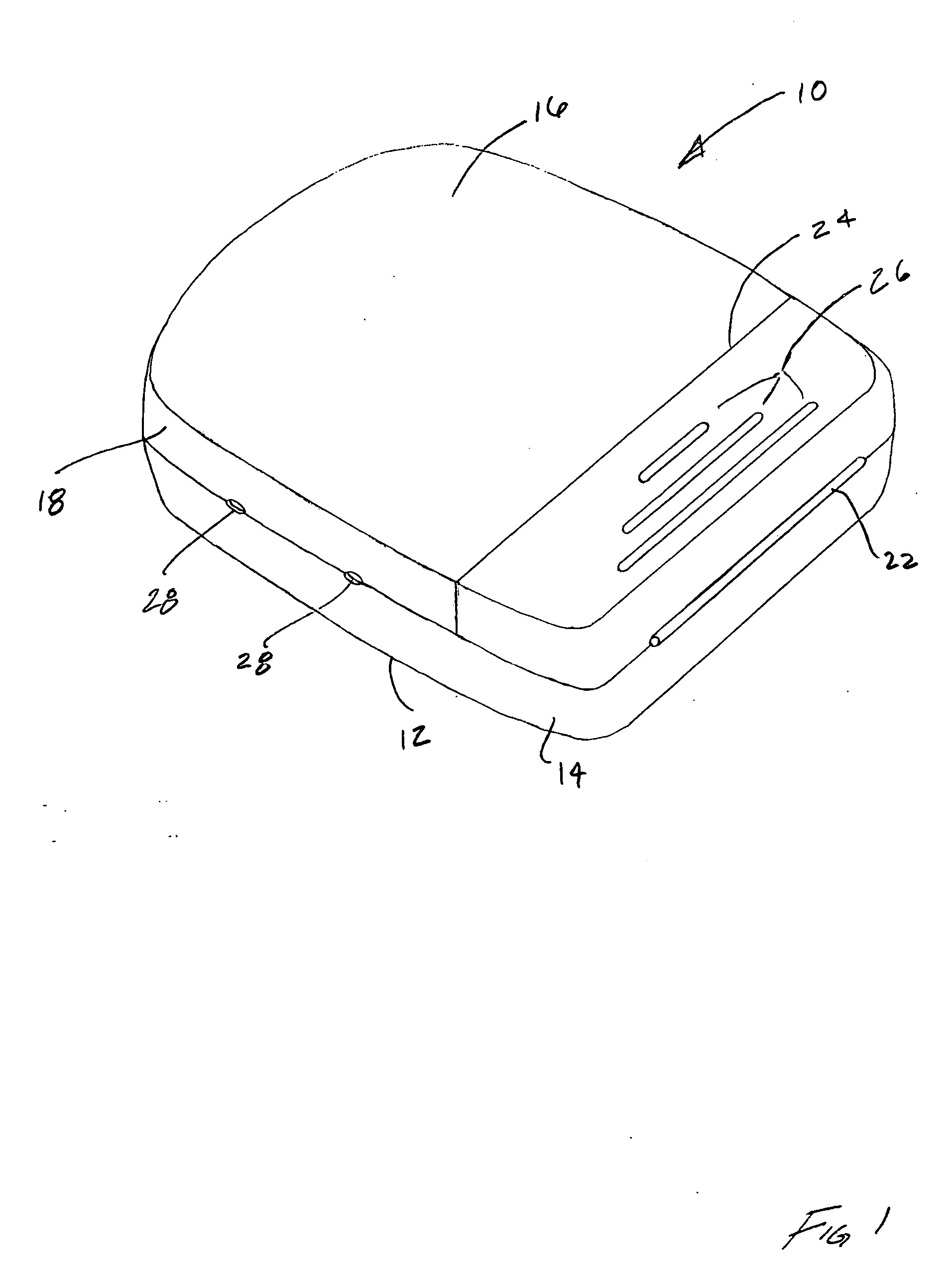

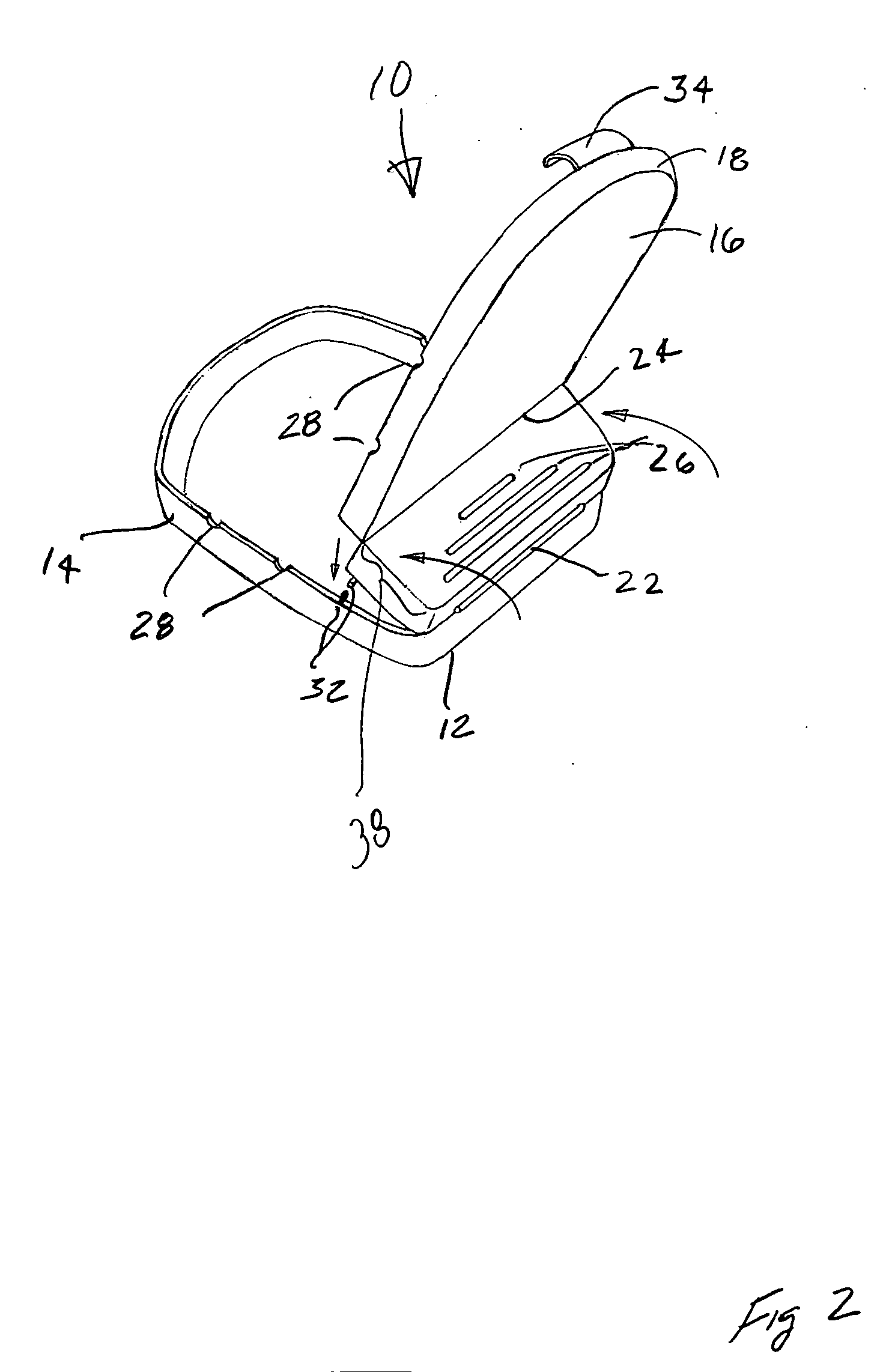

Medical device and information container

InactiveUS20050194391A1Efficient high volume assemblyEfficient packagingLidsNon-removalbe lids/coversTamper resistanceProduct gas

A dynamically configurable medical device and information container is disclosed. The container includes ergonomic features that enable ease of handling and unloading of the contents of the container. Specifically, a configurable section serves as an ergonomic gripping section and a containment section. The container also includes tamper-proof strips that are visible indications of prior opening or tampering with the container. Furthermore, vent holes are implemented to release sterilization gas residues to limit the sterilization gas content of the container.

Owner:MEDTRONIC INC

Mobile milling head with torque motor drive

InactiveUS7470095B2Rapid corrective movementReduce stiffnessMachine tool componentsWorkpiecesDynamic stiffnessGear drive

A milling head (16) for a milling machine (1) arranged for machining large-size workpieces comprises a fork 18, which is rotatably arranged around a first axis (C) and demonstrates a pair of fork arms (21, 22), which are separated from one another, a spindle device (23), which is arranged between the fork arms and rotatable around a second axis A, a first torque motor (42), which is coupled to the fork 18 for directly driving and controlling of the rotation of the fork around the first axis (C), and a second torque motor (57) for driving and controlling the rotation of the spindle around the second axis (A), said second torque motor being coupled to the spindle device (23) by means of a one-stage toothed gearing (61), which is mechanically clamped free of backlash. The configuration according to the invention is arranged to achieve high torque with high dynamic stiffness and small interference contour of the milling head (16).

Owner:F ZIMMERMAN GMBH & CO KG

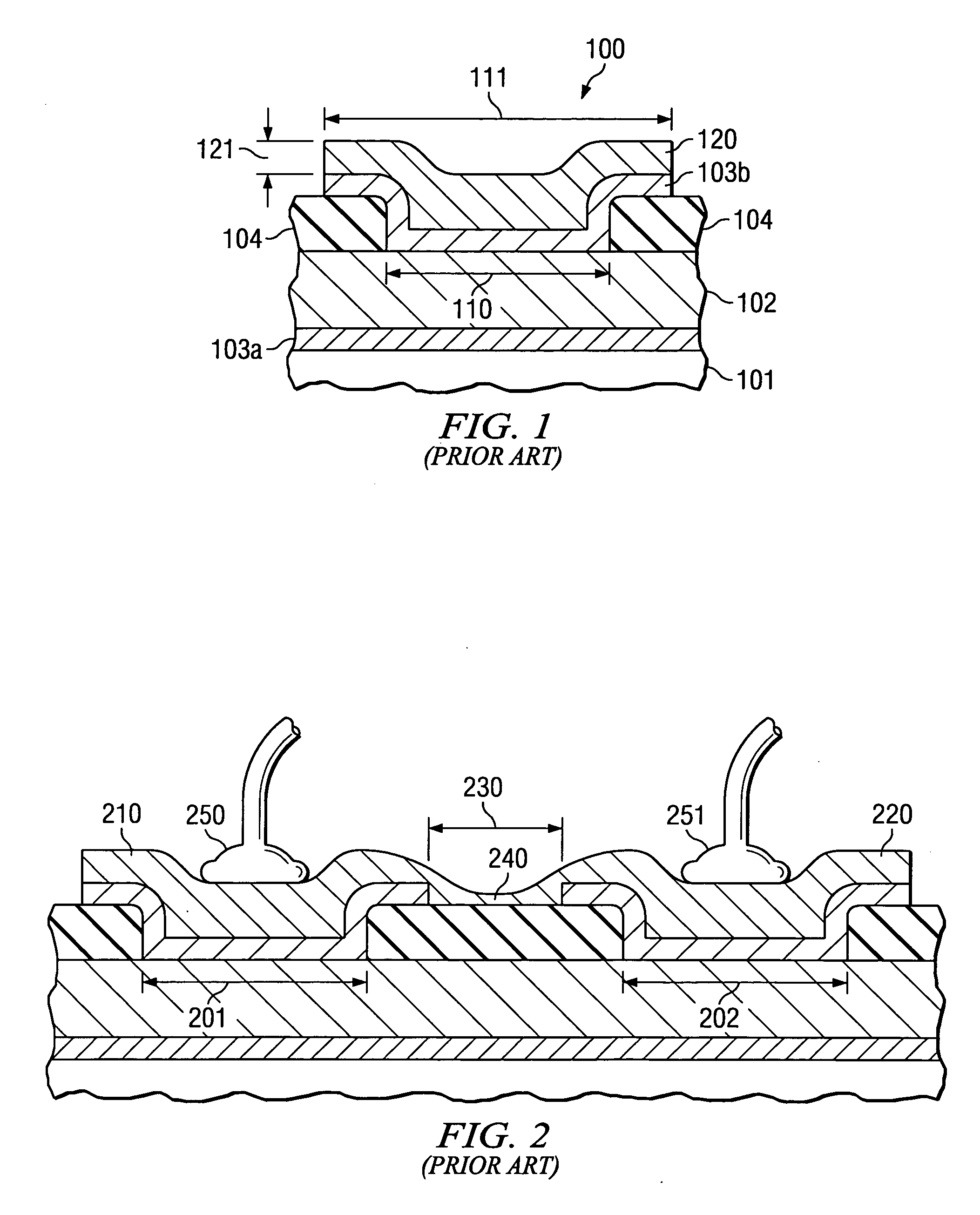

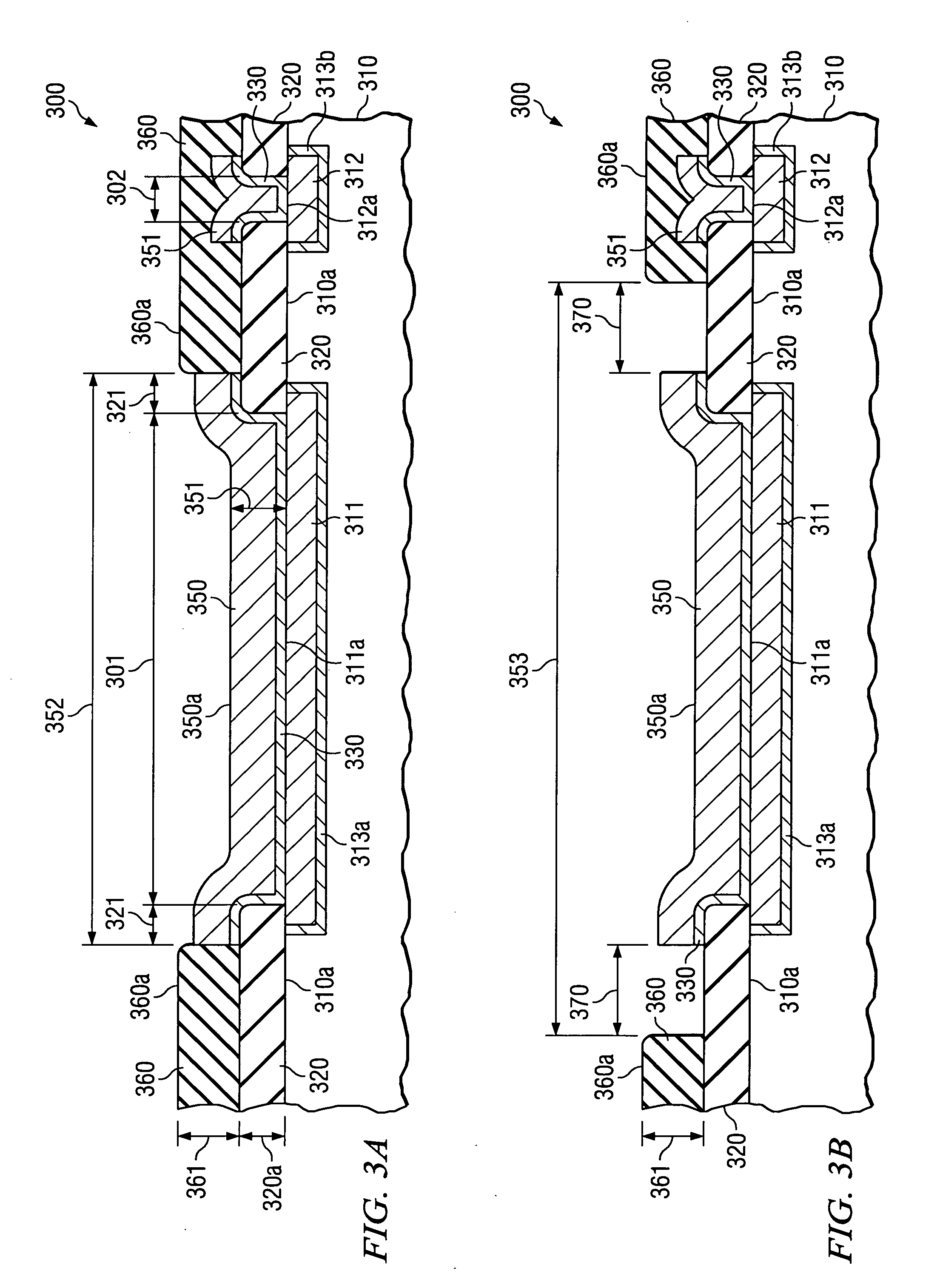

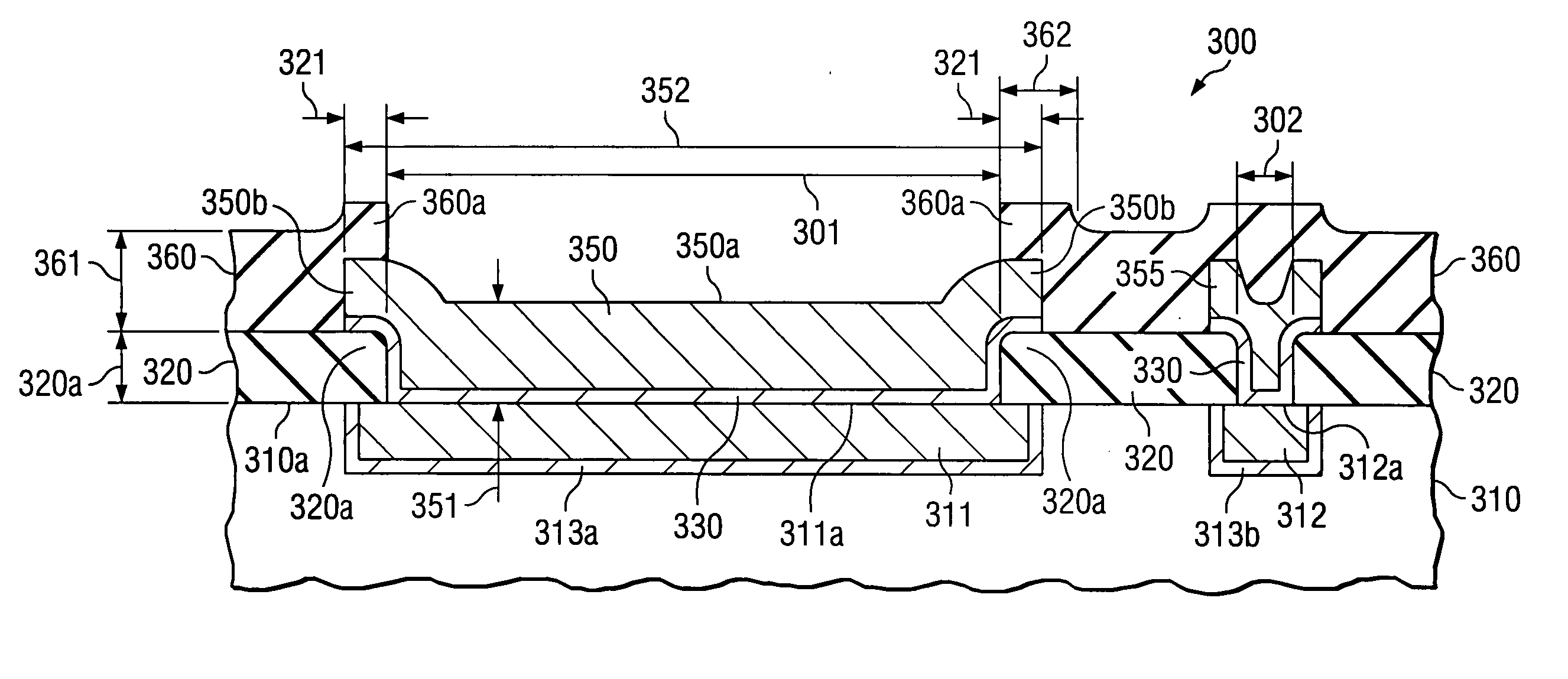

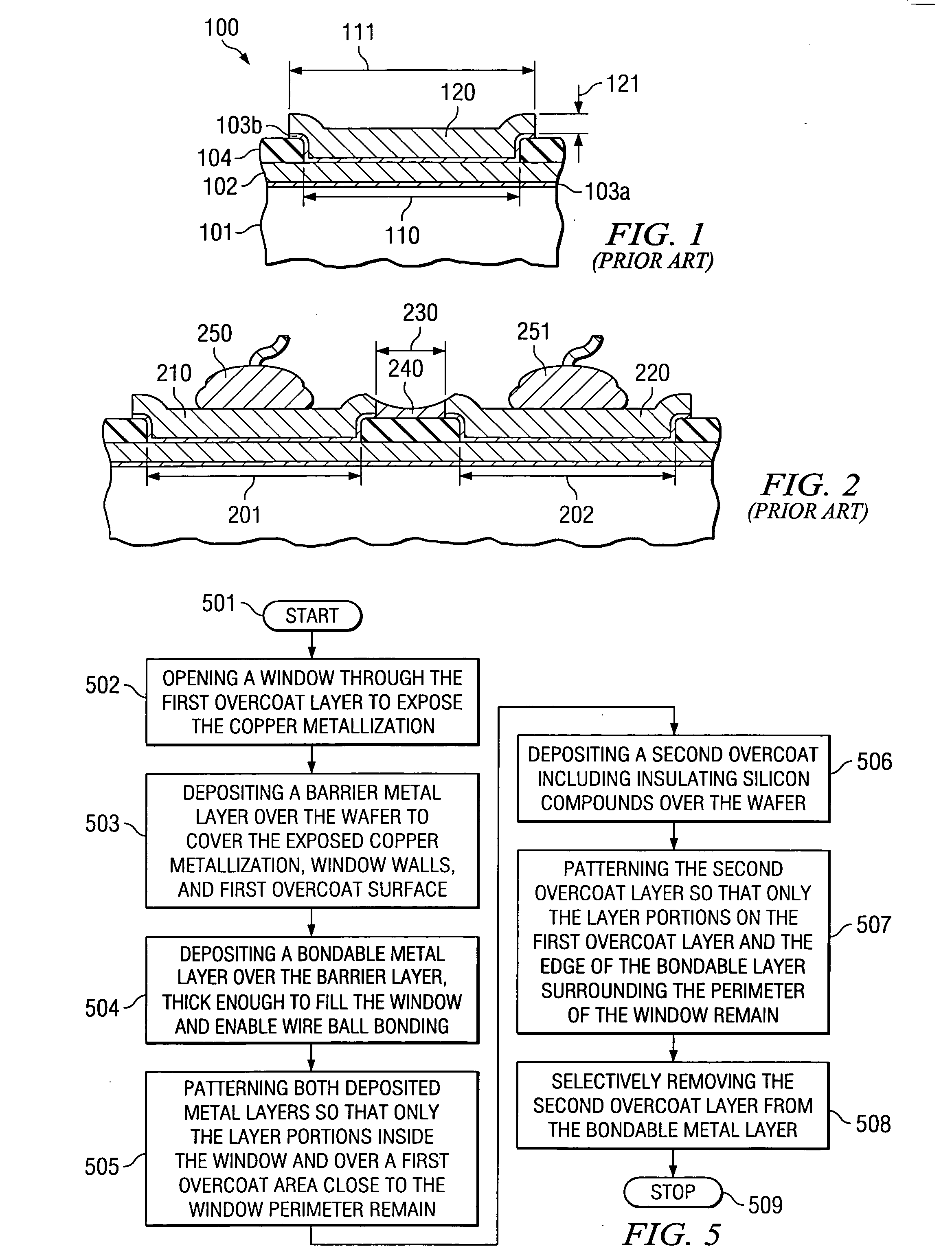

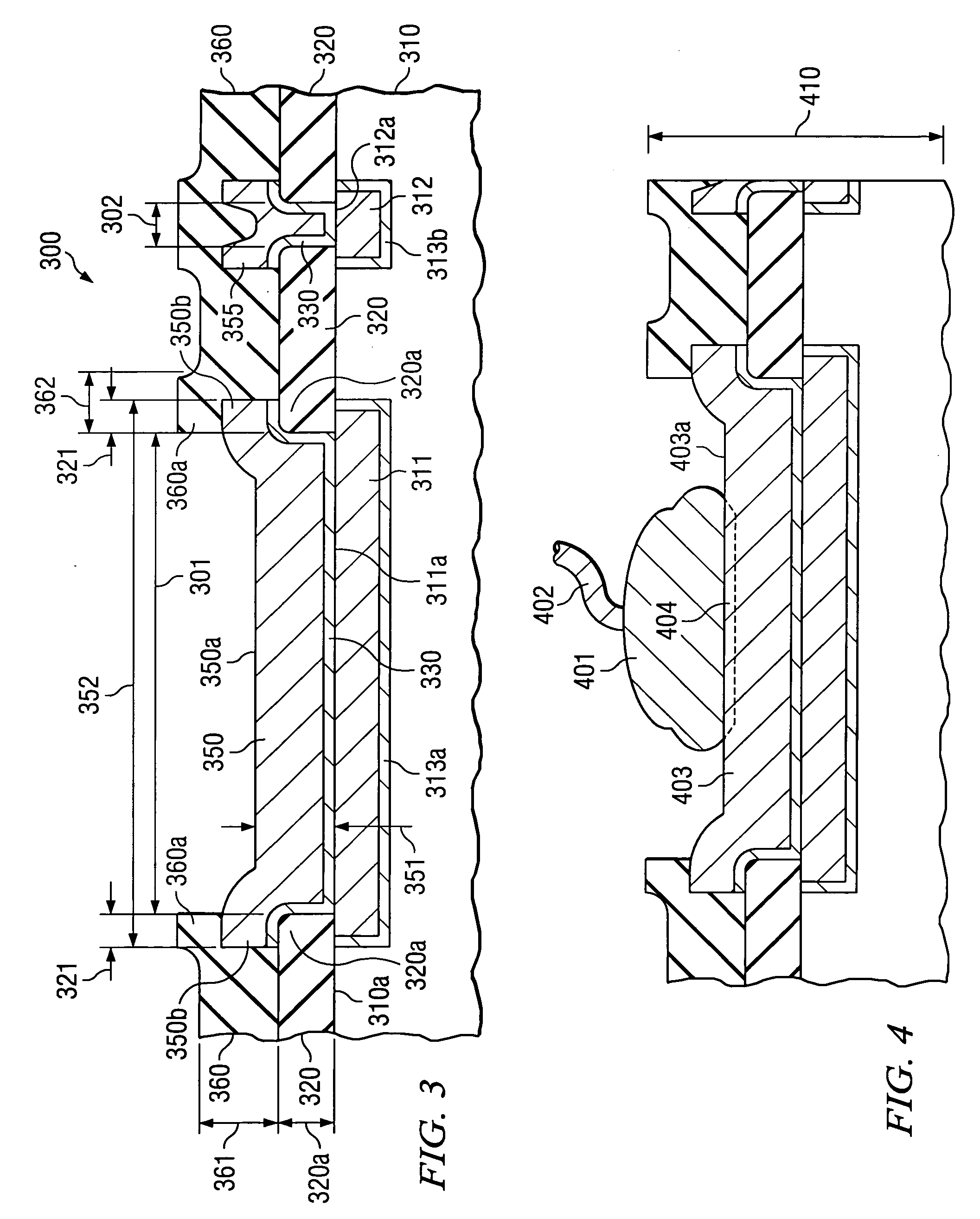

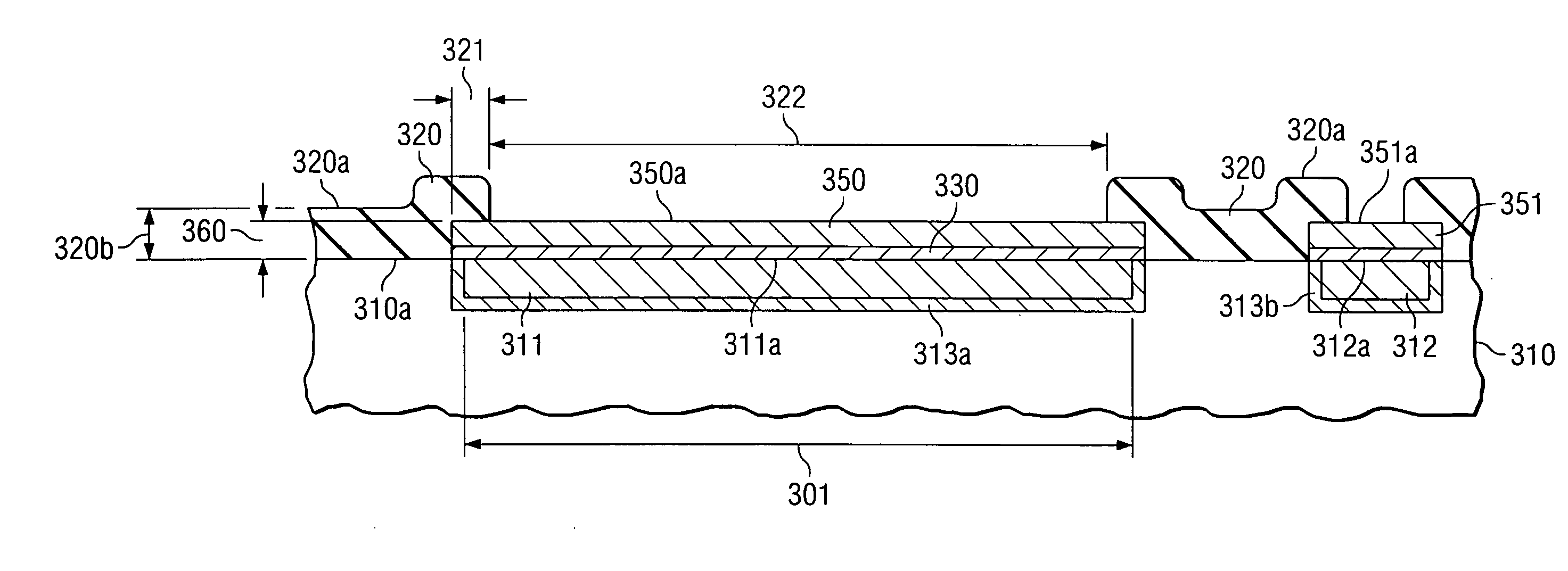

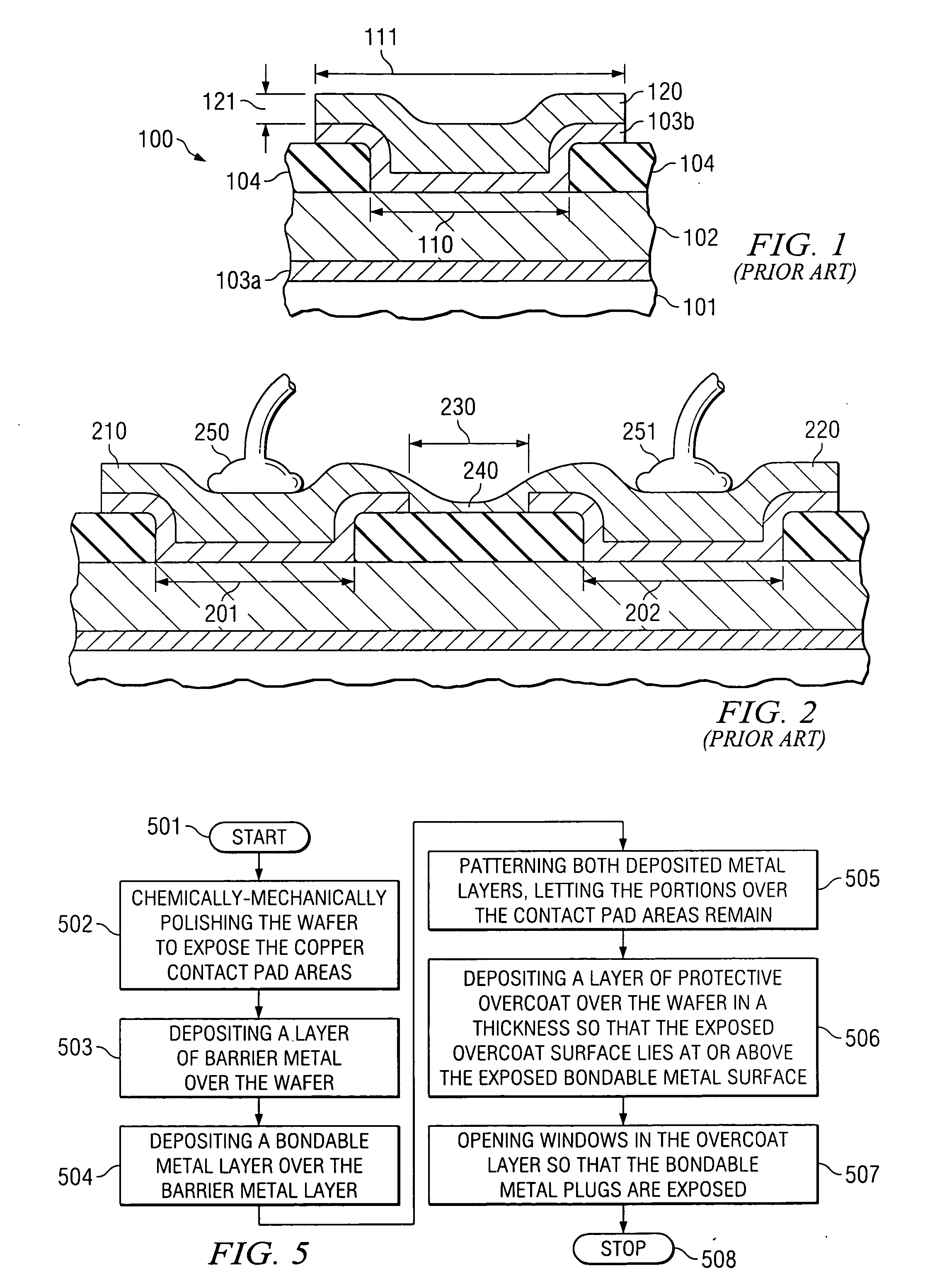

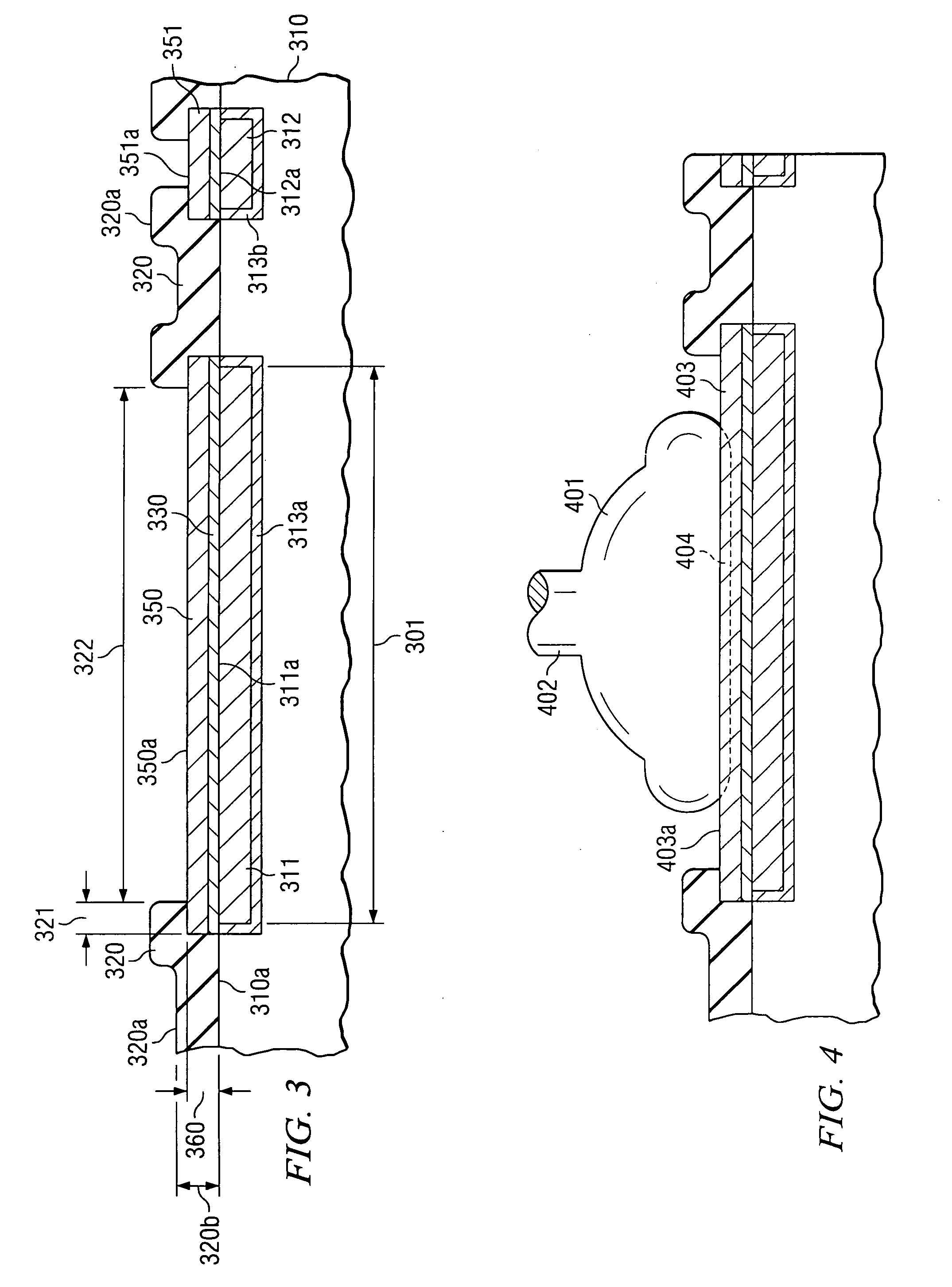

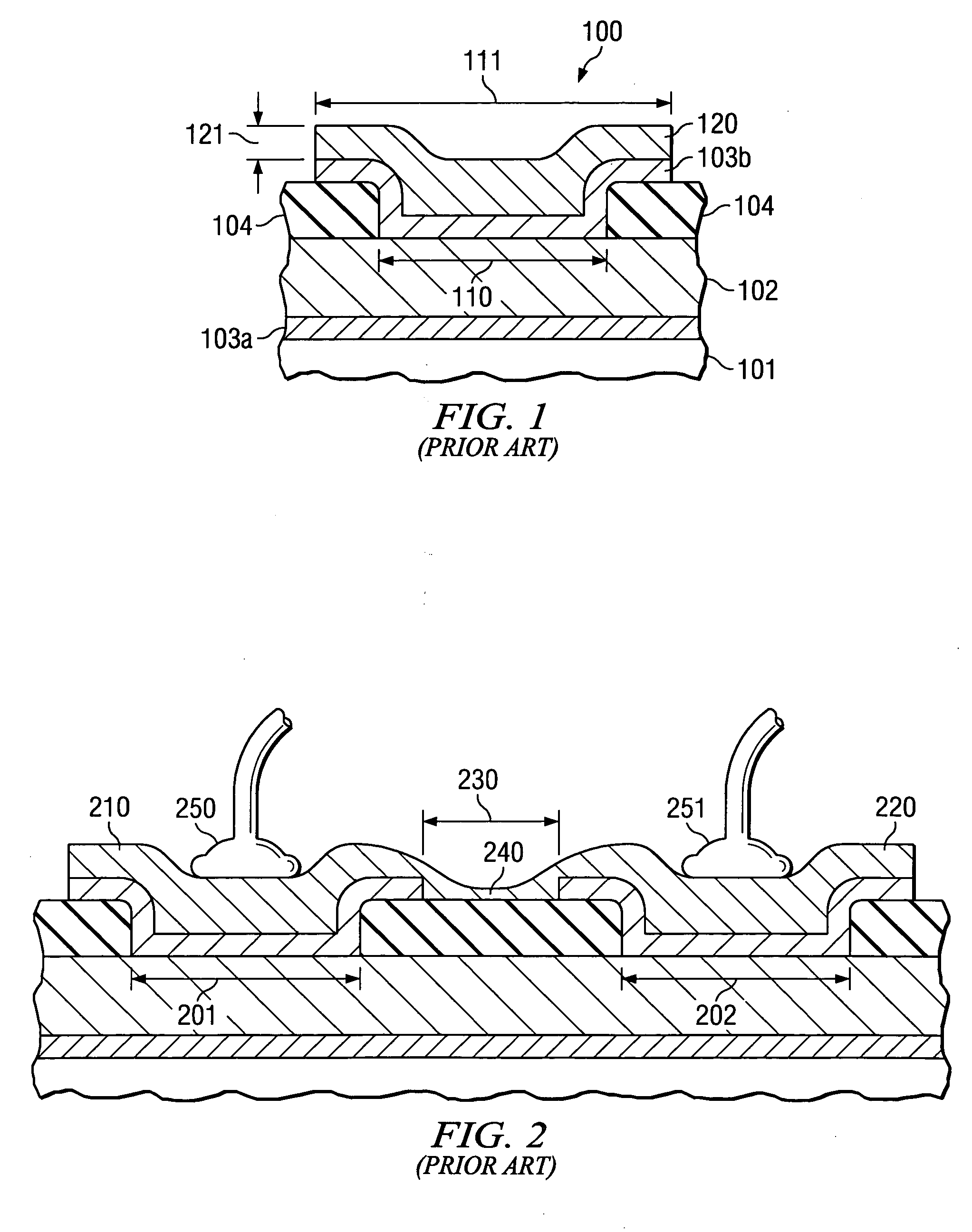

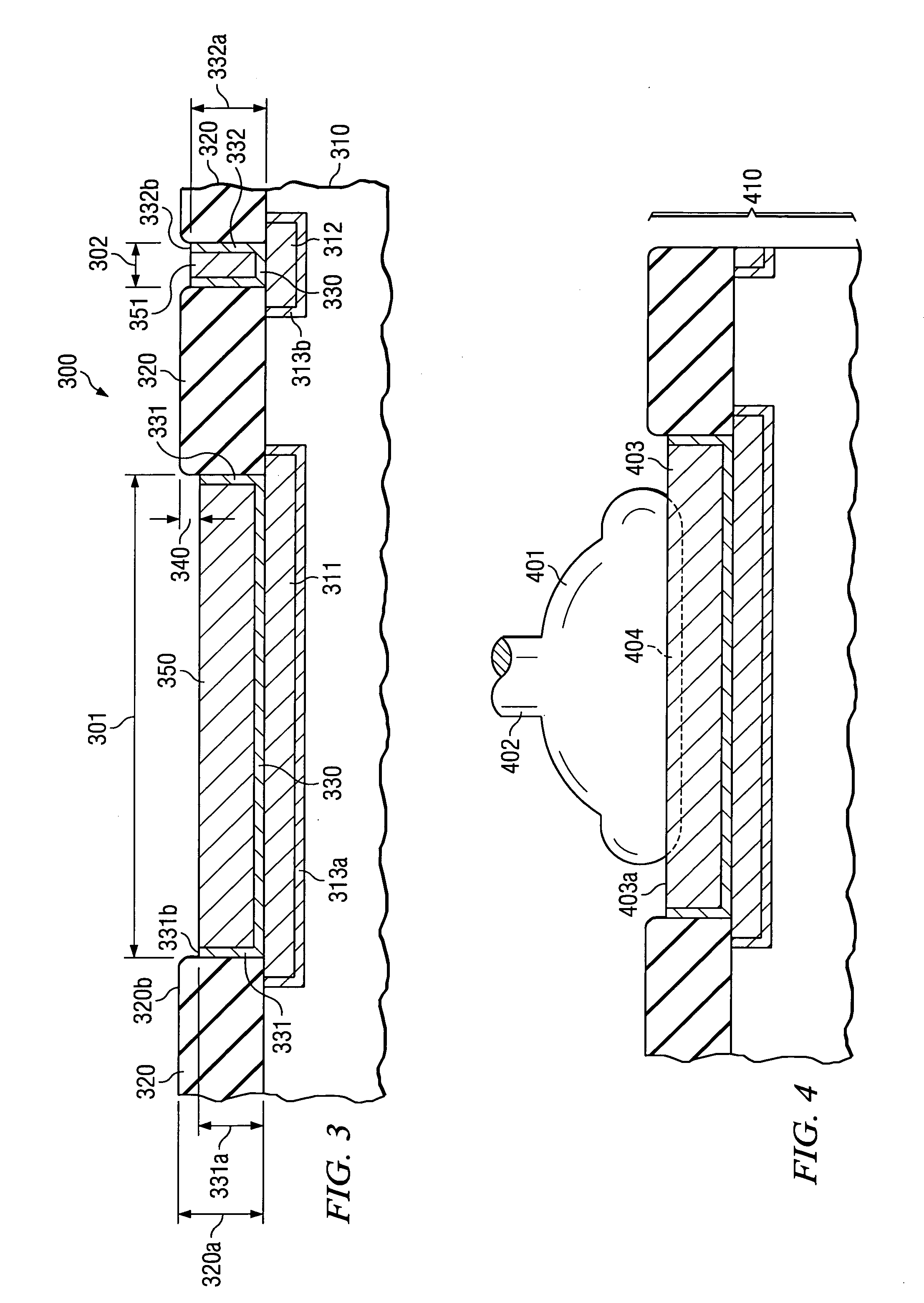

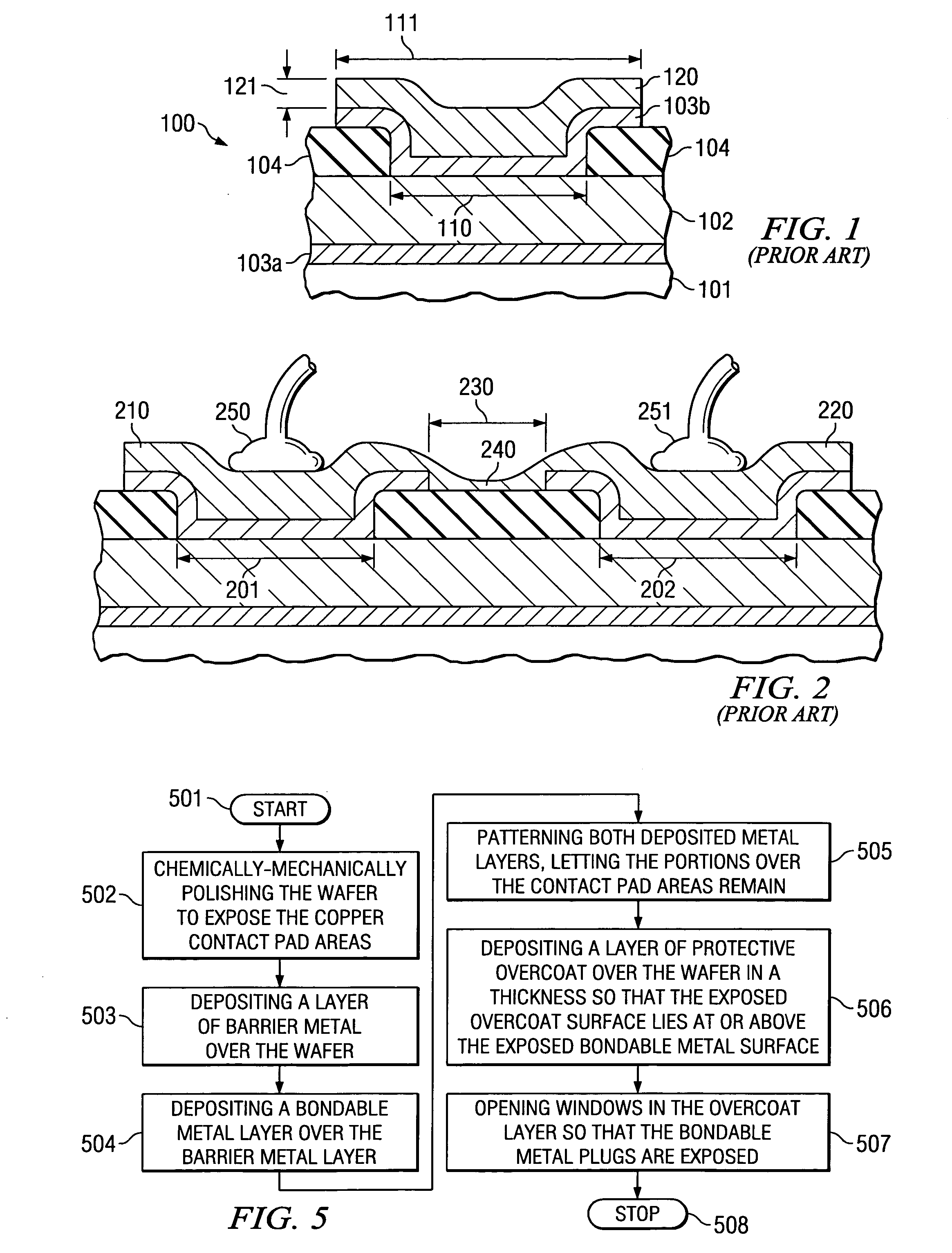

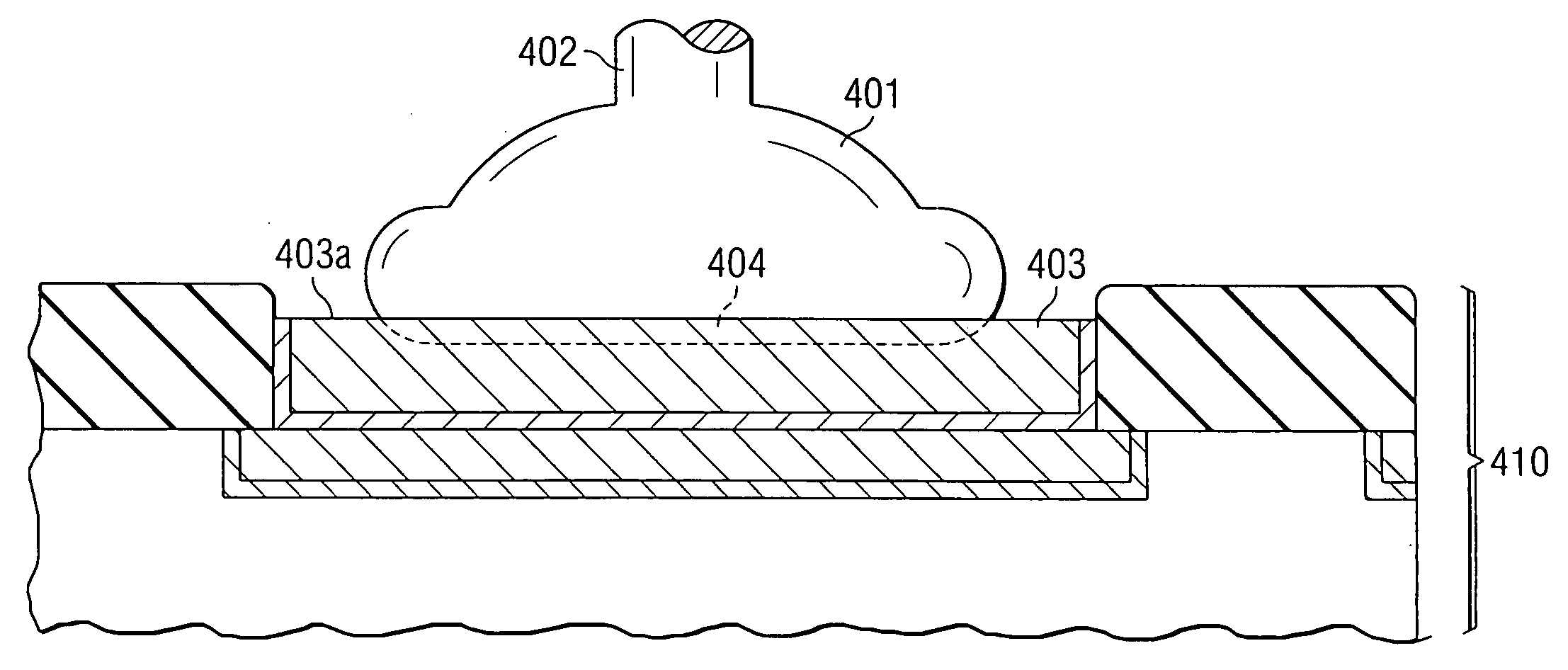

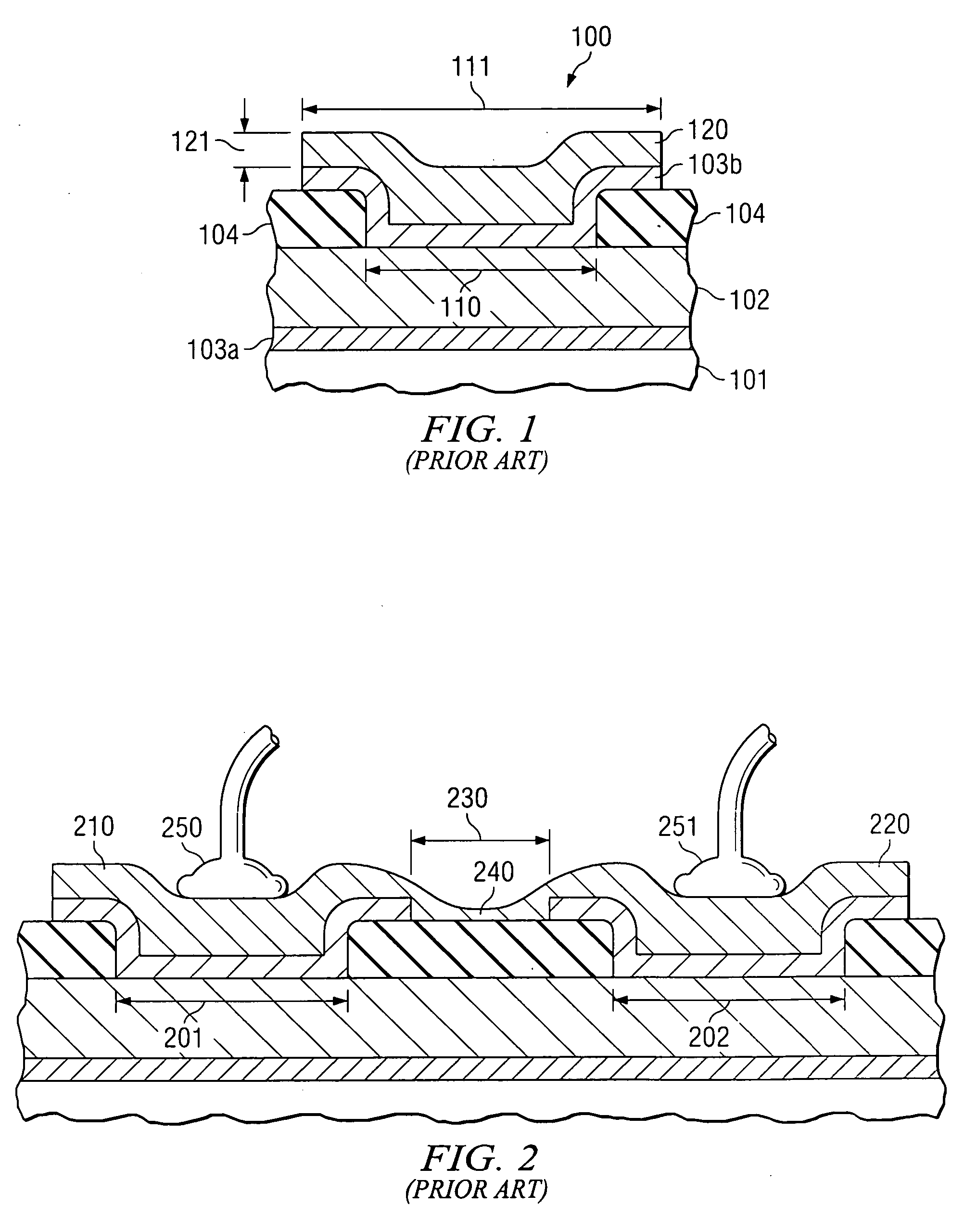

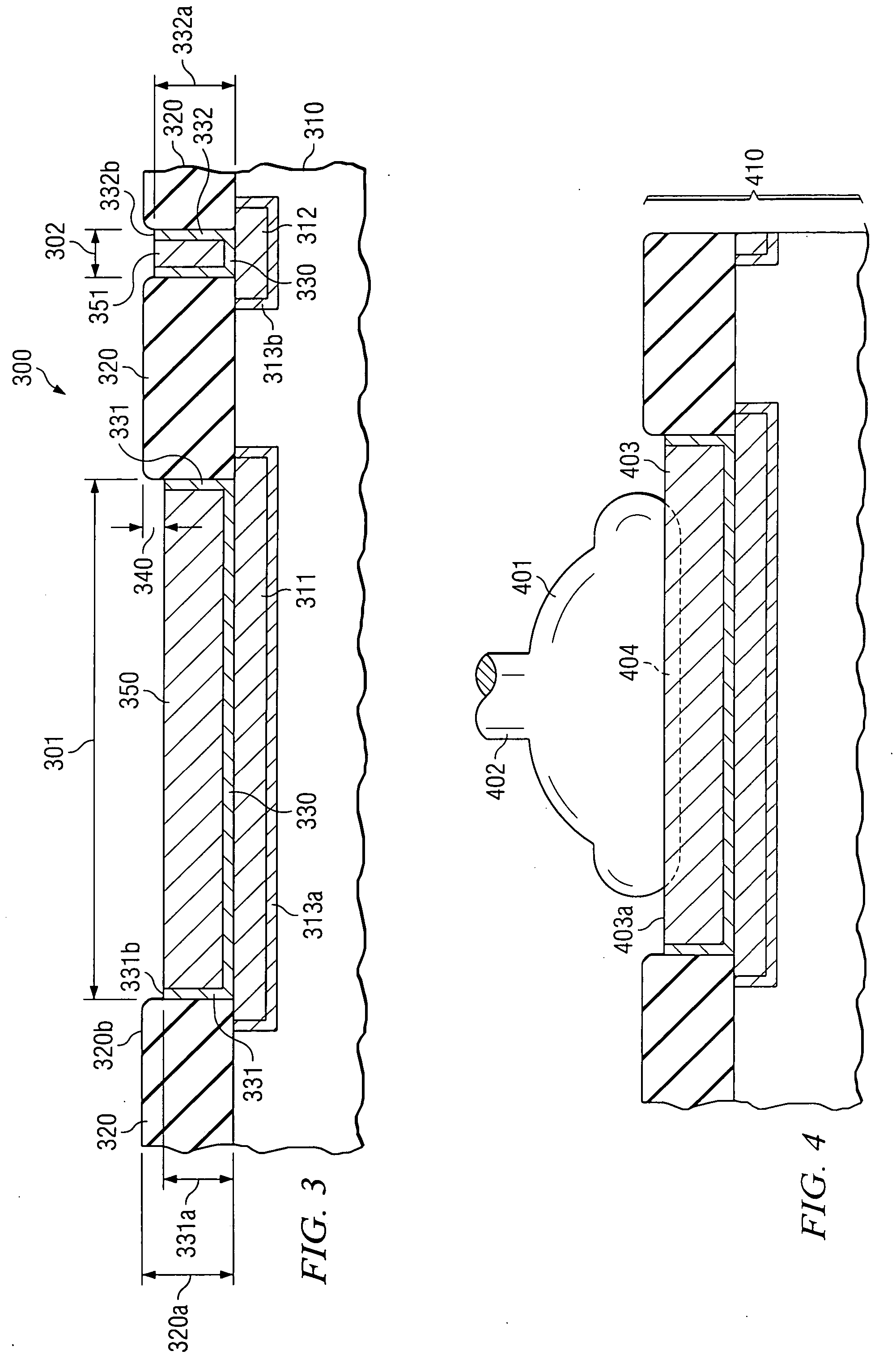

Structure and method for contact pads having a protected bondable metal plug over copper-metallized integrated circuits

ActiveUS20050224984A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

An integrated circuit having copper interconnecting metallization (311, 312) protected by a first, inorganic overcoat layer (320), portions of the metallization exposed in windows (301, 302) opened through the thickness of the first overcoat layer. A patterned conductive barrier layer (330) is positioned on the exposed portion of the copper metallization and on portions of the first overcoat layer surrounding the window. A bondable metal layer (350, 351) is positioned on the barrier layer; the thickness of this bondable layer is suitable for wire bonding. A second, organic overcoat layer (360) is surrounding the window so that the surface (360a) of this second overcoat layer at the edge of the window is at or above the surface (350a) of the bondable layer. The second overcoat layer may be spaced (370) from the edge of the bondable metal layer.

Owner:TEXAS INSTR INC

Miniature package for translation of sensor sense axis

InactiveUS20070101812A1Small sizeHigh assembly issueSolid-state devicesSpeed/acceleration/shock instrument detailsEngineeringPrinted circuit board

A ceramic L-shaped or T-shaped packaging apparatus for a Micro Electro-Mechanical System (MEMS) inertial sensor die that translates the sensor sense axis perpendicular to the normal input plane for direct attachment to a system-level printed circuit board (PCB).

Owner:HONEYWELL INT INC

Flowable compositions and use in filling vias and plated through-holes

InactiveUS6427325B1Improve routing densityCleanliness or solderability of the unfilled plated through-hole barrelsCeramic layered productsGlass/slag layered productsEngineeringPrinted circuit board

A printed circuit board or card having plated through-holes is provided wherein plated through-holes are filled with a photocured polymerized composition. Also, a method for fabricating these printed circuit boards or cards is provided. Also provided are compositions and methods of providing carrier films coated with the compositions for use in filling vias or plated through-holes.

Owner:INT BUSINESS MASCH CORP

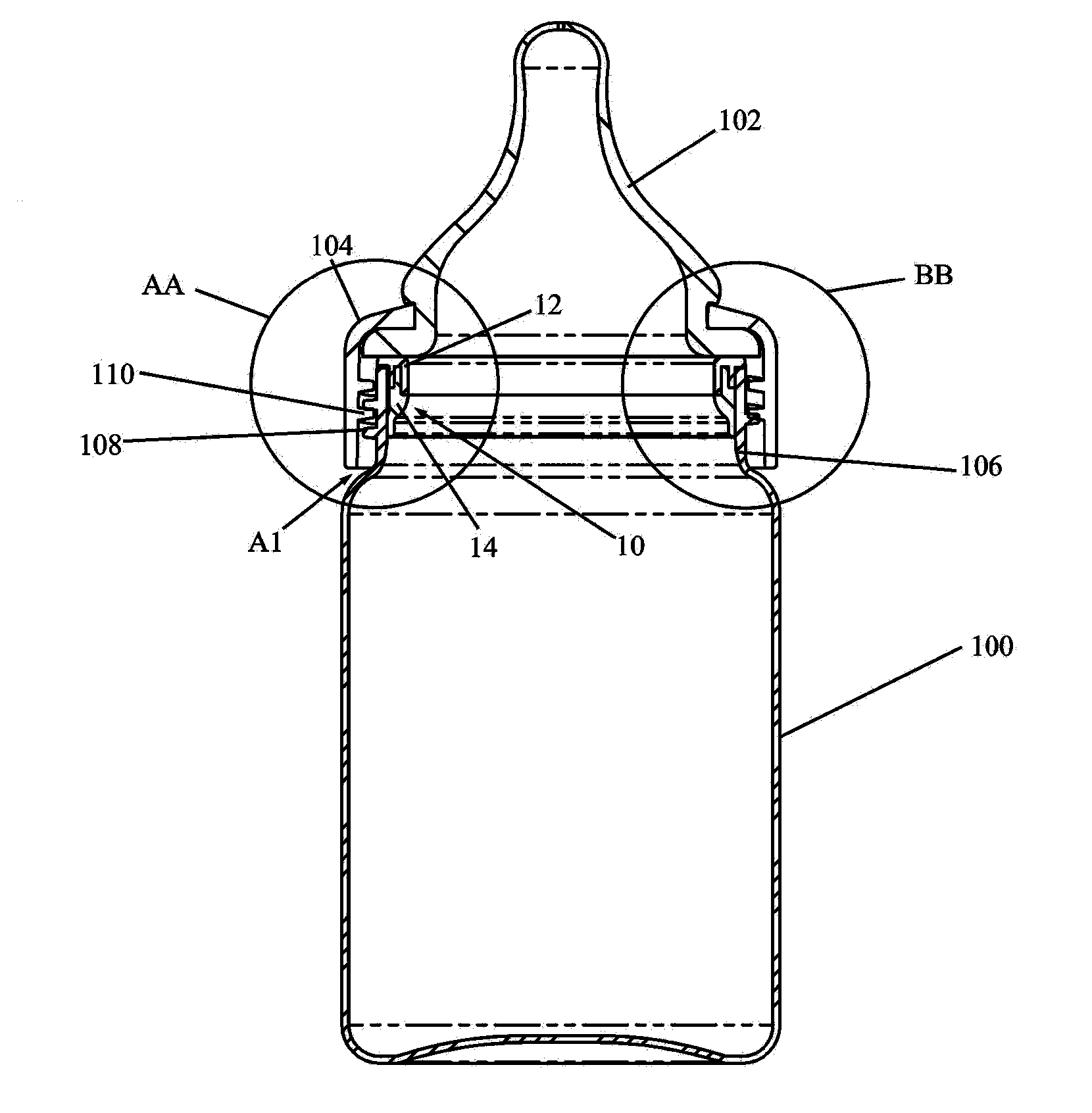

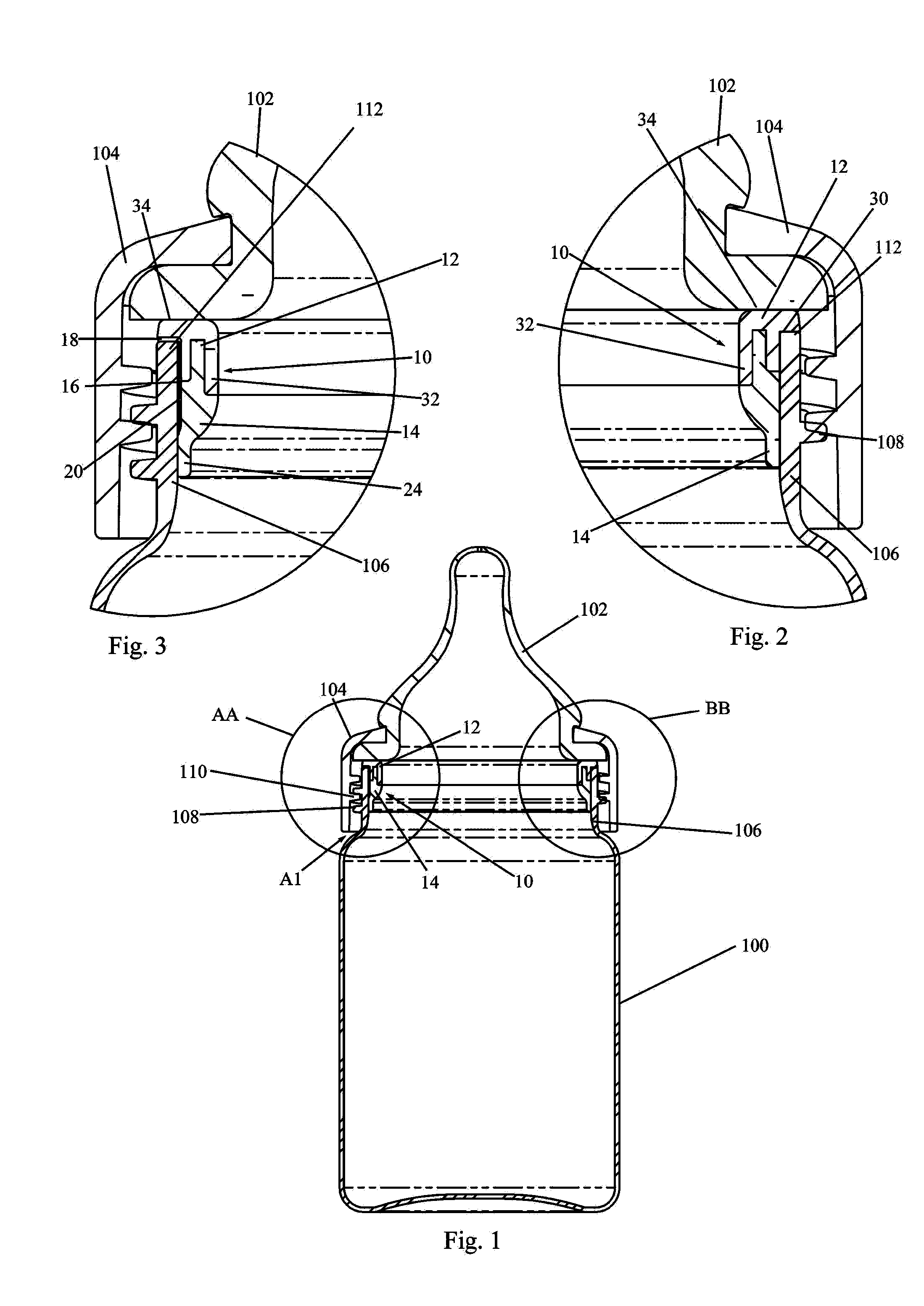

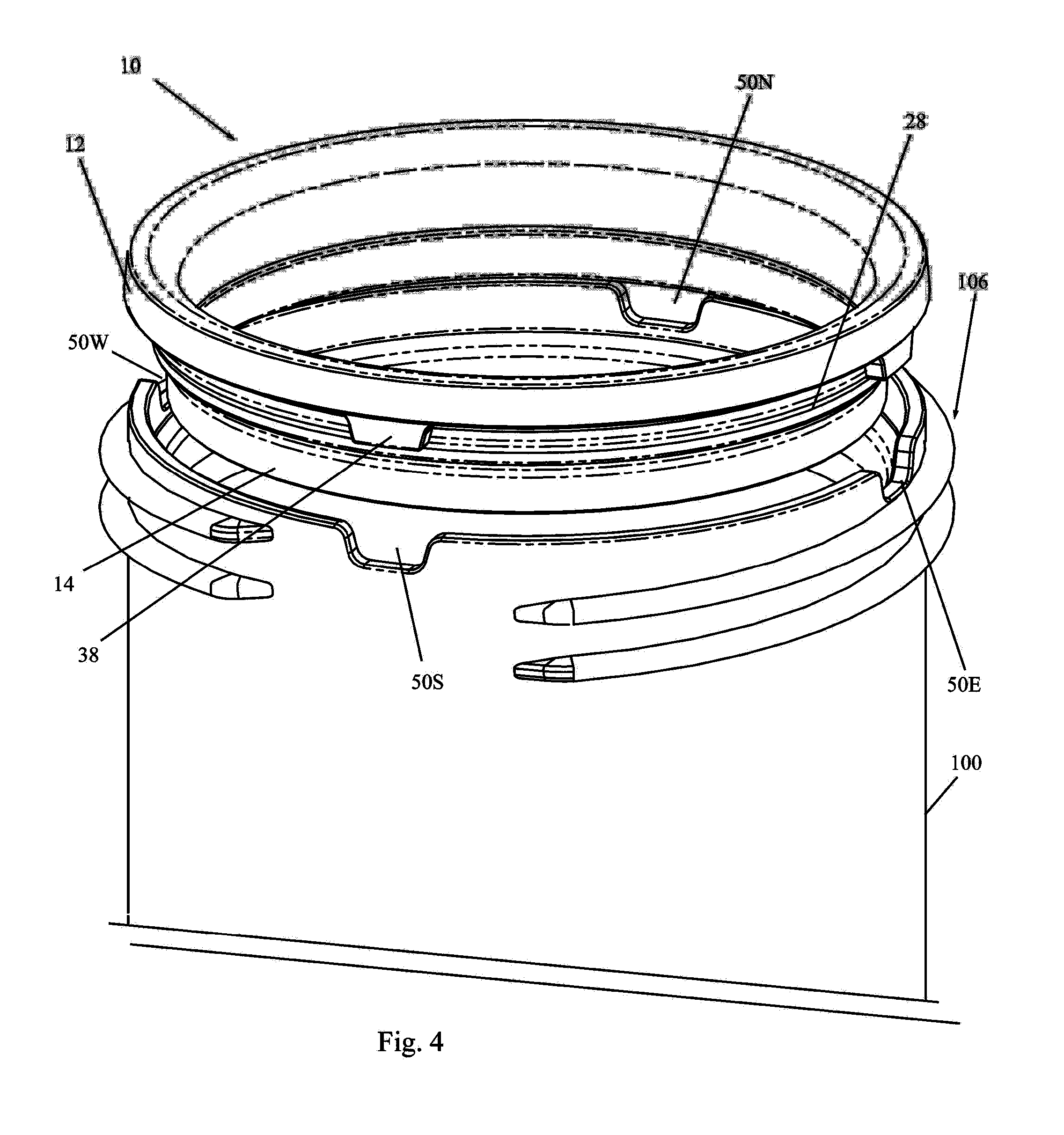

Container and venting mechanism assembly

A venting assembly for a closed container having a lid and a container portion with a neck and a rim. The assembly comprises a venting unit having a substantially rigid ring having a lid-interfacing surface; and a resilient annular valve member having a one-way valve disposed at the inner wall of the neck. The assembly further comprises at least one air passageway leading from the ambient atmosphere to the one-way valve member; and a fixing mechanism adapted to prevent planar movement between the venting unit and the container.

Owner:TIROSH TAMIR

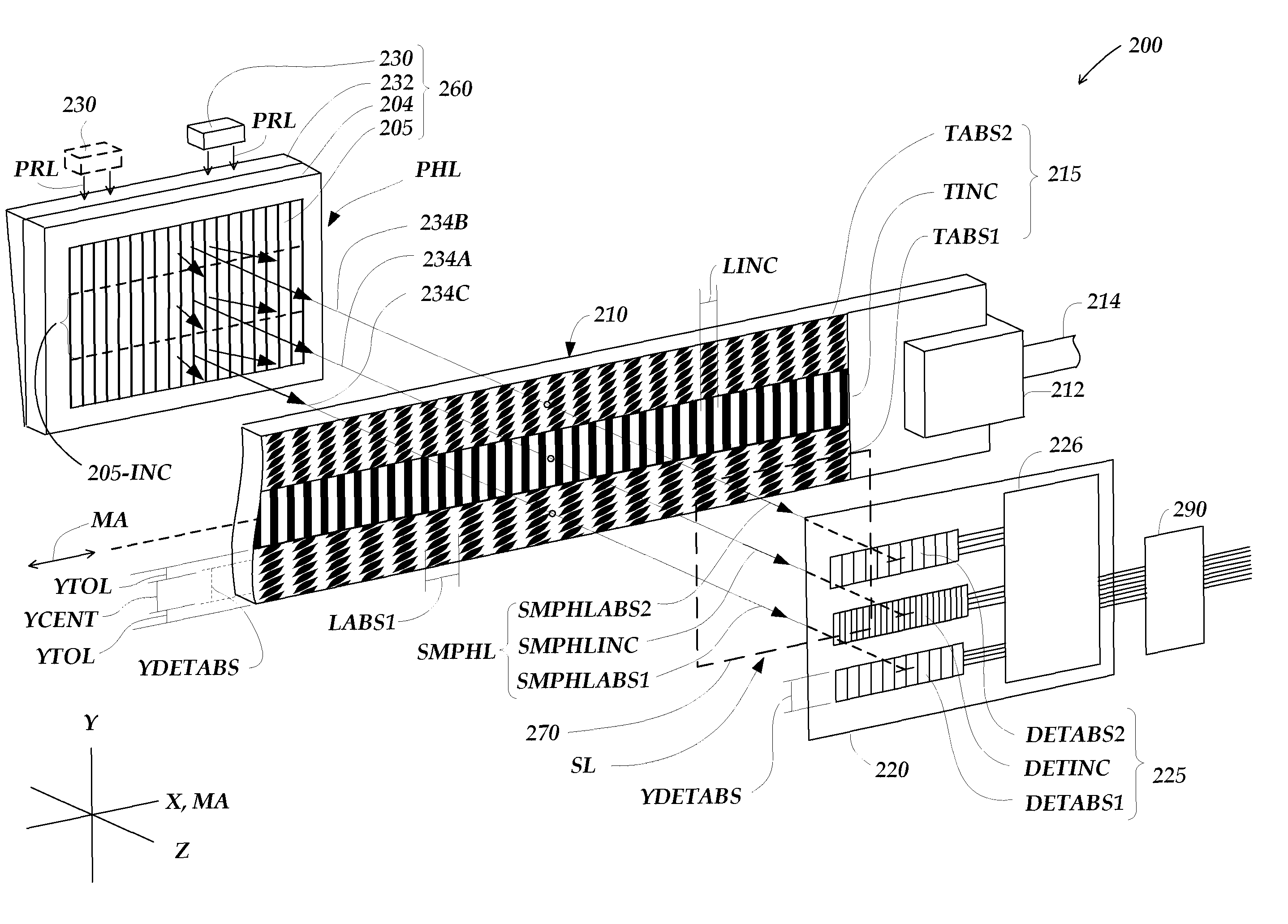

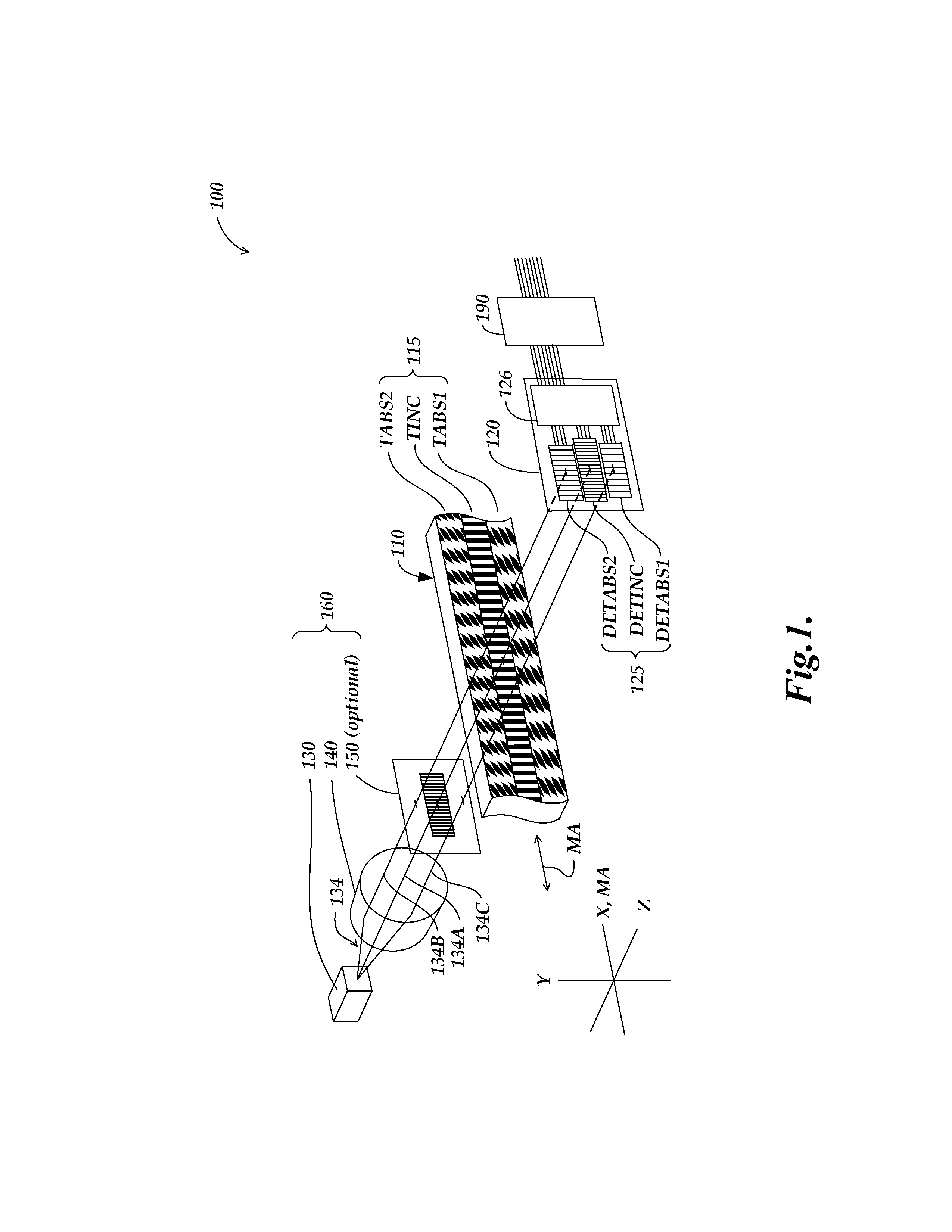

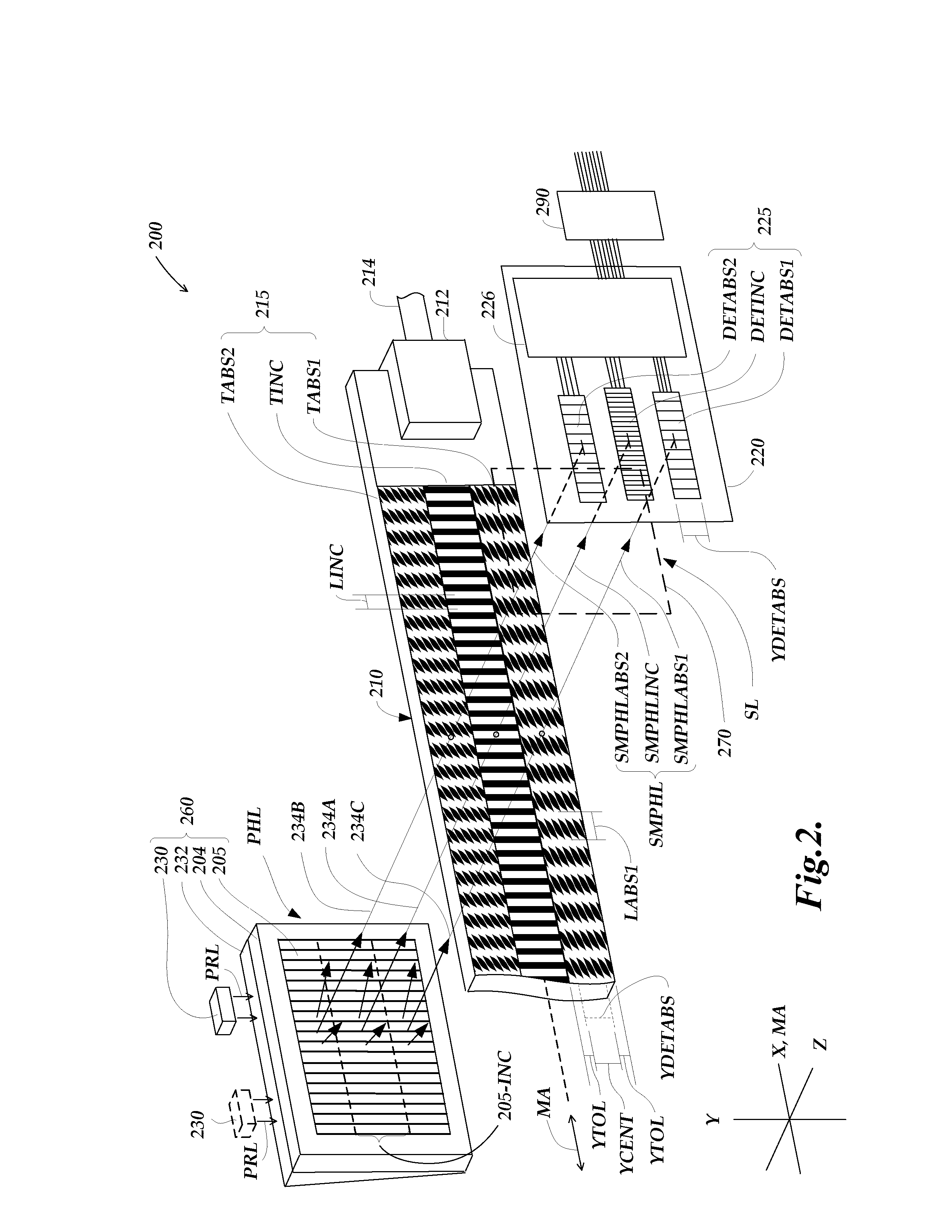

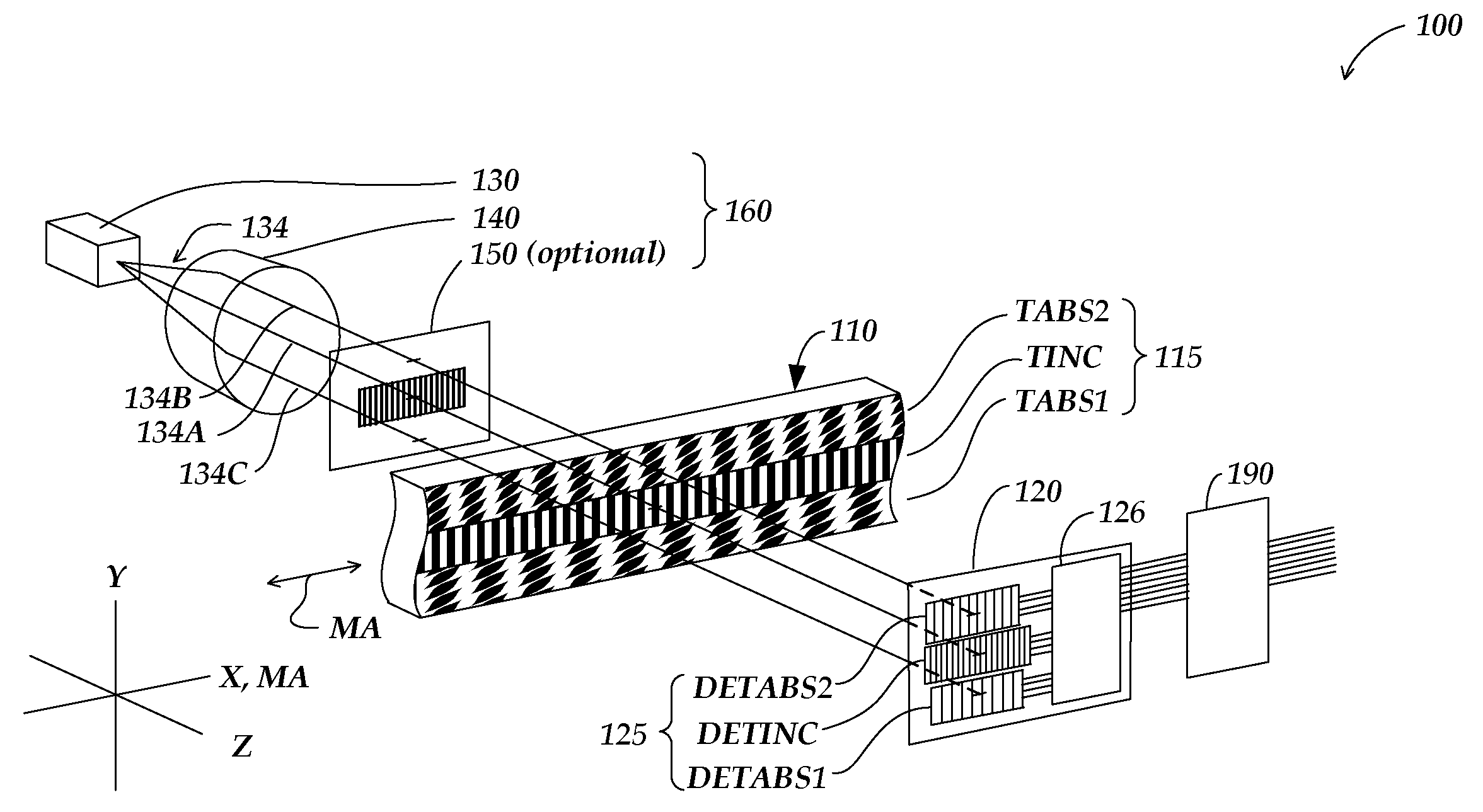

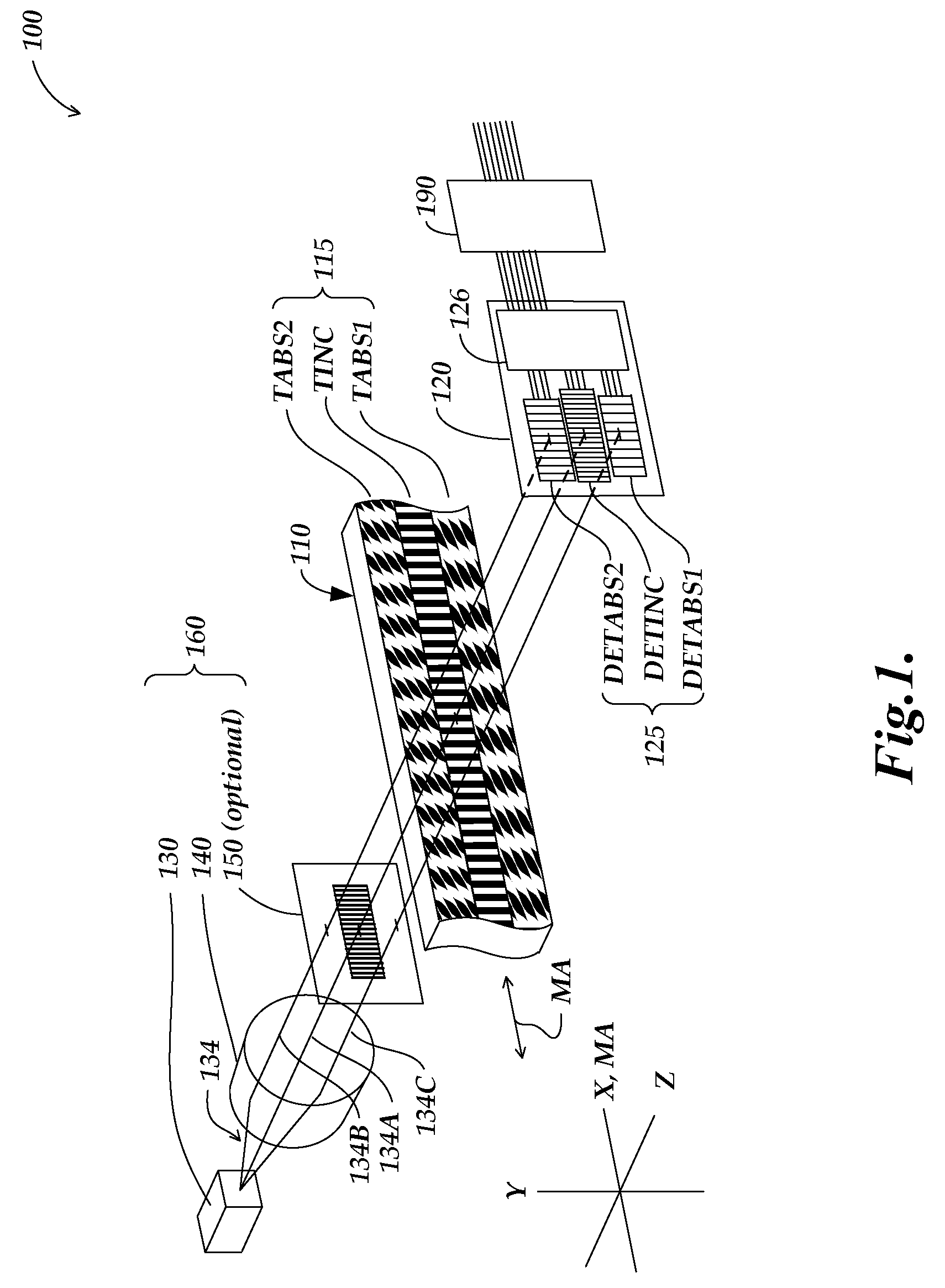

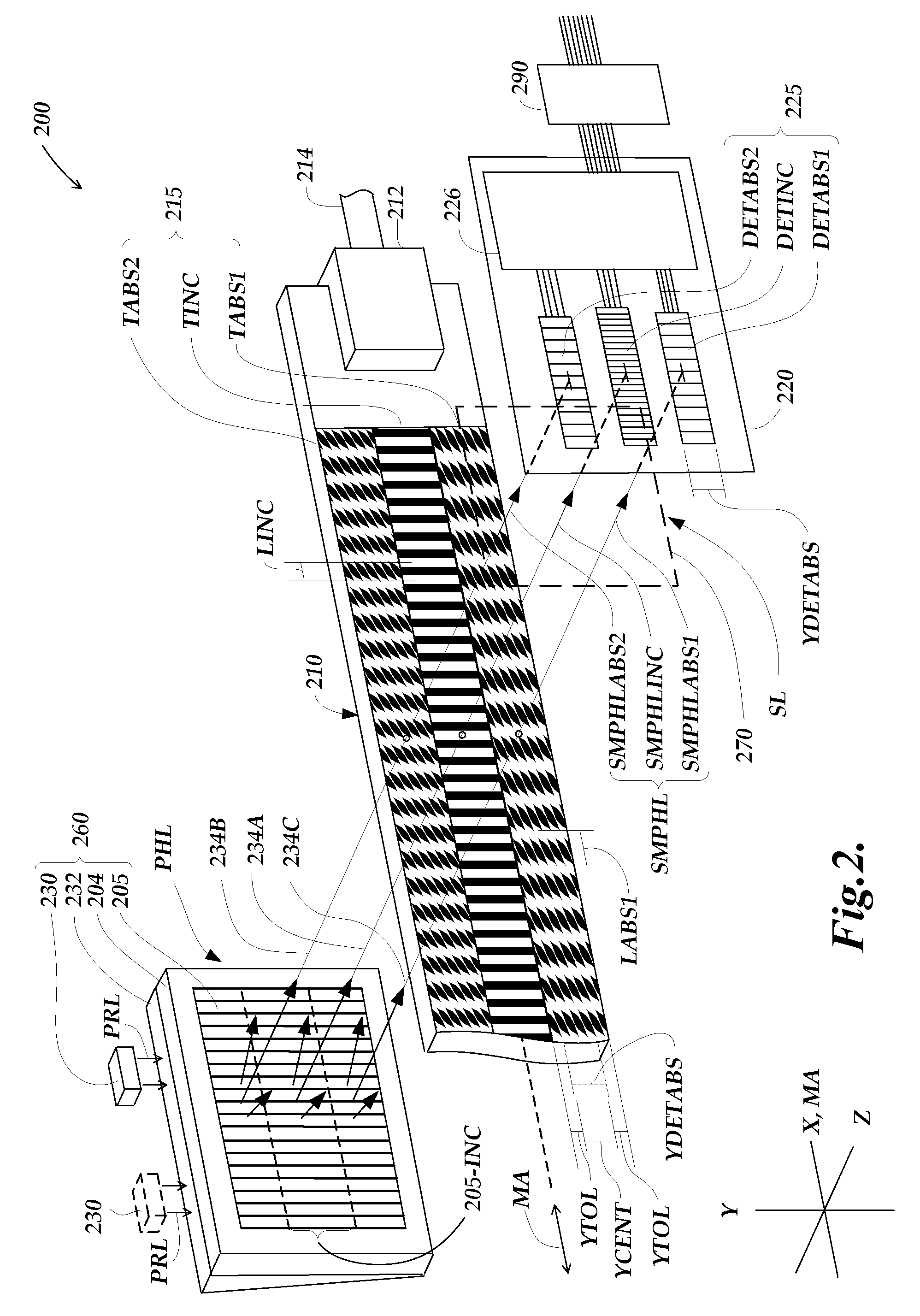

Displacement encoder including phosphor illumination source

ActiveUS8094323B2OptimizationEasy to combineMaterial analysis by optical meansUsing optical meansPhotovoltaic detectorsPath length

A position sensing optical encoder includes an illumination source that operates by providing primary radiation having a first level of intensity uniformity to saturate at least a portion of a relatively broad phosphor area including uniformly distributed phosphor. The phosphor area absorbs the primary radiation and emits phosphor radiation to illuminate the encoder scale pattern. The scale pattern spatially modulates the phosphor light, and the spatially modulated pattern of phosphor light is sensed by a photodetector arrangement. Due at least partially to saturation of the phosphor, the phosphor light has a second level of phosphor light intensity uniformity that is more uniform than the first level of primary light intensity uniformity, which enhances the encoder accuracy. The uniform phosphor illumination intensity is economically provided over a broad area with few components and minimized optical path length, particularly for path length perpendicular to the scale.

Owner:MITUTOYO CORP

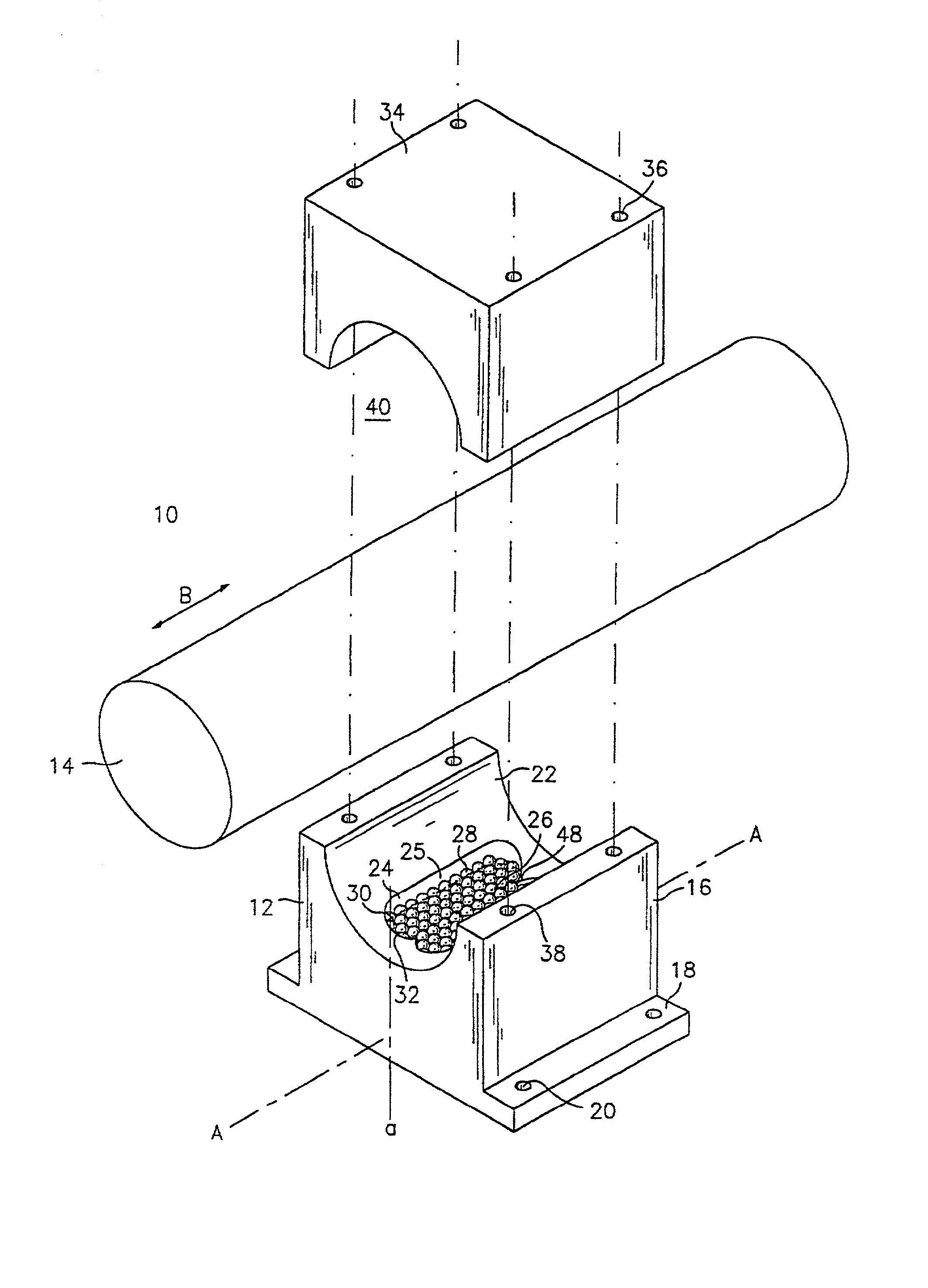

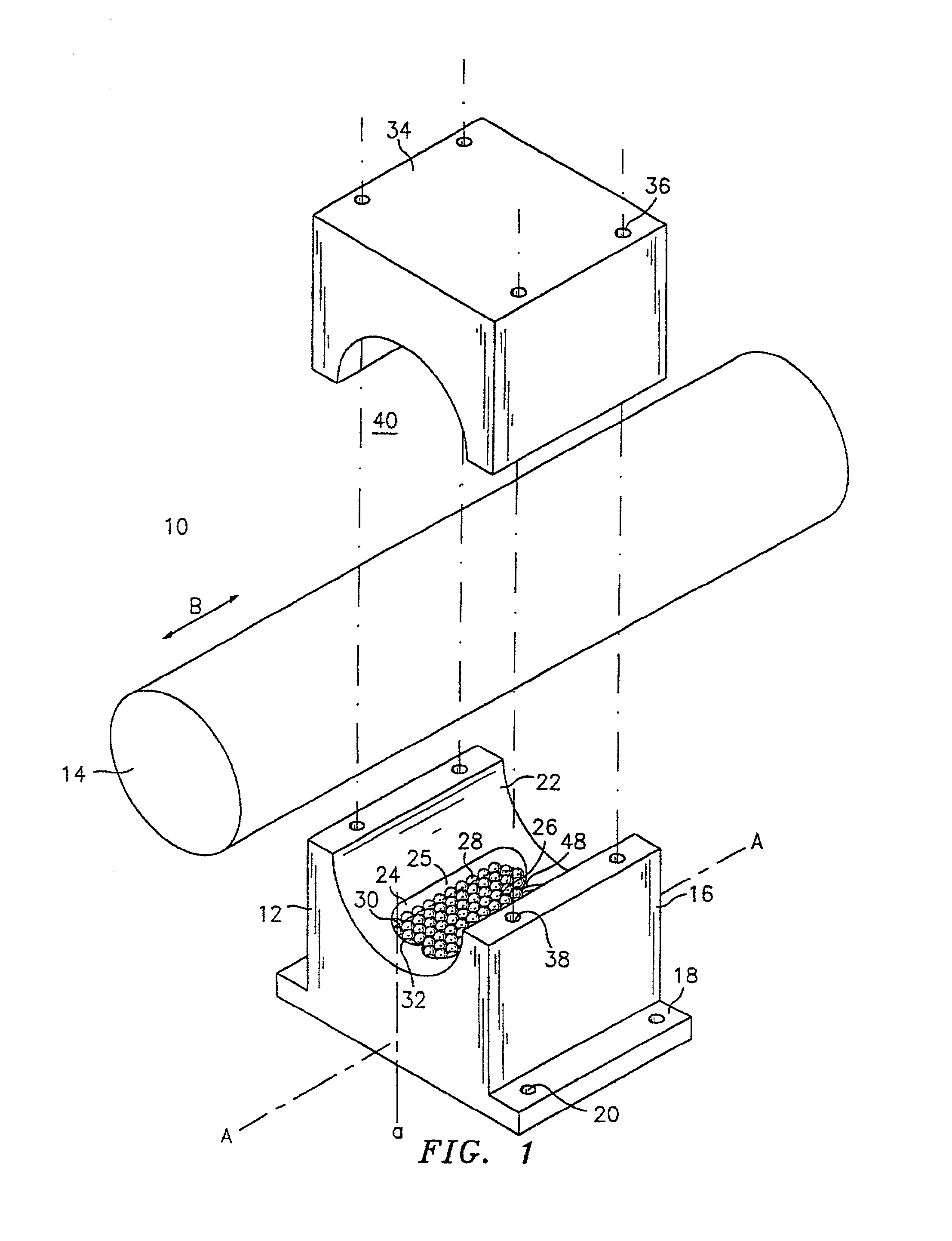

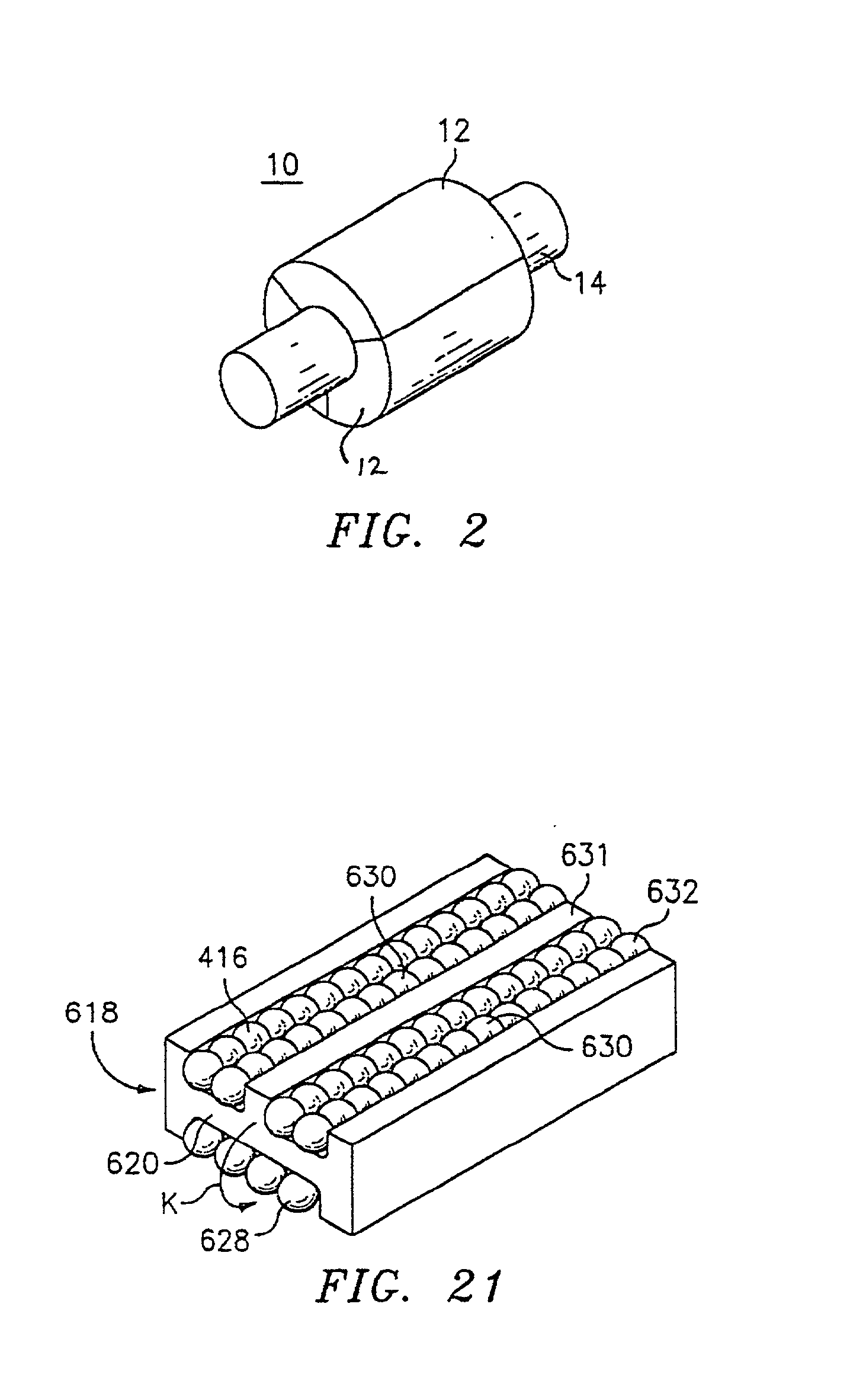

Axial ball transfer assemblies

InactiveUS20020067868A1Reduce frictionSafer driving conditionRolling contact bearingsLinear bearingsEngineeringMechanical engineering

A bearing assembly is disclosed that 410 includes at least one ball track having a load bearing portion, a return portion and a turnaround portion interconnecting the load bearing and return portions. A plurality of bearing balls are disposed in the ball tracks. At least a portion of the ball tracks are configured for unguided recirculation of the bearing balls. The bearing assembly may include a pair of ball tracks separated by a center rib. In an alternate embodiment, the bearing assembly includes at least one island disposed in at least a portion of the ball tracks. The islands facilitate recirculation of the bearing balls in the ball tracks. In another alternate embodiment, a bearing assembly is provided that includes a rail. A bearing carriage is configured to move along the rail. At least one ball track is disposed adjacent the rail and the bearing carriage. The ball tracks include a load bearing portion, a return portion and a turnaround portion interconnecting the load bearing and return portions. A plurality of bearing balls are disposed in the ball tracks. The ball tracks are configured for unguided recirculation of the bearing balls. The bearing assembly may include at least one insert having at least a portion of the ball tracks formed therein.

Owner:THOMSON IND INC

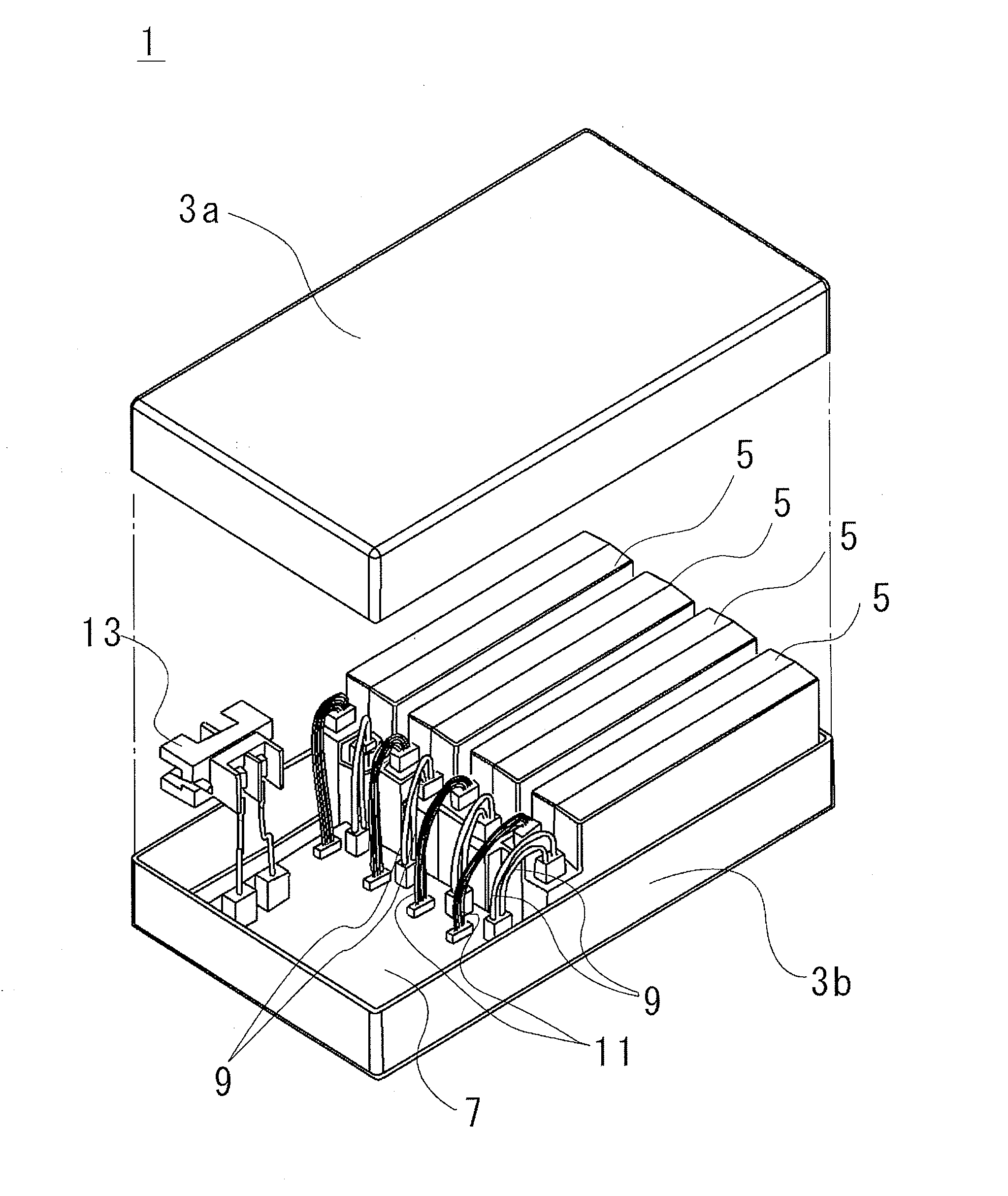

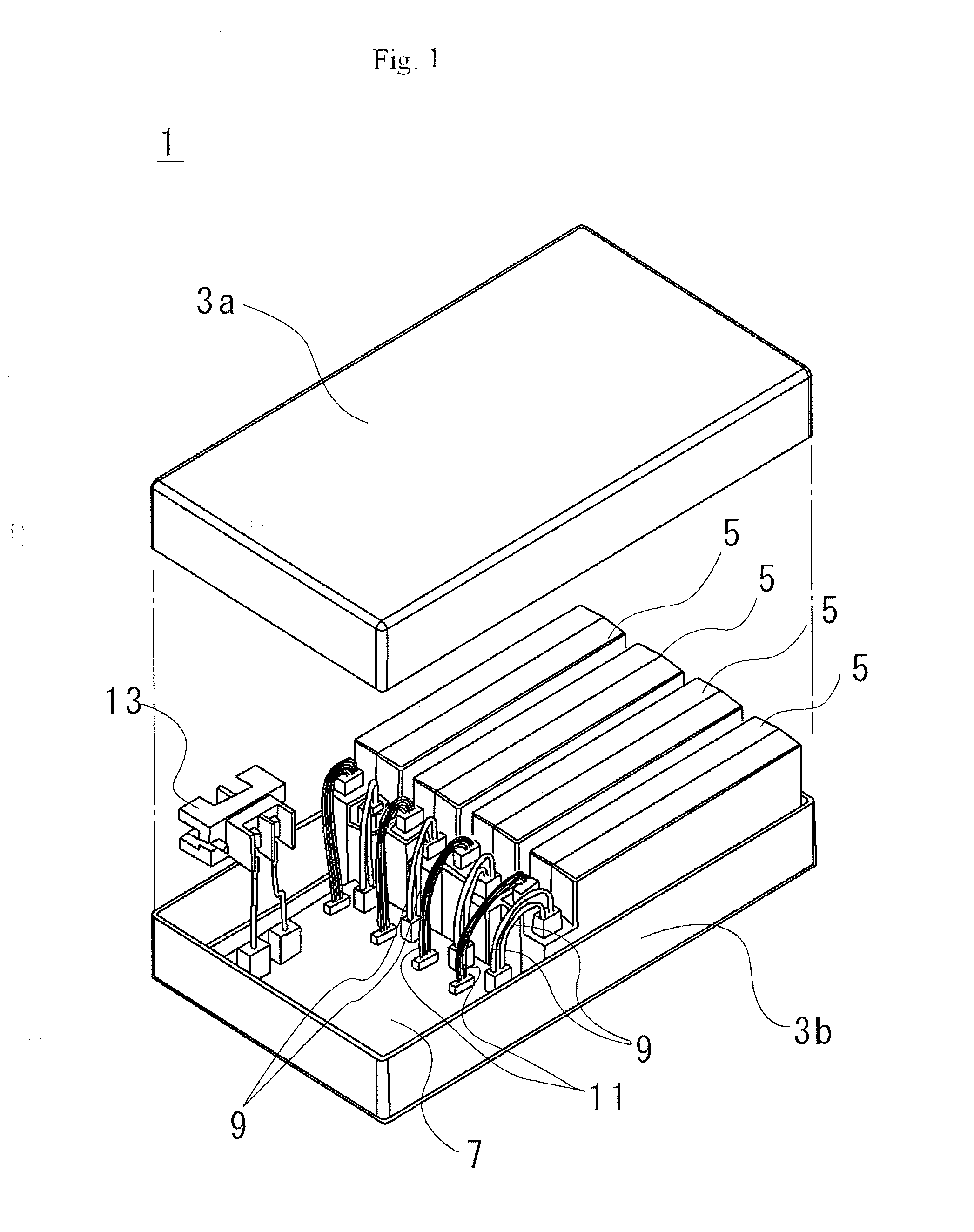

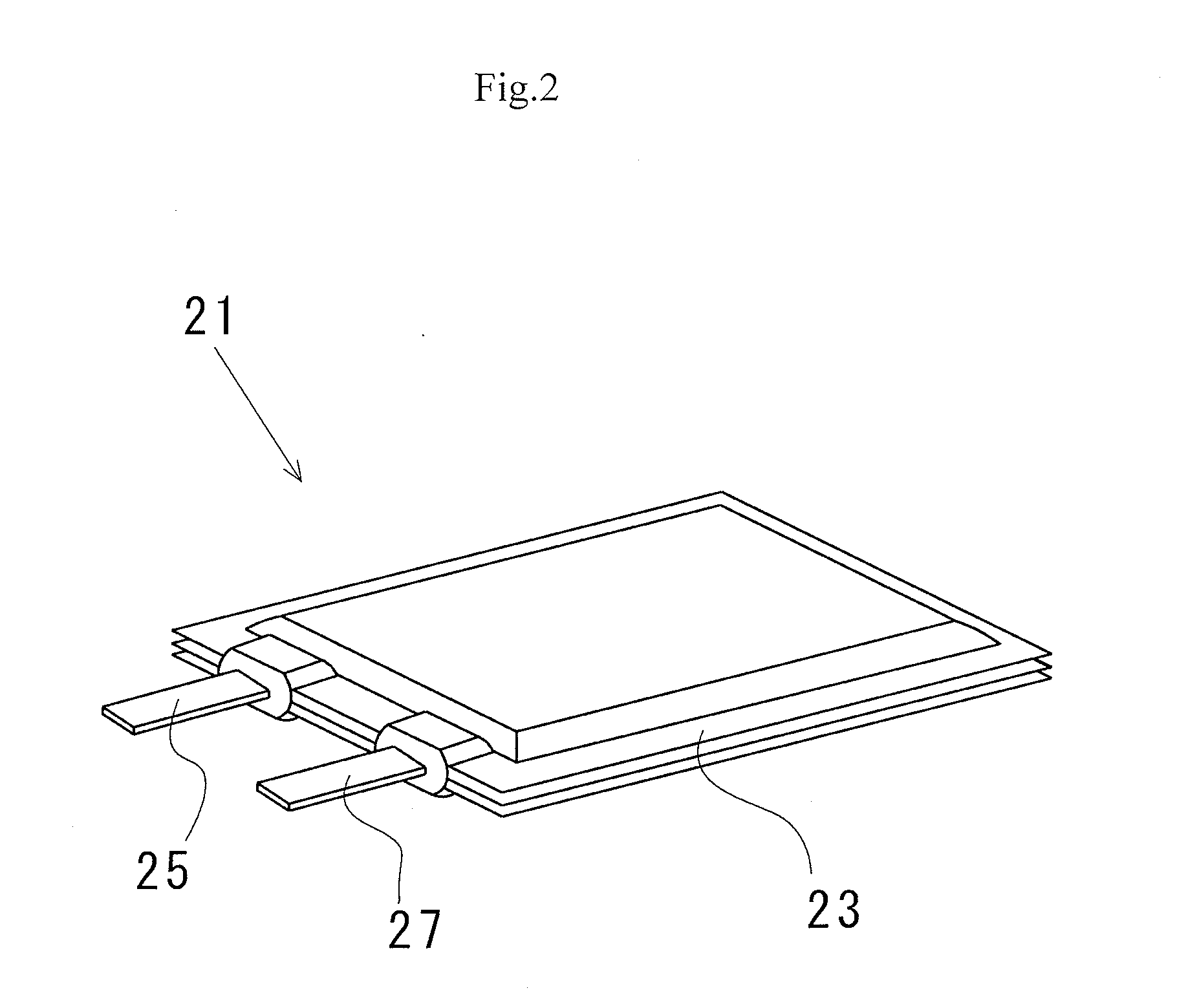

Battery pack

ActiveUS20110115437A1High in assembly productivityHigh volume energy densityCells structural combinationElectric powerElectrical batteryProduction rate

A battery pack includes a plurality of battery modules that house a plurality of unit cells in a case; and a protection circuit board that controls the charge and discharge of a plurality of the battery modules at once. The battery pack is highly flexible in series and parallel connection, high in assembly productivity and excellent in energy density.

Owner:NEC ENERGY DEVICES LTD

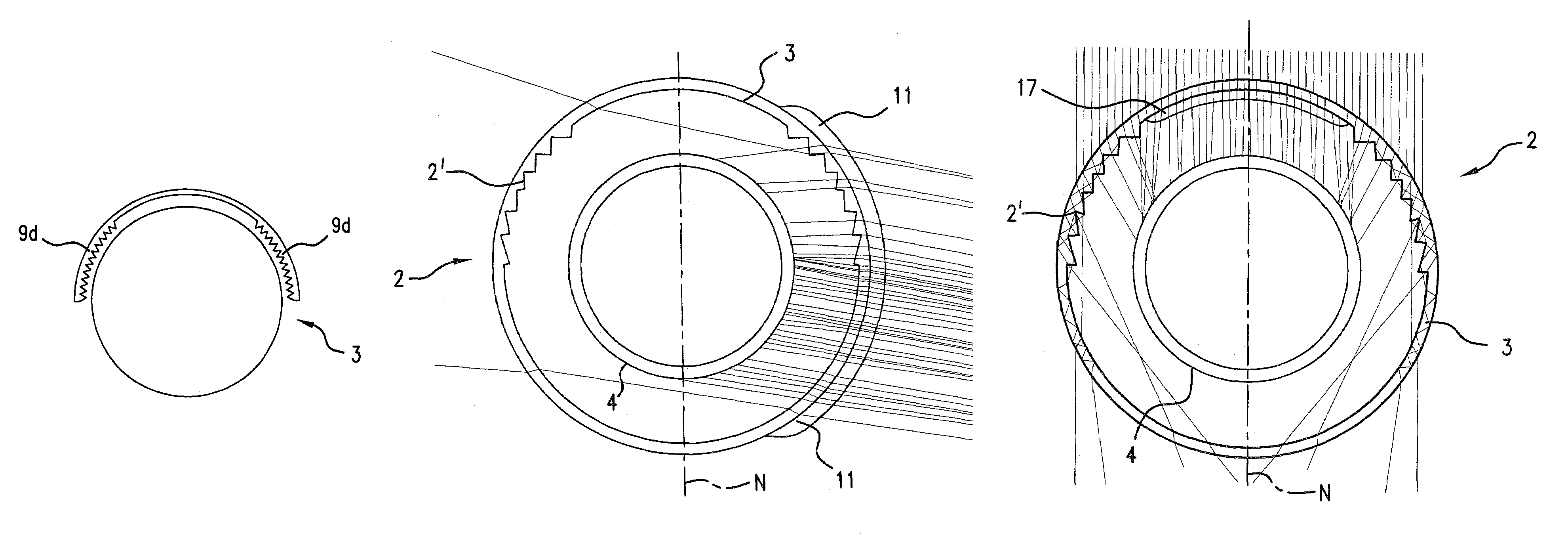

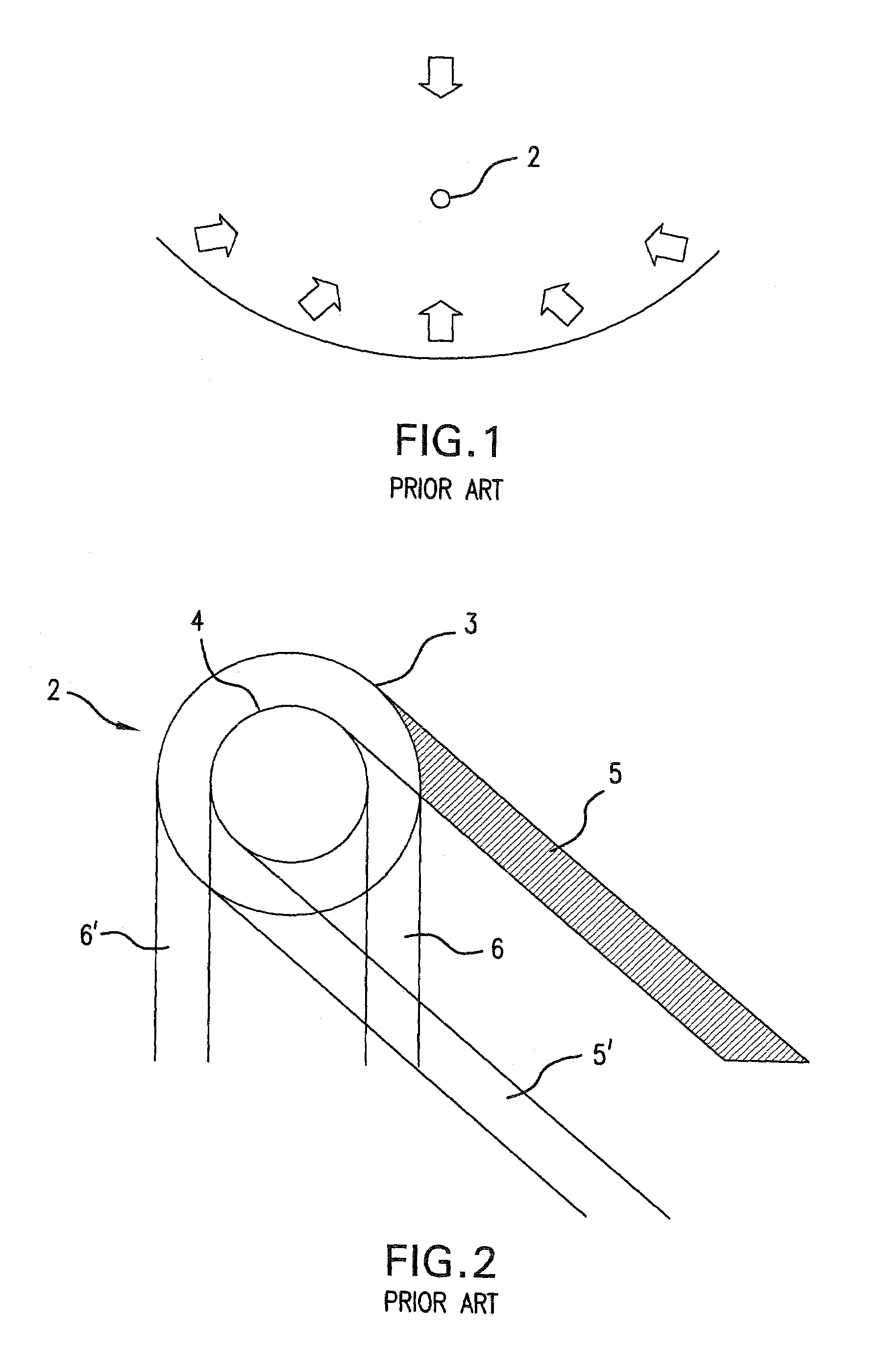

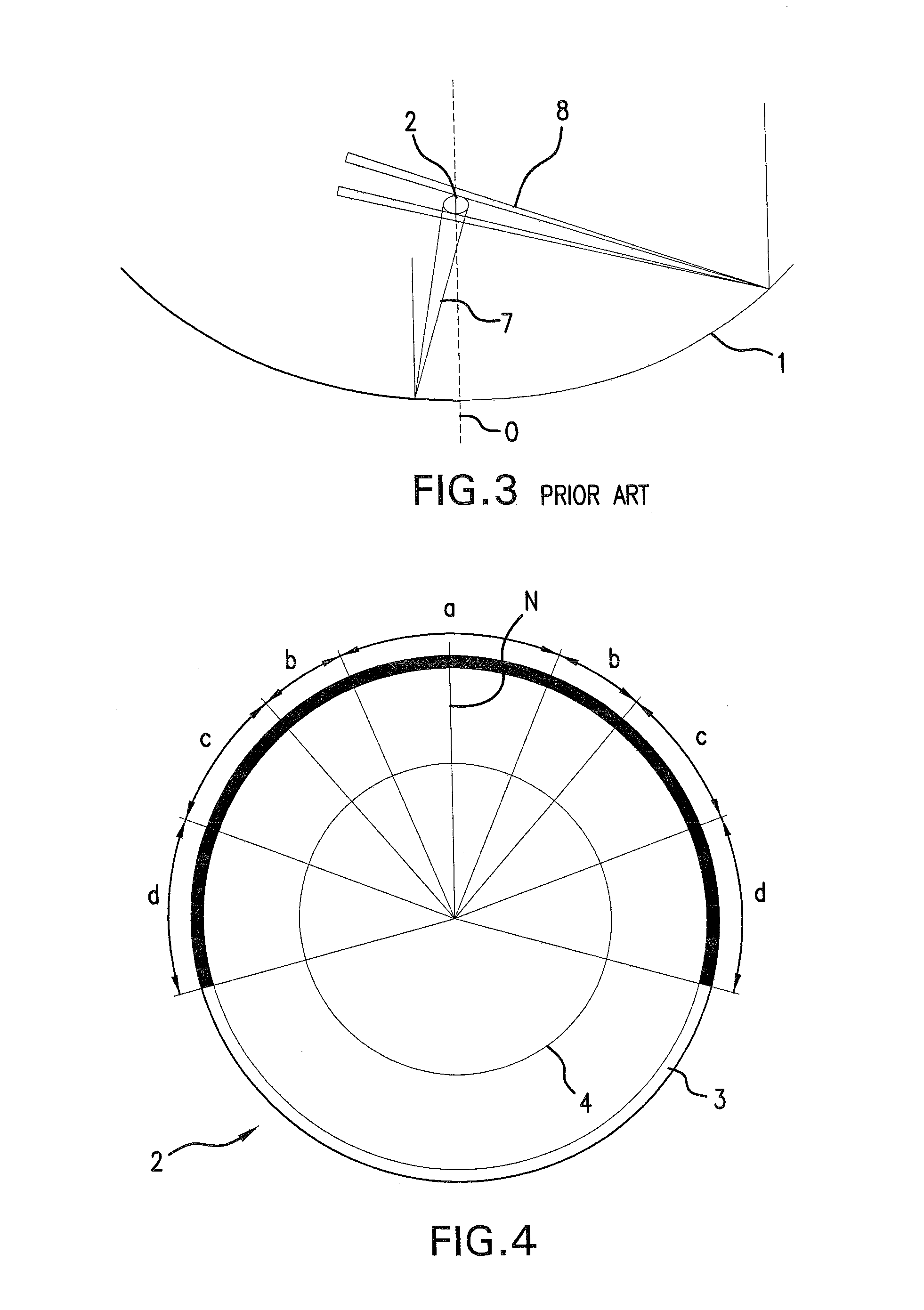

Receiver tube with receiver tubular jacket and parabolic trough collector containing same

InactiveUS7395820B2Small overall deformationPrevent bulk materialSolar heating energySolar heat devicesStructural elementEngineering

The parabolic trough collector includes a single-axis parabolic mirror (1) and a receiver tube (2) arranged at the focal point (F) of the parabolic mirror (1). The receiver tube (2) includes an absorber tube (4) and an outer tubular glass jacket (3) around it. To compensate for focusing errors in the parabolic collector and thus to reduce associated geometric optical losses, the tubular jacket (3) is provided with structural elements (9a, 9b, 9c, 9d), which focus sunlight reflected from the mirror as well as sunlight that falls directly on the receiver tube from the sun on the absorber tube. The receiver tube is preferably arranged relative to the parabolic mirror, so that its center is displaced from the focal point (F) by a distance equal to half the spacing between the tubular jacket (3) and the absorber tube (4).

Owner:SCHOTT AG

Structure and method for contact pads having double overcoat-protected bondable metal plugs over copper-metallized integrated circuits

InactiveUS20050224987A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

An integrated circuit having copper interconnecting metallization (311, 312) protected by a first overcoat layer (320), portions of the metallization exposed in windows (301, 302) opened through the thickness of the first overcoat layer. A patterned conductive barrier layer (330) is positioned on the exposed portion of the copper metallization and on portions of the first overcoat layer surrounding the window. A bondable metal layer (350, 351) is positioned on the barrier layer; the thickness of this bondable layer is suitable for wire bonding. A second overcoat layer (360) including insulating silicon compounds is positioned on the first overcoat layer so that the edge (362) of the second overcoat layer overlays the edge of the bondable layer positioned on the portions (321) of the first overcoat layer surrounding the window.

Owner:TEXAS INSTR INC

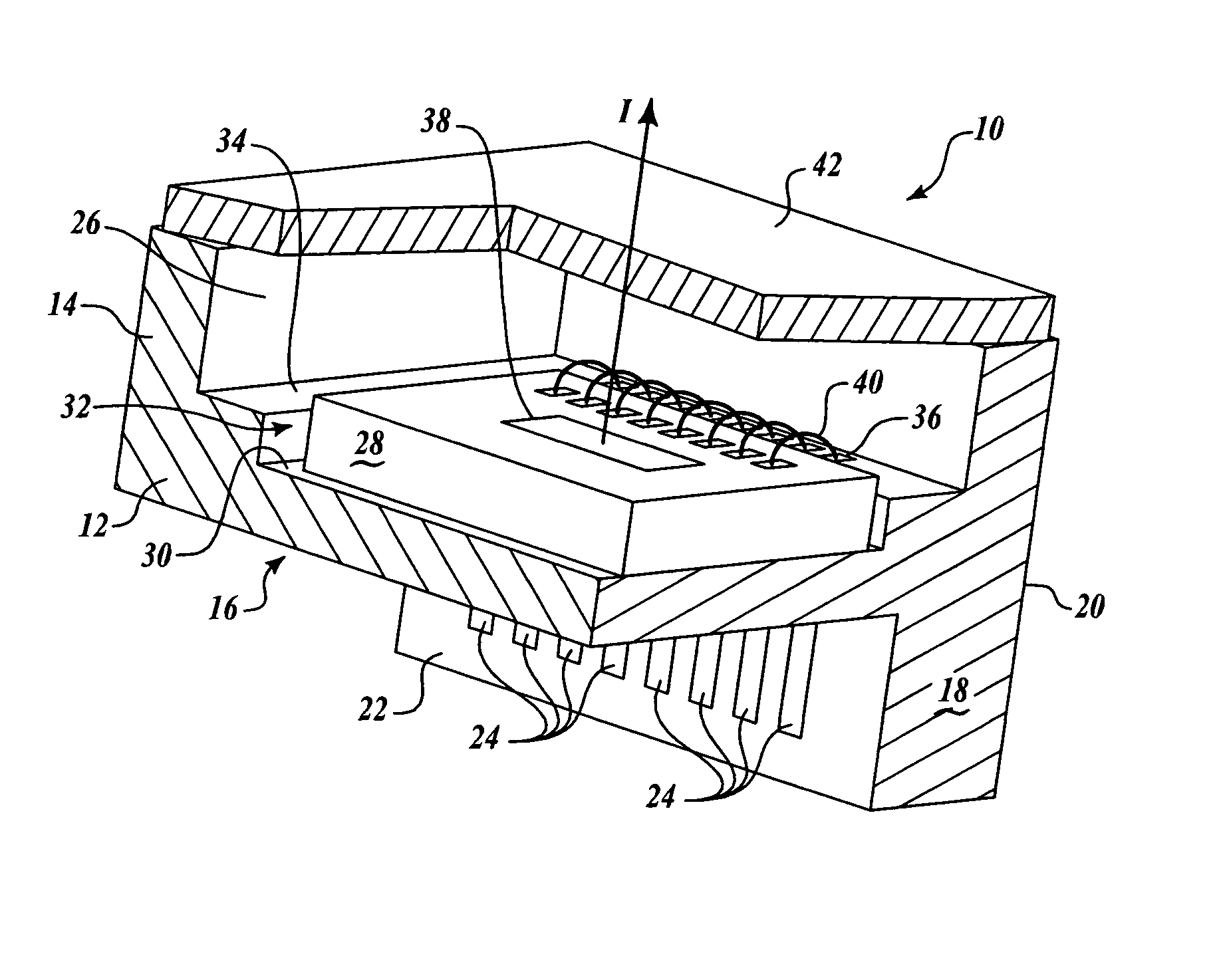

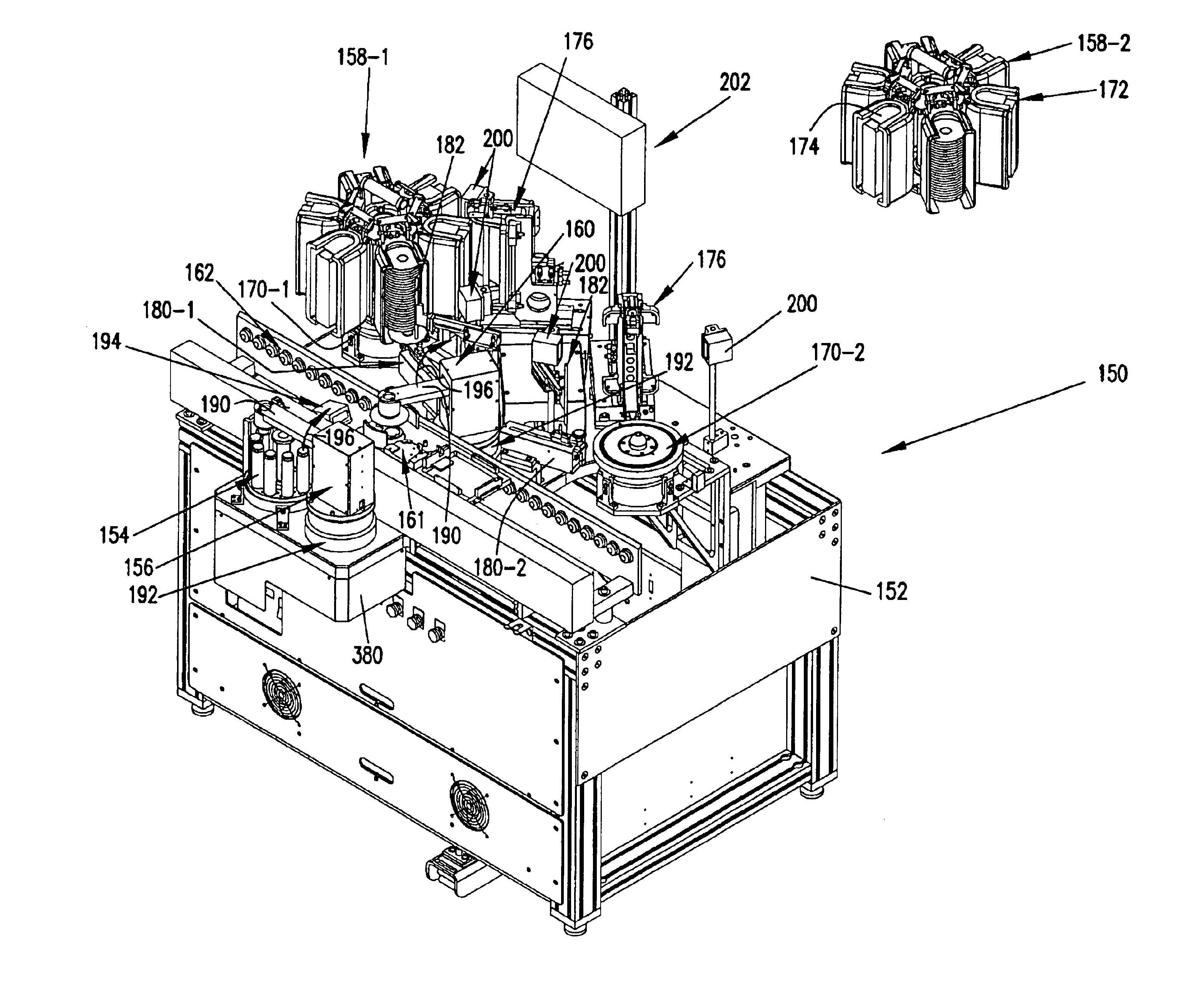

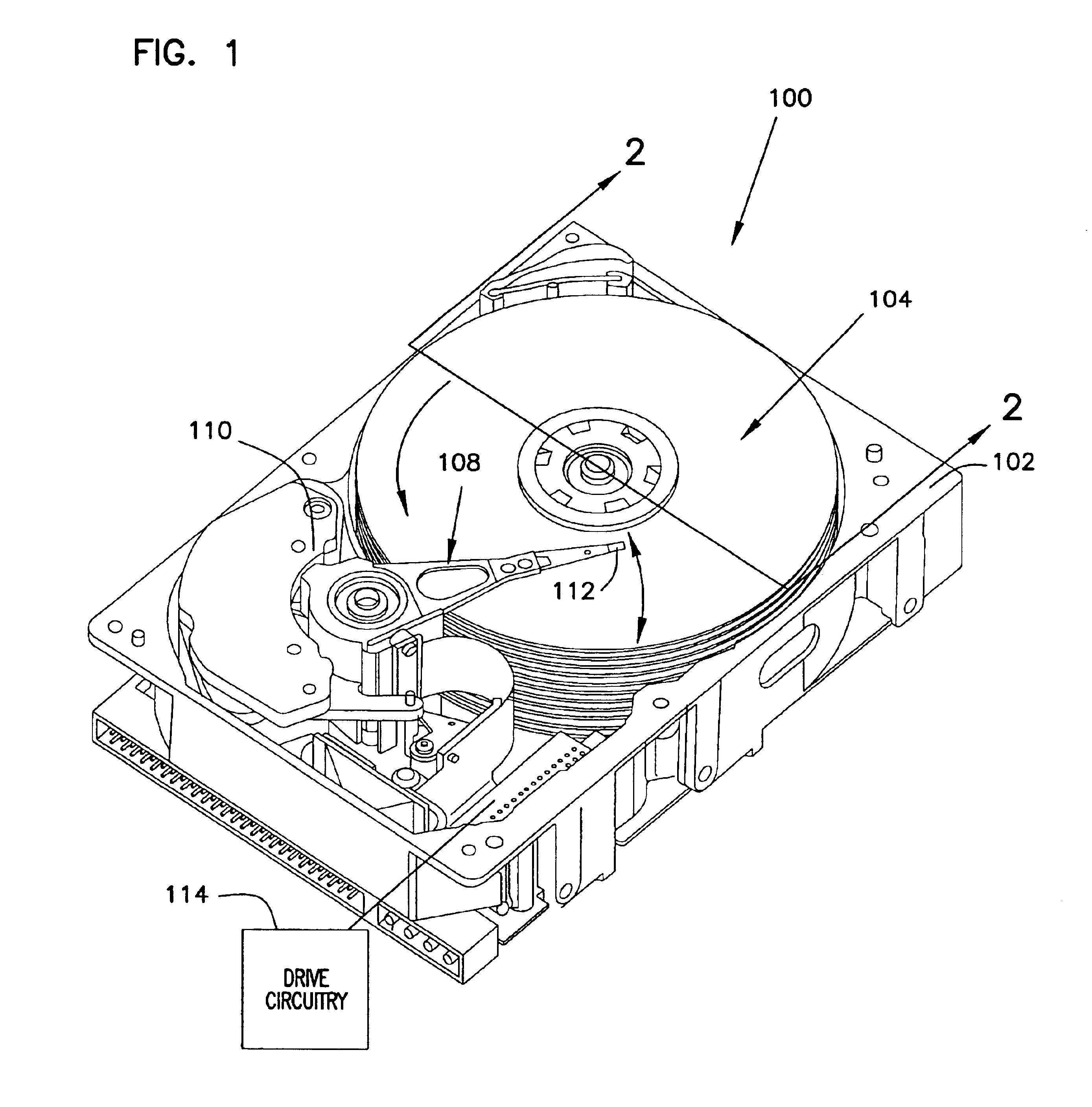

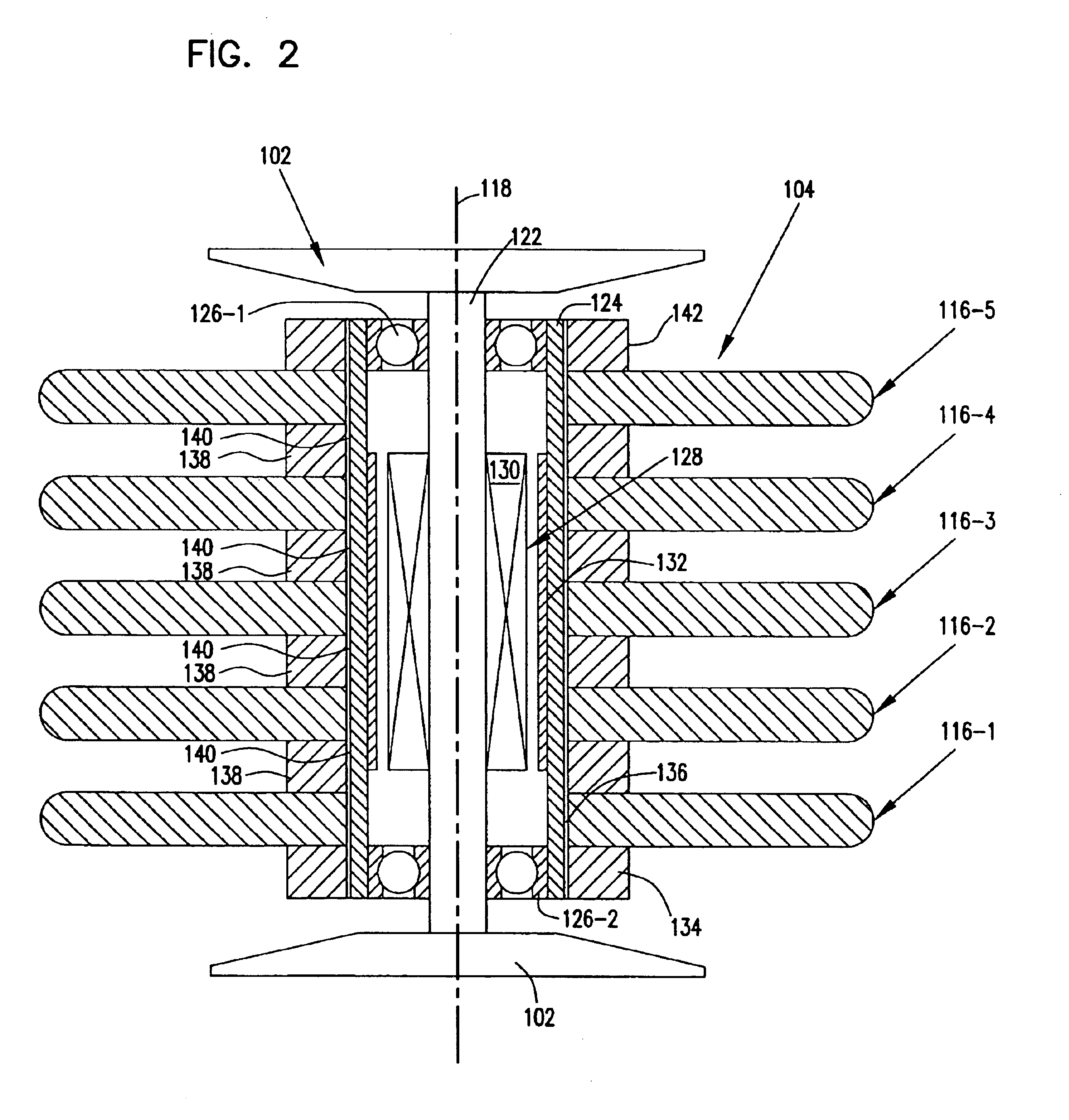

Assembly device for assembling components

InactiveUS6912775B1High assemblyIncrease capacityElectrical transducersApparatus for flat record carriersLarge capacityData storage system

An apparatus for assembling components of a data storage system. Assembly components are housed by a component storage member removably coupled to the frame of the apparatus for supporting a plurality of component stacks for automated assembly. The apparatus includes an assembly coupled to the component storage member for sequentially unloading components and assembling the unloaded components in a data storage system. The apparatus is adapted for high capacity, production and speed assembly.

Owner:SEAGATE TECH LLC

Fiber bundle termination with reduced fiber-to-fiber pitch

InactiveUS20080069502A1Reduced fiber-to-fiber pitchHigh yieldGlass making apparatusCoupling light guidesOptoelectronicsFiber bundle

A method of fabrication of a fiber bundle termination with reduced fiber-to-fiber pitch which includes reducing the outside diameter of fibers in the fiber bundle by etching and provides means for preventing breakage of the etched fibers during etching and assembly. A high yield fabrication and assembly process is described.

Owner:THE BOEING CO

Structure and method for contact pads having an overcoat-protected bondable metal plug over copper-metallized integrated circuits

InactiveUS20060094228A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper interconnectContact pad

A metal structure for a contact pad of an integrated circuit (IC), which has copper interconnecting metallization (311). A portion (301) of this metallization is exposed to provide a contact pad to the IC. A conductive barrier layer (330) is positioned on the exposed portion o the copper metallization. A plug (350) of bondable metal, preferably aluminum between about 0.4 and 1.4 μm thick, is positioned on the barrier layer. A protective overcoat layer (320) surrounds the plug and has a thickness (320b) so that the exposed surface (322) of the plug lies at or below the exposed surface (320a) of the overcoat layer. Optionally, a portion (321) of the overcoat layer between about 0.1 and 0.3 μm wide may overlap the perimeter of the plug.

Owner:LI LEI +1

Decelerating stop device for a movable member, in particular a furniture door or drawer, fittable to a stop surface of the movable member

InactiveUS8104140B2Improve deceleration efficiencyReduce manufacturing costSpringsBuilding braking devicesViscous liquidStops device

A decelerating device intended to intercept an end-of-stroke part of a closing path of a mobile member, such as a furniture drawer or door, including: a body fastenable in use to an abutting surface for the mobile member and internally defining a sealed chamber filled in use with a viscous fluid; a pushrod at least in part overhanging from the body and being adapted to cooperate in use with the mobile member, the pushrod being integral with a stem slidingly accommodated in the body against the bias of elastic means between an extracted position of the pushrod and a retracted position; and a piston accommodated in the sealed chamber so as to divide it into two portions hydraulically connected to each other and mechanically connected to the stem; wherein the stem presents a first end integrally connected to the pushrod and a second end opposite to the first, both slidingly accommodated in the body outside the sealed chamber and fluid-tightly towards the sealed chamber itself; the piston is provided with a mobile sealing member to choke the hydraulic communication between the two portions of the sealed chamber only during the stroke of the stem towards the retracted position.

Owner:ITW IND COMPONENTS SRL

Structure and method for contact pads having a recessed bondable metal plug over of copper-metallized integrated circuits

InactiveUS20050206007A1Reduce riskImprove assembly yieldSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

A metal structure for an integrated circuit, which has copper interconnecting metallization (311) protected by an overcoat layer (320). A portion of the metallization is exposed in a window (301) opened through the thickness of the overcoat layer. The metal structure comprises a patterned conductive barrier layer (330) positioned on the copper metallization, wherein this barrier layer forms a trough with walls (331) conformal with the overcoat window. The height (331a) of the wall is less (between 3 and 20%) than the overcoat thickness (320a), forming a step (340). A plug (350) of bondable metal, preferably aluminum, is positioned in the trough and has a thickness equal to the trough wall height (331a).

Owner:TEXAS INSTR INC

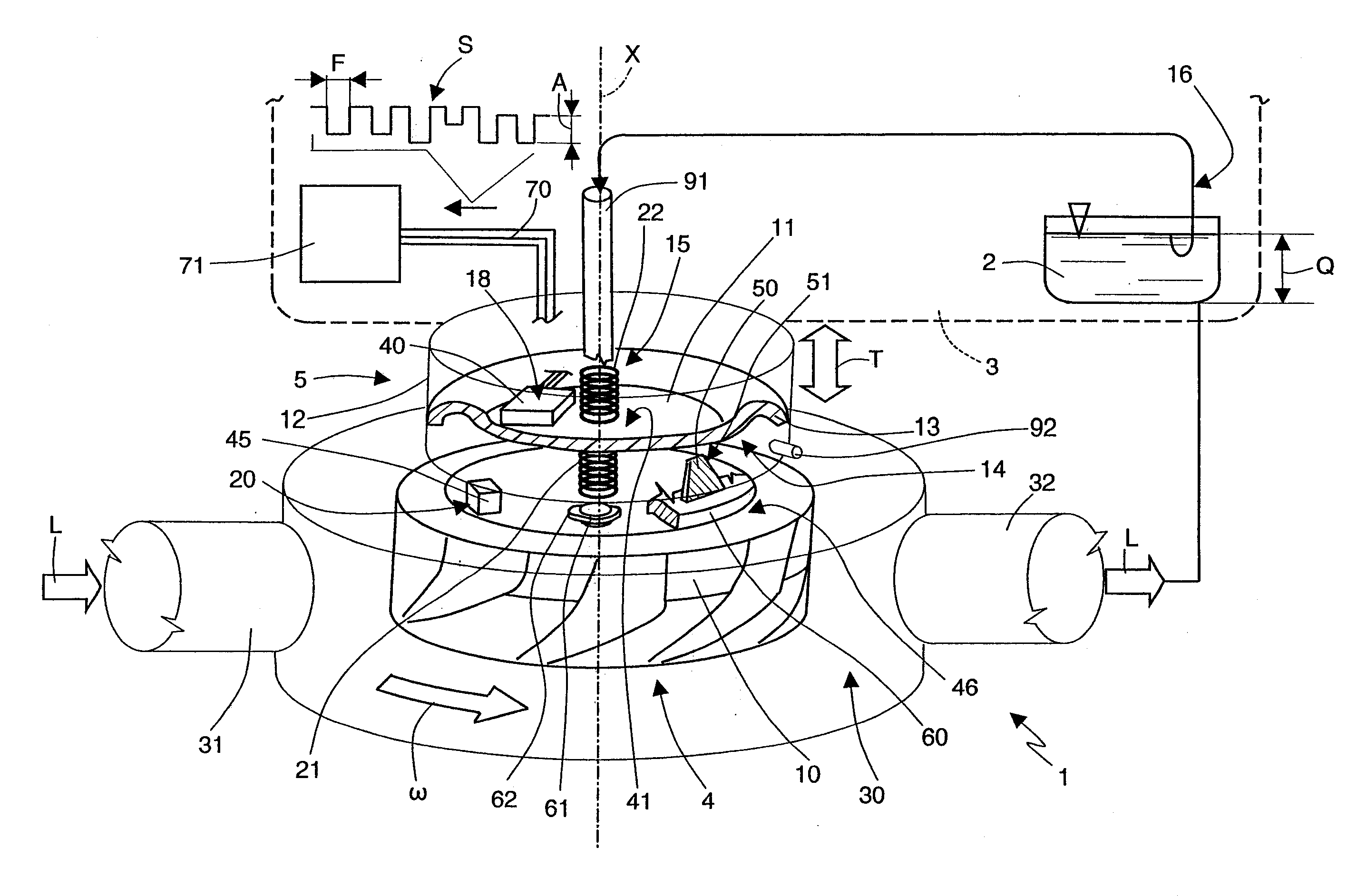

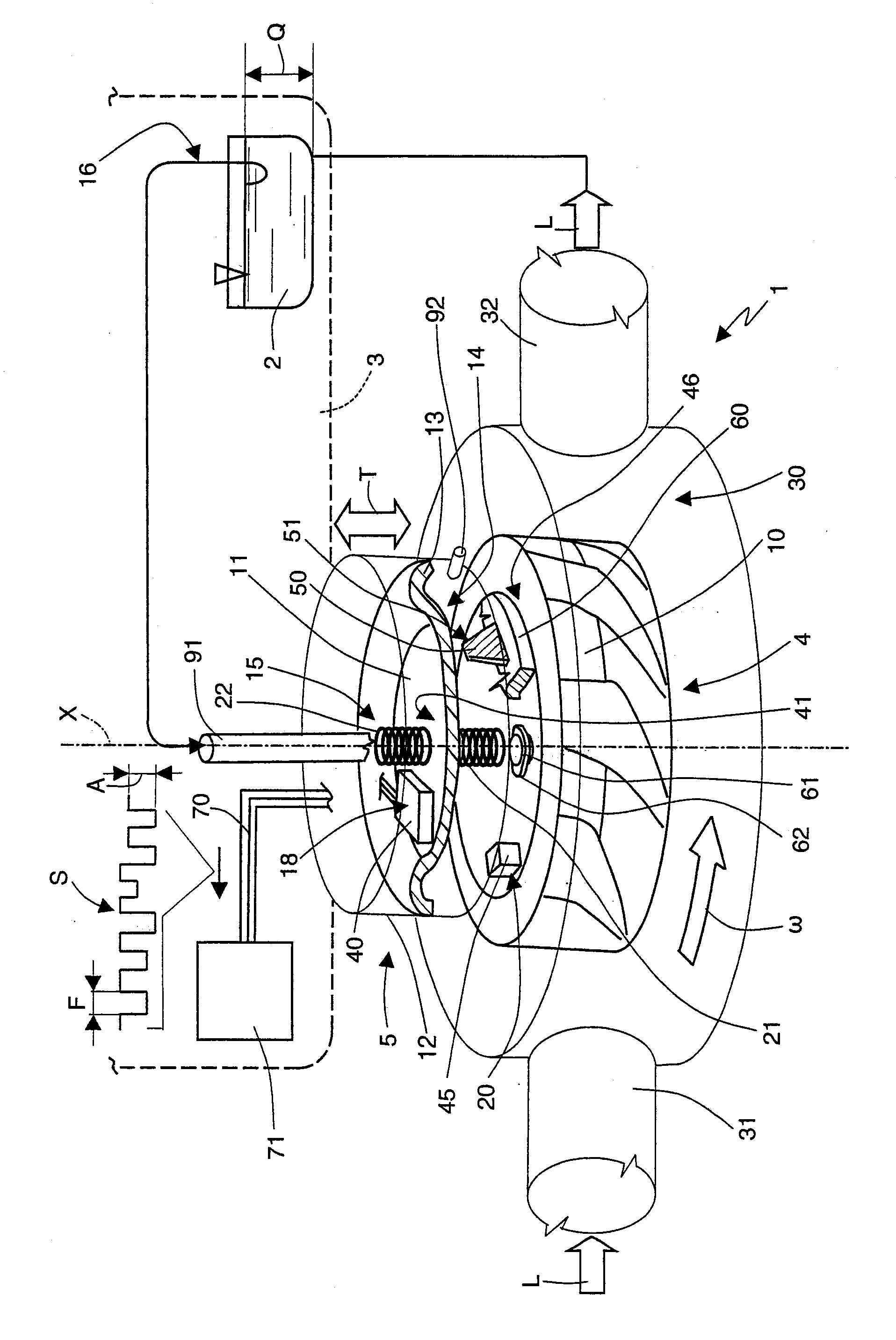

Monitoring device of the feed to an electric household appliance of an operative fluid, in particular of a flow of water to a tank of a washing machine or dishwasher

InactiveUS20100032026A1Less spaceConvenient ArrangementLevel controlVolume/mass flow measurementSiphonWorking fluid

A monitoring device including first detector means of a flow rate of operative fluid in an electric household appliance towards a tank of the electric household appliance and second detector means of the level of such a fluid in the tank; wherein the first and second detector means are operatively and reciprocally associated to issue a single signal (S) characterised by at least two different parameters, a first parameter (F) correlated to the flow rate of the fluid and a second parameter (A) correlated to the level of fluid in the tank. Typically, the first and the second detector means consist of a turbine mounted so as to be crossed in use by the flow of operative fluid and thereby turned at a speed proportional to the flow rate of fluid; in a membrane mounted within a casing to fluid-tightly divide the same into a first and second chamber connected respectively to atmospheric pressure and to siphon means arranged within the tank; in sensor means mounted on the membrane integral with the same and in interaction means with the sensor means, angularly and integrally mounted on the turbine and in a position so as to periodically transit in use in front of the sensor means in consequence of the rotation of the turbine.

Owner:ITW IND COMPONENTS SRL

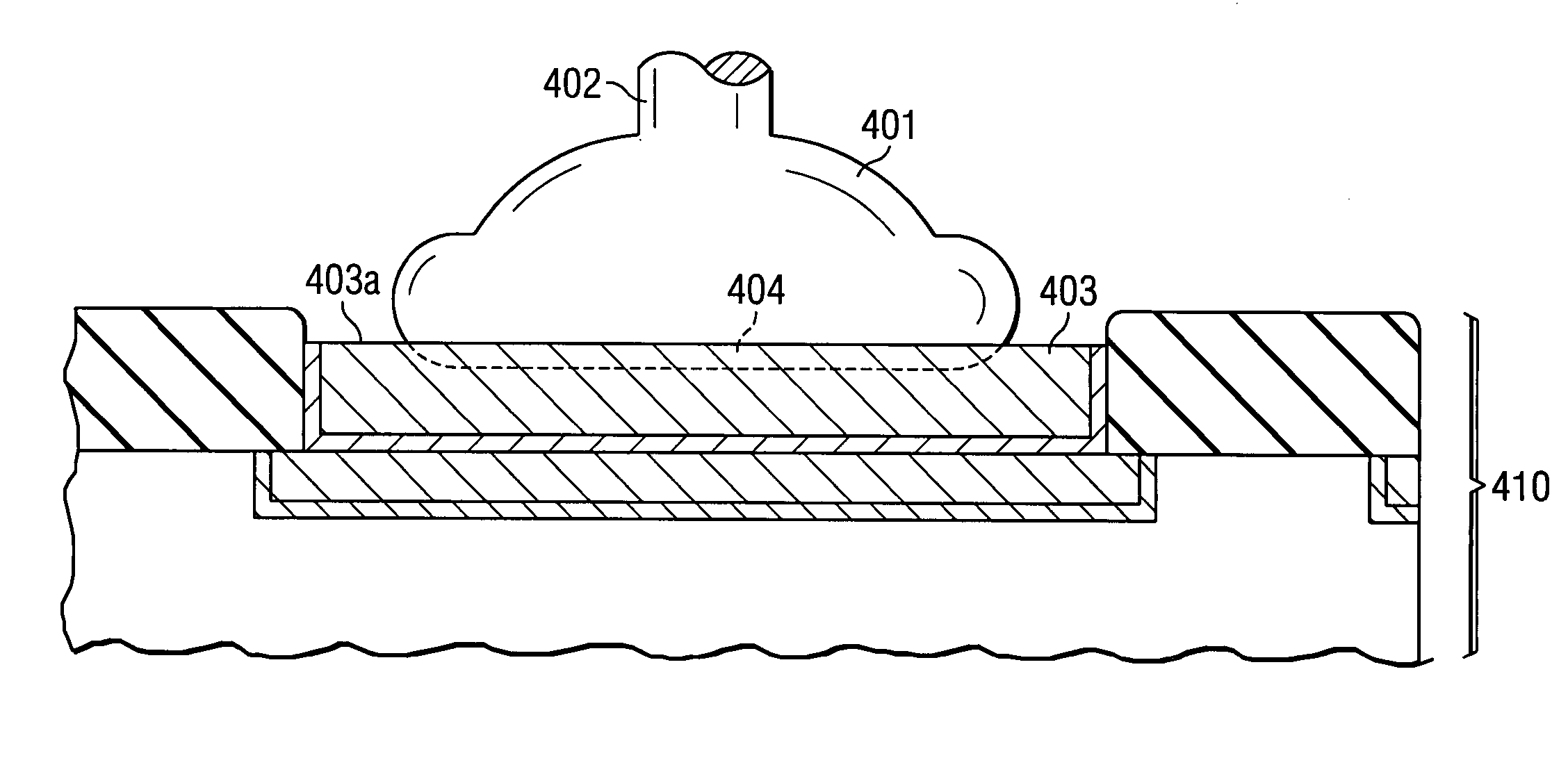

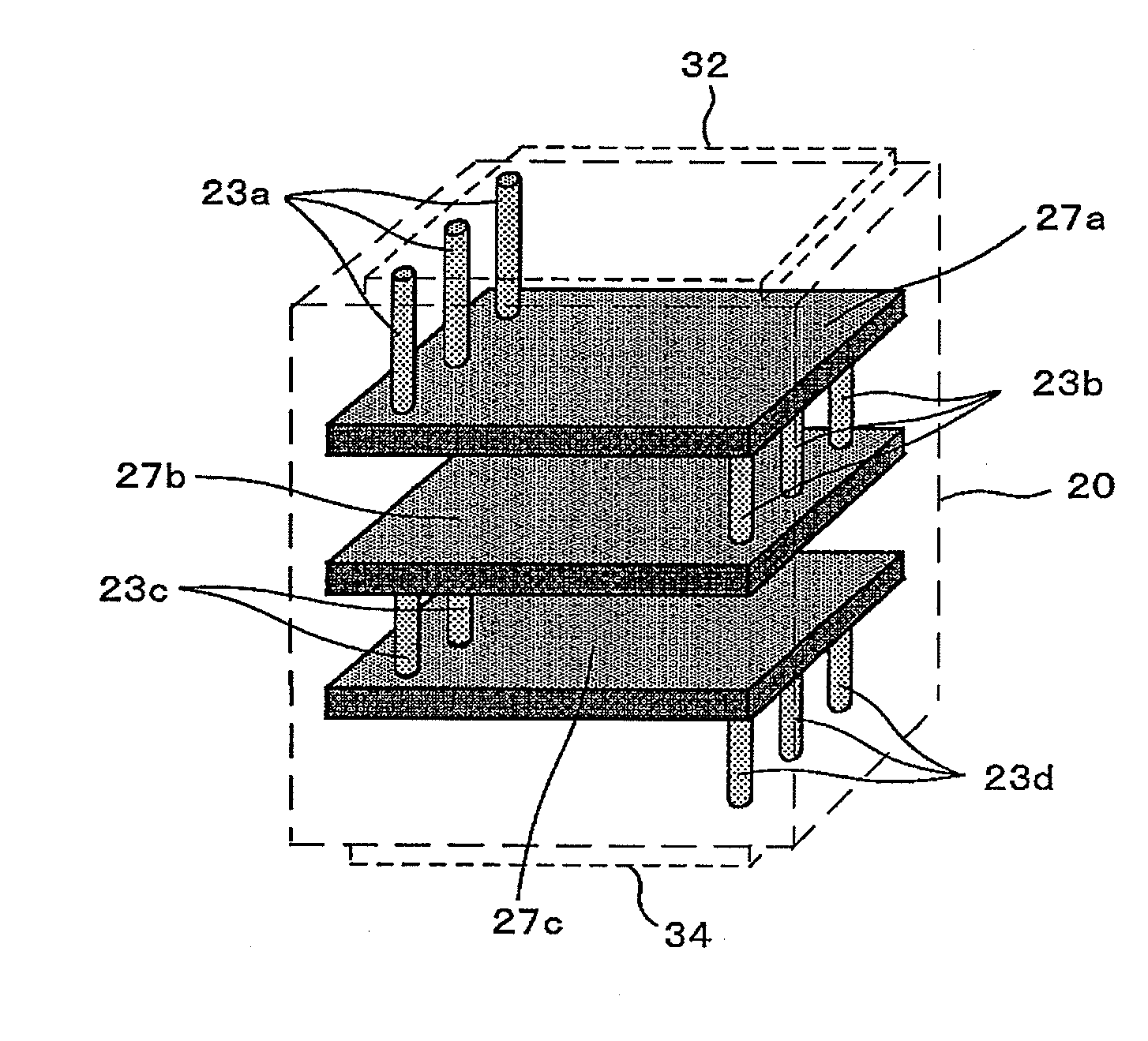

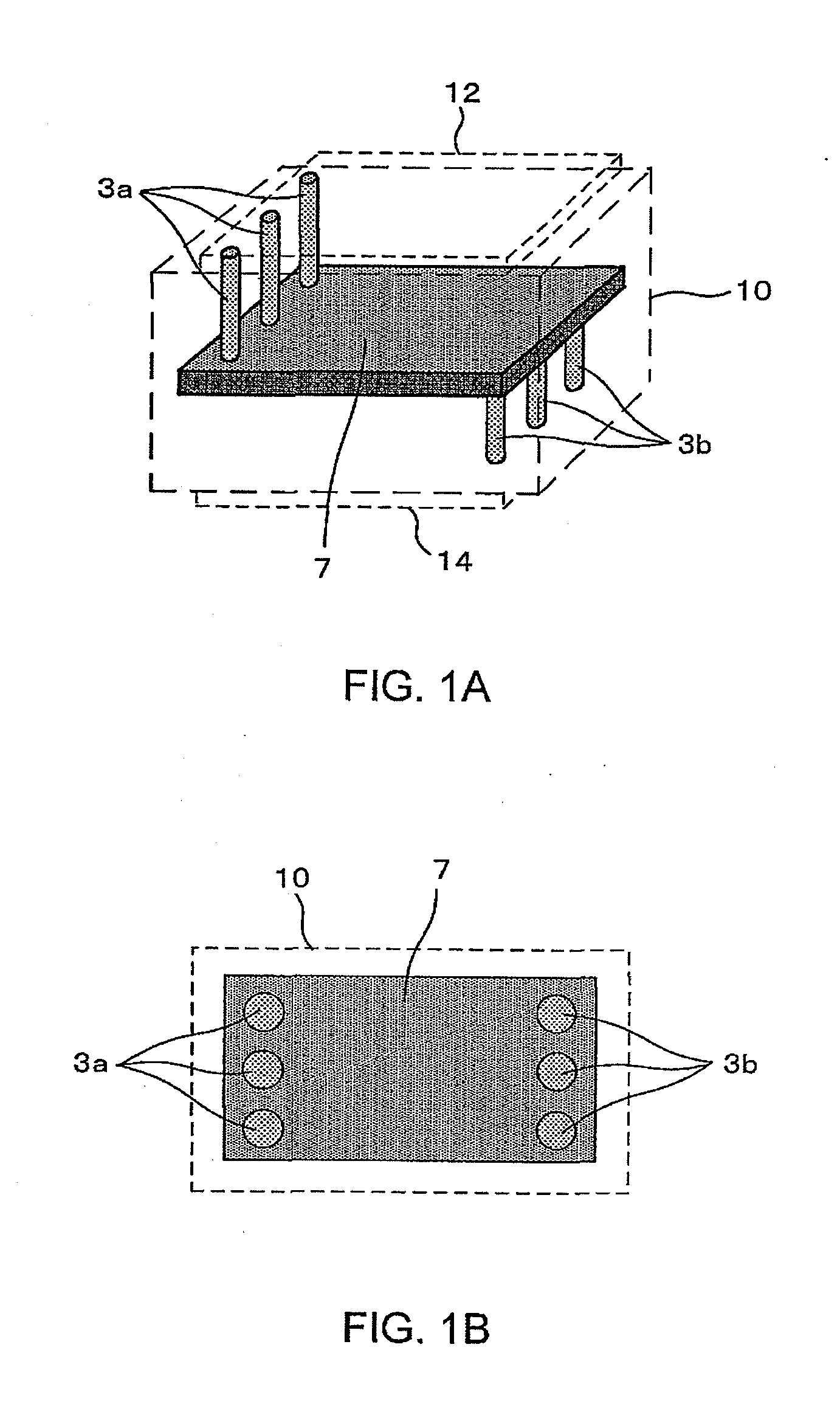

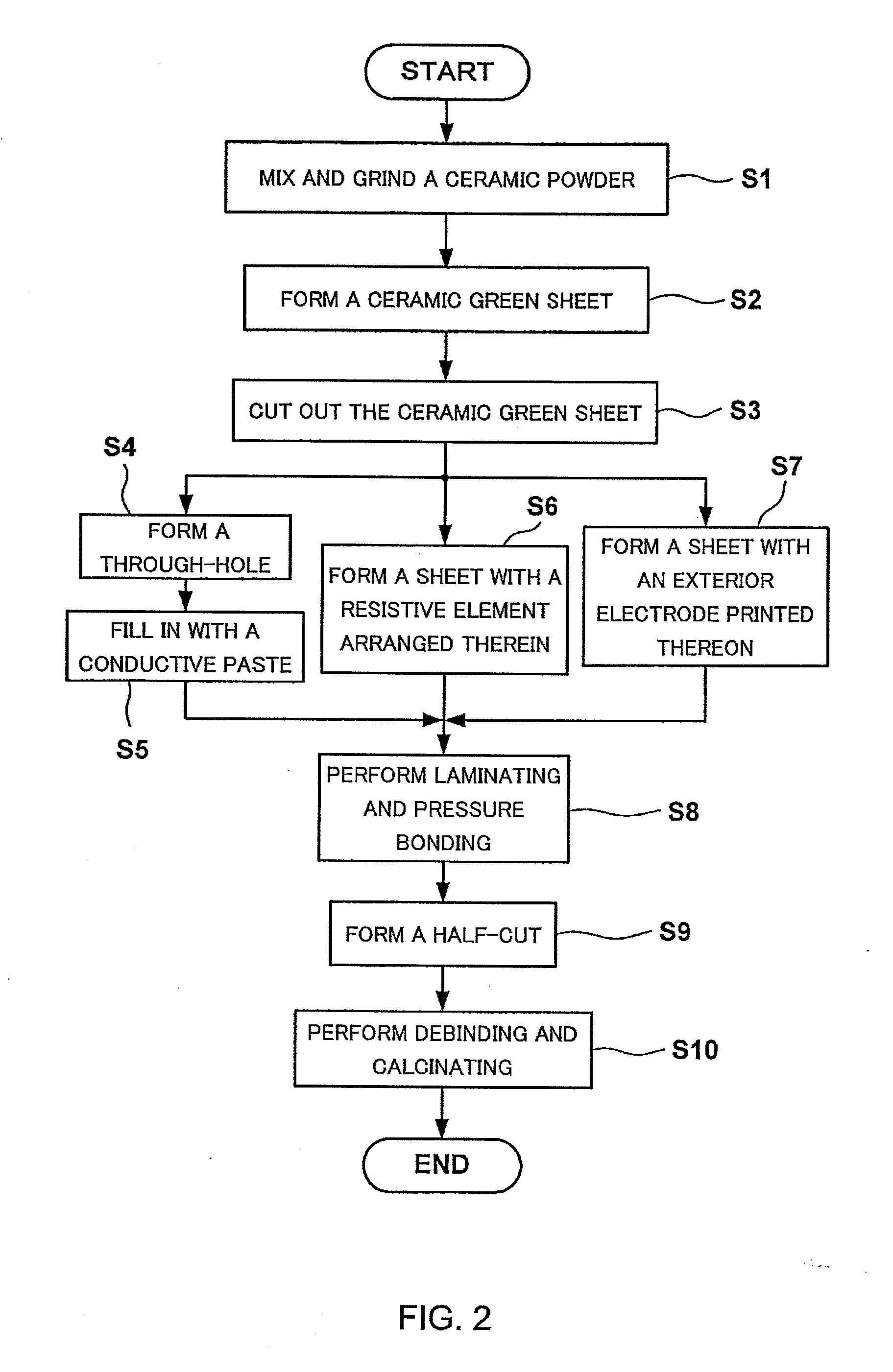

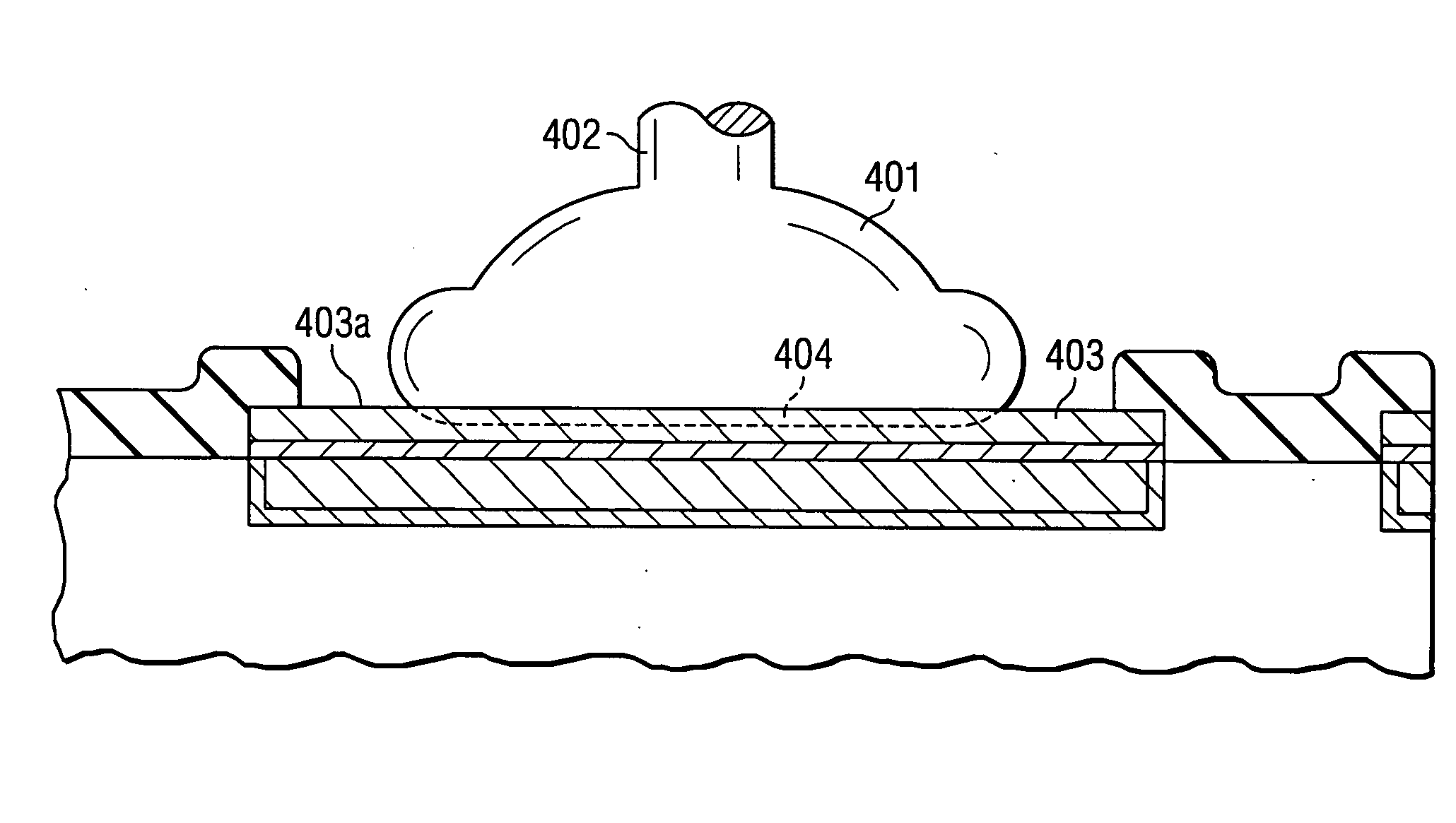

Laminated body and manufacturing method thereof

ActiveUS20100097172A1Variation in resistanceImprove connectivityResistor terminals/electrodesPrinted circuit aspectsEngineeringCeramic substrate

A laminated body and fabrication method thereof, which allow space saving and control of variation in internal layer resistance, are provided. When forming an internal-layer resistive element 7 in a multilayer ceramic substrate 10, the internal-layer resistive element 7 is connected to exterior electrodes (an upper surface electrode 32 and an undersurface electrode 34) via multiple via-electrodes 3a and 3b arranged in parallel, without a pad electrode adopted in the conventional laminated body. Moreover, in a multilayer ceramic substrate having multiple internal-layer resistive elements arranged in a multilayer structure, multiple internal-layer resistive elements are directly connected via multiple via-electrodes arranged in parallel.

Owner:KOA CORP

Structure and method for contact pads having an overcoat-protected bondable metal plug over copper-metallized integrated circuits

InactiveUS20050215048A1Reduce riskImprove assembly yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper interconnectContact pad

A metal structure for a contact pad of an integrated circuit (IC), which has copper interconnecting metallization (311). A portion (301) of this metallization is exposed to provide a contact pad to the IC. A conductive barrier layer (330) is positioned on the exposed portion of the copper metallization. A plug (350) of bondable metal, preferably aluminum between about 0.4 and 1.4 μm thick, is positioned on the barrier layer. A protective overcoat layer (320) surrounds the plug and has a thickness (320b) so that the exposed surface (322) of the plug lies at or below the exposed surface (320a) of the overcoat layer. Optionally, a portion (321) of the overcoat layer between about 0.1 and 0.3 μm wide may overlap the perimeter of the plug.

Owner:TEXAS INSTR INC

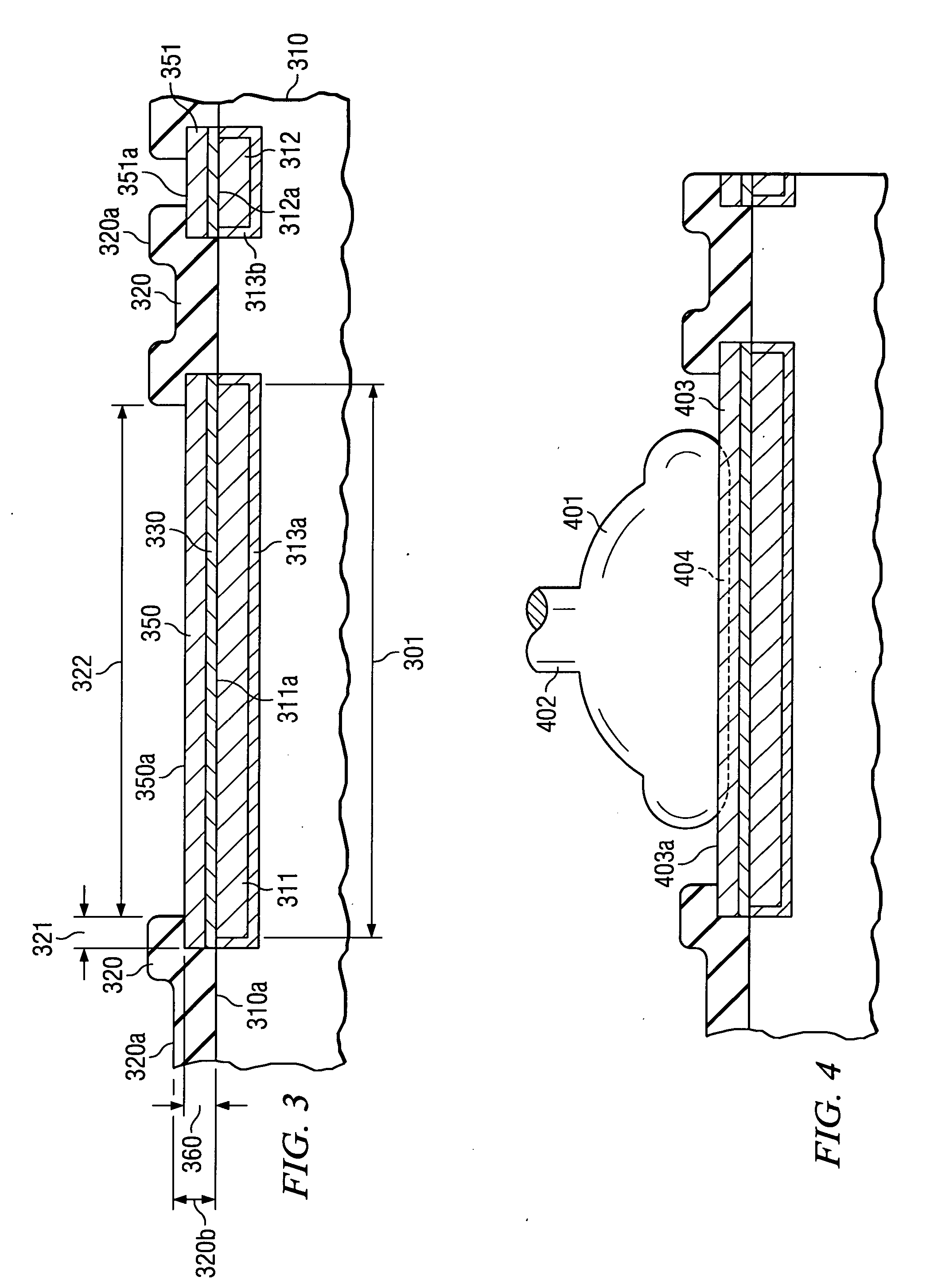

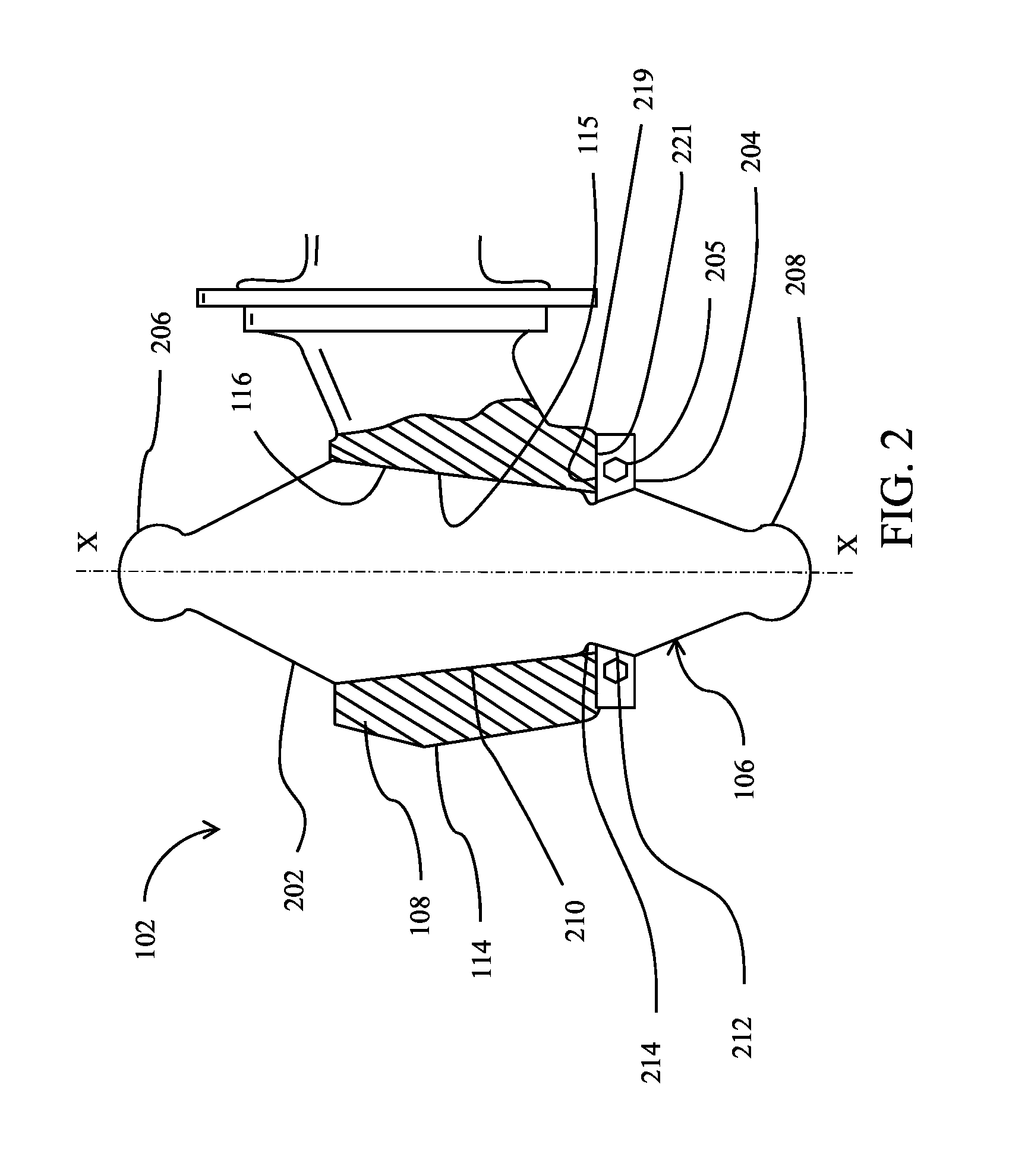

Kingpin assembly for steering and suspension linkage assembly

InactiveUS20140361505A1Smooth rotationHigh assemblySteering linkagesResilient suspensionsMechanical engineeringSteering linkage

A kingpin assembly for pivotally supporting a steering knuckle of a steering linkage assembly is disclosed herein. The kingpin assembly includes a pin and a bearing mount assembly. The pin includes a shoulder disposed between a first tapered portion and a second tapered portion. The first tapered portion is structured and arranged for load bearing and is in engagement with the steering knuckle. The second tapered portion is in reverse taper configuration relative to the first tapered portion, measured axially along the pin. The bearing mount assembly has a first bearing half and a second bearing half. The first and second bearing halves sandwiches the second tapered portion for retention thereof. Each of the first and second bearing halves is in engagement with the steering knuckle.

Owner:CATERPILLAR INC

Displacement encoder including phosphor illumination source

ActiveUS20100328681A1OptimizationEasy to combineMaterial analysis by optical meansUsing optical meansPhotodetectorOptical pathlength

A position sensing optical encoder includes an illumination source that operates by providing primary radiation having a first level of intensity uniformity to saturate at least a portion of a relatively broad phosphor area including uniformly distributed phosphor. The phosphor area absorbs the primary radiation and emits phosphor radiation to illuminate the encoder scale pattern. The scale pattern spatially modulates the phosphor light, and the spatially modulated pattern of phosphor light is sensed by a photodetector arrangement. Due at least partially to saturation of the phosphor, the phosphor light has a second level of phosphor light intensity uniformity that is more uniform than the first level of primary light intensity uniformity, which enhances the encoder accuracy. The uniform phosphor illumination intensity is economically provided over a broad area with few components and minimized optical path length, particularly for path length perpendicular to the scale.

Owner:MITUTOYO CORP

Structure and method for contact pads having a recessed bondable metal plug over of copper-metallized integrated circuits

ActiveUS20060082000A1Eliminate riskReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectContact pad

A metal structure for an integrated circuit, which has copper interconnecting metallization (311) protected by an overcoat layer (320). A portion of the metallization is exposed in a window (301) opened through the thickness of the overcoat layer. The metal structure comprises a patterned conductive barrier layer (330) positioned on the copper metallization, wherein this barrier layer forms a trough with walls (331) conformal with the overcoat window. The height (331a) of the wall is less (between 3 and 20 %) than the overcoat thickness (320a), forming a step (340). A plug (350) of bondable metal, preferably aluminum, is positioned in the trough and has a thickness equal to the trough wall height (331a).

Owner:TEXAS INSTR INC

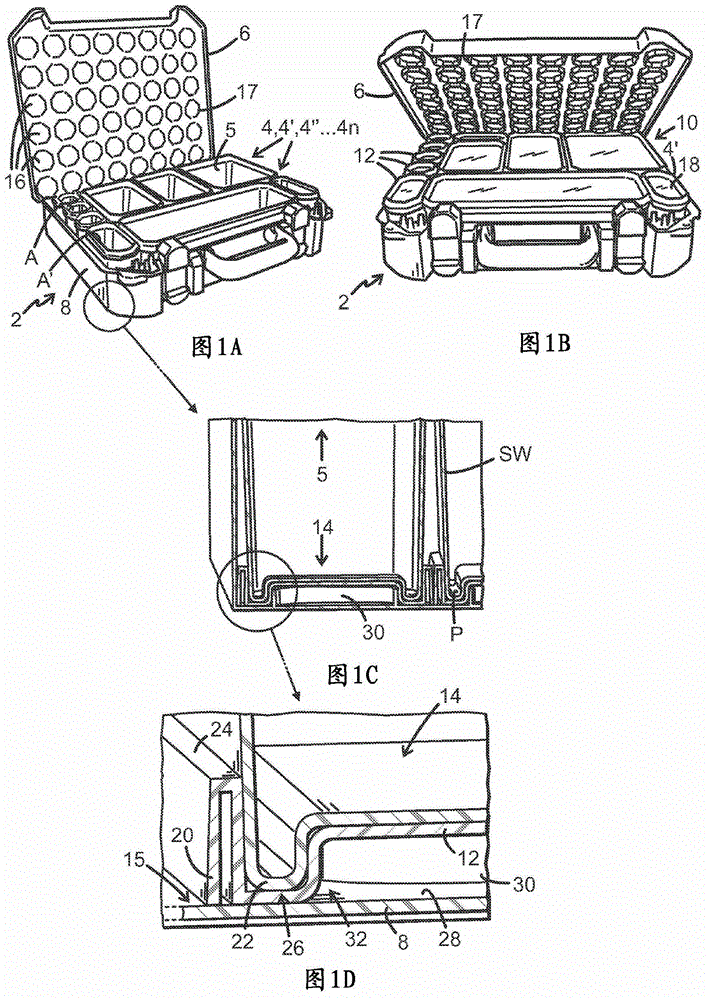

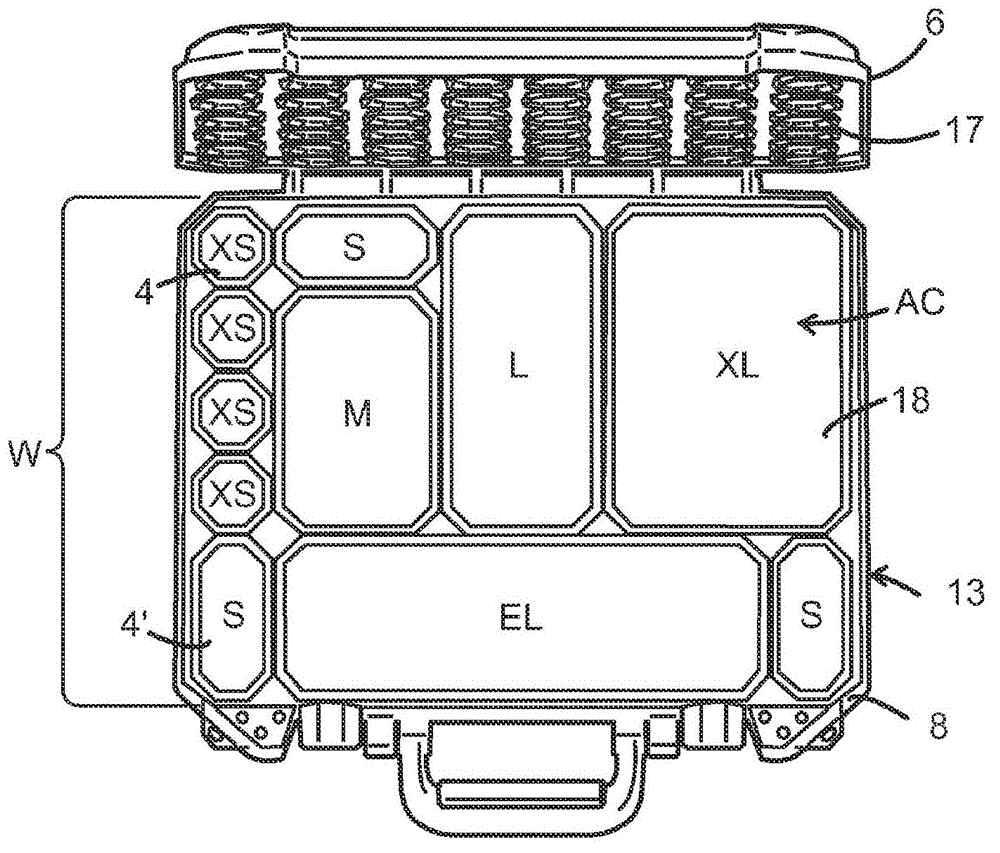

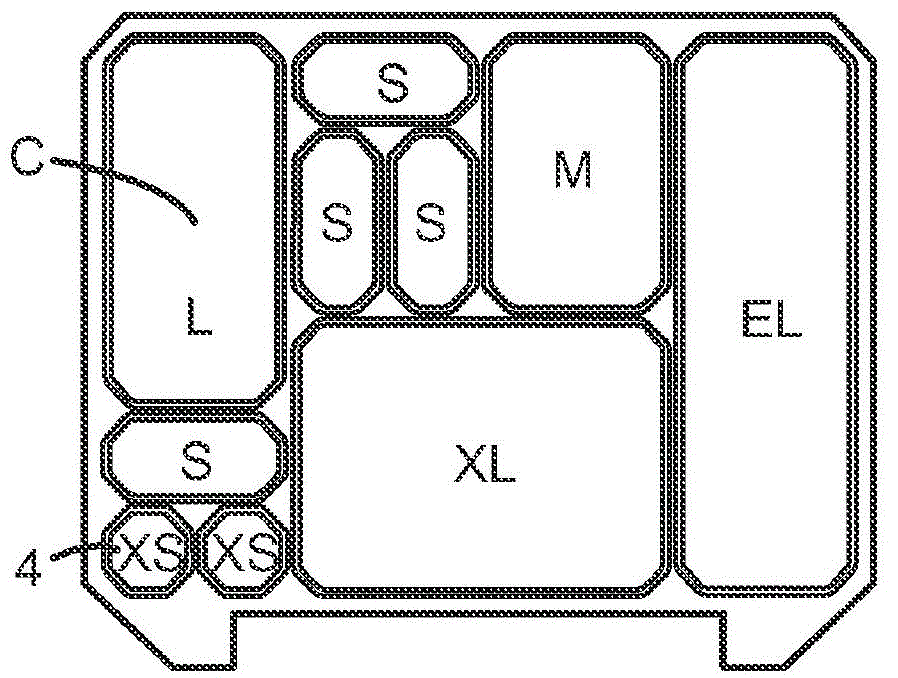

Module system comprising a case and a number of boxes

The present invention relates to a module system comprising a case (2) and a number of boxes (4, 4 '...4n). Each box is defined by a cross-sectional area of an opening (A, A '...An) of the respective box. The case has a case lid (6) and a case bottom part (8). The case lid and the case bottom part forms an interior space (10) within the case (2), and the boxes (4) are to be stored in the interior space (10) of the case (2). The cross-sectional area (A) of one box (4) is approximately a multiple (n) of any cross-sectional area (A, A ' ...An) of any of the number of boxes (4, 4 '...4n) that are to be stored in the interior space (10) of the case (2). The case lid (6) is provided with sealing means (16) that sealingly fits over and in abutment with an upper surface (18) of at least one box (4, 4 '...4n), with the case (2) in closed position, when the boxes (4, 4 '... 4n) are stored in the interior space (10) of the case (2).

Owner:ESSVE PROD

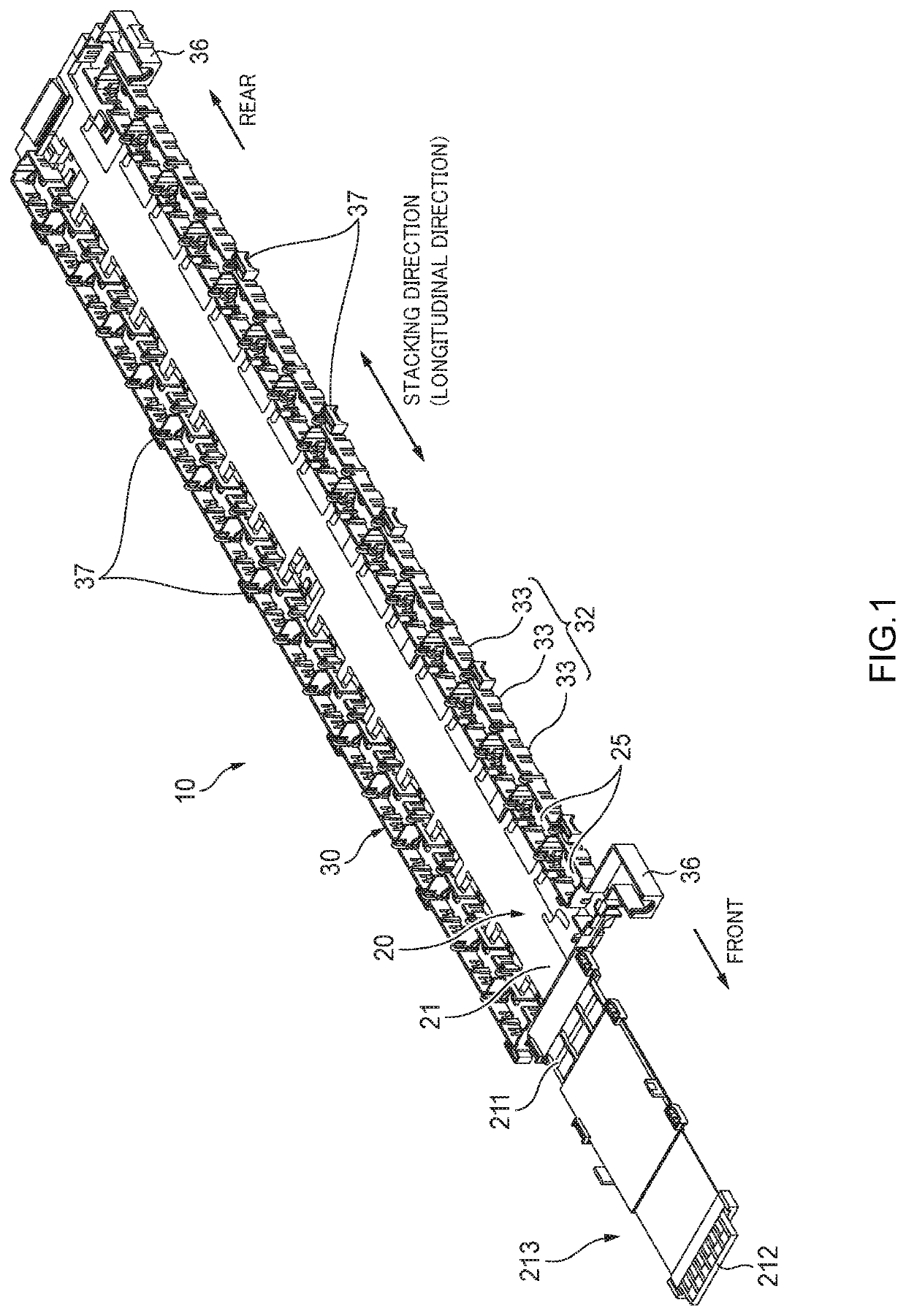

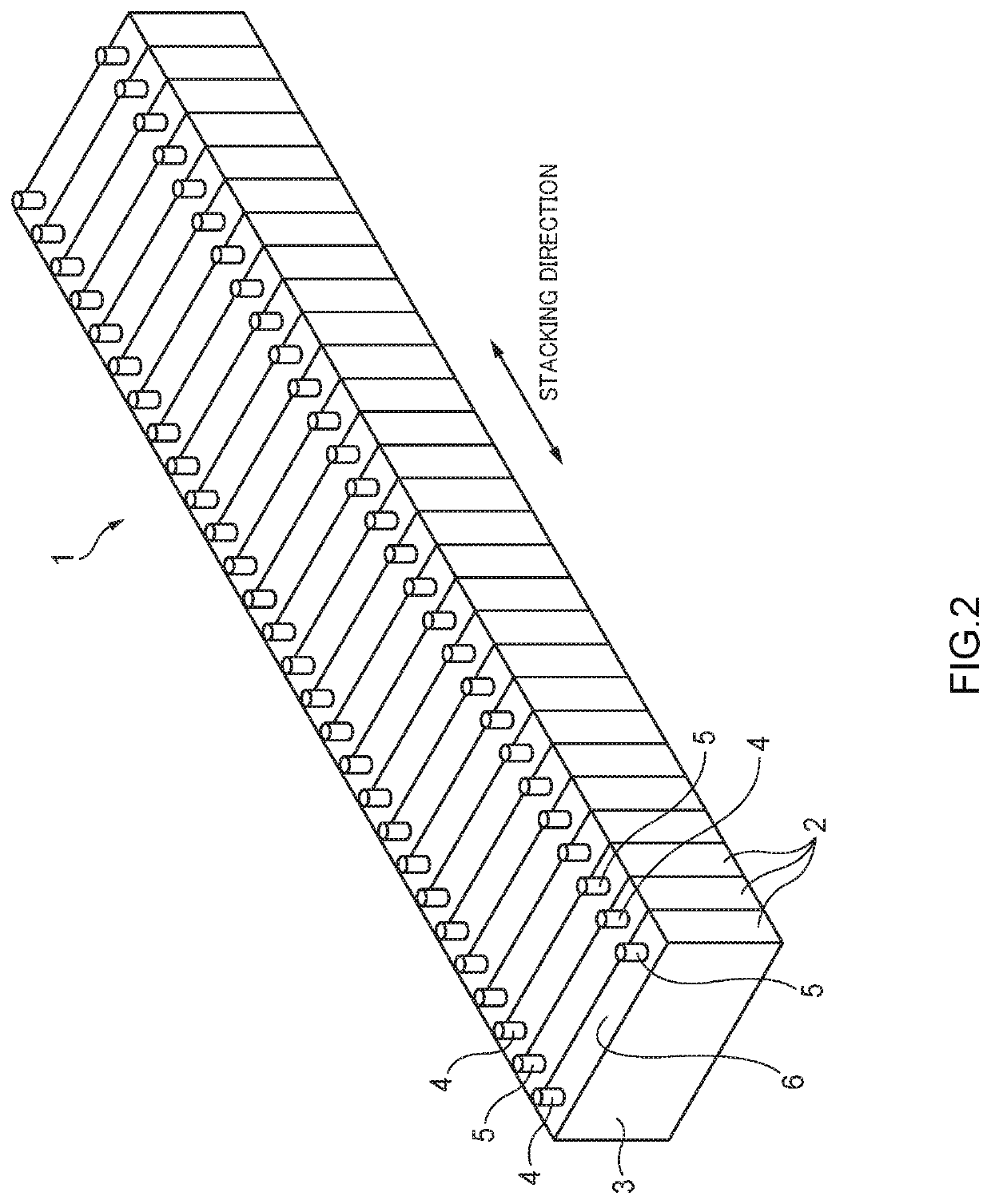

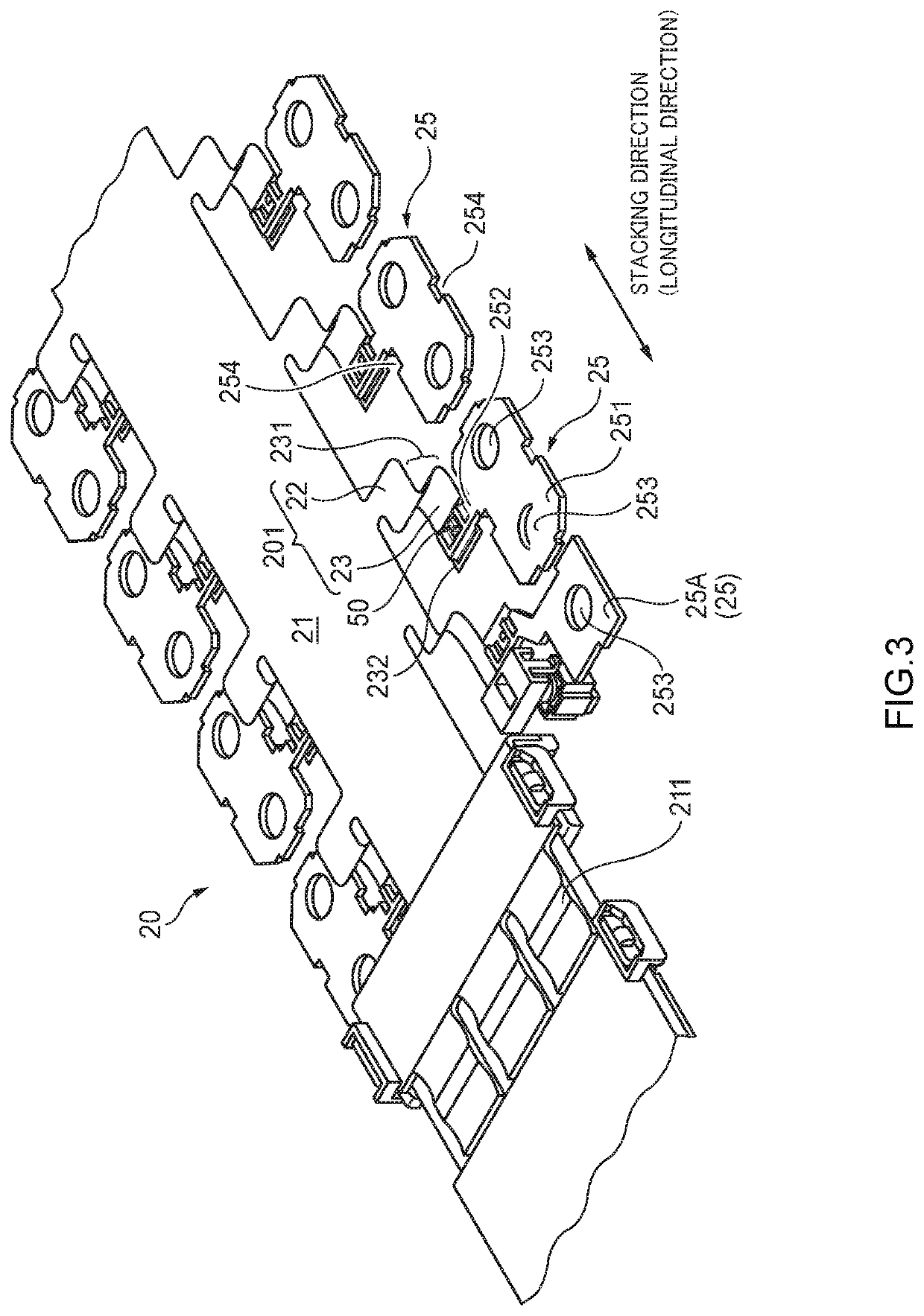

Busbar Module

ActiveUS20200396830A1Flexible deformationAttached with easeCircuit bendability/stretchabilityPrinted circuit aspectsFlexible circuitsBusbar

A busbar module includes: a circuit body having a flexible circuit board; busbars; and a holder. The circuit body has: a band-shaped main strip to be located to extend in a stacking direction of cells; a band-shaped first branch strip branched from the main strip and extending toward a corresponding busbar; and a second branch strip branched from the main strip and extending toward an external device. The first branch strip has: a bent portion extending in the stacking direction and having a bent shape around an axis crossing the stacking direction; and a busbar connection portion disposed closer to an end of the first branch strip than the bent portion and connected to the corresponding busbar. The second branch strip has a device connection portion to be connected to the external device.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com