Patents

Literature

51results about How to "Improve deceleration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

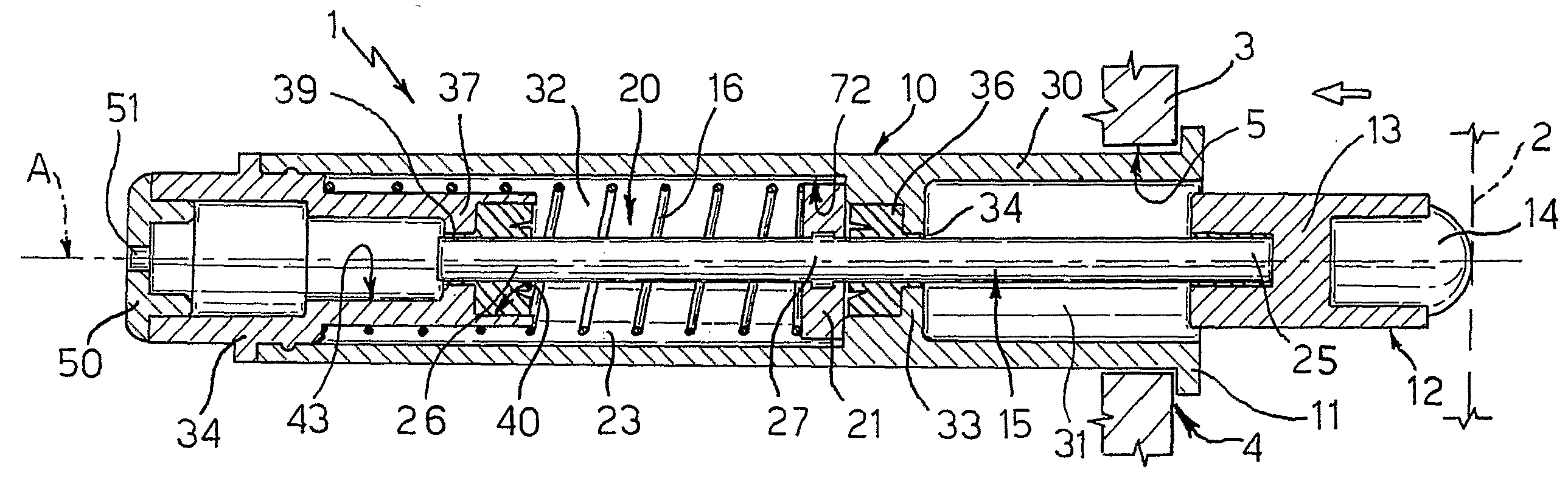

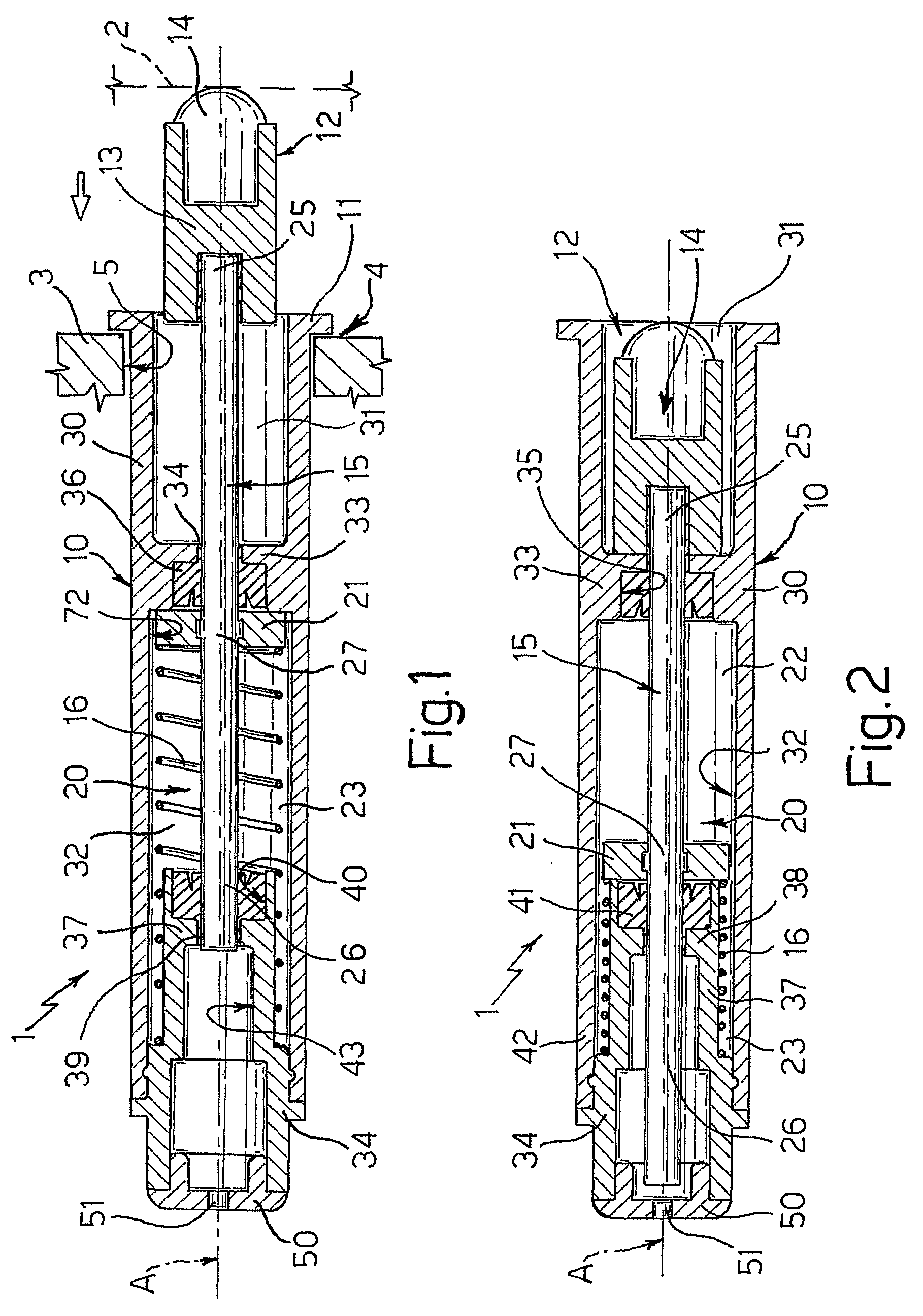

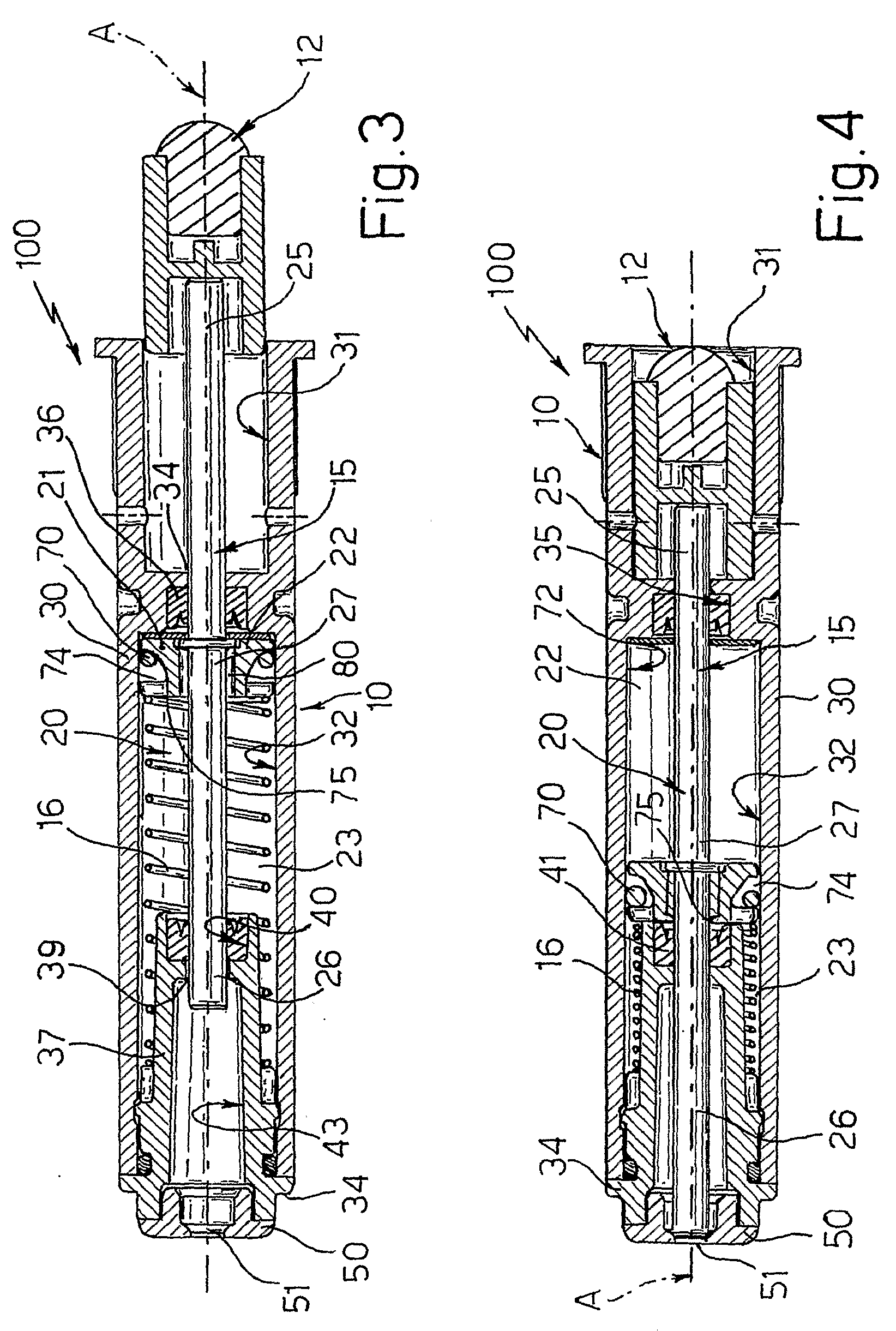

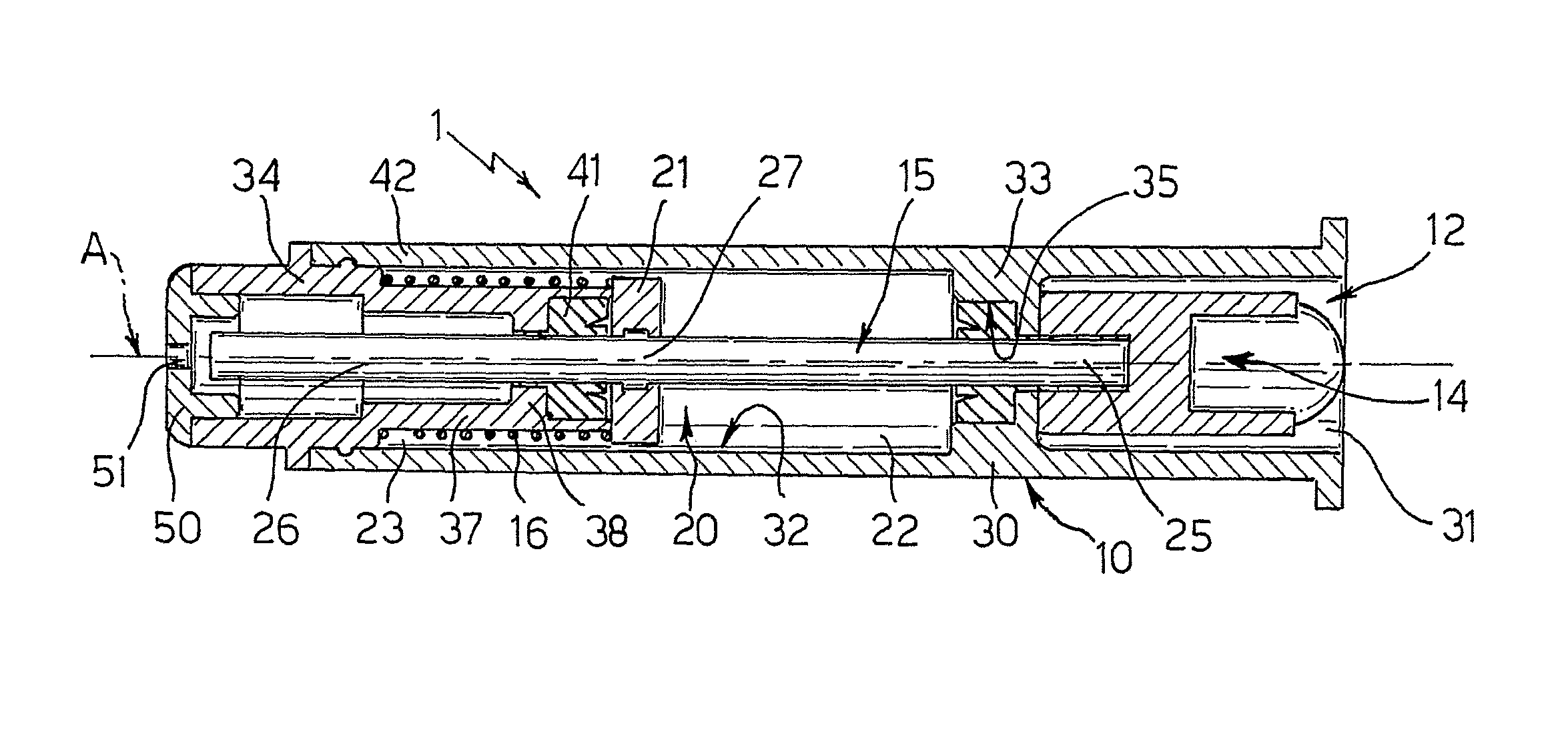

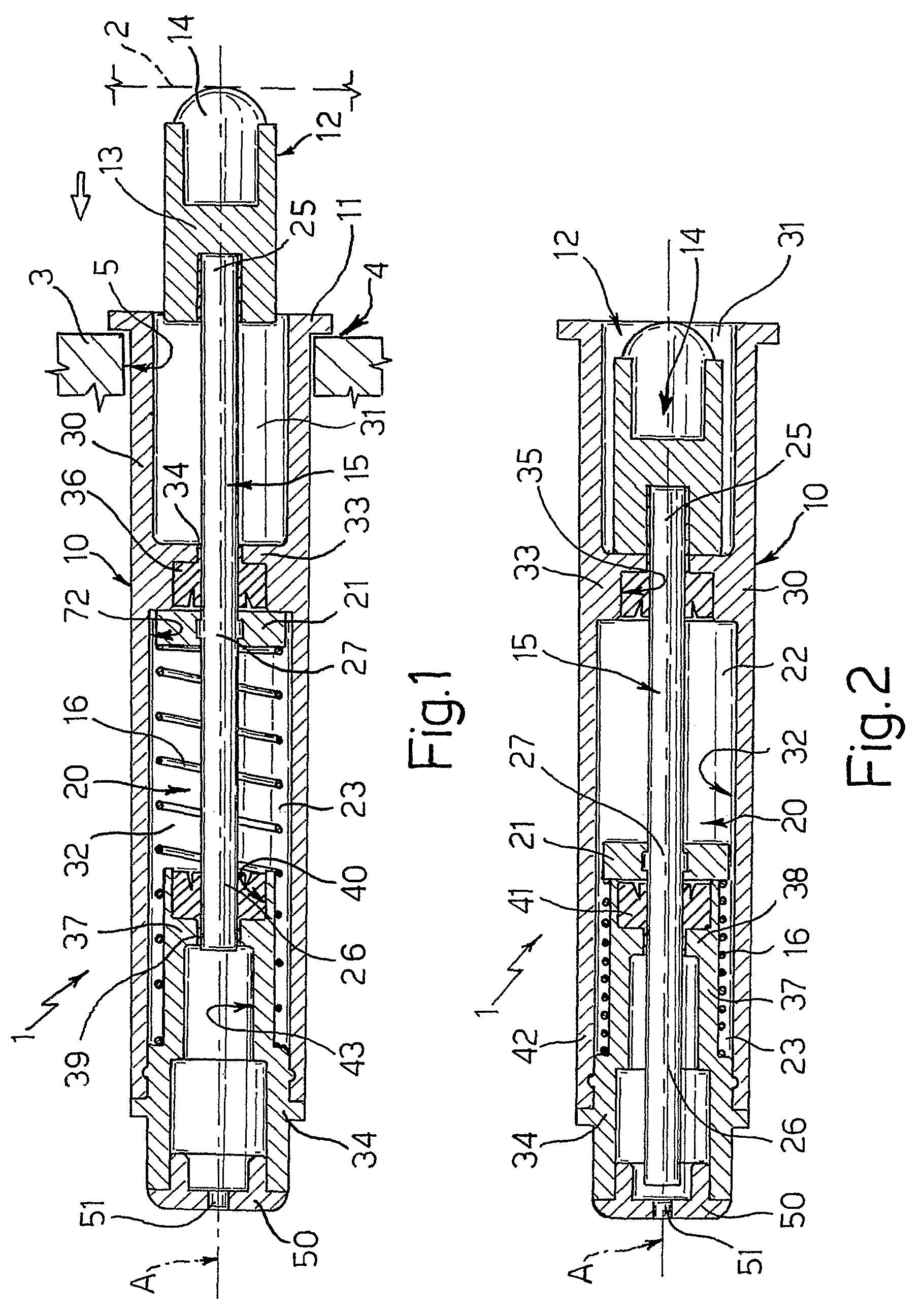

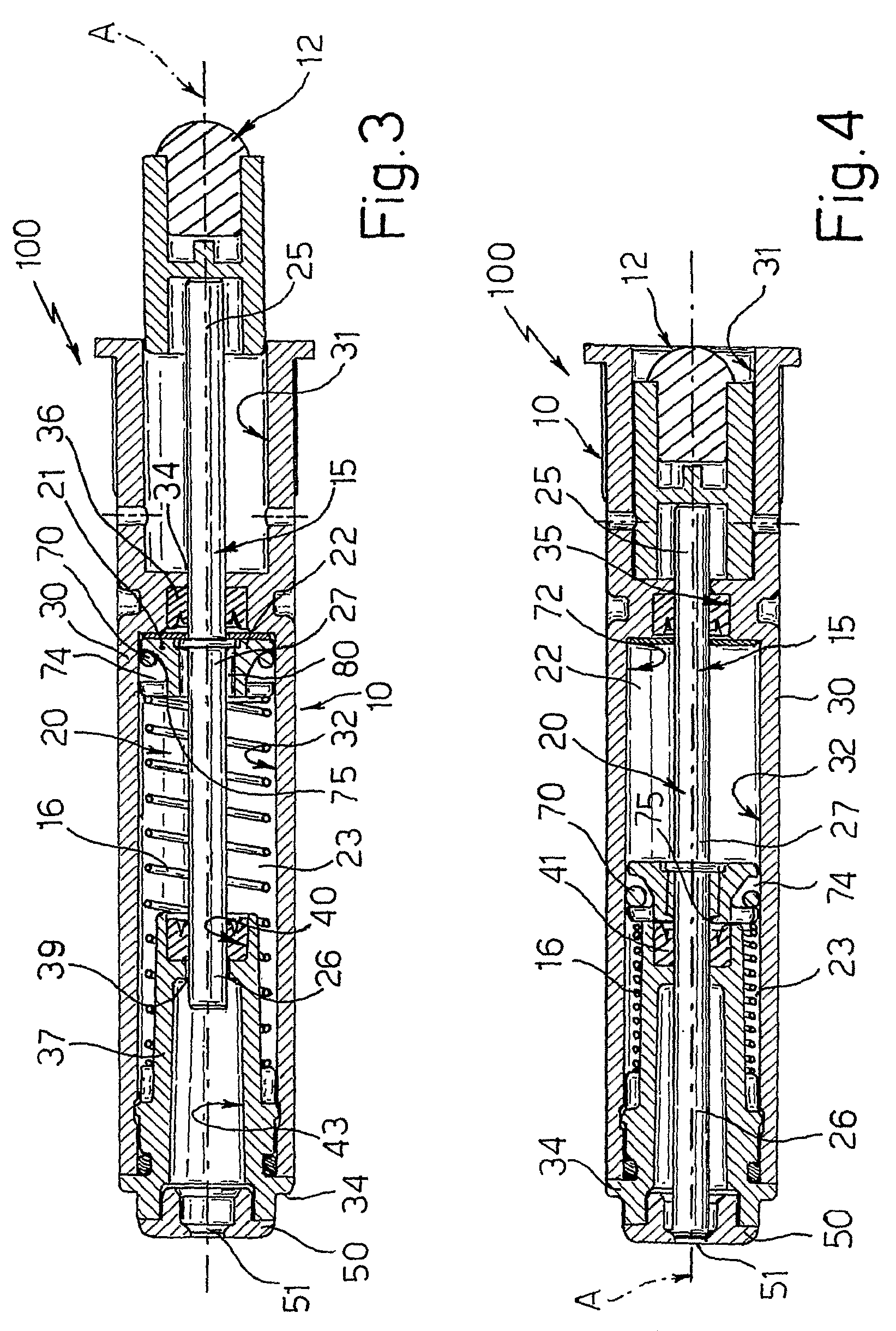

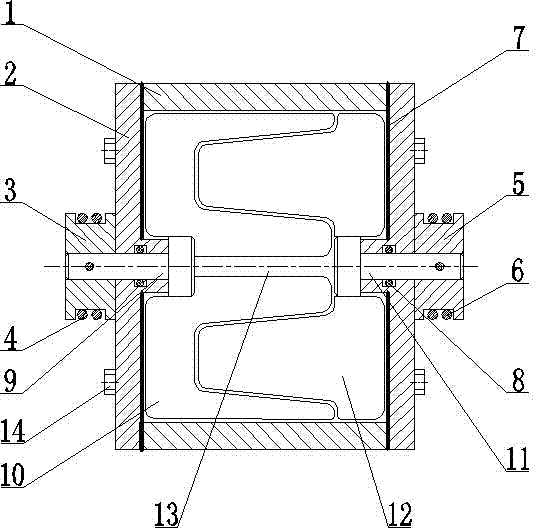

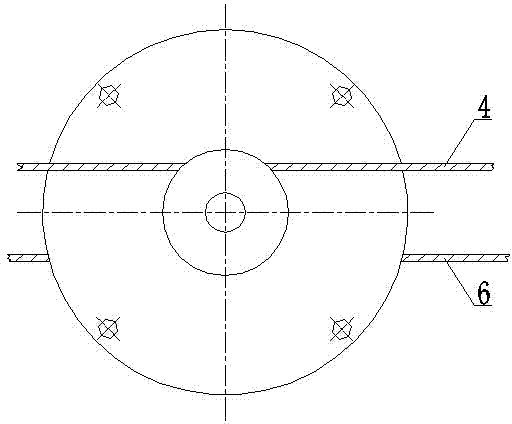

Decelerating stop device for a movable member, in particular a furniture door or drawer, fittable to a stop surface of the movable member

InactiveUS20090119873A1Small dimensionReduce manufacturing costSpringsBuilding braking devicesViscous liquidStops device

A decelerating device intended to intercept an end-of-stroke part of a closing path of a mobile member, such as a furniture drawer or door, including: a body fastenable in use to an abutting surface for the mobile member and internally defining a sealed chamber filled in use with a viscous fluid; a pushrod at least in part overhanging from the body and being adapted to cooperate in use with the mobile member, the pushrod being integral with a stem slidingly accommodated in the body against the bias of elastic means between an extracted position of the pushrod and a retracted position; and a piston accommodated in the sealed chamber so as to divide it into two portions hydraulically connected to each other and mechanically connected to the stem; wherein the stem presents a first end integrally connected to the pushrod and a second end opposite to the first, both slidingly accommodated in the body outside the sealed chamber and fluid-tightly towards the sealed chamber itself; the piston is provided with a mobile sealing member to choke the hydraulic communication between the two portions of the sealed chamber only during the stroke of the stem towards the retracted position.

Owner:ITW IND COMPONENTS SRL

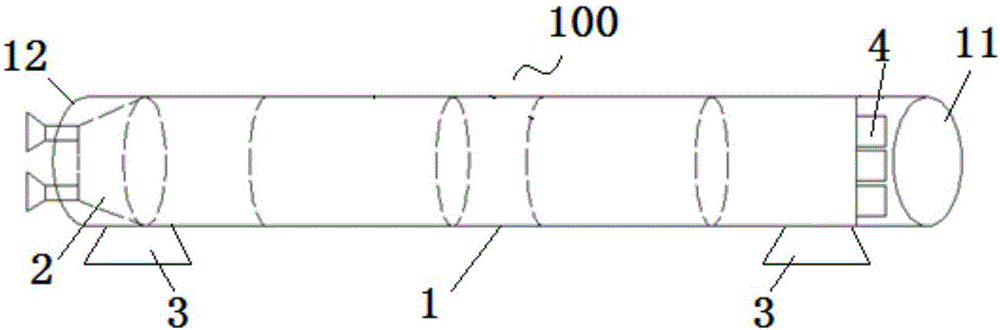

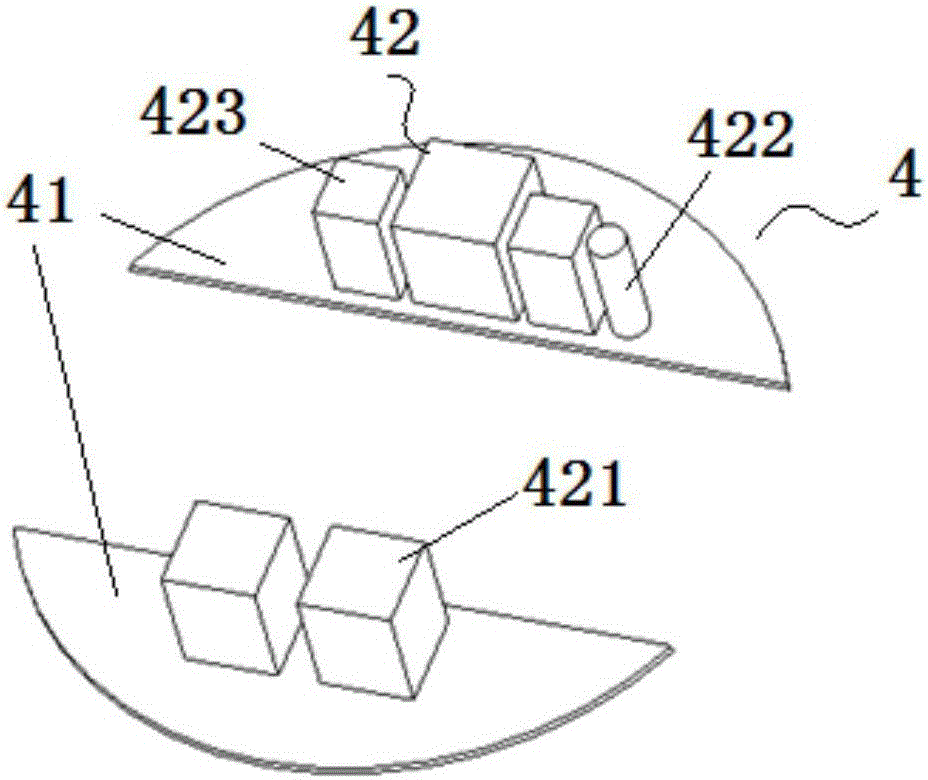

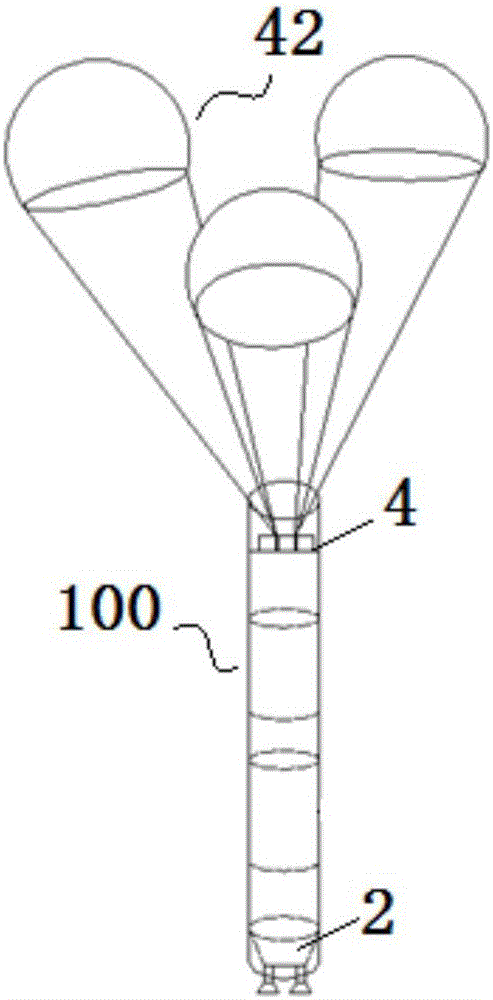

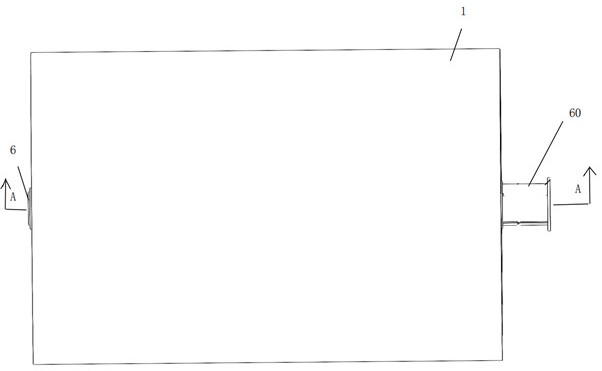

First-child-stage parachuting-recovery carrier rocket

InactiveCN106628269AImprove deceleration efficiencyReduce shock loadSystems for re-entry to earthCosmonautic landing devicesAirbag deploymentRocket

The invention relates to a first-child-stage parachuting-recovery carrier rocket. The first-child-stage parachuting-recovery carrier rocket is combined by two stages of rockets and comprises a recovery system arranged in a shell of a first-child-stage rocket, wherein the recovery system comprises a speed reducing device and a buffering device; the speed reducing device is arranged at the position close to the interstage section of the shell and comprises a supporting frame connected with the inner wall of the shell; a parachuting device is arranged on the supporting frame and is used for reducing the speed of the separated first-child-stage rocket in the falling process; the buffering device comprises two buffering airbags, one buffering air bag is arranged at the position close to the interstage section, the other buffering airbag is arranged at the position close to the tail section, and the two buffering airbags are used for buffering the first-child-stage rocket in the landing process. The first-child-stage parachuting-recovery carrier rocket has the advantages that the first-child-stage rocket can land smoothly without damage under the common action of the buffering device and the speed reducing device, so that non-damage recovery of the first-child-stage rocket can be realized, and the first-child-stage rocket can be secondarily utilized, so that the launching cost can be reduced.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Decelerating stop device for a movable member, in particular a furniture door or drawer, fittable to a stop surface of the movable member

InactiveUS8104140B2Improve deceleration efficiencyReduce manufacturing costSpringsBuilding braking devicesViscous liquidStops device

A decelerating device intended to intercept an end-of-stroke part of a closing path of a mobile member, such as a furniture drawer or door, including: a body fastenable in use to an abutting surface for the mobile member and internally defining a sealed chamber filled in use with a viscous fluid; a pushrod at least in part overhanging from the body and being adapted to cooperate in use with the mobile member, the pushrod being integral with a stem slidingly accommodated in the body against the bias of elastic means between an extracted position of the pushrod and a retracted position; and a piston accommodated in the sealed chamber so as to divide it into two portions hydraulically connected to each other and mechanically connected to the stem; wherein the stem presents a first end integrally connected to the pushrod and a second end opposite to the first, both slidingly accommodated in the body outside the sealed chamber and fluid-tightly towards the sealed chamber itself; the piston is provided with a mobile sealing member to choke the hydraulic communication between the two portions of the sealed chamber only during the stroke of the stem towards the retracted position.

Owner:ITW IND COMPONENTS SRL

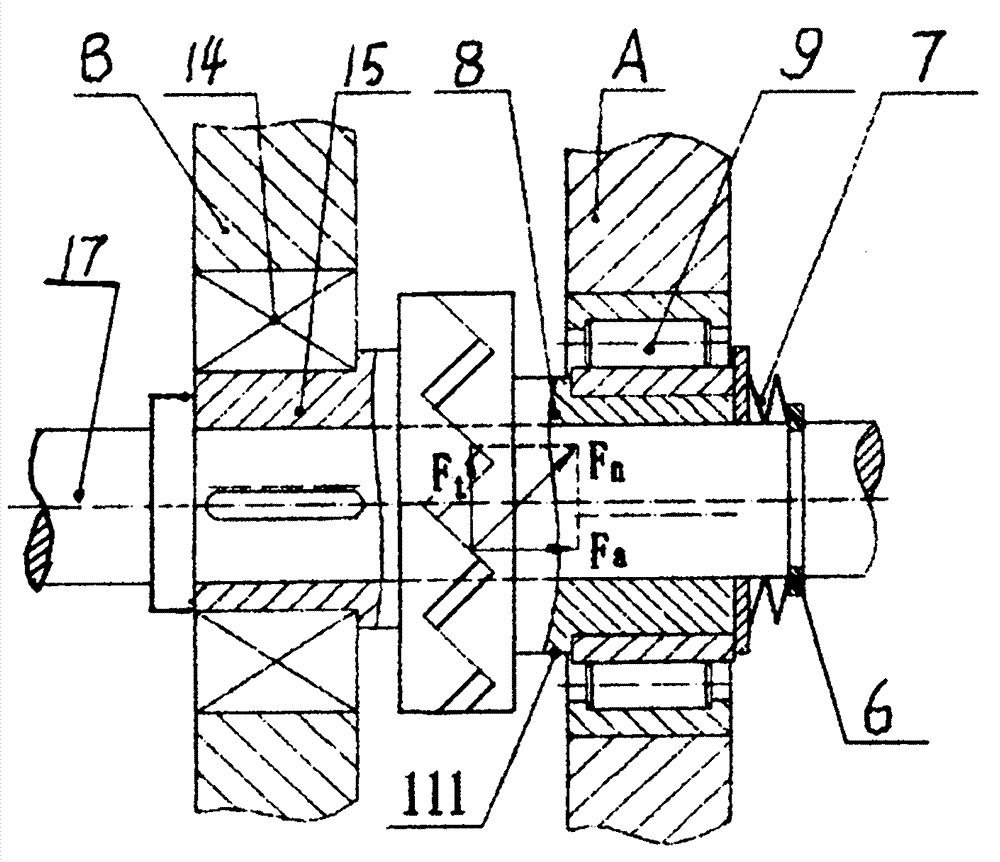

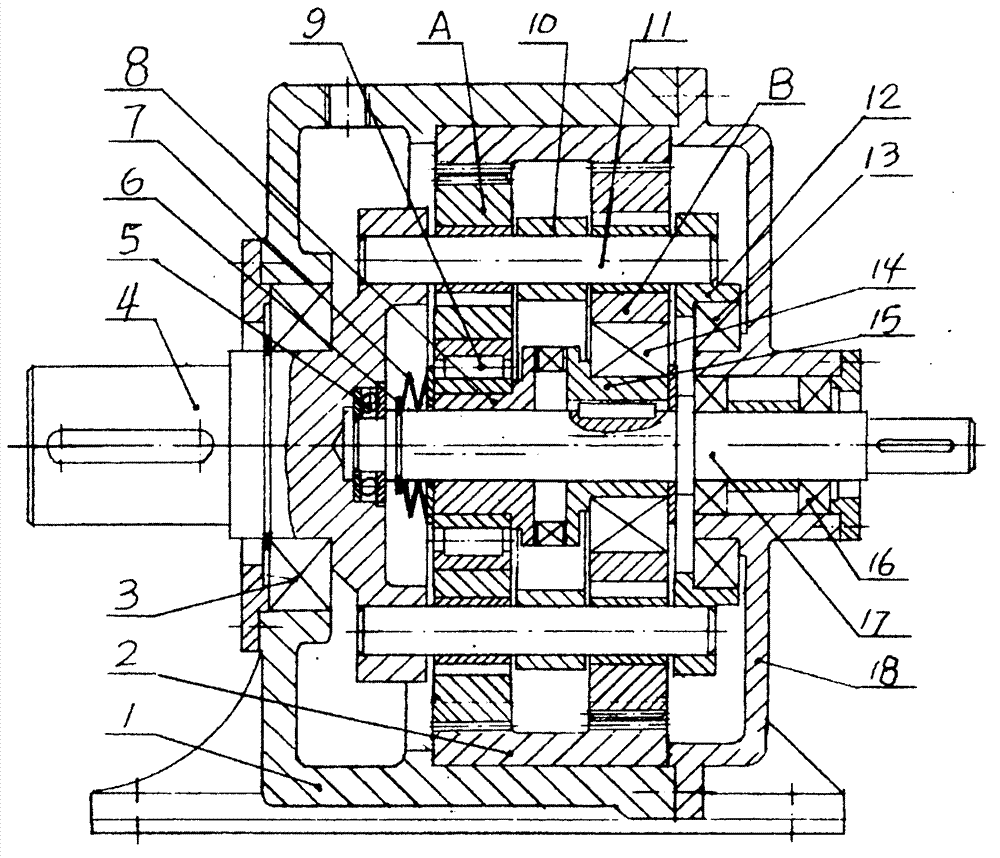

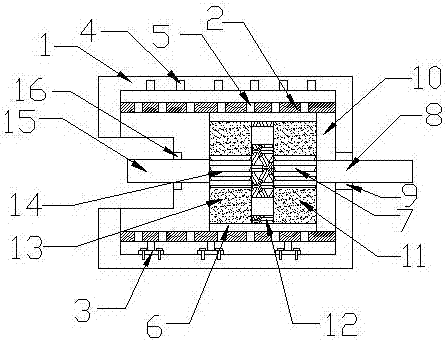

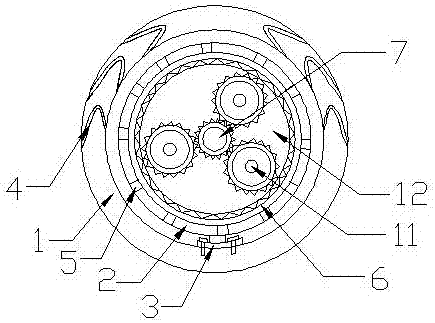

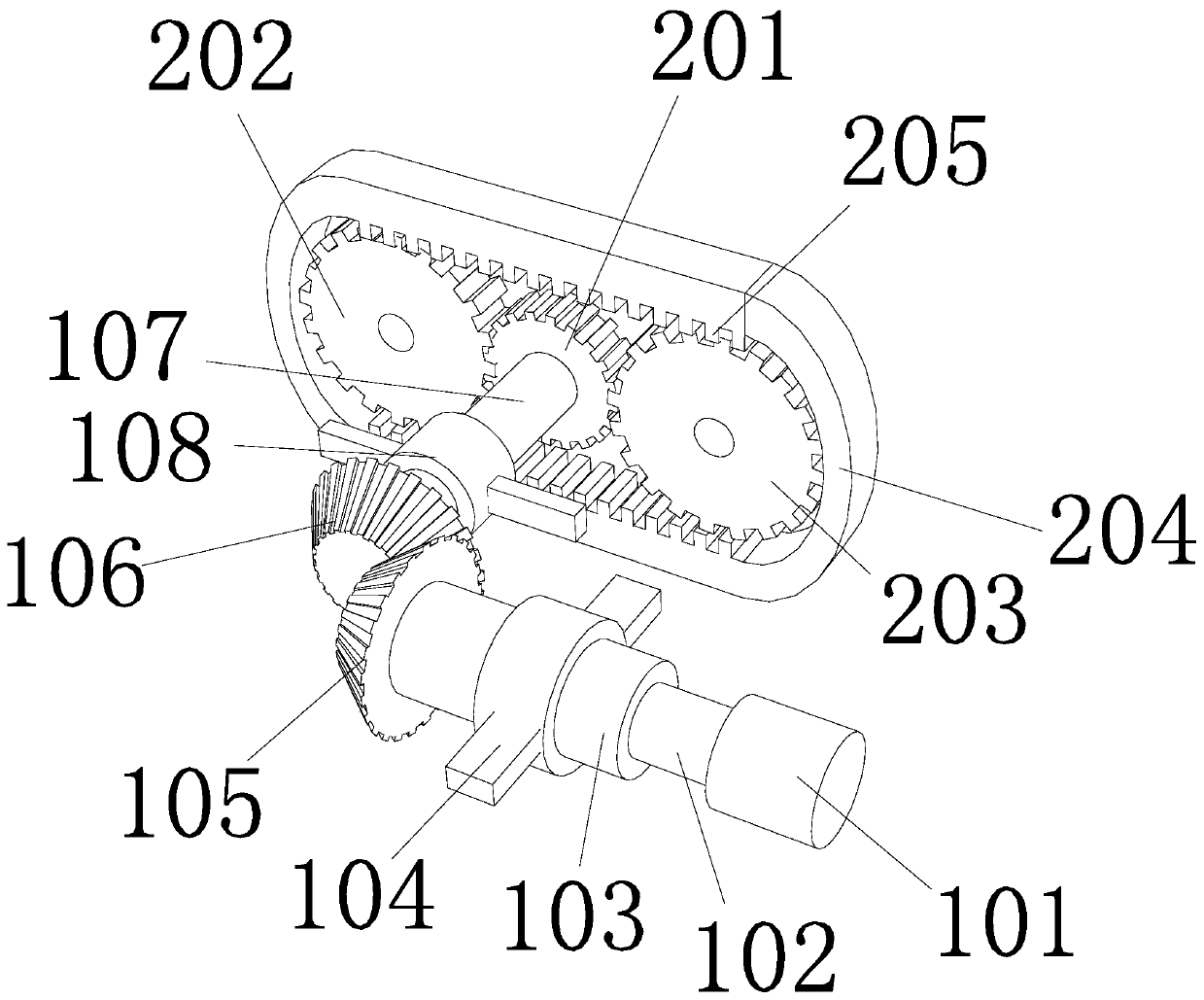

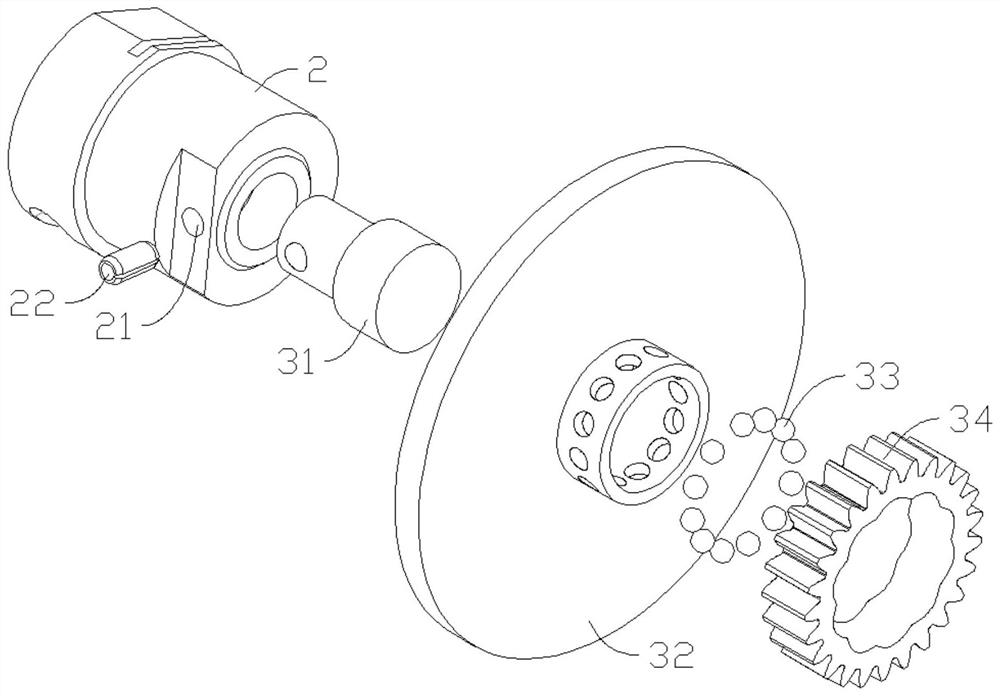

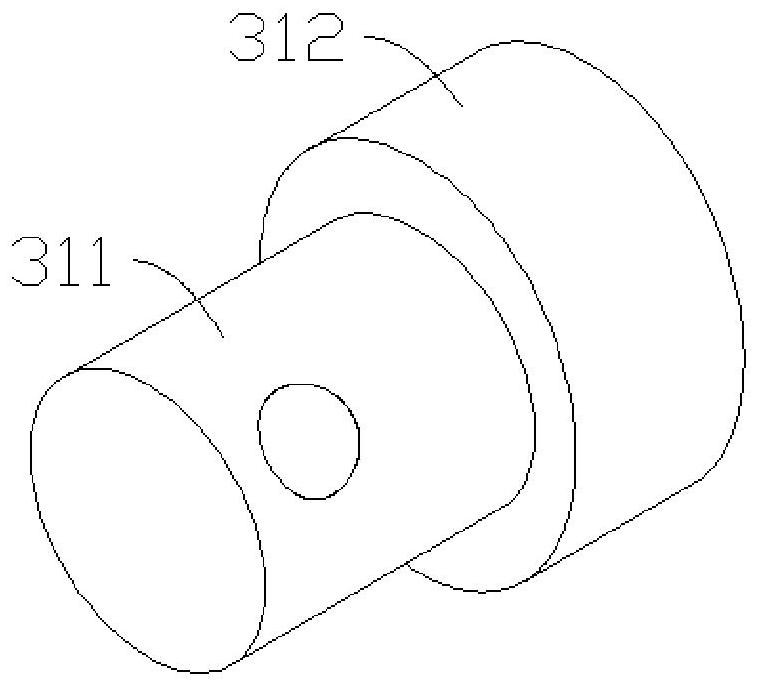

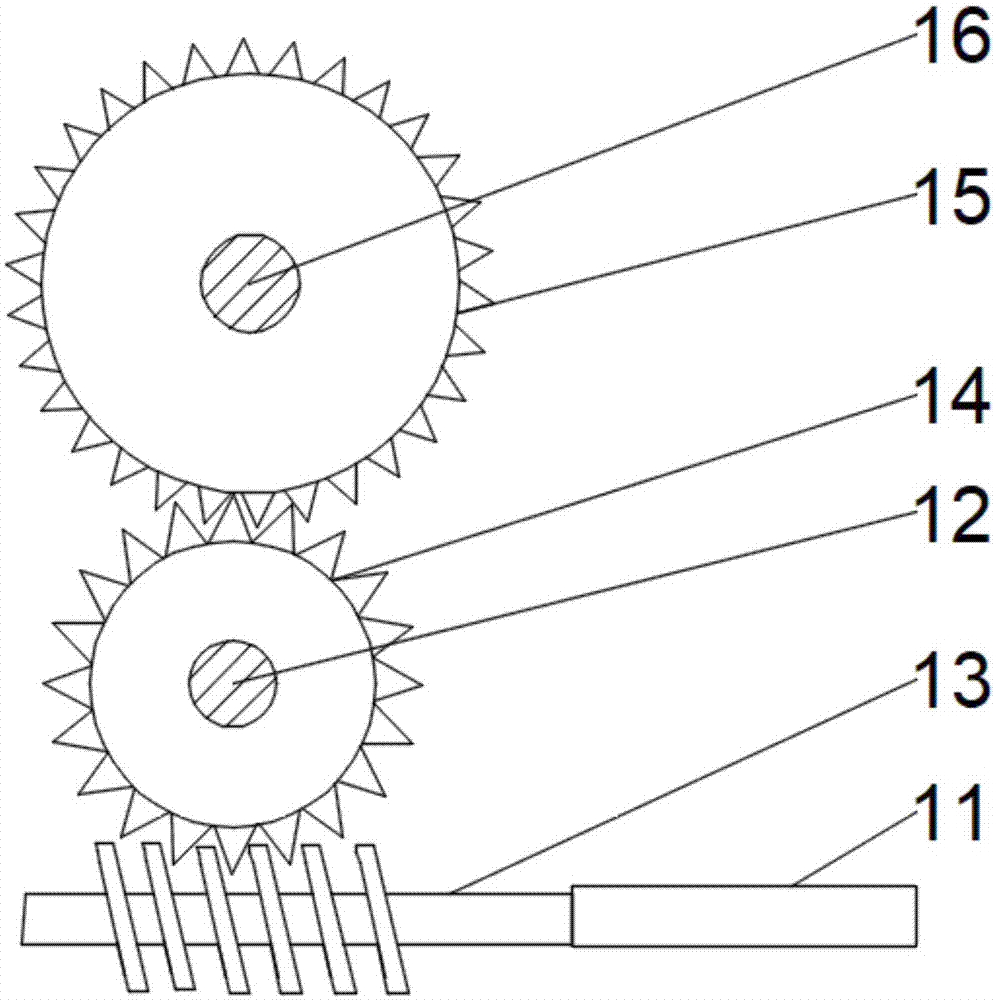

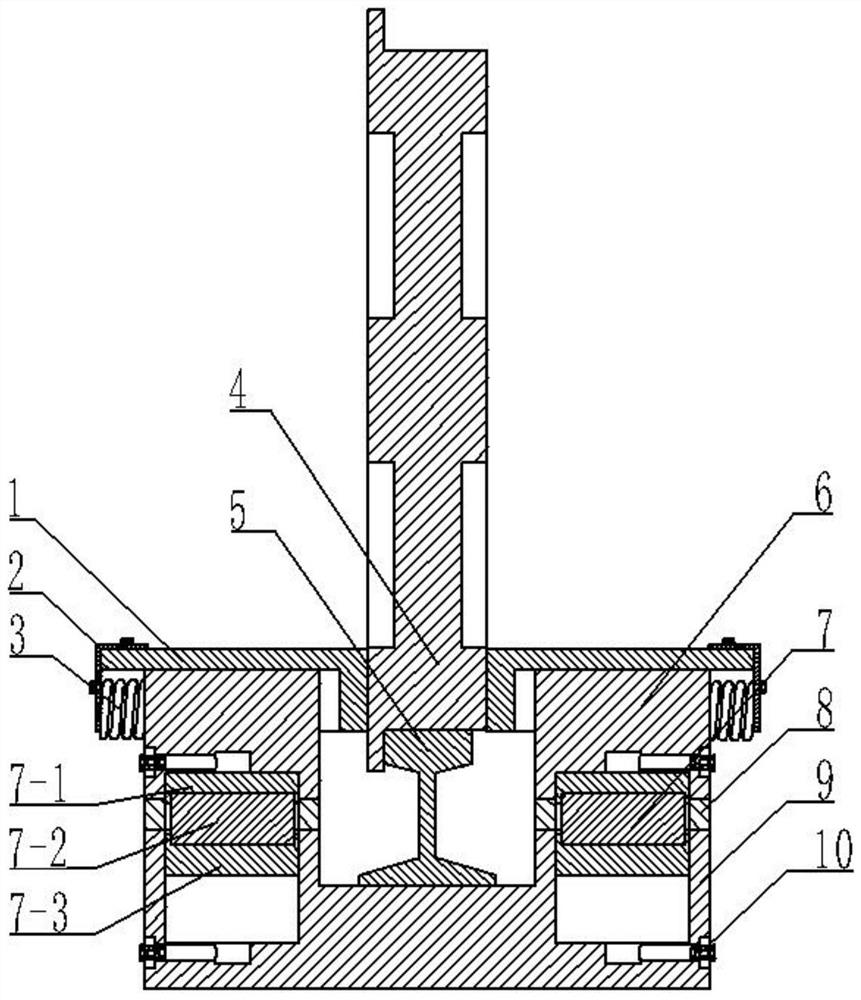

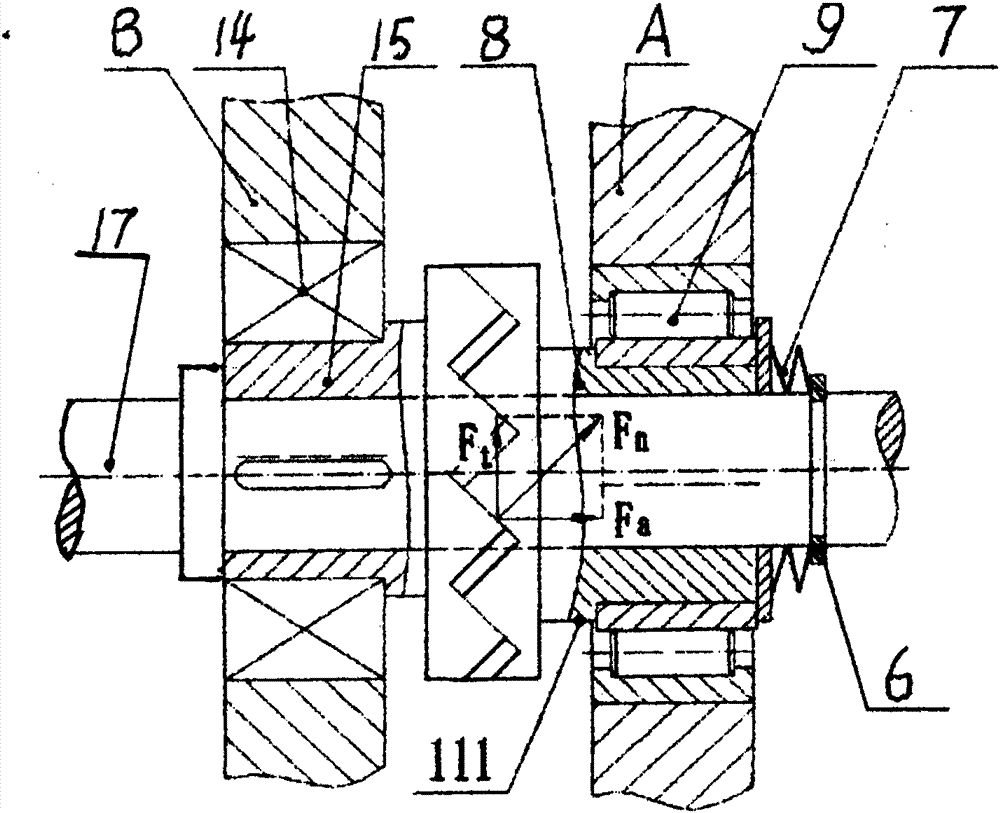

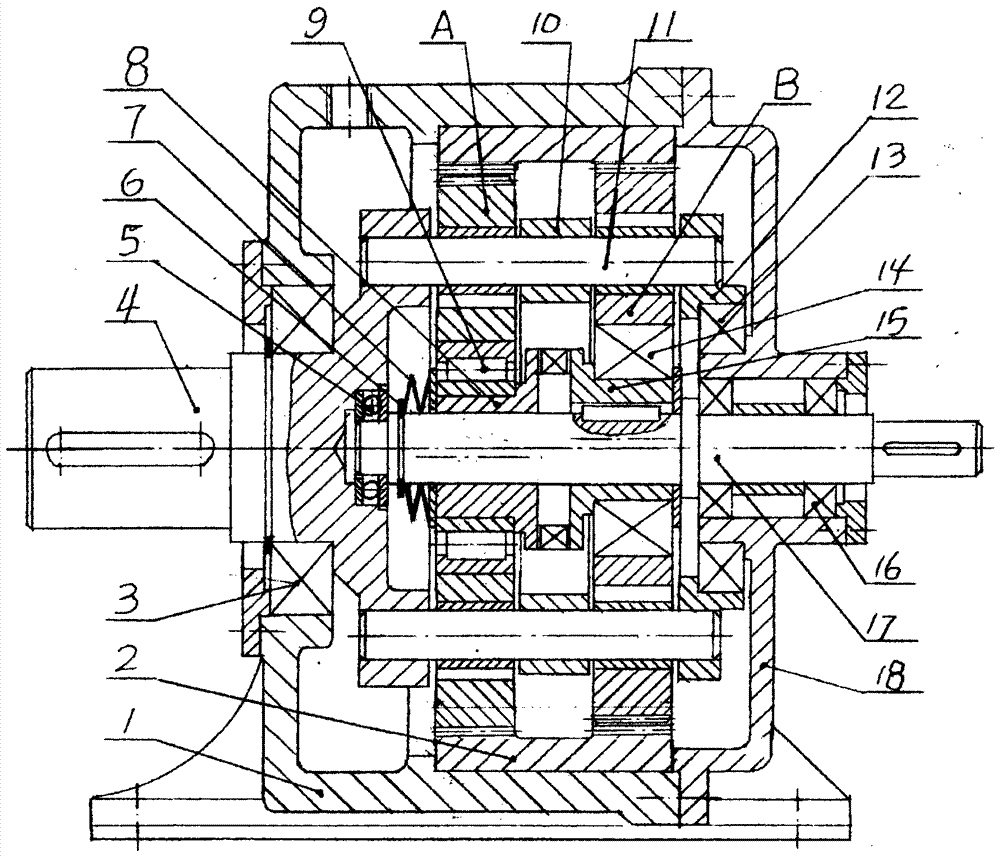

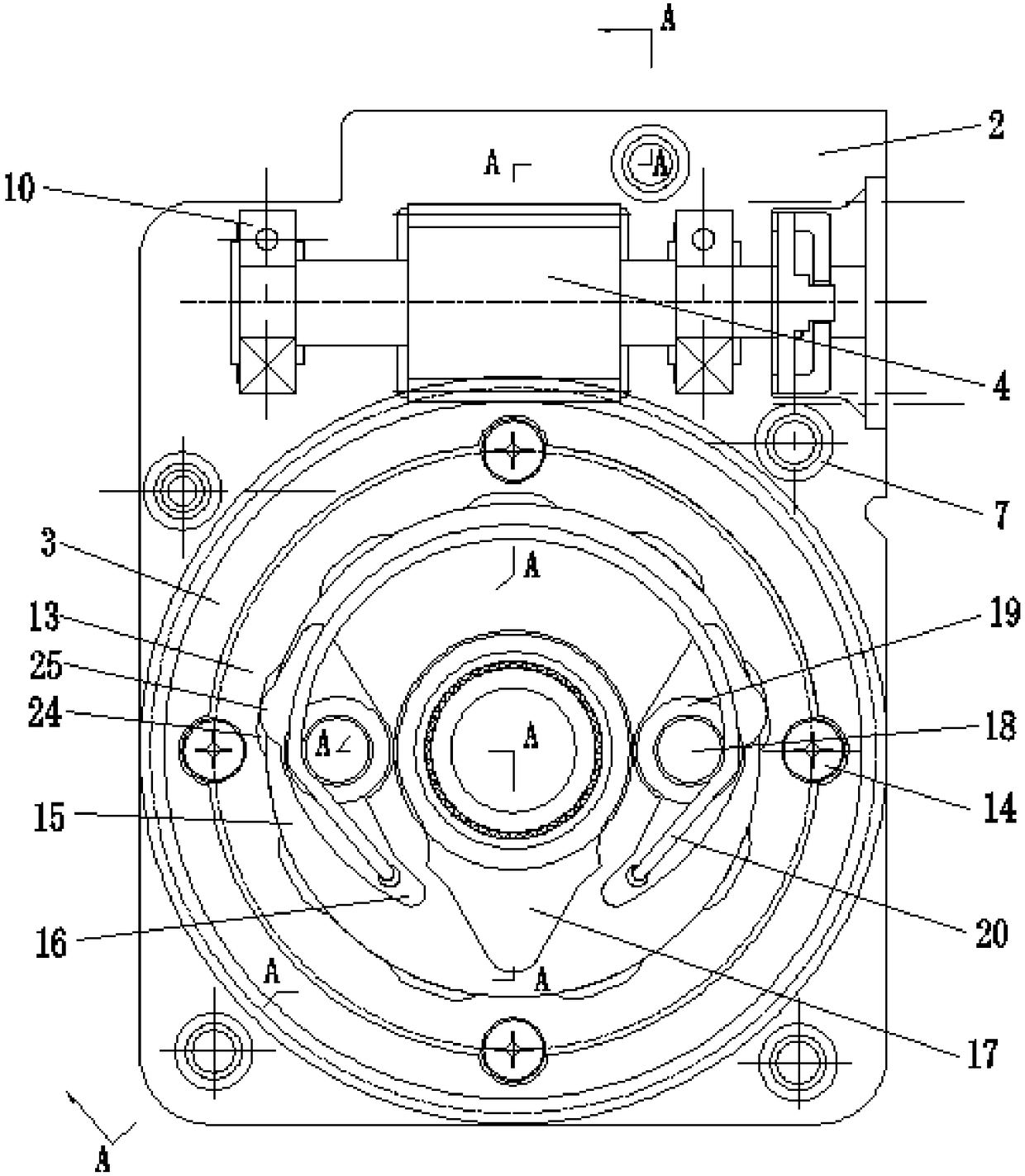

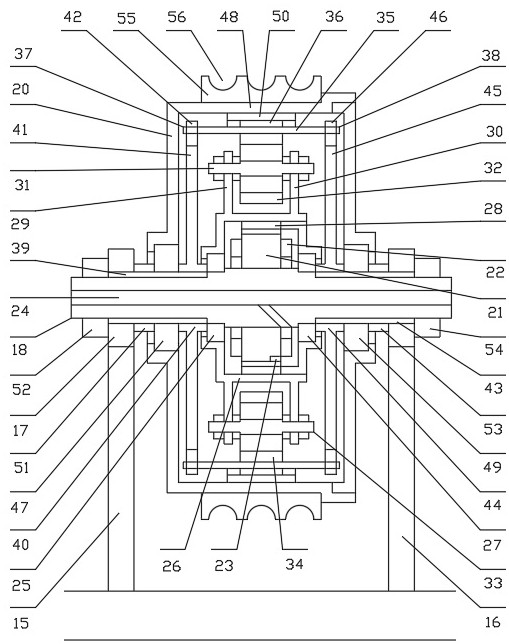

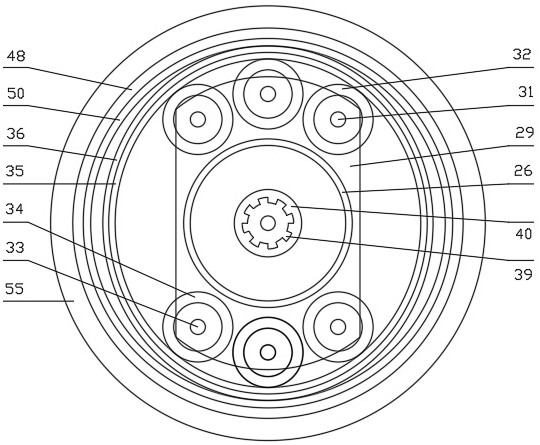

Zero-return-difference involute small-tooth-difference reduction box

ActiveCN104747658ADifferent performanceEasy to processToothed gearingsGearing detailsThree levelPhase difference

The invention relates to the technical field of involute small tooth differences, in particular to a zero-return-difference involute small-tooth-difference reduction box which comprises a base, planet wheels A and B, an inner gear ring, an input shaft, an end cover and a w-shaped output mechanism. The zero-return-difference involute small-tooth-difference reduction box is characterized in that the inner gear ring is connected to an inner hole of the base, and wheel teeth of the planet wheel B are abut against the anticlockwise side of inner teeth in an upper half area of the inner gear ring; wheel teeth of the planet wheel A abut against the clockwise side of the inner teeth in the lower half area of the inner gear ring, and the phase difference between the two planet wheels is smaller than 180 degrees; a check ring is arranged at the extending end of an input shaft, two eccentric bushings are arranged between the check ring and the shoulder of the input shaft, the inner end faces of the two eccentric bushings are provided with trapezoid teeth which are meshed with each other, the second eccentric bushing is connected to the input shaft, the outer end of the second eccentric bushing abuts against the shoulder of the input shaft, the first eccentric bushing is matched with the input shaft in a sliding mode, and a spring is arranged between the outer end of the first eccentric bushing and the elastic check ring. The zero-return-difference involute small-tooth-difference reduction box has the advantages that the manufacturing technique is simple, zero return difference is achieved, the reduction box can be applied to a radar rotation tracking reduction gear and the like, is high in efficiency, can replace three levels of planet gears, is large in transmission ratio, small in size, low in weight, stable in operation, and convenient to assemble and disassemble, and the tooth profile is easy to machine.

Owner:ZHEJIANG HUIXIN DRIVING MACHINE

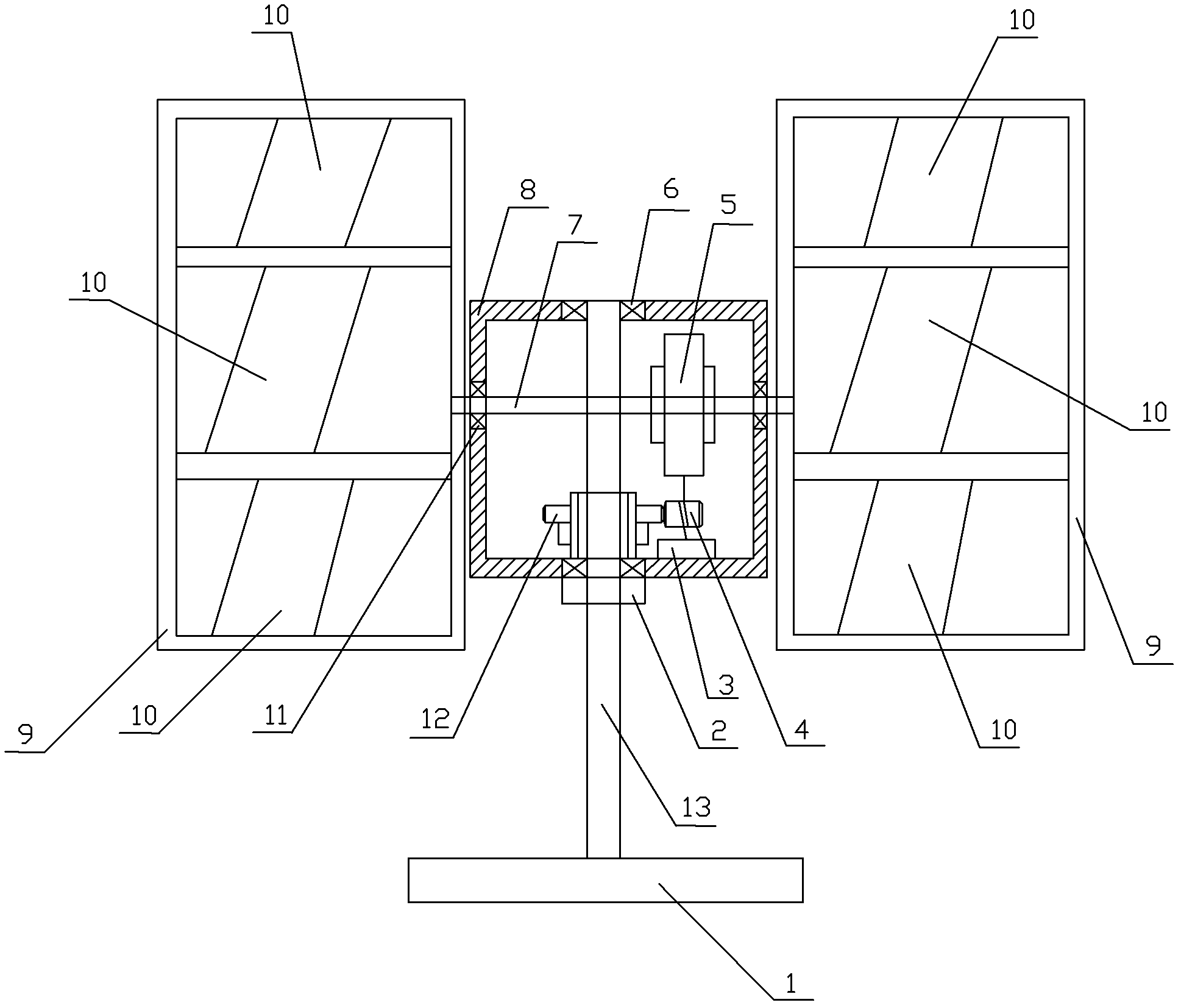

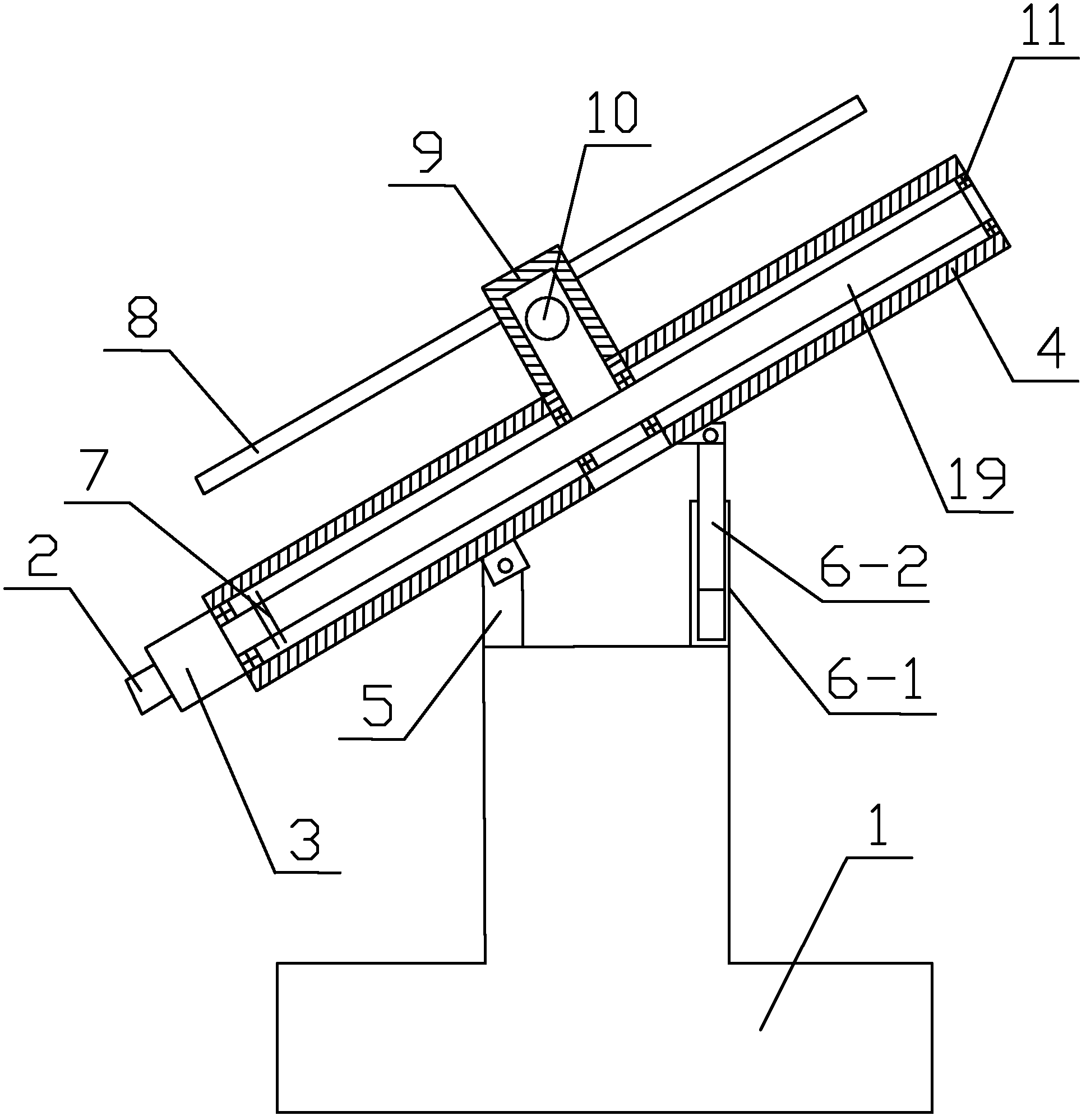

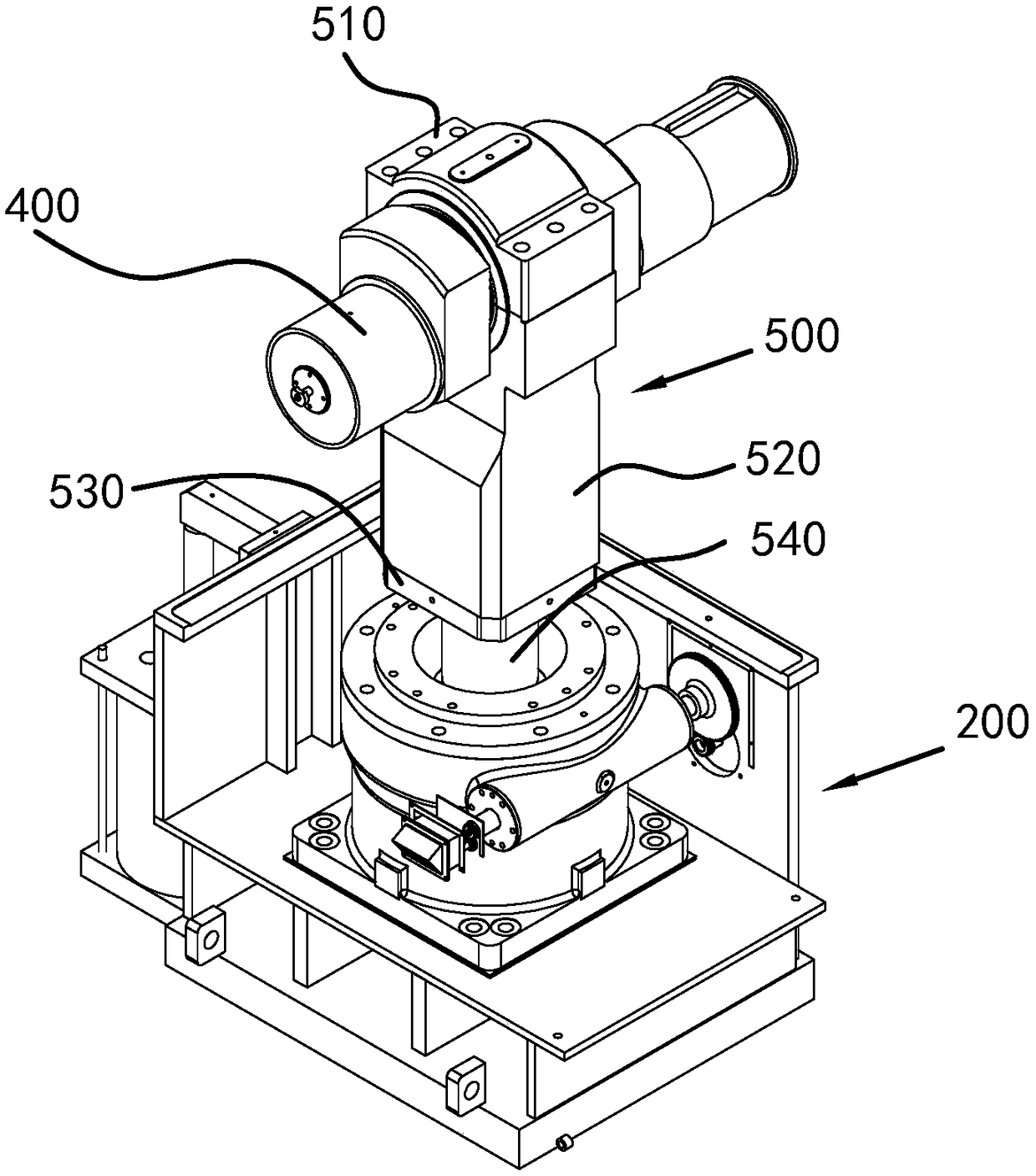

Double-shaft full-automatic solar tracking mechanism

InactiveCN103135562ASimple structureReasonable designPosition/direction controlElectricityElectromagnetic clutch

The invention discloses a double-shaft full-automatic solar tracking mechanism. The tracking mechanism comprises a transmission case, a horizontal spindle, a vertical spindle, a base and two photovoltaic brackets, wherein the horizontal spindle and the vertical spindle are installed in the transmission case in a cross mode, the base is rotatably connected at the bottom of the vertical spindle, the two photovoltaic brackets are fixedly connected at two ends of the horizontal spindle, and a plurality of solar photovoltaic panels are installed on each two photovoltaic bracket. A servo motor, a transmission gear, a reducer and an electromagnetic clutch are mounted in the transmission case, the transmission gear and the reducer are connected with the servo motor, the electromagnetic clutch is meshed with the transmission gear, the reducer is connected with the horizontal spindle, and the electromagnetic clutch is connected with the vertical spindle. The tracking mechanism is simple in structure, reasonable in design, convenient to install, easy to implement, low in maintenance and operation costs, high in working reliability, capable of farthest improving the generating efficiency of the solar photovoltaic panels and widely applicable to remote non-electricity areas.

Owner:XIAN DAYU PHOTOELECTRIC TECH

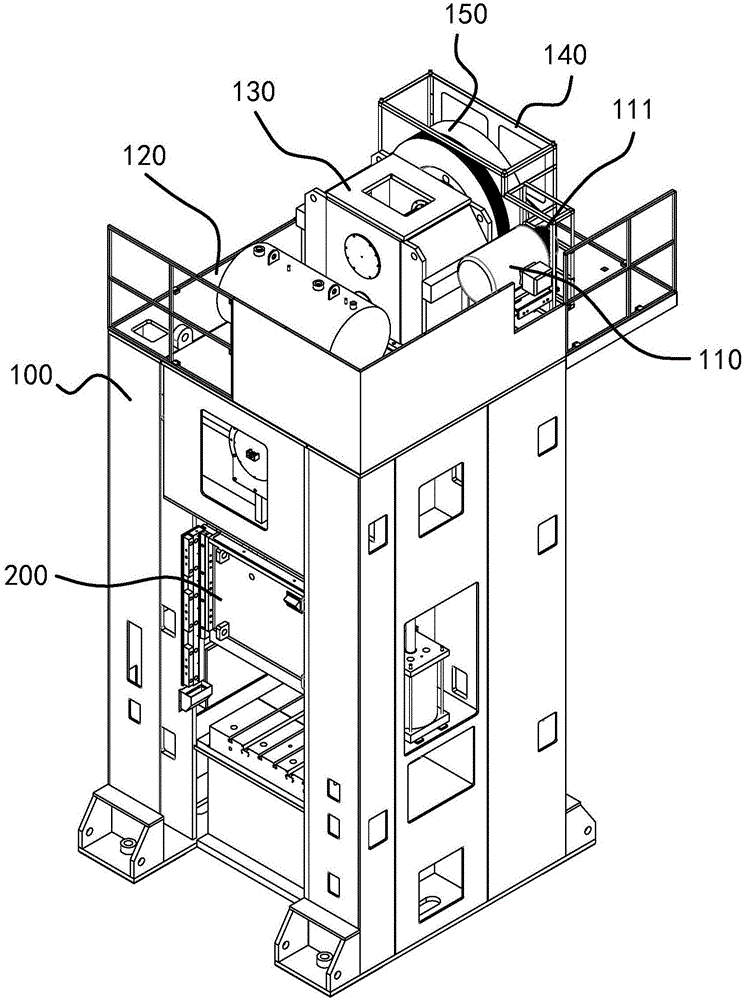

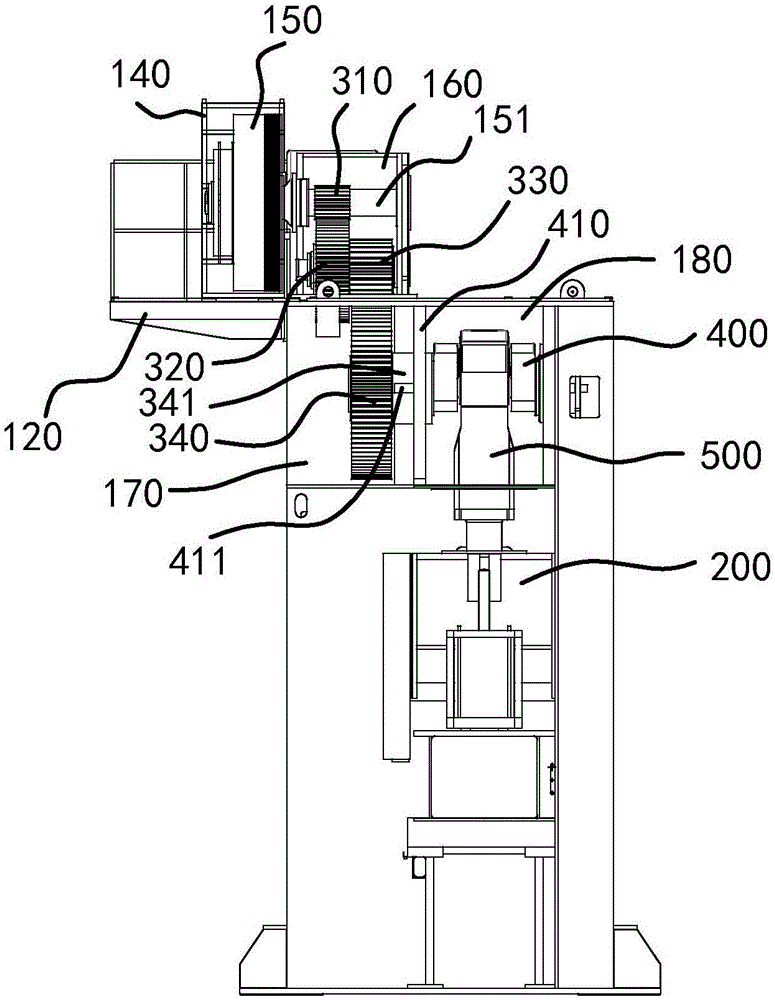

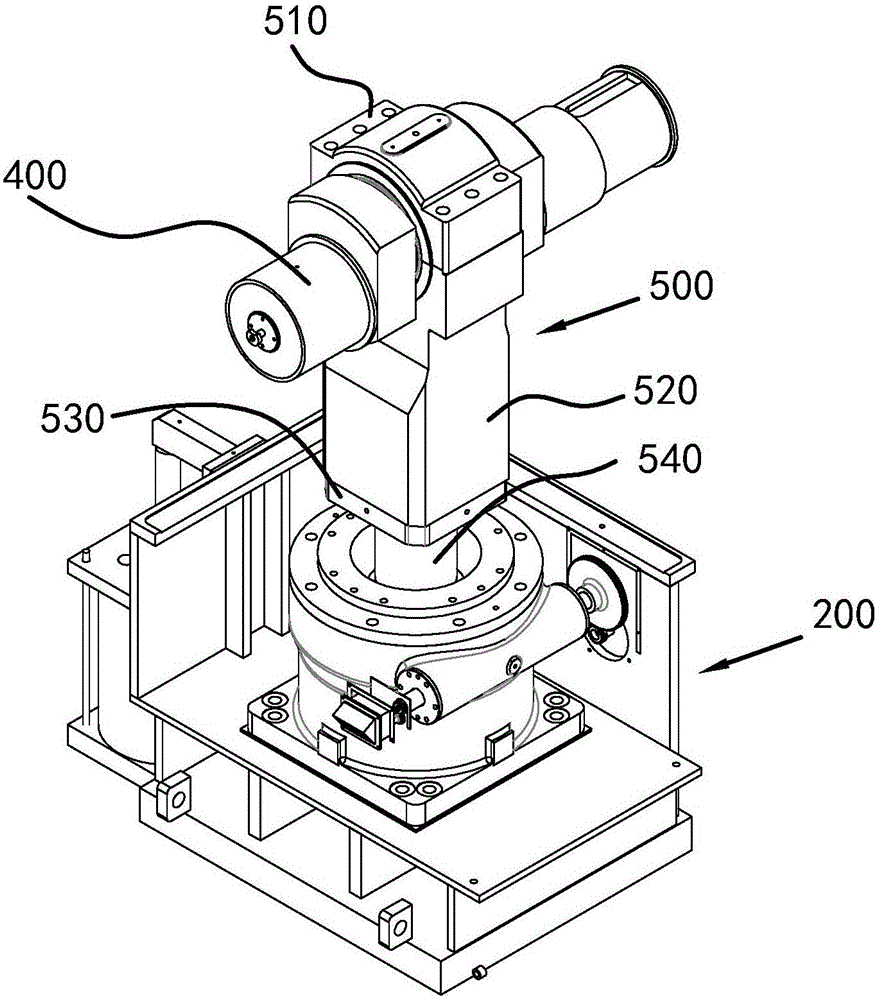

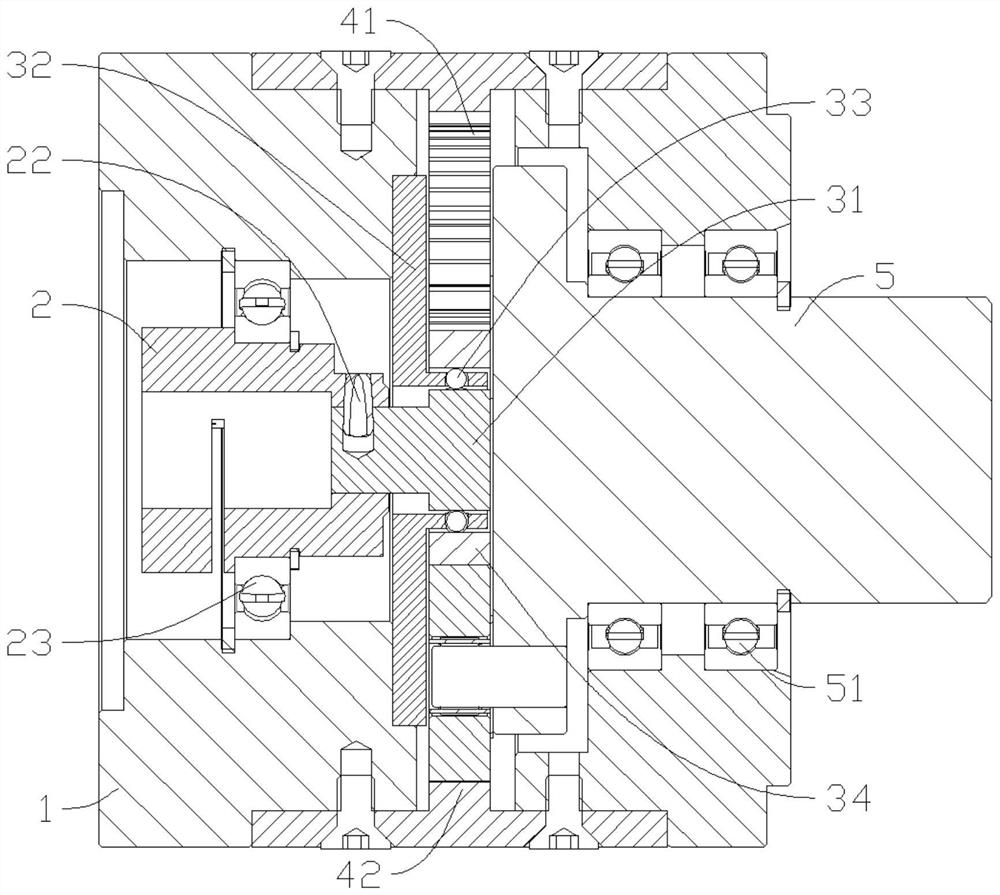

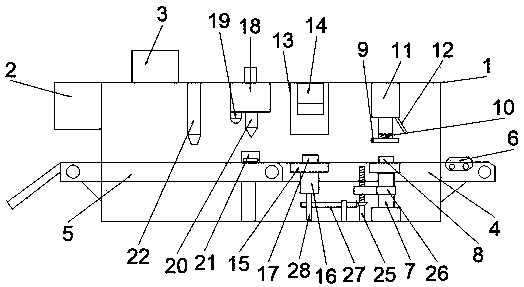

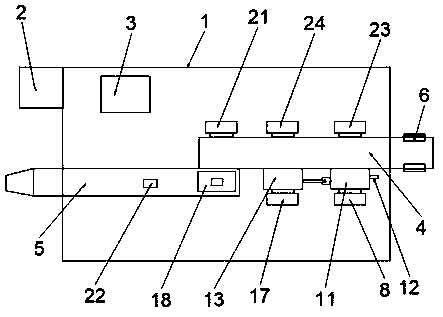

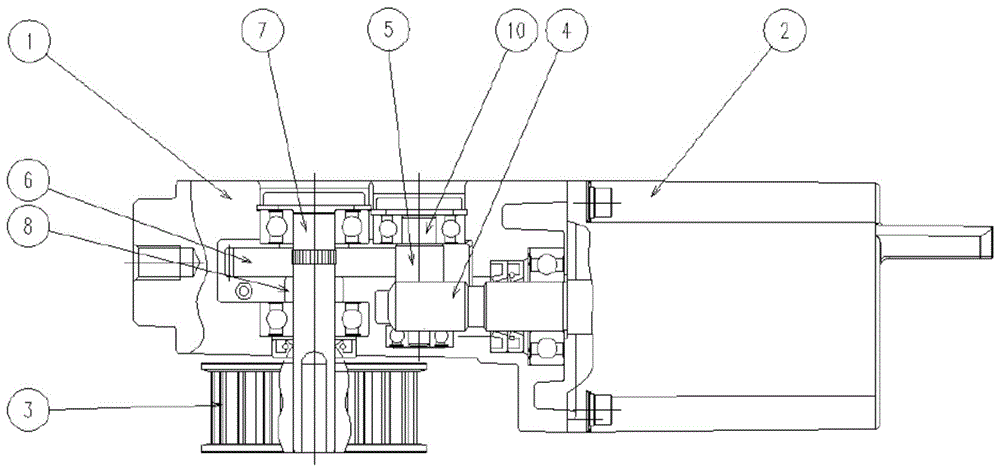

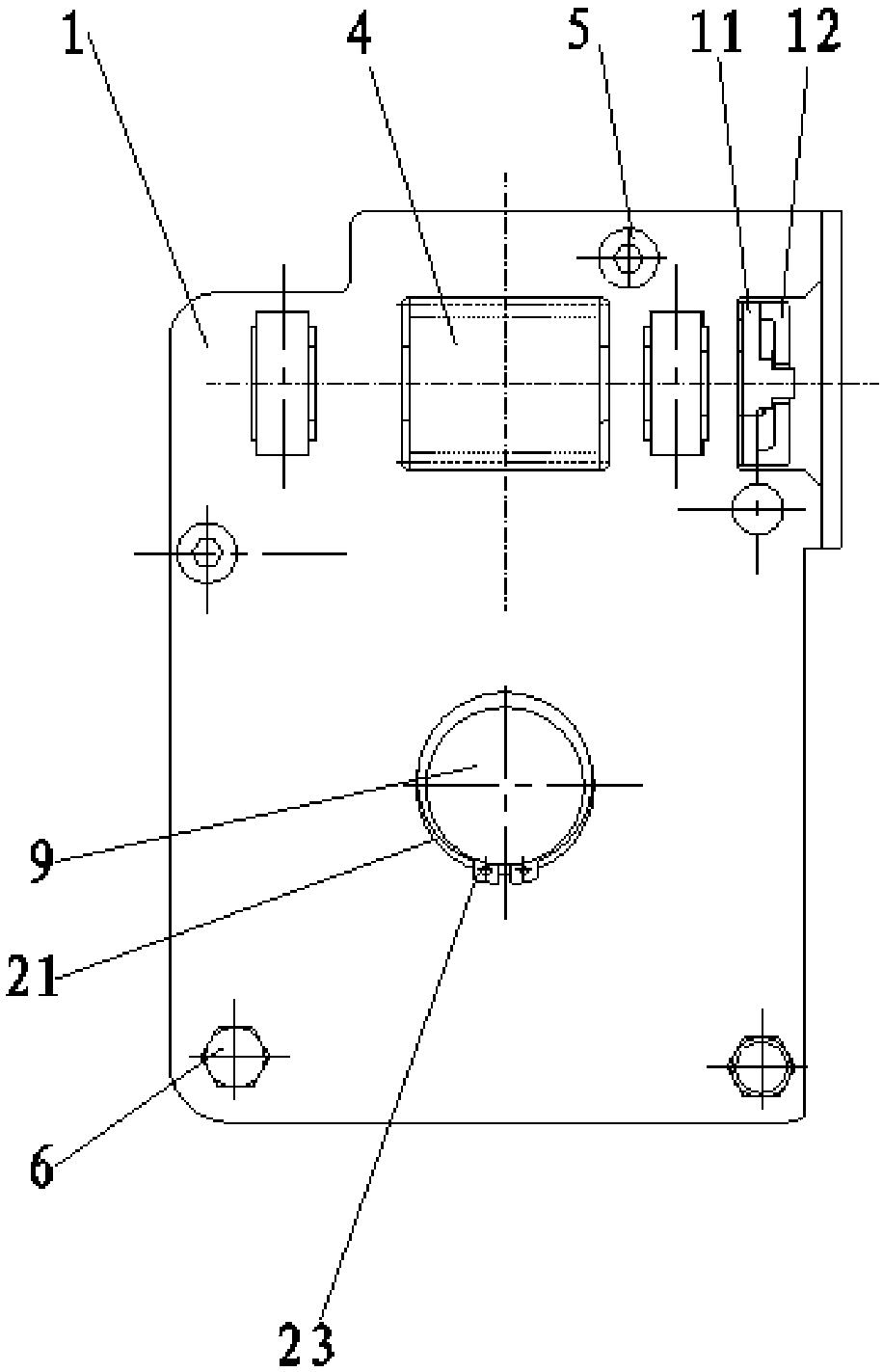

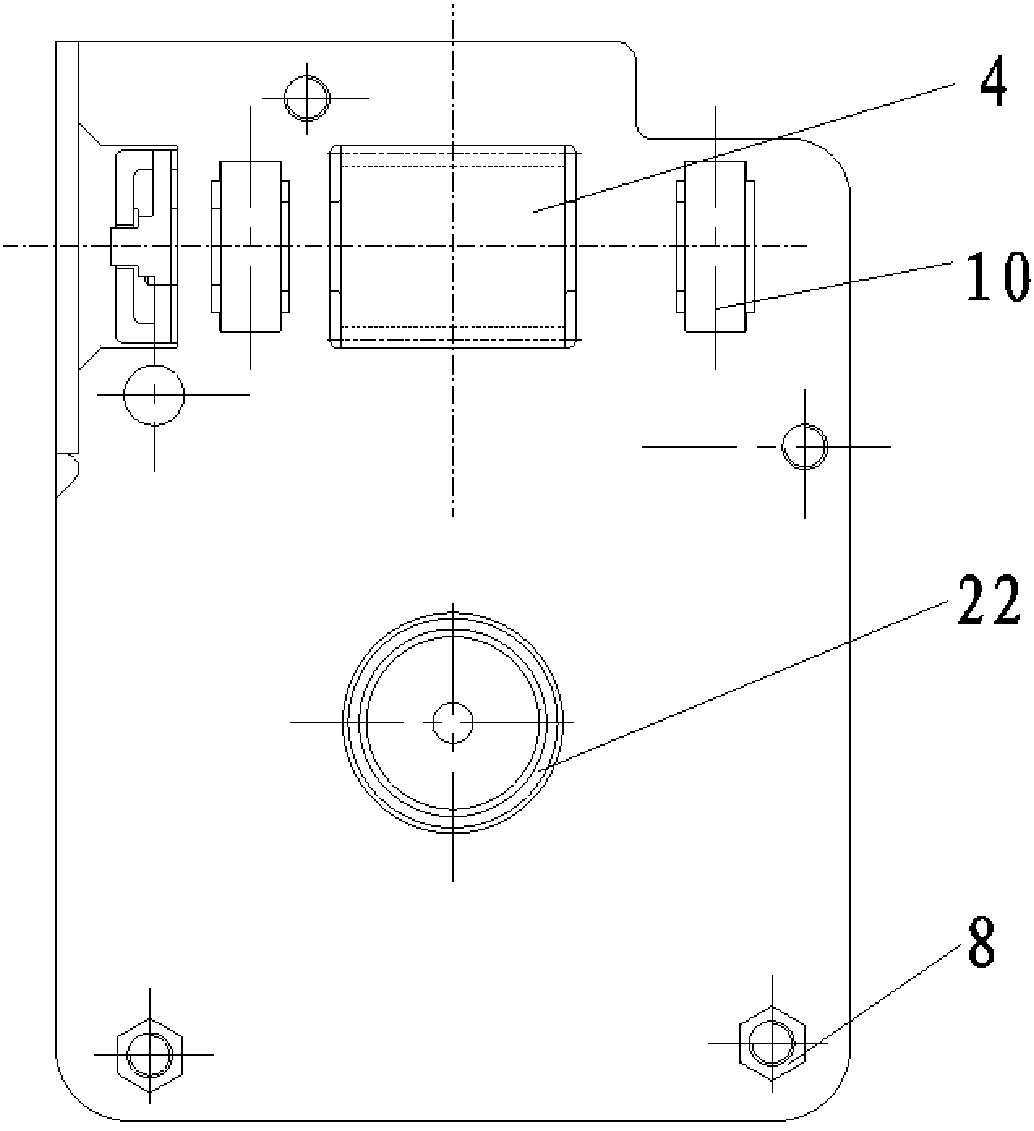

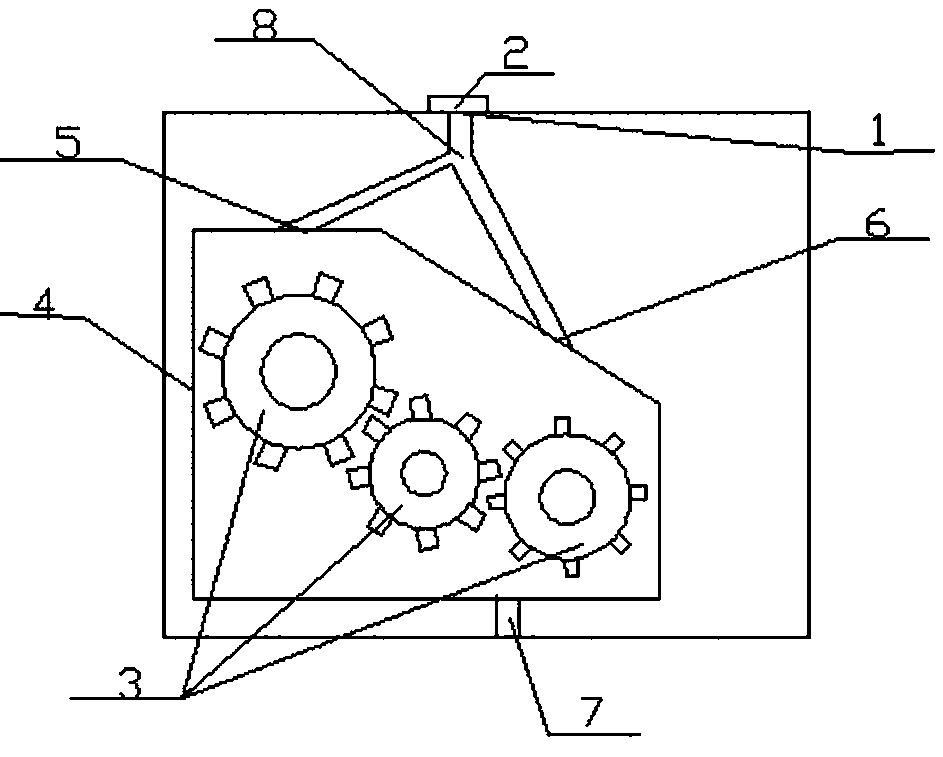

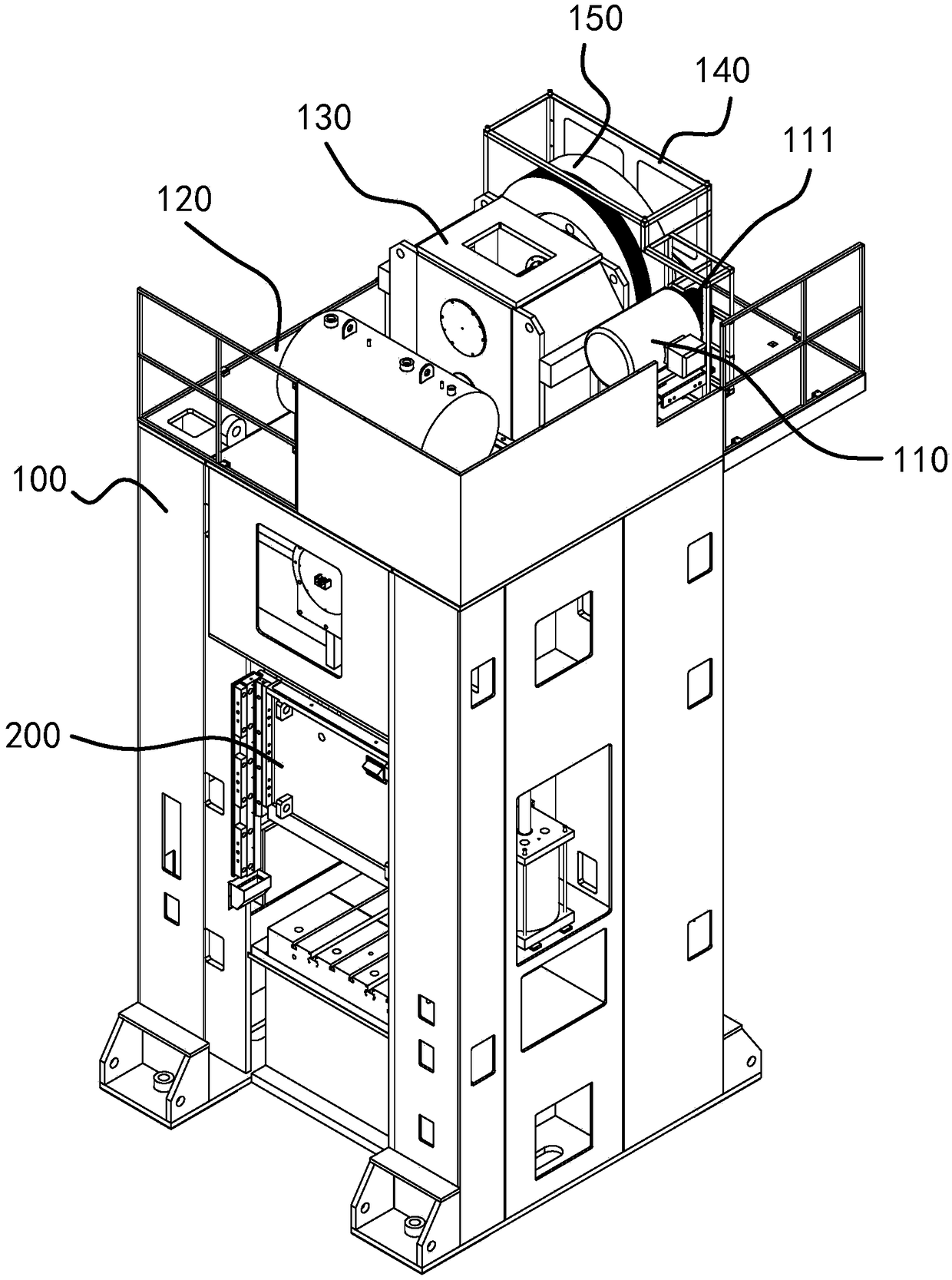

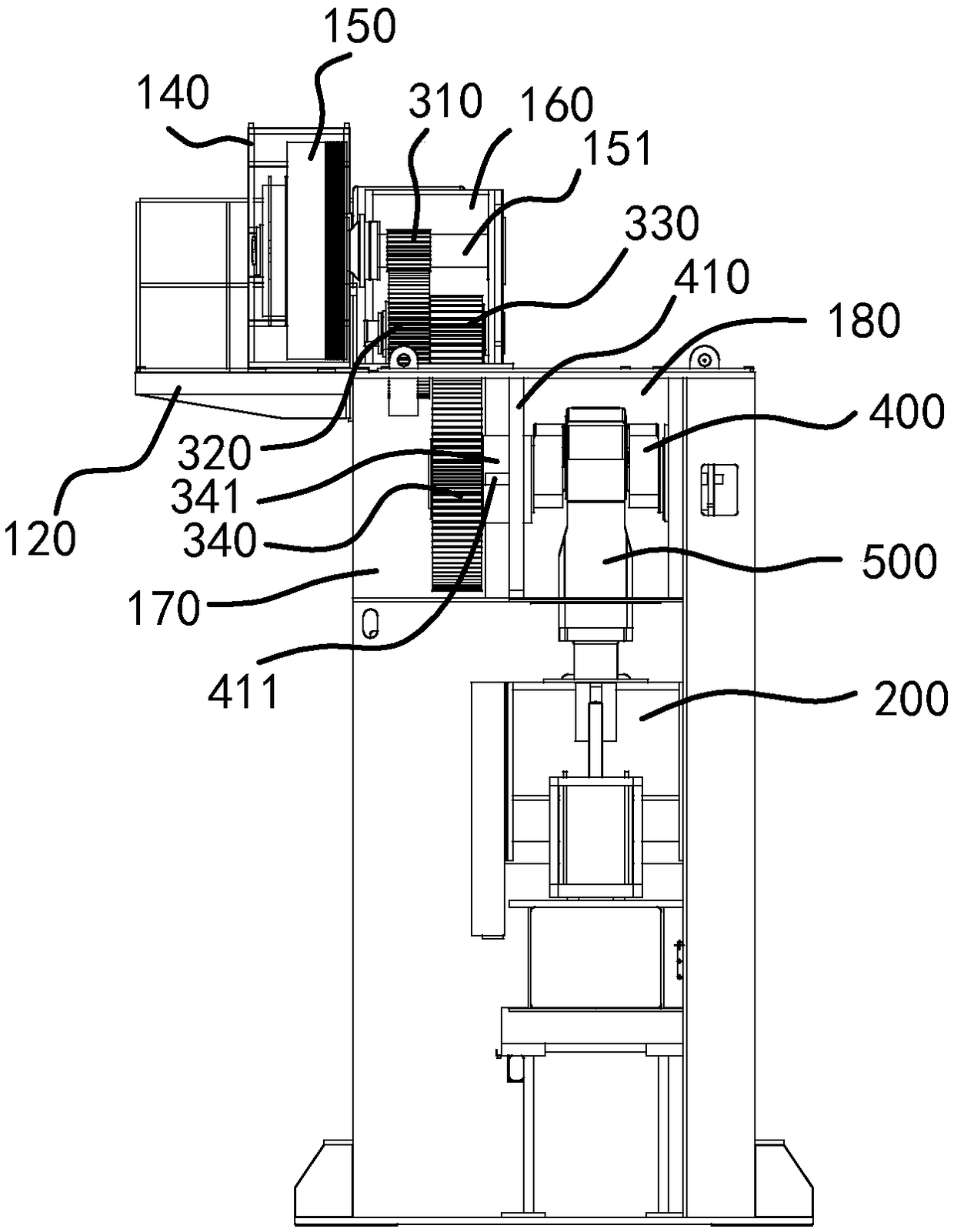

Punching device for punching machine

The invention provides a punching device for a punching machine, and belongs to the technical field of machines. The punching device solves the technical problems that an existing punching structure of a punching machine is poor in structure stability and large in abrasion. The punching device comprises an installation support, a motor, a retarding mechanism, a crankshaft and a connecting rod; the installation support is provided with an installation plate, a first installation position is arranged on the upper end face of the installation plate, a second installation position and a third installation position are arranged on the lower end face of the installation plate; the motor is arranged on the side portion of the first installation position and is provided with a power shaft, and a rotary wheel is connected to the power shaft in a sleeving manner; the retarding mechanism comprises a flywheel and multiple stages of reduction gears, the multiple stages of reduction gears are arranged in the first installation position and the second installation position correspondingly, and the flywheel is in transmission connection with the rotary wheel and is in transmission connection with the multiple stages of reduction gears; the crankshaft is arranged in the third installation position and is in transmission connection with the multiple stages of reduction gears; and the connecting rod is arranged on a crank throw of the crankshaft, and a punching pin is connected to the lower end of the connecting rod. The punching device has the beneficial effects of being high in stability and small in abrasion.

Owner:宁波澳玛特高精冲压机床股份有限公司

Efficient planet gear speed reducer with cooling function

InactiveCN107131293AWith waterproof functionImprove deceleration efficiencyGear lubrication/coolingToothed gearingsCooling effectReducer

The invention discloses a high-efficiency planetary gear reducer with heat dissipation function, which includes an outer shell, an inner shell, a first sun gear and a first planetary gear; the high-efficiency planetary gear reducer with heat dissipation function of the present invention, through There are several heat dissipation holes on the shell wall, which can dissipate the heat in the inner shell, and a number of arc-shaped heat dissipation pipes are symmetrically arranged on both sides of the shell wall of the outer shell to discharge the heat from the heat dissipation holes, and the arc-shaped The central position of the heat dissipation pipe is bent upwards, which can prevent the water on the shell wall from flowing into the interior of the shell, and then enter the inner shell through the heat dissipation holes, and damage the equipment in the inner shell. The reducer has a high-efficiency heat dissipation function, which improves its service time, and through the driven action of the planetary gear and the sun gear, the reducer can have a high-efficiency deceleration function, good cooling effect, high deceleration efficiency, and easy promotion and use.

Owner:JIANGSU OUBANG MOTOR MFG CO LTD

Two-dimensional sunlight automatically tracking device

InactiveCN103135561ACompact structureReasonable designPosition/direction controlRotational stabilityEngineering

The invention discloses a two-dimensional sunlight automatically tracking device which comprises a bearing frame, a first supporting column and a second supporting column which are arranged at the top end of the supporting frame and an inclined rotation mechanism housing and a horizontal rotation mechanism housing which are cradled at the top end of the first supporting column and the second supporting column. An inclined rotation shaft which is connected with an inclined rotation power mechanism is arranged in the inclined rotation mechanism housing; a small gear shaft which is provided with a small gear is arranged in the horizontal rotation mechanism housing; the horizontal rotation mechanism housing which is arranged above the small gear shaft is provided with a horizontal rotation shaft; the horizontal rotation shaft is provided with a big gear which is meshed with the small gear; the end portion of one end of the small gear shaft is connected with a horizontal rotation power mechanism; and two ends of the horizontal rotation shaft are respectively provided with a solar cell panel. The two-dimensional sunlight automatically tracking device has the advantages of being compact in structure, reasonable in design, convenient to install, convenient and rapid to use, high in rotating stability and tracking precision, low in achievement cost, power consumption and operating cost, good in using effect and convenient to popularize and utilize.

Owner:XIAN DAYU PHOTOELECTRIC TECH

Coaxial multi-stage gearbox

InactiveCN105889464AReduce lossExtended service lifeGearboxesToothed gearingsGear wheelOutput device

The invention discloses a coaxial multi-stage gearbox. The coaxial multi-stage gearbox comprises a box body, wherein a driving device and a speed changing adjusting device are arranged in the box body; the speed changing adjusting device can be engaged with the driving device so that the driving device outputs various powers; the driving device comprises an input system and an output system; the input system comprises an input driving gear shaft; the output system comprises an output spindle which can be engaged with the input driving gear shaft and outputs power; the speed changing adjusting device comprises a clutch gear; and the output spindle penetrates through the clutch gear. The box body comprises a first shell; the output system comprises a driving output device and a driven output device; the driving output device comprises an output spindle and a first clutch inner gear ring which is fixedly arranged on a reverse side, which is opposite to the first shell, of the clutch gear; and the driven output device comprises a second clutch inner gear ring. The coaxial multi-stage gearbox has the advantages that a speed changing range is large, retardation efficiency is high, various powers can be output, speed changing in various grades is realized, and an infinite step speed changing range can be obtained.

Owner:ZHEJIANG HUIXIN DRIVING MACHINE

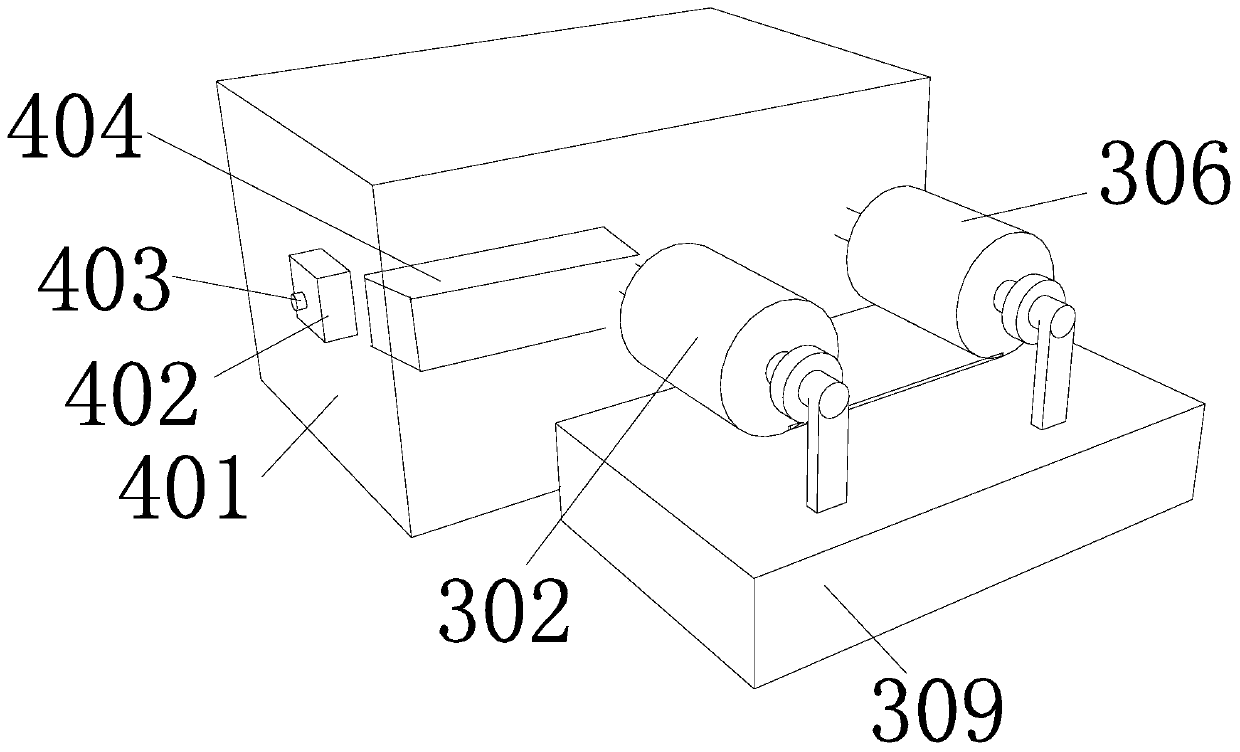

High-reduction-efficiency reducer exclusive to tension leveling of continuous casting machine

PendingCN111594594ADecelerate fastImprove efficiencyGearingMechanical energy handlingDrive shaftReduction drive

The invention relates to the technical field of mechanical equipment, and discloses a high-reduction-efficiency reducer exclusive to tension leveling of a continuous casting machine. The reducer comprises a driving device, a transmission device, a rotating device and a controlling device. The driving device comprises a motor; a motor rotating shaft is arranged on the motor; a transmission shaft Iis fixedly connected with the left side face of the motor rotating shaft; a conical gear I is fixedly connected with the left side face of the transmission shaft I; a conical gear II is engaged with the conical gear I; a transmission shaft II is fixedly connected with the rear side face of the conical gear II; a fixing sleeve ring I is connected with the circumferential surface of the transmissionshaft II in a penetrating mode; the transmission device comprises a gear I and a track; a transmission shaft II is fixedly connected with the front side face of the gear I; a gear II and a gear III are engaged with the gear I; a toothed groove is formed in the inner side face of the track; and the gear II and the gear III are engaged with the toothed groove. When the motor is initiated, the rotating direction of the gear II and the gear III is opposite to the rotating direction of the motor rotating shaft I and a motor rotating shaft II, so rapid reduction of equipment is realized.

Owner:TIANJIN CORE PRECISION MECHANICAL ELECTRIC EQUIP

Cycloid planetary gear speed reducing mechanism

PendingCN113565932AIncrease gear ratioLarge reduction ratioGear vibration/noise dampingToothed gearingsPrime moverGear wheel

The invention relates to the technical field of speed reducers, and discloses a cycloid planetary gear speed reducing mechanism comprising a shell, a coupler and an output shaft. The coupler and the output shaft are both rotationally connected with the shell, a first-stage speed reducing assembly and a second-stage speed reducing assembly are arranged in the shell, and the coupler penetrates into the shell and then is connected with the first-stage speed reducing assembly. The output shaft penetrates into the shell and then is connected with the second-stage speed reducing assembly, and the first-stage speed reducing assembly is connected with the second-stage speed reducing assembly. A prime motor works to drive the coupler to rotate, the coupler drives the first-stage speed reducing assembly to work, and first-stage speed reduction is achieved; the first-stage speed reducing assembly and the second-stage speed reducing assembly cooperate to drive the second-stage speed reducing assembly to work, and second-stage speed reduction is achieved; and the transmission ratio of the speed reducing mechanism is effectively increased through cooperation of two-stage speed reduction effects, and the cycloid planetary gear speed reducing mechanism is simple in structure and has the advantages of being large in speed reduction ratio, small in axial size, large in output torque and low in noise.

Owner:合肥波林新材料股份有限公司

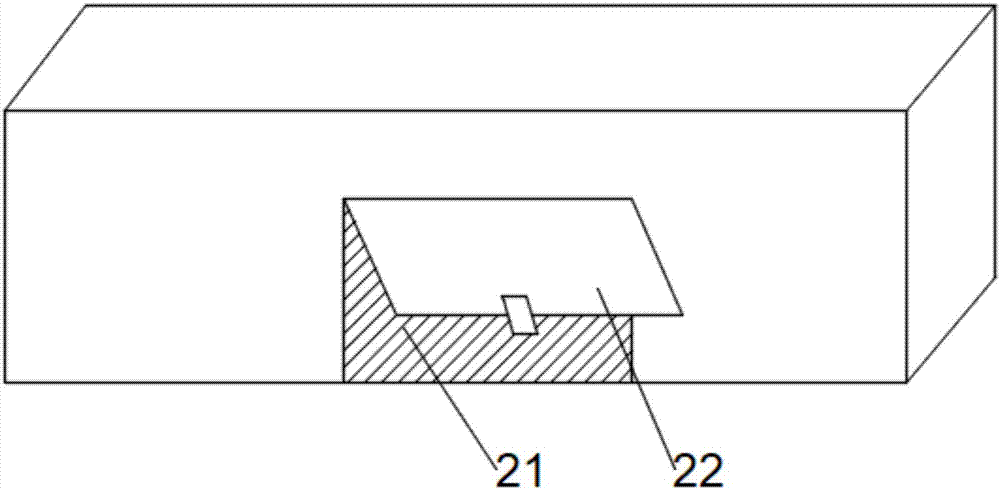

Automatic test equipment

InactiveCN111307607AShort stayImprove deceleration efficiencyWeather/light/corrosion resistanceMaterial heat developmentCorrosion resistantElectrical connection

The invention relates to automatic test equipment. The equipment comprises a shell, a transmission mechanism and a controller, the controller is fixed on outer side of shell, and the transmission mechanism is fixed in the shell; the conveying mechanism comprises a first conveying belt and a second conveying belt. The first conveying belt is parallel to the second conveying belt; the second conveying belt is located on the left side of the first conveying belt. A compression resistance testing mechanism and a heat insulation testing mechanism are sequentially arranged beside the first conveyingbelt in the conveying direction. A corrosion resistance testing mechanism is arranged right above the second conveying belt; the first conveying belt, the second conveying belt, the compression resistance testing mechanism, the heat insulation testing mechanism and the corrosion resistance testing mechanism are all electrically connected with the controller, the compression resistance testing mechanism is connected with the heat insulation testing mechanism through the transmission device, automatic testing of plates is achieved, and the testing efficiency of the plates is improved.

Owner:李跃华

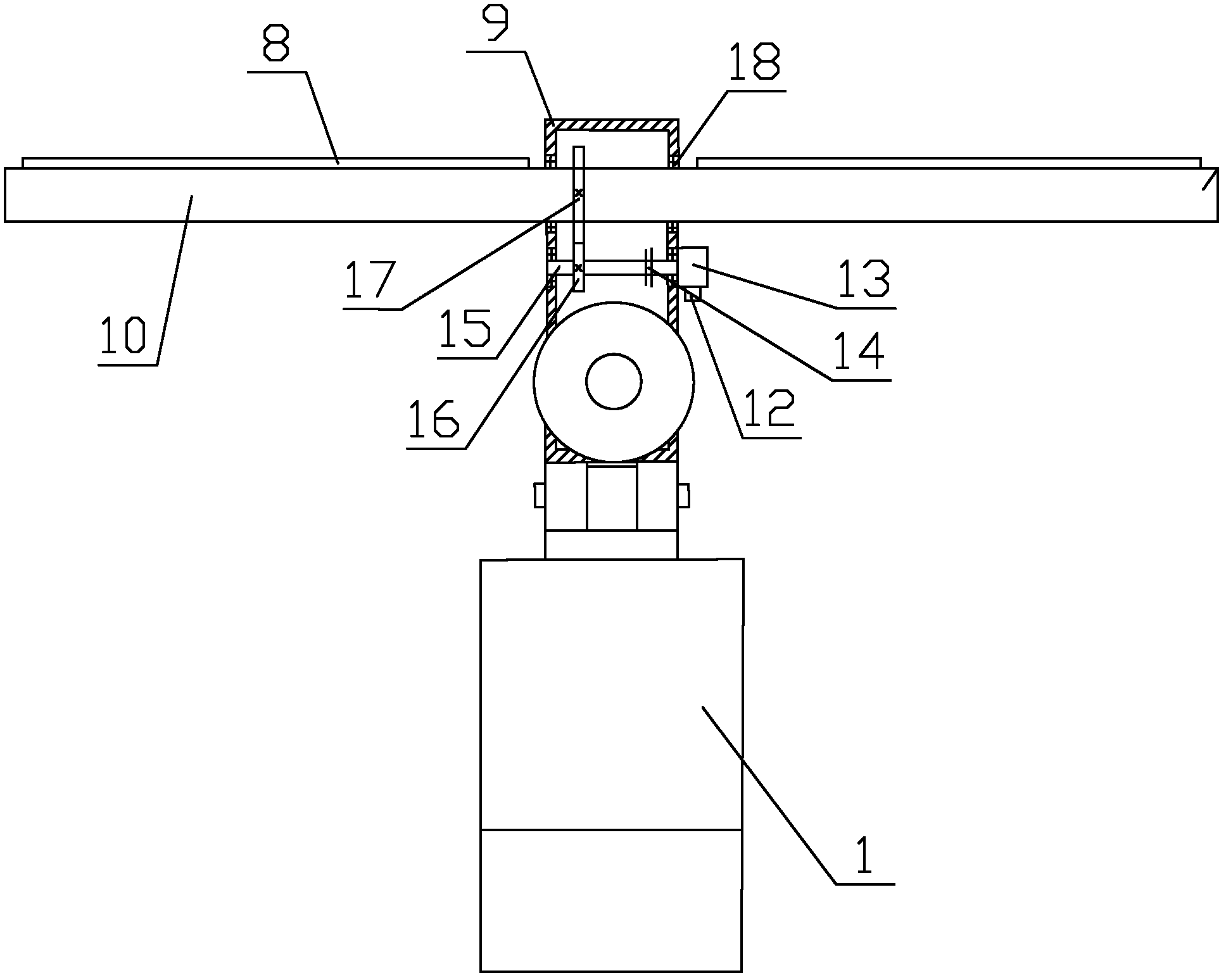

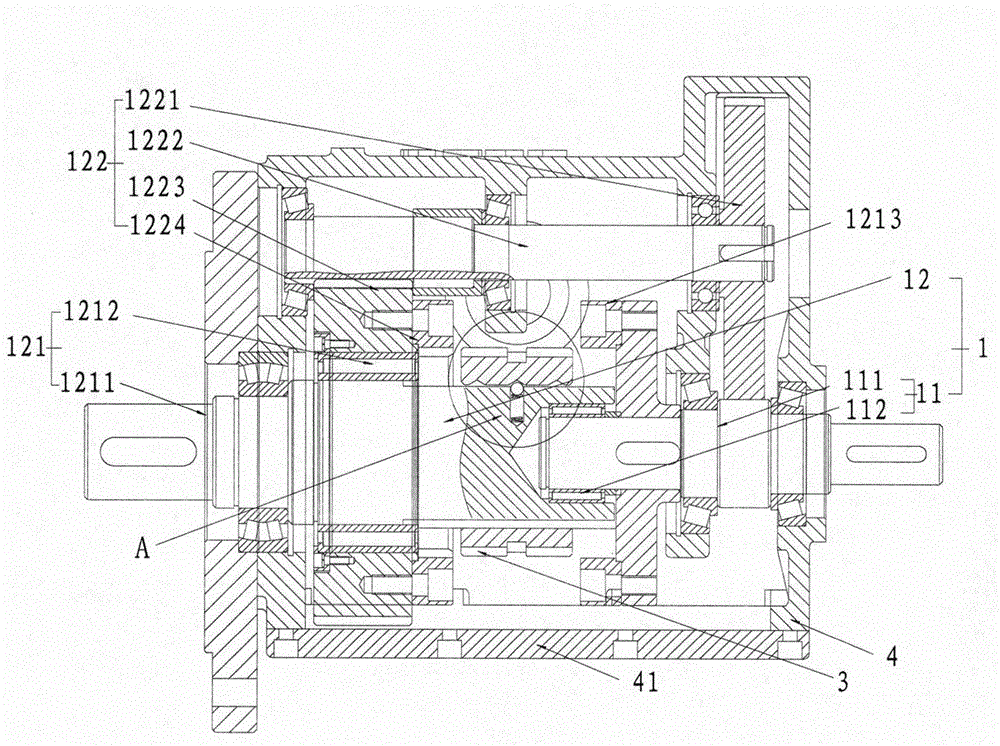

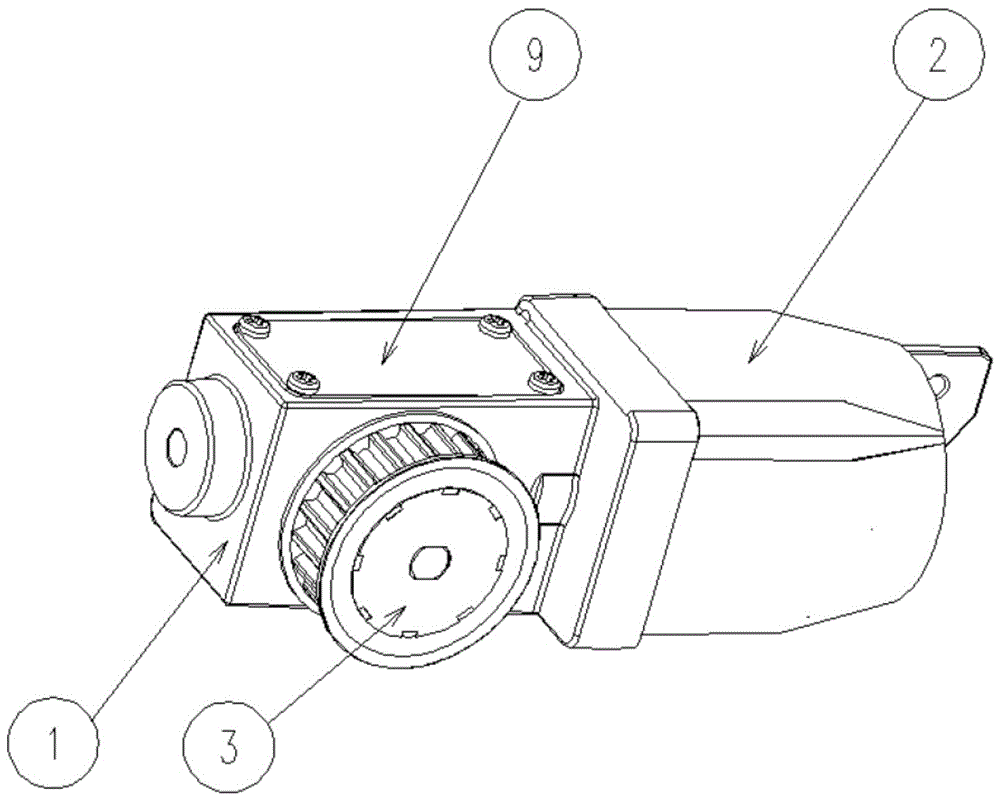

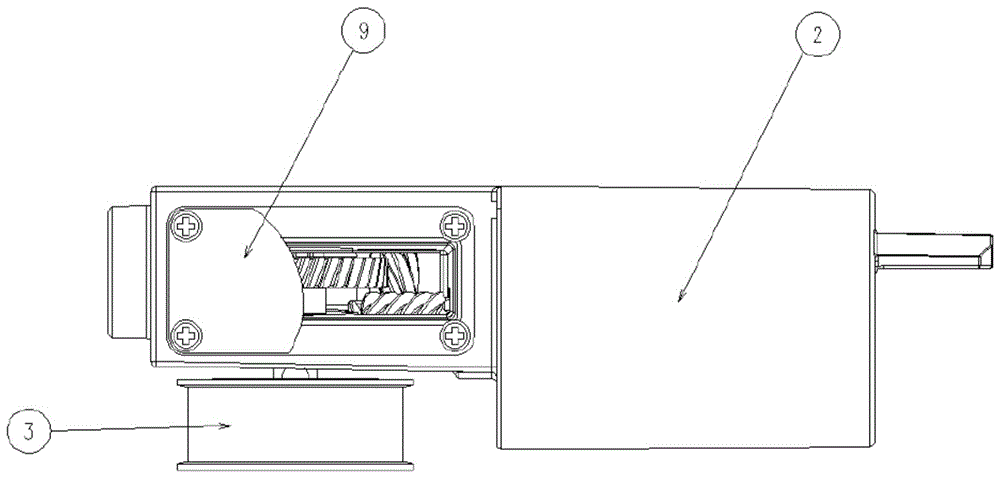

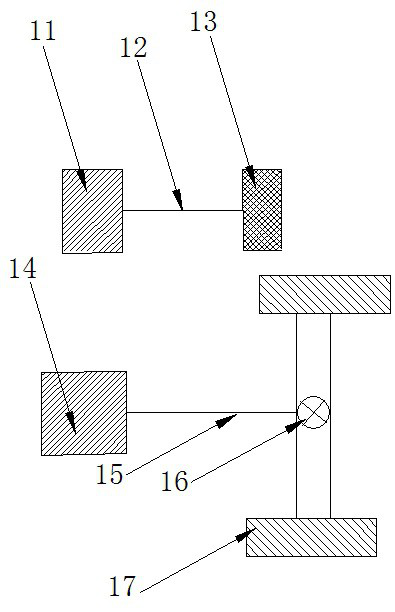

Motor system with precisely controllable output rotating speed

ActiveCN113131668ACompact designImprove deceleration efficiencyMechanical energy handlingControl engineeringElectric machinery

The invention discloses a motor system with precisely controllable output rotating speed. The motor system comprises a shell, a power member, a speed reduction switching piece, a speed reduction piece and a deceleration switching output piece; the speed reduction switching piece comprises a first speed reduction switching part, a second speed reduction switching part and a third speed reduction switching part, the first speed reduction switching part, the second speed reduction switching part and the third speed reduction switching part are all arranged on the power member; the speed reduction piece comprises a first speed reduction part, a second speed reduction part and a third speed reduction part; the first speed reduction part is in meshing transmission with the first speed reduction switching part, the second speed reduction part is in meshing transmission with the second speed reduction switching part, and the third speed reduction part is in meshing transmission with the third speed reduction switching part; and the deceleration switching output piece comprises a first output piece, a second output piece and a third output piece. The motor system is compact in structural design, high in speed reduction efficiency, high in applicability, large in output torque, low in failure rate, low in maintenance cost, reliable in operation and capable of meeting various precision requirements and output torque requirements.

Owner:JIANGSU UNIV OF SCI & TECH

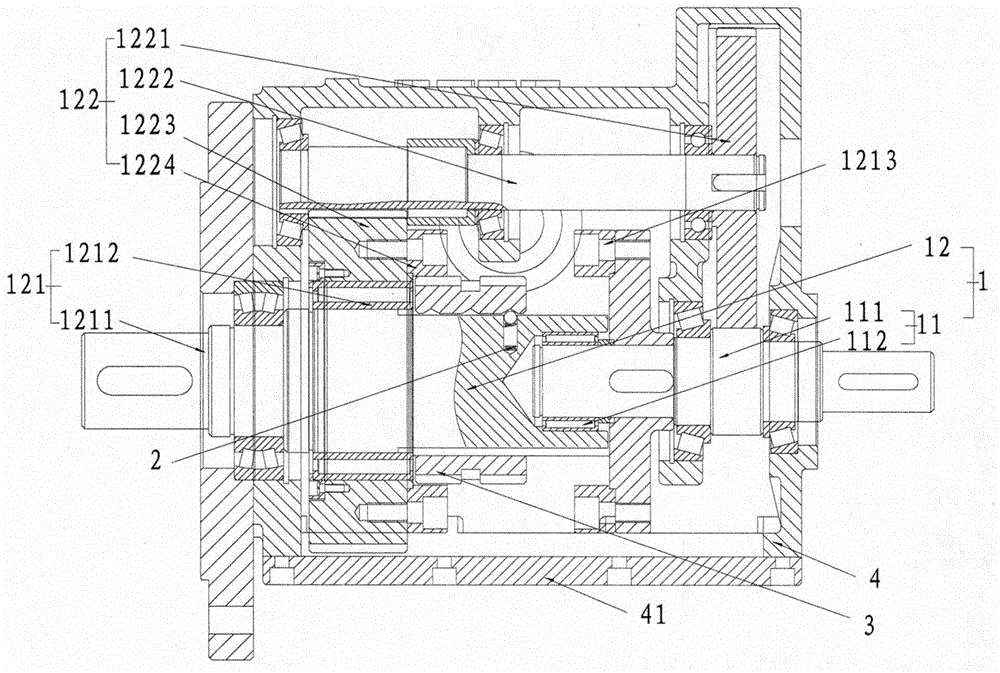

Gear motor aluminum wire motor for stereo garage

ActiveCN111934488AReasonable structural designImprove deceleration efficiencyMechanical energy handlingRotational axisReduction drive

The invention discloses a gear motor aluminum wire motor for a stereo garage, which comprises a speed reduction bearing piece, a speed reduction input piece and a speed reduction output piece, whereinthe speed reduction bearing piece comprises a speed reduction housing, a rotating bearing and a gear speed reducer, the rotating bearing is disposed in the speed reduction housing, and the gear speedreducer is disposed on the rotating bearing; the speed reduction input piece comprises a first transmission input piece, an inserting and pulling piece and a second transmission input piece, the first transmission input piece and the second transmission input piece are both arranged on the gear speed reducer, and the inserting and pulling piece is arranged on the speed reduction housing; the first transmission input piece comprises a first turbine, and the second transmission input piece comprises a second turbine; and the speed reduction output piece comprises a second transmission pipe, a third transmission pipe and a selection output piece, the second transmission pipe and the third transmission pipe are both arranged on the gear speed reducer, and the selection output piece is arranged on the rotary bearing. The gear motor aluminum wire motor is reasonable in structural design, high in speed reduction efficiency, long in service life and capable of achieving various speed reduction modes.

Owner:JIANGSU CHUANTIAN MCN ELECTRICAL MASCH CO LTD

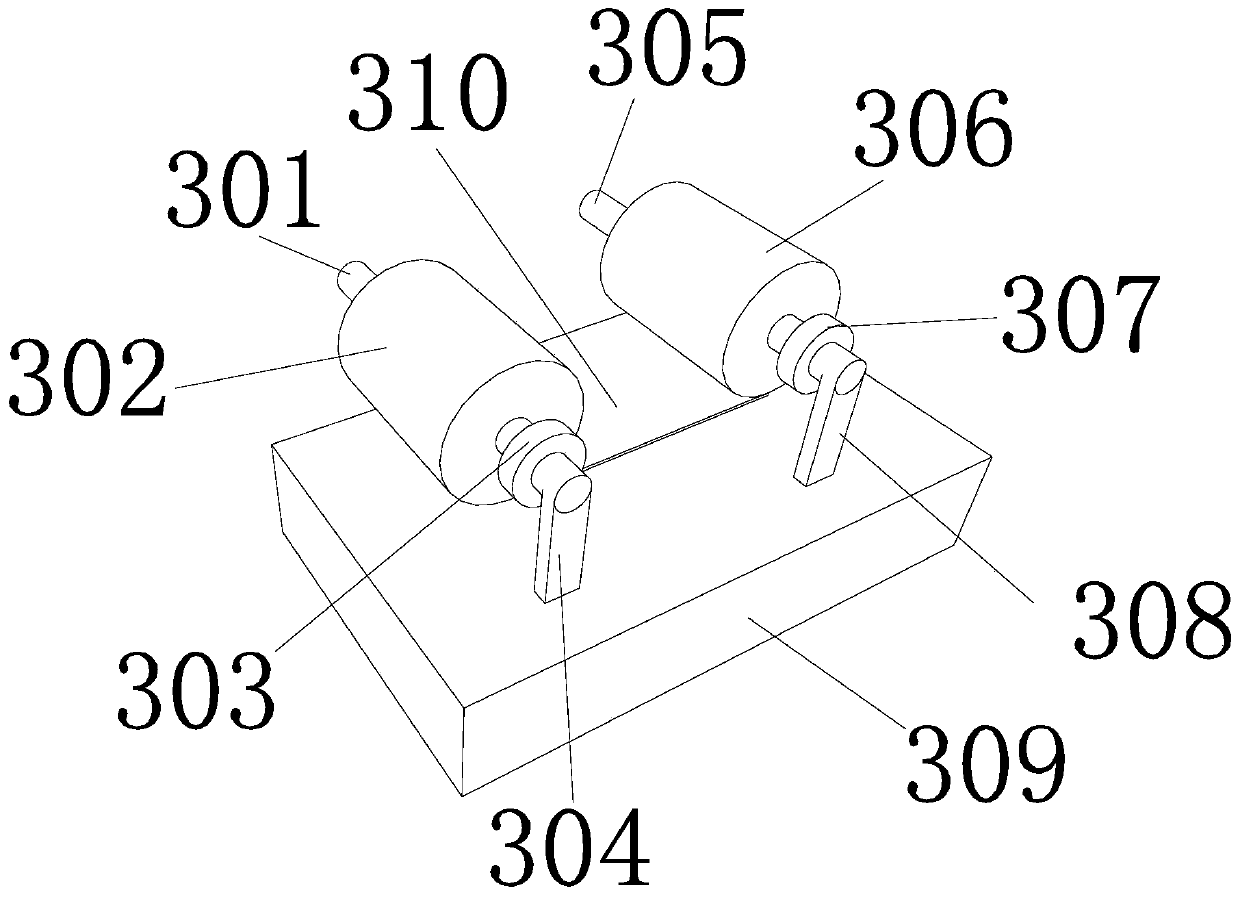

Double-rope hydraulic damping descent control device

InactiveCN104225821AImprove deceleration efficiencyReasonable structureBuilding rescueEngineeringConstant speed

A double-rope hydraulic damping descent control device is mainly composed of a cylinder sleeve, an end cover, a left descent control rope, a right descent control rope, a left rope winding wheel, a right rope winding wheel, a left rotating shaft, a right rotating shaft, a left blade, a right blade, damping liquid and the like. One end of the left descent control rope and one end of the right descent control rope are connected with a person or an object which needs to descend slowly. The left descent control rope and the right descent control rope are reversely wound on the left rope winding wheel and the right rope winding wheel respectively. The person or the object drives the left descent control rope and the right descent control rope when descending. The left descend control rope and the right descend control rope make the left blade and the right blade oppositely rotate in the space composed of the cylinder sleeve and the end cover through the left rope winding wheel, the right rope winding wheel, the left rotating shaft and the right rotating shaft respectively, wherein the space is filled with damping liquid. The momentum generated when the damping liquid moves impacts on the left blade and the right blade, the left blade and the right blade generate opposite torques, and therefore the aim of slowly descending the person or the object at a constant speed is achieved. The descent control device has the advantages of being simple in structure, safe, reliable, low in manufacturing cost, durable in use and the like.

Owner:李国栋

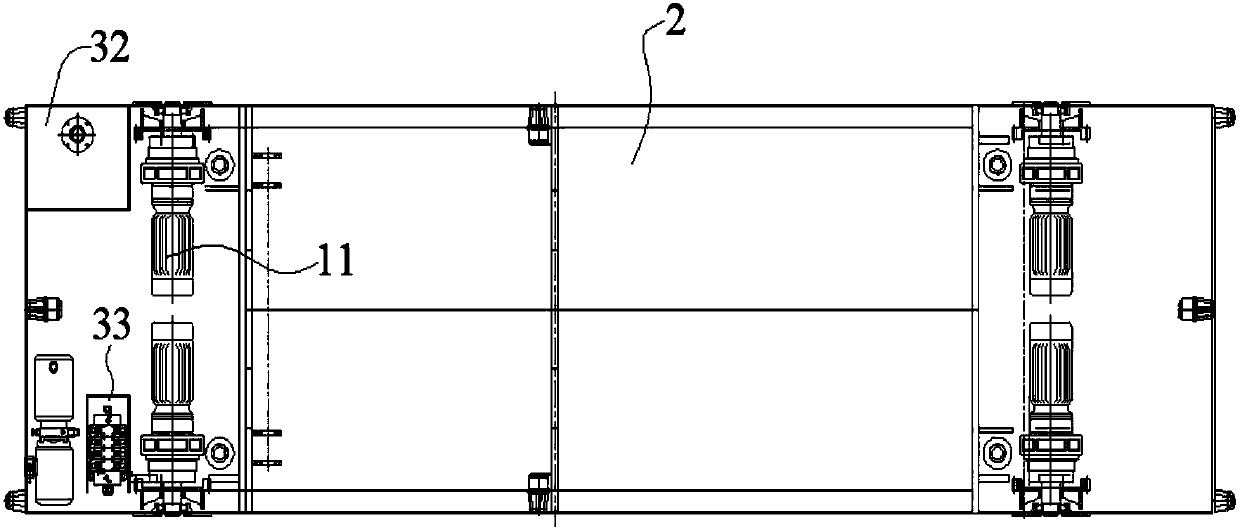

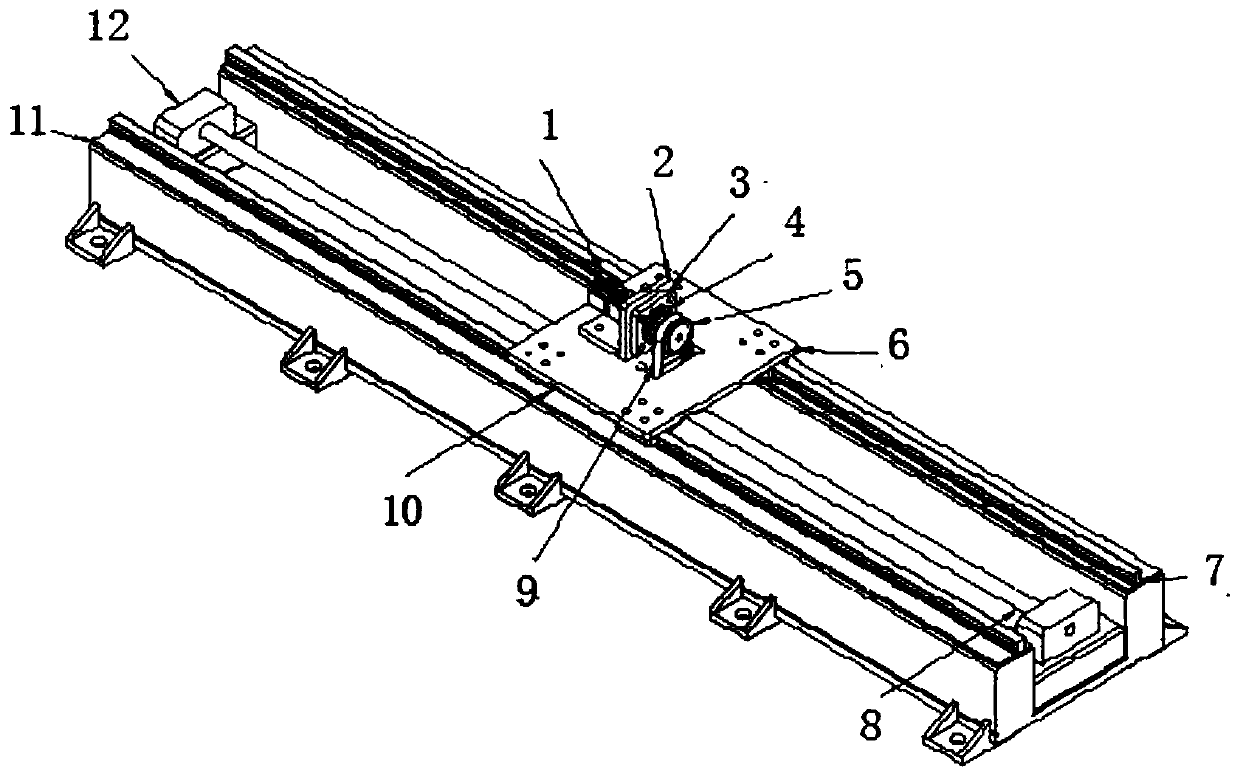

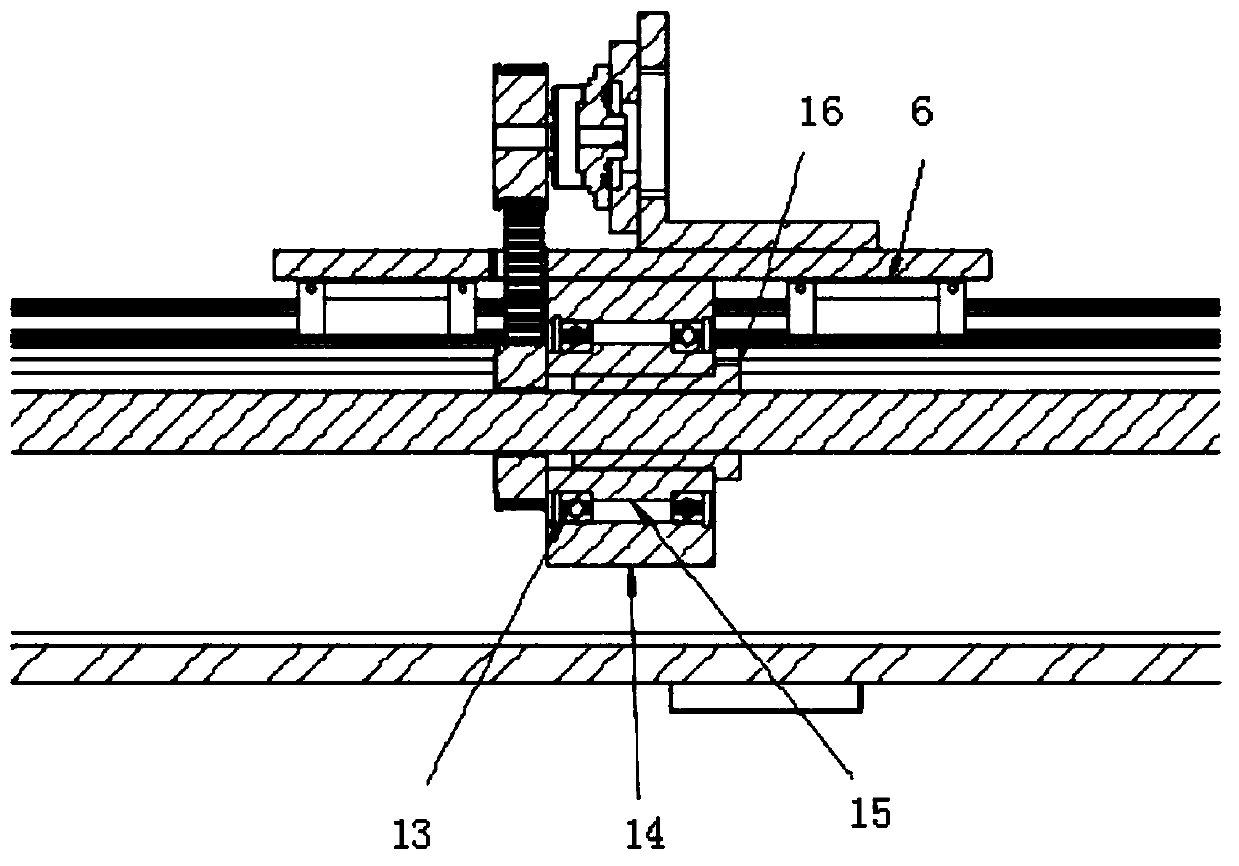

Electric driving track trolley

The invention discloses an electric driving track trolley, and relates to the technical field of ship transportation equipment. The electric driving track trolley comprises a trolley body, a supporting table, a hydraulic mechanism and a control assembly. The bottom of the trolley body is provided with four wheels which are in track connection with a trolley track of the interior of a ship cabin. Each wheel is connected with a motor. The four motors are connected in series. The supporting table is arranged on the trolley body in a liftable mode. A shear fork structure used for connecting the supporting table with the trolley body is arranged between the supporting table and the trolley body. The hydraulic mechanism comprises a hydraulic oil cylinder. The hydraulic oil cylinder is connectedwith the shear fork structure and used for driving the supporting table to be lifted. The control assembly is electrically connected with the motors and the hydraulic mechanism correspondingly. According to the electric driving track trolley, the problem that a small ship cannot complete ship-picking, displacing and placing in a large ship transport cabin is solved by using the hydraulic oil cylinder to lift the supporting table used for supporting the ship to be moved and driving the track trolley to move through the motors.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Bridge frame walking driving mechanism of bridge crane

InactiveCN107298376ALess prone to rail gnawingShort transmission distanceTravelling gearCouplingReducer

The invention discloses a bridge frame walking driving mechanism of a bridge crane. The bridge frame walking driving mechanism comprises a main beam, wherein the two ends of the main beam are fixedly provided with end beams; a motor and a speed reducer are arranged at the center inside the main beam; each end beam is provided with a wheel through an angle type bearing box; each angle type bearing box comprises a wheel shaft; one end of the motor extends out of a motor shaft; the motor shaft is connected with an input shaft through a plum shaft coupler; one end of the input shaft is connected with a worm rod; the worm rod is sequentially connected with a transmission wheel and an output wheel; an output shaft is fixedly arranged in the center of the output wheel; the two ends of the output shaft are connected with speed reducing rods; the top of the shaft coupler is provided with a brake. The wheels at the left side and the right side of the main beam are simultaneously controlled to rotate through the motor and the speed reducer; the wheels and tracks are protected; through the design of the plum shaft coupler, the transmission efficiency of the motor on the speed reducer is higher; a worm wheel-worm rod speed reducer is used for speed reduction, so that the speed reduction efficiency is higher; the self-lock structure of the speed reducer is matched with the brake, so that the braking is faster and more timely; the work efficiency of the crane is improved.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

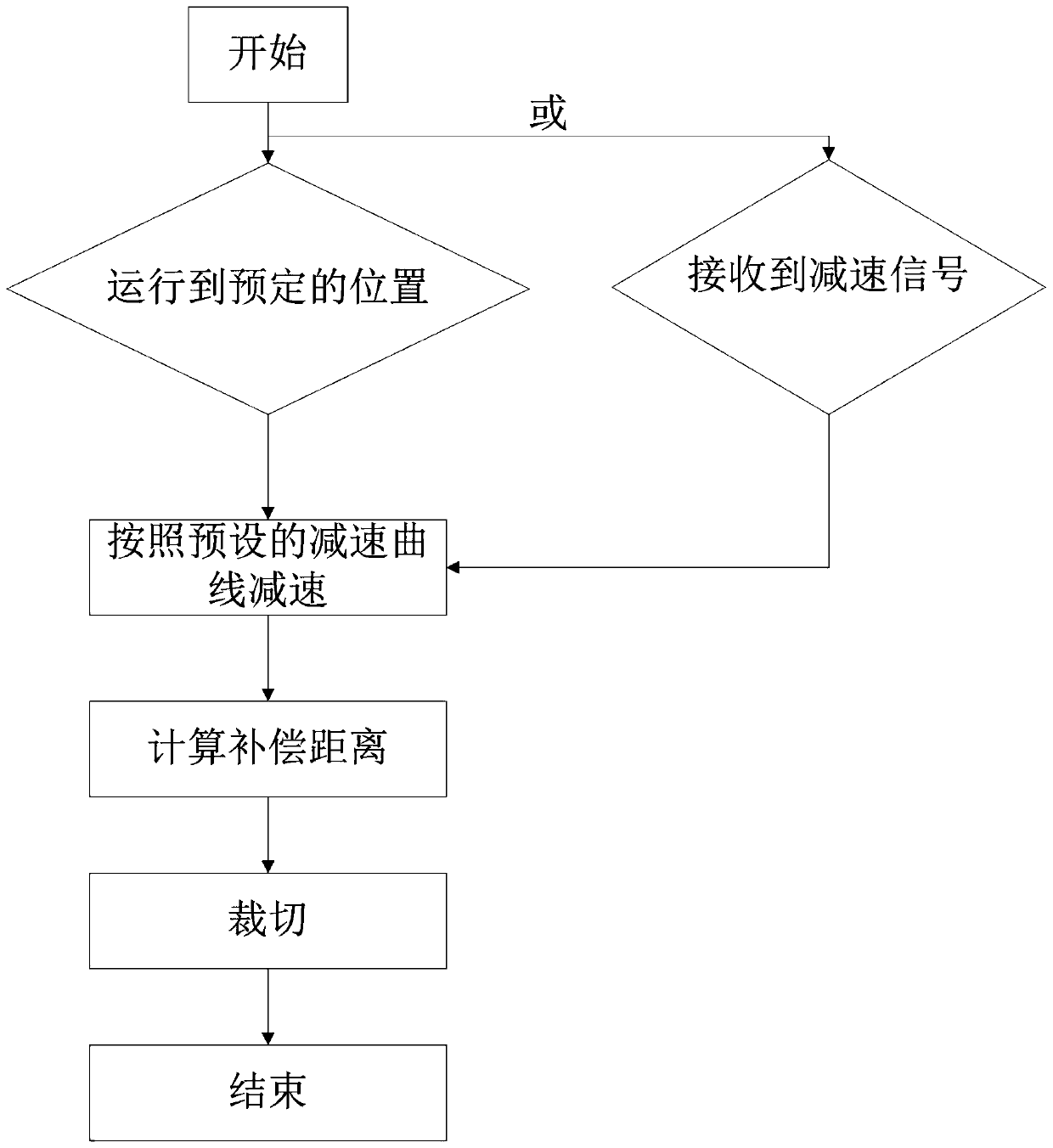

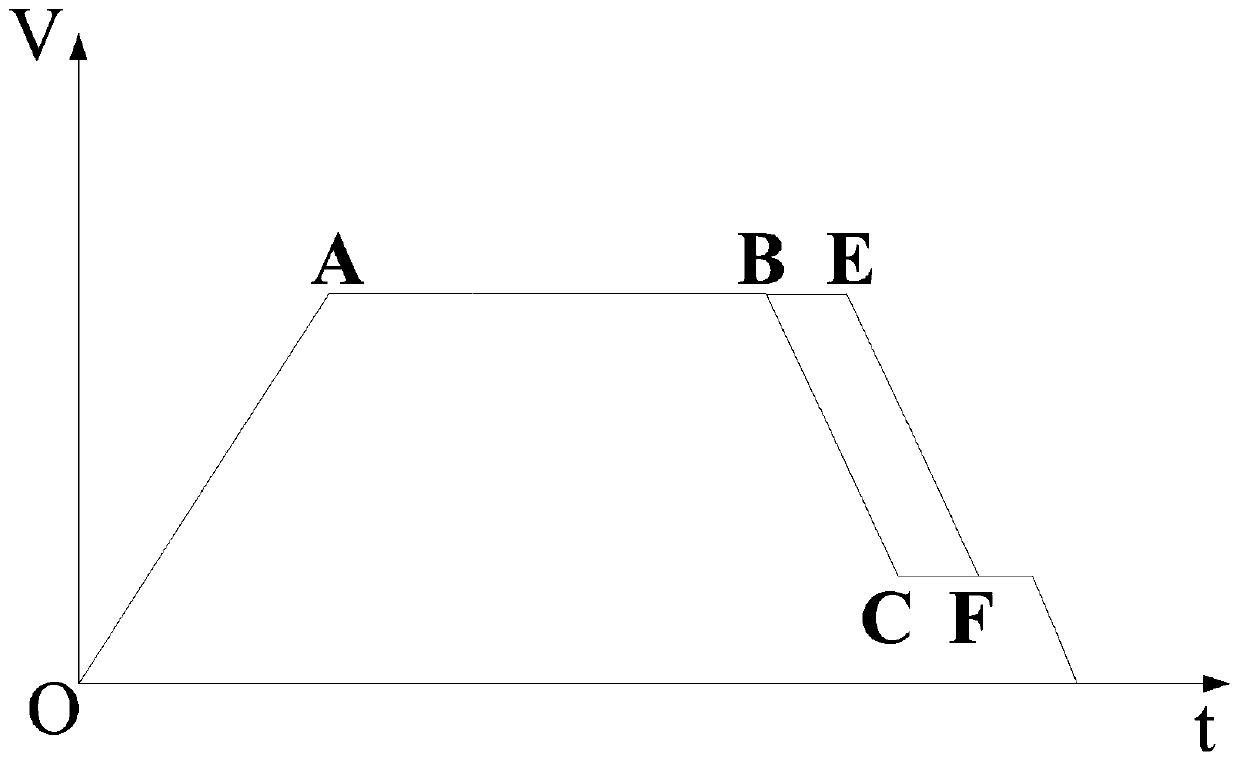

Deceleration cutting control method and control device

ActiveCN110329832AShorten the deceleration timeImprove deceleration efficiencyProgramme controlFunction indicatorsDeceleration timeEngineering

The invention discloses a deceleration cutting control method and control device. The deceleration cutting control method comprises the steps that when a product to be cut runs to the preset positionor receives a deceleration signal, the product to be cut is decelerated according to a preset deceleration curve; and when the product to be cut finishes deceleration according to the preset deceleration curve, the product to be cut is cut. The control device comprises a conveying piece, a detection element, a sensor, a controller and a cutting piece. That the product to be cut runs to the presetposition or receives the deceleration signal is adopted as a control signal for decelerating the product to be cut, that is, the product to be cut is decelerated according to the preset deceleration curve as long as any one of the signal that the product to be cut runs to the preset position or the deceleration signal is received is received, and the product to be cut is decelerated according to the preset deceleration curve; and the deceleration curve is preset in advance, so that the preset deceleration curve is flexibly planned, the product to be cut is decelerated according to the deceleration curve, the deceleration time is shortened, and the deceleration efficiency is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

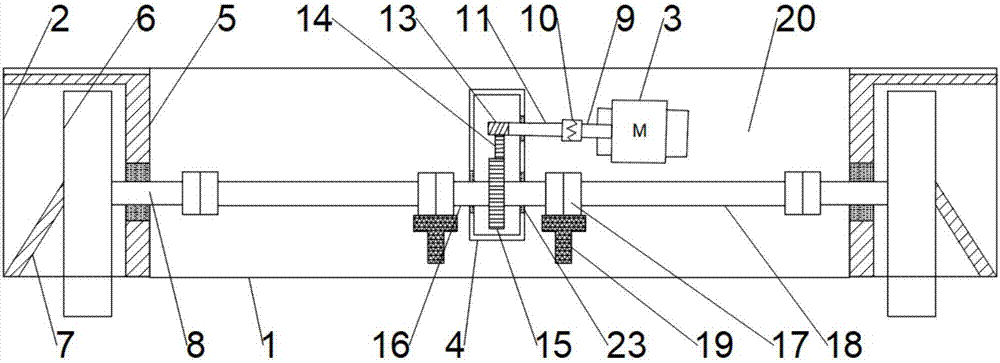

Rapid automatic door deceleration device

InactiveCN106285284AImprove deceleration efficiencyOpen to save effortGearingPower-operated mechanismDrive shaftGear wheel

The invention discloses a rapid automatic door deceleration device and belongs to the technical field of automatic door deceleration devices. The technical problems that the automatic door deceleration device is low in deceleration efficiency and an automatic door is labor-consuming to open are solved. According to the solution, a gearbox is arranged on one side of a motor; a motor rotor stretches into a gearbox shell; a worm is fixedly arranged at the end of the motor rotor; a gear shaft is meshed with the worm perpendicular to the worm axis direction; a transmission gear is arranged on the upper part of the gear shaft; the transmission gear transmits power to a belt pulley drive shaft through a bevel wheel meshed with the transmission gear; the axis direction of the belt pulley drive shaft is parallel to an axis direction of the gear shaft; and a belt wheel is fixedly arranged on a part, which is positioned on the outer side of the gearbox, of the belt pulley drive shaft. According to the invention, a power transmission system in the gearbox is changed, so that the automatic door is labor-saving to open, a reduction ratio is increased, and the deceleration efficiency of the automatic door deceleration device is improved.

Owner:SIGMA GIKEN (SHANGHAI) CO LTD

A hump vehicle reducer with permanent magnet excitation

ActiveCN112389496BImprove deceleration efficiencyImprove reliabilityRailway hydrostatic brakesRailway hydrodynamic brakesMagnetic effectReduction drive

The invention discloses a hump vehicle reducer with permanent magnet excitation, which belongs to the technical field of railway speed regulation. The hump vehicle speed reducer includes a brake part and a cylinder part. The brake part includes a friction plate, a cover plate and a return spring; the cylinder part includes a top cover, a permanent magnet group, a magnetic isolation plate, a base and a connector, and the permanent magnet assembly includes an upper armature, a permanent magnet and a lower armature. The hump vehicle reducer generates braking through the magnetic force of permanent magnets, including eddy current braking and friction braking. It uses the cylinder to realize the on-off of the magnetic circuit, and then controls the working state. It has a simple structure and simple operation. The hump vehicle speed reducer of the present invention combines eddy current braking with traditional mechanical braking, and has the advantages of simple structure, higher safety factor, longer service life, energy saving and better braking effect.

Owner:BEIJING UNIV OF TECH

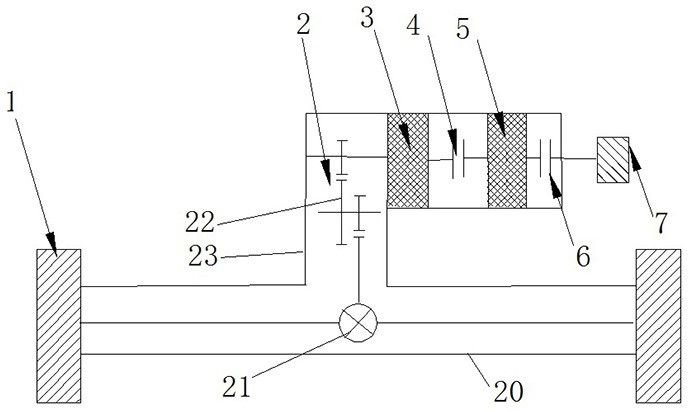

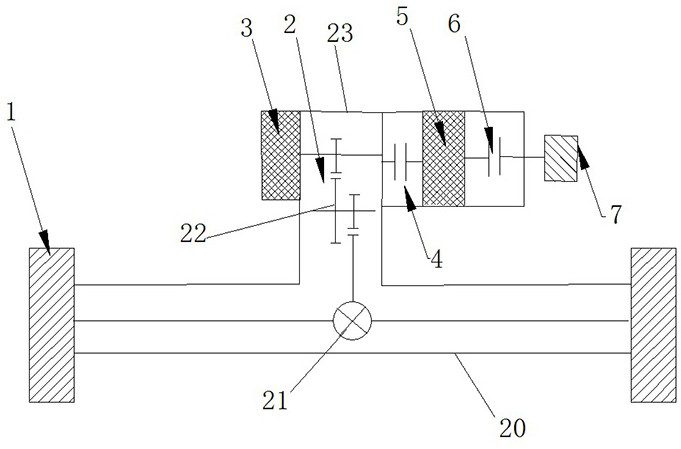

Mechanism capable of saving space and improving speed reduction efficiency

PendingCN110242717AReduce occupancyImprove deceleration efficiencyGearingMechanical energy handlingEngineeringReducer

The invention discloses a mechanism capable of saving the space and improving the speed reduction efficiency. The mechanism comprises a power device, an external thread guide part, a transmission assembly, a sliding assembly, a base and an external thread guide part fixing base. An internal thread rotating part is connected to the external thread guide part in a threaded mode, a swirling part is arranged on the internal thread rotating part, and one side of the swirling part is connected with a harmonic speed reducer through the transmission assembly. The harmonic speed reducer is connected with an output shaft of the power device, the power device is arranged on a fixing part, and the fixing part is connected with the harmonic speed reducer through a connecting plate and arranged on a moving bearing platform. The moving bearing platform is connected with the swirling part. According to the mechanism capable of saving the space and improving the speed reduction efficiency, the harmonic speed reducer is adopted to replace a conventional planetary reducer, the small space is occupied when the high speed reduction ratio is used, and the speed reduction efficiency is high.

Owner:上海玖蓥智能科技有限公司

Zero hysteresis involute less tooth difference reducer

ActiveCN104747658BDifferent performanceEasy to processToothed gearingsGearing detailsThree levelRadar

The invention relates to the technical field of involute small tooth differences, in particular to a zero-return-difference involute small-tooth-difference reduction box which comprises a base, planet wheels A and B, an inner gear ring, an input shaft, an end cover and a w-shaped output mechanism. The zero-return-difference involute small-tooth-difference reduction box is characterized in that the inner gear ring is connected to an inner hole of the base, and wheel teeth of the planet wheel B are abut against the anticlockwise side of inner teeth in an upper half area of the inner gear ring; wheel teeth of the planet wheel A abut against the clockwise side of the inner teeth in the lower half area of the inner gear ring, and the phase difference between the two planet wheels is smaller than 180 degrees; a check ring is arranged at the extending end of an input shaft, two eccentric bushings are arranged between the check ring and the shoulder of the input shaft, the inner end faces of the two eccentric bushings are provided with trapezoid teeth which are meshed with each other, the second eccentric bushing is connected to the input shaft, the outer end of the second eccentric bushing abuts against the shoulder of the input shaft, the first eccentric bushing is matched with the input shaft in a sliding mode, and a spring is arranged between the outer end of the first eccentric bushing and the elastic check ring. The zero-return-difference involute small-tooth-difference reduction box has the advantages that the manufacturing technique is simple, zero return difference is achieved, the reduction box can be applied to a radar rotation tracking reduction gear and the like, is high in efficiency, can replace three levels of planet gears, is large in transmission ratio, small in size, low in weight, stable in operation, and convenient to assemble and disassemble, and the tooth profile is easy to machine.

Owner:ZHEJIANG HUIXIN DRIVING MACHINE

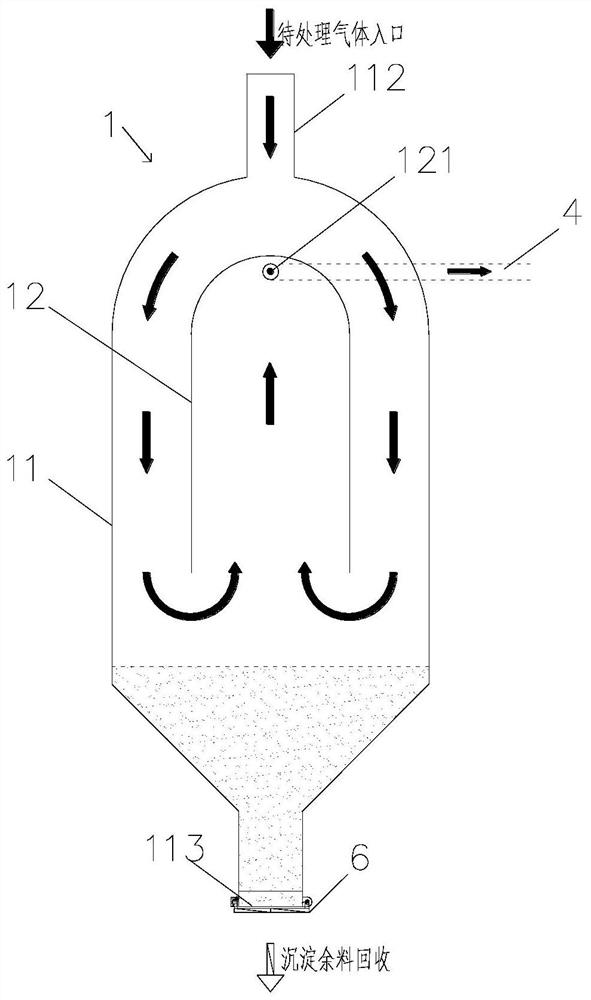

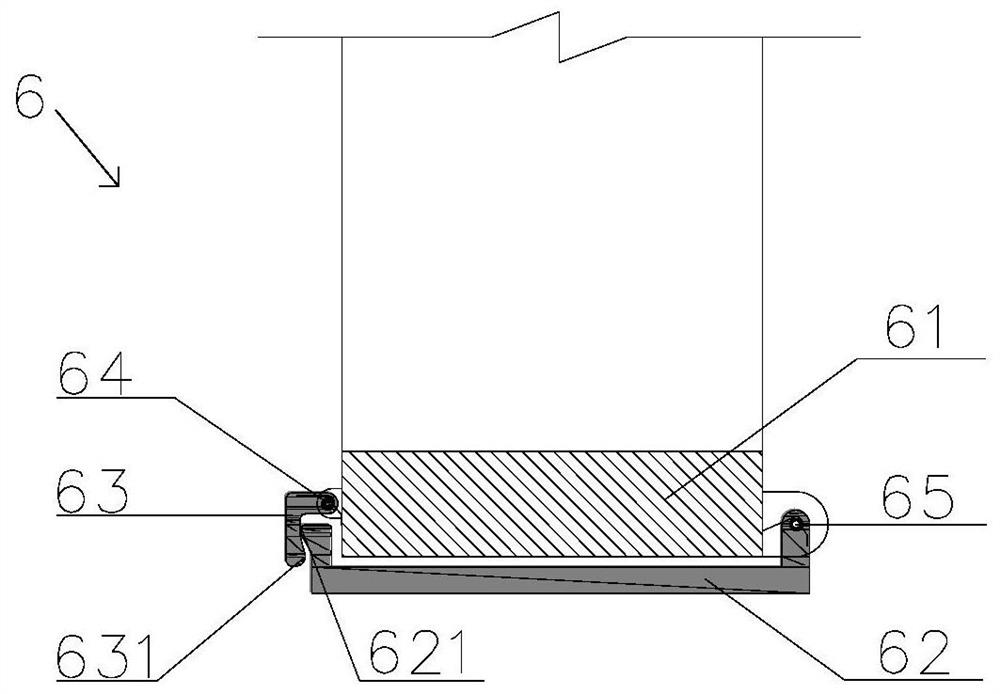

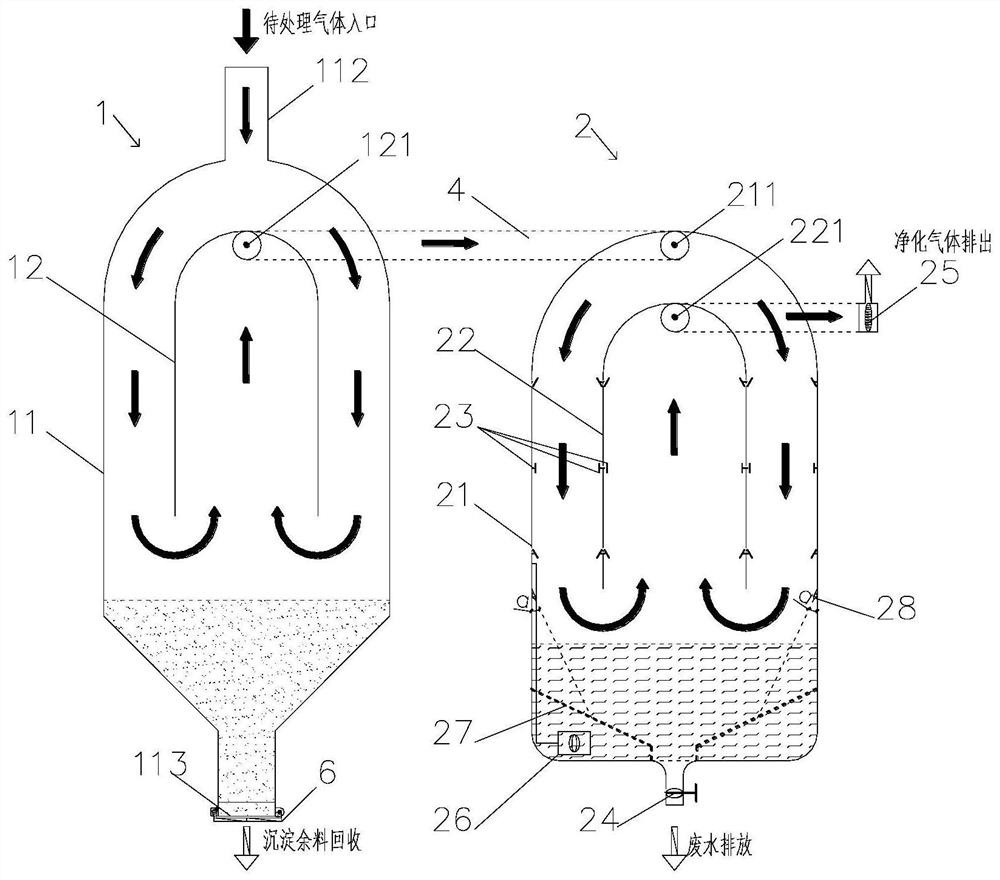

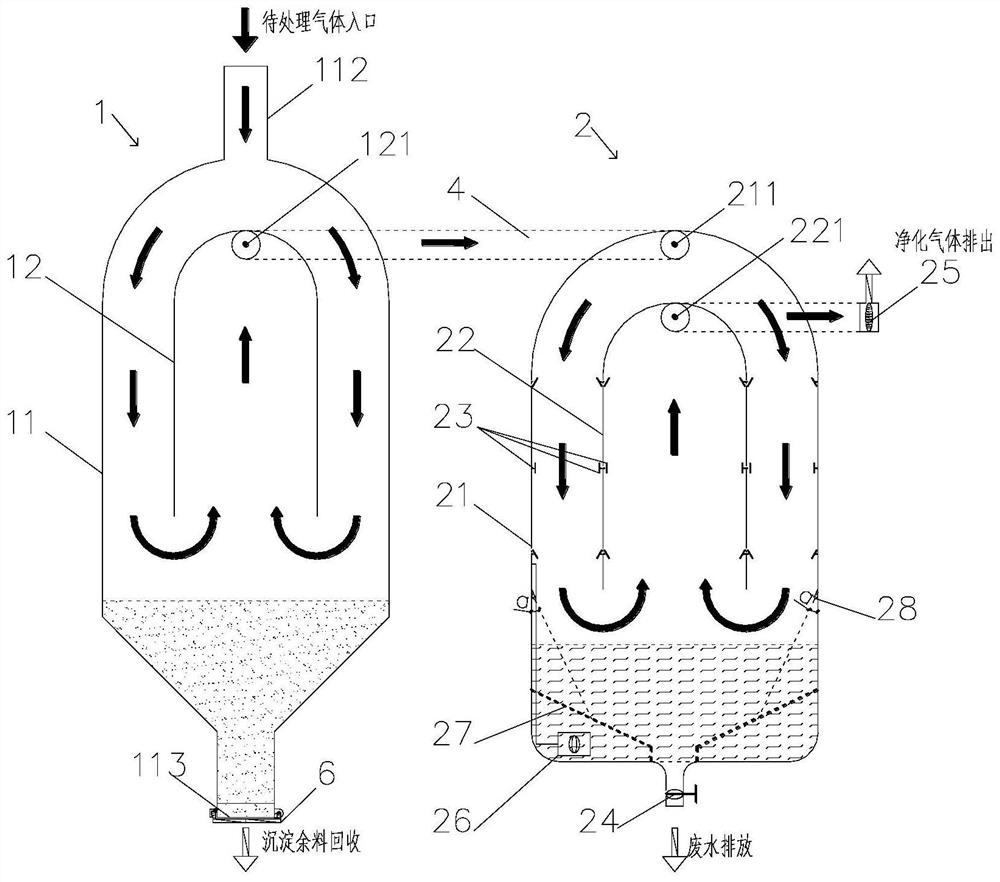

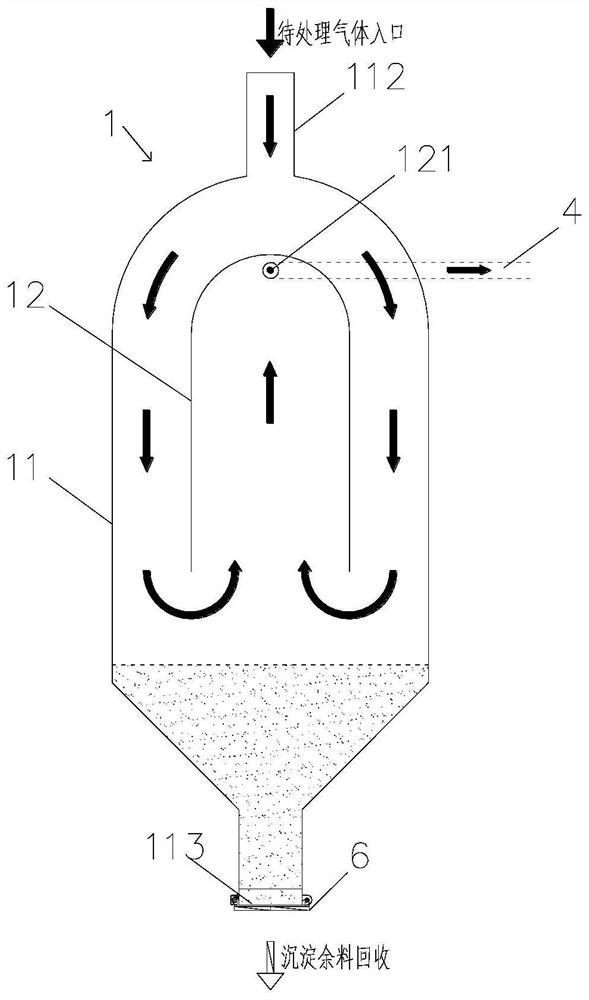

Gravity type precipitation device and method

ActiveCN111714967AAvoid the disadvantages of quadratic accelerationImprove deceleration efficiencyCombination devicesUsing liquid separation agentMechanical engineeringMechanics

Owner:SHANGHAI NO 4 CONSTR

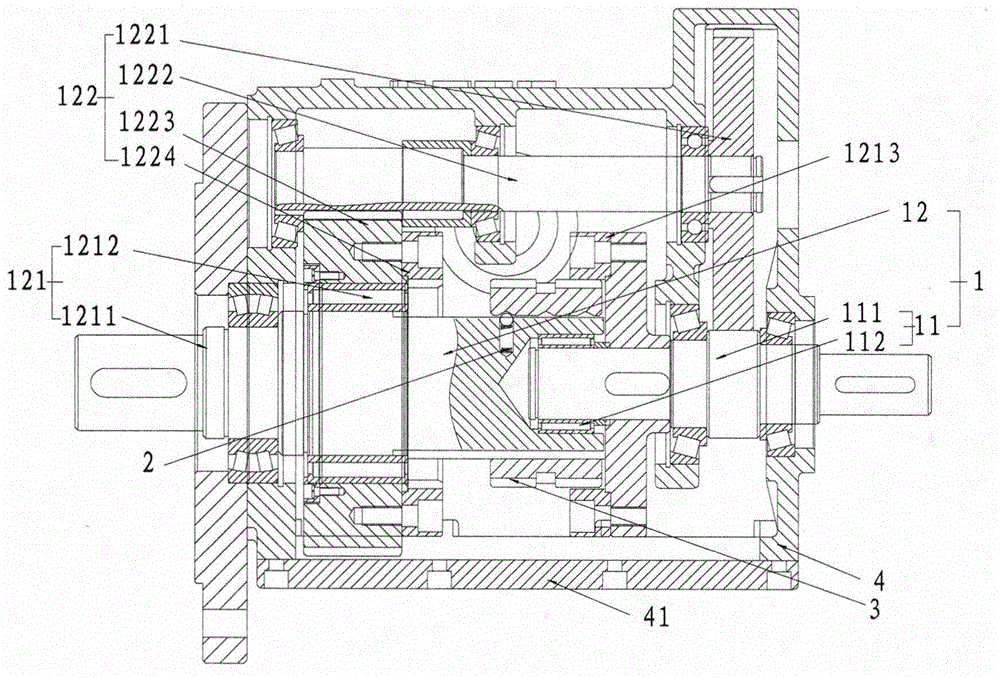

A worm gear reducer

ActiveCN105889448BSimple structure and principleReduce volumeGearingGearing detailsEngineeringReducer

The invention discloses a worm gear reducer which comprises an upper cover plate, a lower cover plate, a worm gear, a worm, an inner cam and an output sleeve. The upper cover plate and the lower cover plate are fixedly connected through a screw and a hexagon bolt. The worm gear and the worm are located in a containing space defined by the upper cover plate and the lower cover plate. An output shaft is arranged in the center of the worm gear. The worm is fixedly arranged above the worm gear. The worm gear and the worm are meshed. The two ends of the worm are fixedly provided with bearings respectively. One end of the worm is connected with a first connector and a second connector through one bearing. The inner cam is fixedly arranged on the worm wheel. The center of the inner cam is provided with the output sleeve. The output sleeve is matched with the output shaft. The output sleeve is provided with two pawls and a cam. The pawls are symmetrically arranged on the two sides of the cam. The output shaft is sleeved with the cam. The worm gear reducer is simple in structural principle, small in size, low in cost and capable of achieving output at the larger transmission ration, and the speed reduction efficiency is improved.

Owner:CHANGSHA AIKERUI GEAR MACHINERY

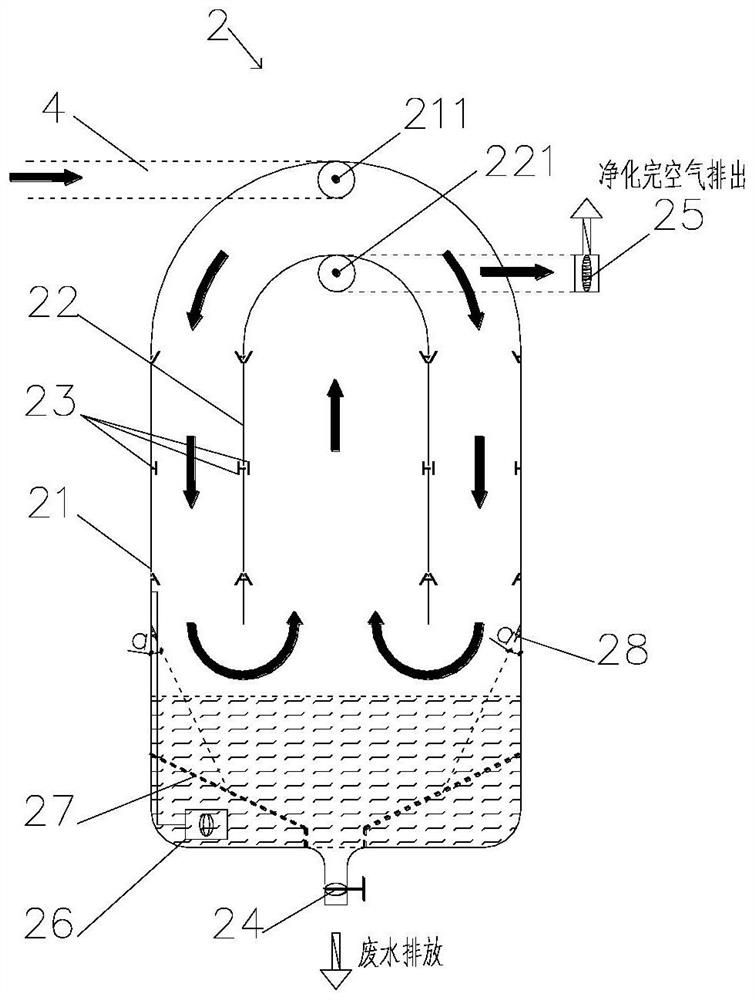

Spray purification device and method

ActiveCN111714999ACompact structureSmall footprintCombination devicesUsing liquid separation agentMechanical engineeringSolid particle

The invention belongs to the field of air purification, and provides a spray purification device and method. The device comprises a closed container, an inverted container and a plurality of pipelineswith spray heads. An air inlet is formed in the top of the closed container; the lower part of the closed container serves as a water collecting tank; a first wastewater discharge valve is arranged at the bottom of the water collecting tank; the inverted container is of an inverted U-shaped structure; the inverted container is coaxially arranged in the closed container, an exhaust port is formedin the top of the inverted container, an opening is formed in the bottom of the inverted container, a plurality of pipelines with spray heads are arranged on the inner wall of the closed container andthe inner wall and the outer wall of the inverted container respectively, and water in the water collecting tank is pumped to the spray heads through a pressure pump. The dust-containing pressurizedgas is humidified by the spray head so that solid particles with the particle size of 2.5-10mu m in the dust-containing pressurized gas are precipitated or the dust is dissolved in the water when meeting the water to increase the weight, thereby achieving the purpose of purifying the air.

Owner:SHANGHAI NO 4 CONSTR

Economical elevator additionally arranged outside building

InactiveCN112079235AImprove deceleration efficiencyLarge reduction ratioElevatorsBuilding liftsCar doorWire rope

An economical elevator additionally arranged outside a building comprises an old building, an old stair, an elevator shaft, a shaft door, a car, a car door, an elevator door platform, a newly-built walkway, a newly-built stair, an elevator machine room, a harmonic speed reduction traction machine, a traction wheel, a traction guide wheel, a steel wire rope, a car guide wheel, a car guide rail, counterweight iron plates, counterweight guide wheels, counterweight guide rails, Hall sensors, strip-shaped permanent magnets, an intelligent controller and operating buttons; the harmonic speed reduction traction machine is a hub type traction machine integrating a harmonic speed reducer, a two-pole outer rotor brushless permanent magnet direct current motor and the traction wheel; when the two-pole outer rotor brushless permanent magnet direct current motor is shut down, large magnetic resistance exists between a rotor and a stator, a speed reduction ratio of the harmonic speed reducer is large; when the harmonic speed reduction traction machine is shut down, the harmonic speed reduction traction machine has a strong self-locking function which is equivalent to a braking state, a braking system of the traction machine is omitted, the harmonic speed reduction traction machine is simple and cheap, and the safety and the reliability meet the standard requirements.

Owner:朱幕松

Planet speed reducer with efficient heat dissipation function

InactiveCN111219449AImprove deceleration efficiencyEfficient cooling functionGear lubrication/coolingToothed gearingsCooling effectReducer

The invention discloses a planet speed reducer with an efficient heat dissipation function. The planet speed reducer comprises an outer shell, an inner shell, a first sun gear and first planet gears.According to the planet speed reducer with the efficient heat dissipation function, a plurality of heat dissipation holes are formed in the shell wall of the inner shell so that heat in the inner shell can be dissipated; a plurality of arc-shaped heat dissipation pipes are symmetrically arranged on the two sides of the shell wall of the outer shell, so that the heat dissipated by the heat dissipation holes is discharged; the central positions of the arc-shaped heat dissipation pipes are bent upwards, the situation that water on the shell wall of the outer shell flows into the interior of the arc-shaped heat dissipation pipes, and enter the inner shell through the heat dissipation holes, equipment in the inner shell is damaged can be prevented from appearing, and the arc-shaped heat dissipation pipes have a waterproof function, so that the speed reducer has the efficient heat dissipation function, and the using time of the speed reducer is prolonged; and through the driven action of theplanet gears and the sun gears, the speed reducer can have an efficient speed reduction function, the cooling effect is good, the speed reduction efficiency is high, and the popularization and the use are facilitated.

Owner:李洁

Electric drive axle system and pure electric operation vehicle using same

PendingCN114734755AReduced Power RequirementsCompact layoutElectric propulsion mountingAxle unitsPower couplingReduction drive

The invention relates to an electric drive axle system and a pure electric operation vehicle using the system.The electric drive axle system comprises an axle, the axle comprises an axle main speed reducer, and the electric drive axle system further comprises a drive motor, an operation motor, a drive clutch and an operation clutch, the driving clutch is fixedly mounted on the driving motor, the operation motor is fixedly connected with the driving clutch, and the operation clutch is fixedly connected with the operation motor, so that the driving motor, the operation motor, the driving clutch and the operation clutch are integrally mounted on the axle, and the whole system is compact in layout; and traditional parts such as a transmission shaft and a motor suspension in an existing scheme are omitted, so that the overall cost is effectively reduced. Moreover, the power coupling of the two motors can be realized by utilizing the driving clutch, so that the vehicle can be driven to run together, the power requirement on the motors is reduced, the motors can work in a high-efficiency area, the transmission efficiency is improved, and the power consumption is reduced.

Owner:ZHENGZHOU YUTONG BUS CO LTD

A stamping device for a punching machine

The invention provides a punching device for a punching machine, and belongs to the technical field of machines. The punching device solves the technical problems that an existing punching structure of a punching machine is poor in structure stability and large in abrasion. The punching device comprises an installation support, a motor, a retarding mechanism, a crankshaft and a connecting rod; the installation support is provided with an installation plate, a first installation position is arranged on the upper end face of the installation plate, a second installation position and a third installation position are arranged on the lower end face of the installation plate; the motor is arranged on the side portion of the first installation position and is provided with a power shaft, and a rotary wheel is connected to the power shaft in a sleeving manner; the retarding mechanism comprises a flywheel and multiple stages of reduction gears, the multiple stages of reduction gears are arranged in the first installation position and the second installation position correspondingly, and the flywheel is in transmission connection with the rotary wheel and is in transmission connection with the multiple stages of reduction gears; the crankshaft is arranged in the third installation position and is in transmission connection with the multiple stages of reduction gears; and the connecting rod is arranged on a crank throw of the crankshaft, and a punching pin is connected to the lower end of the connecting rod. The punching device has the beneficial effects of being high in stability and small in abrasion.

Owner:宁波澳玛特高精冲压机床股份有限公司

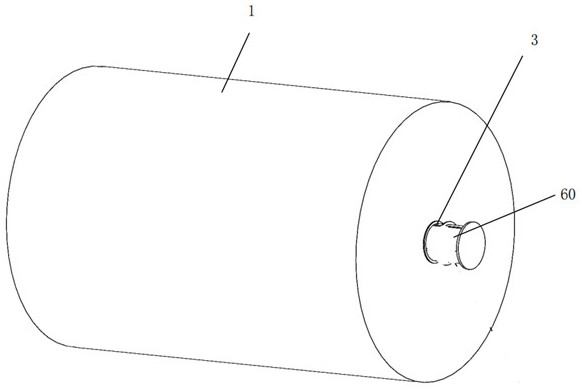

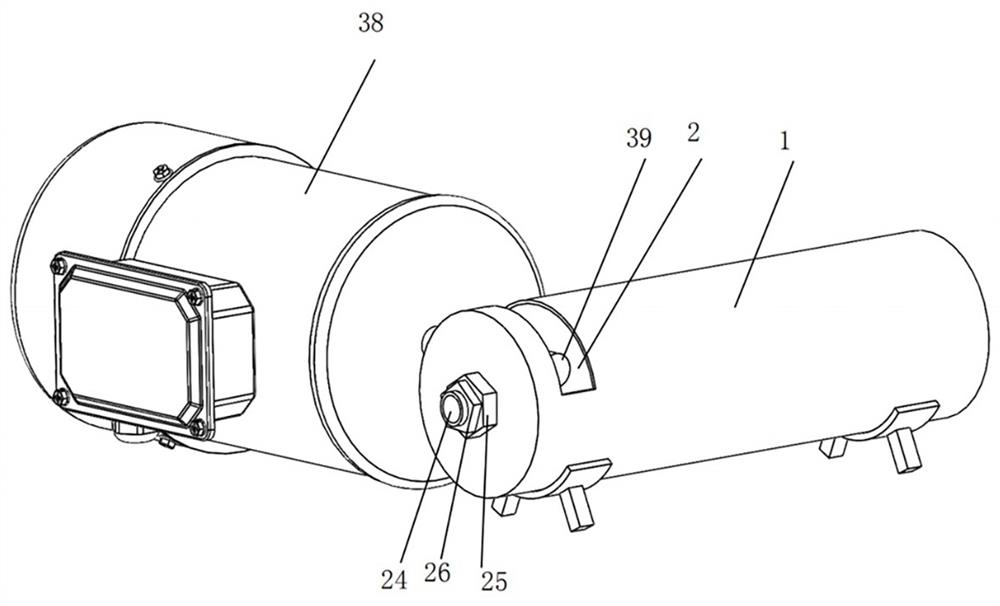

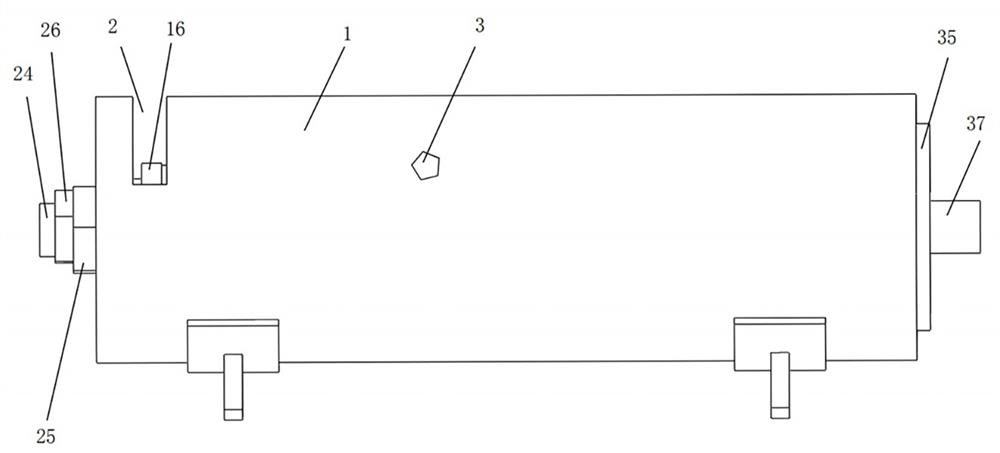

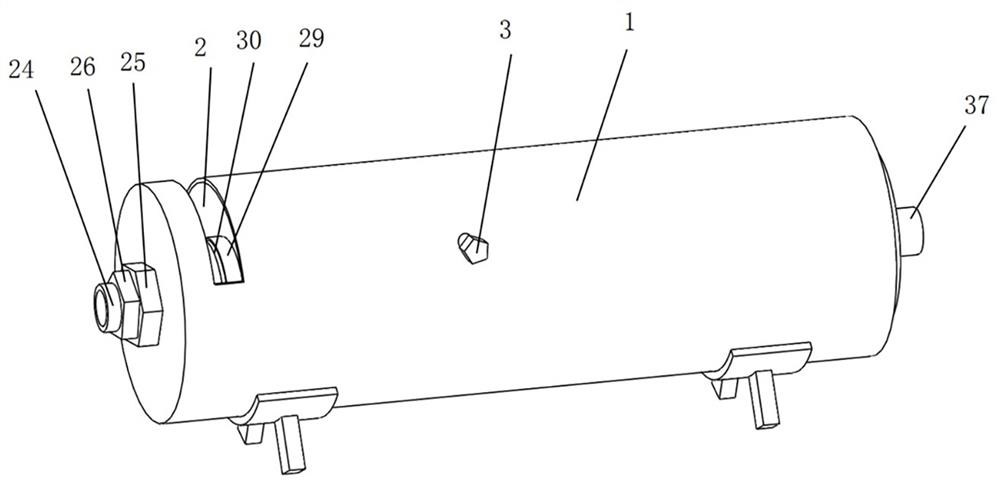

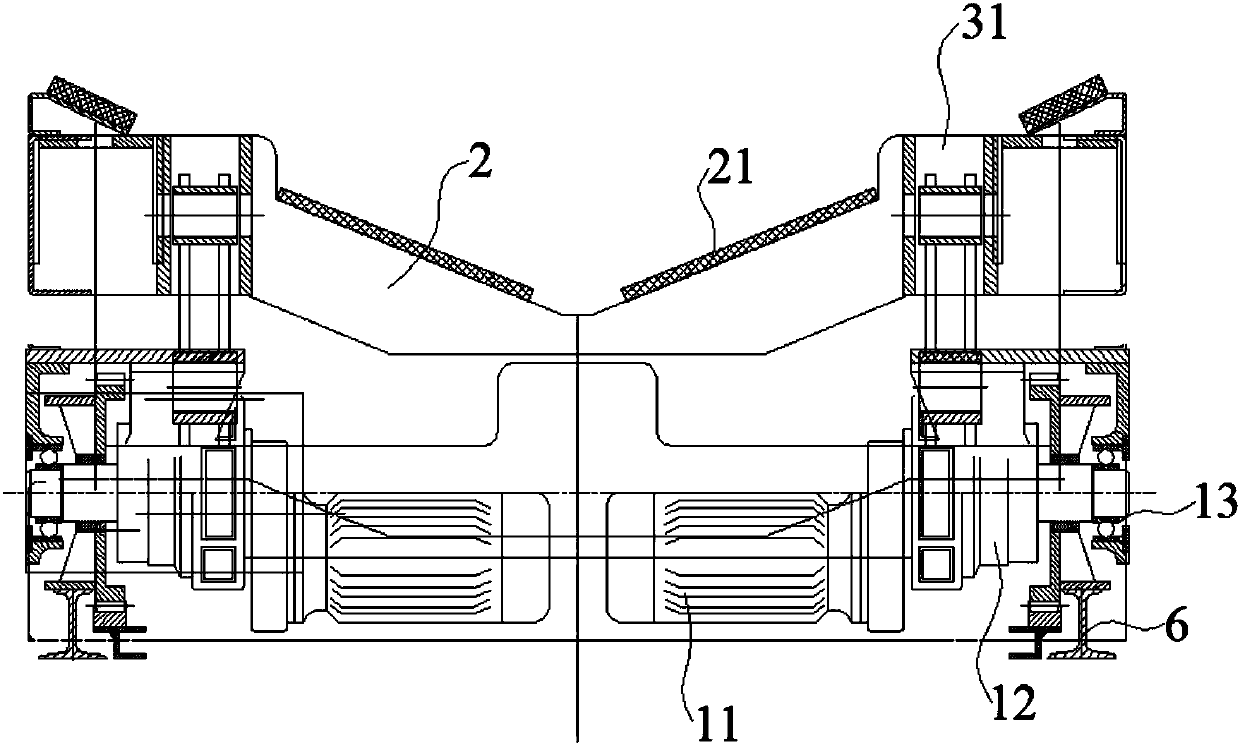

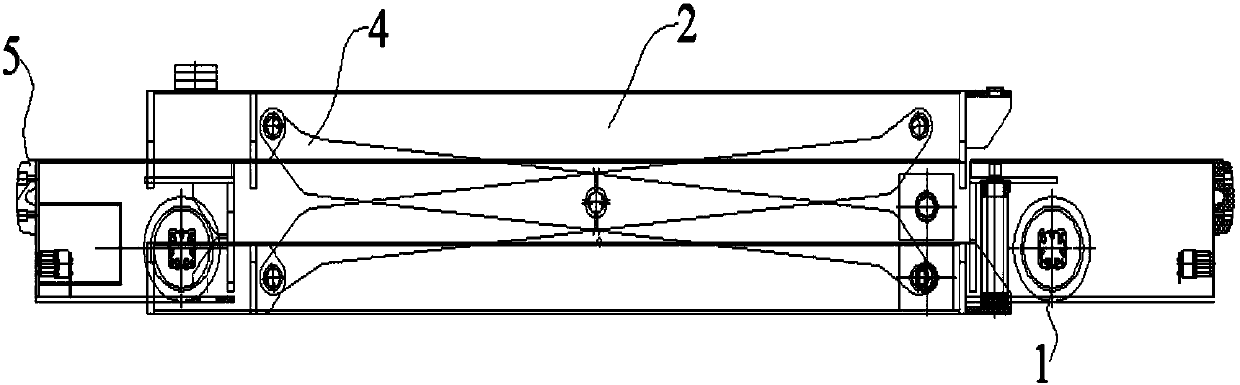

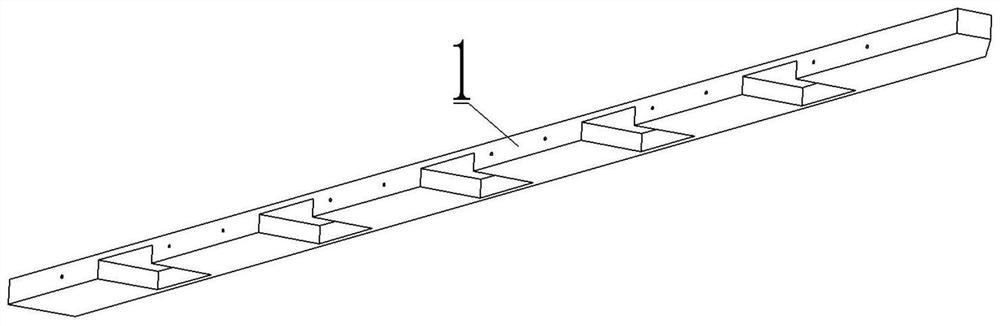

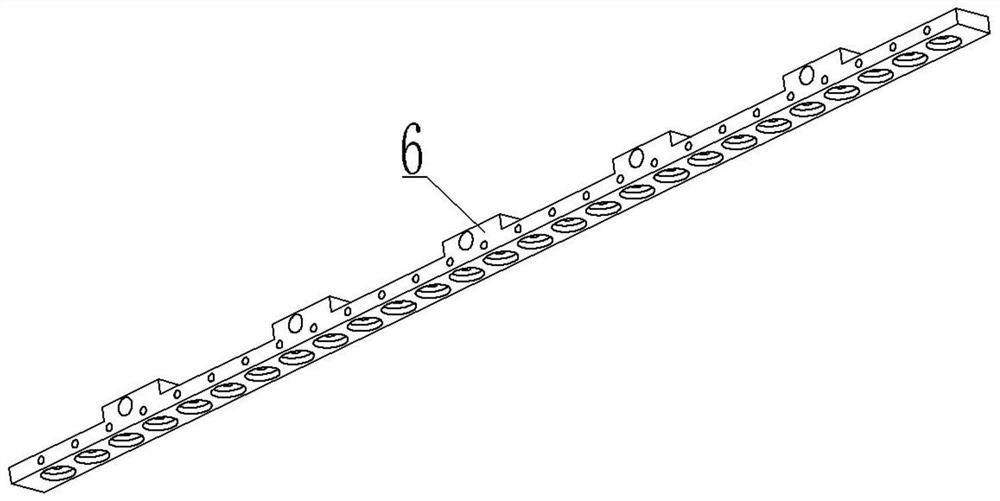

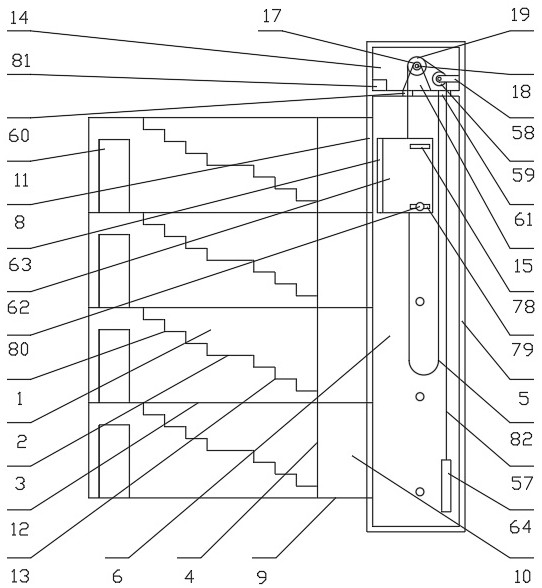

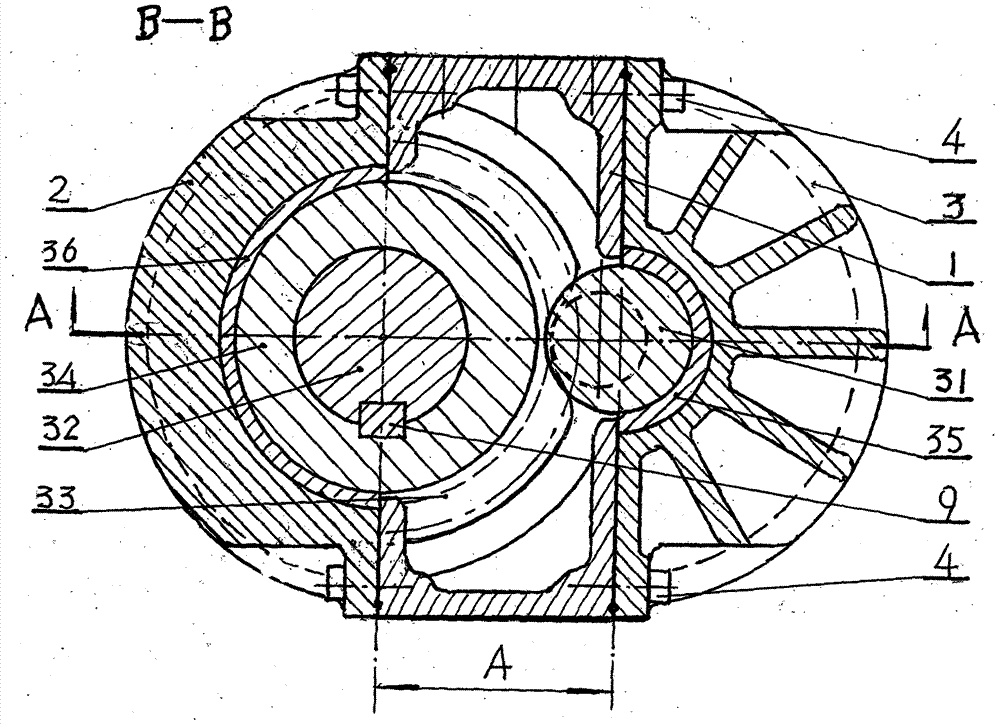

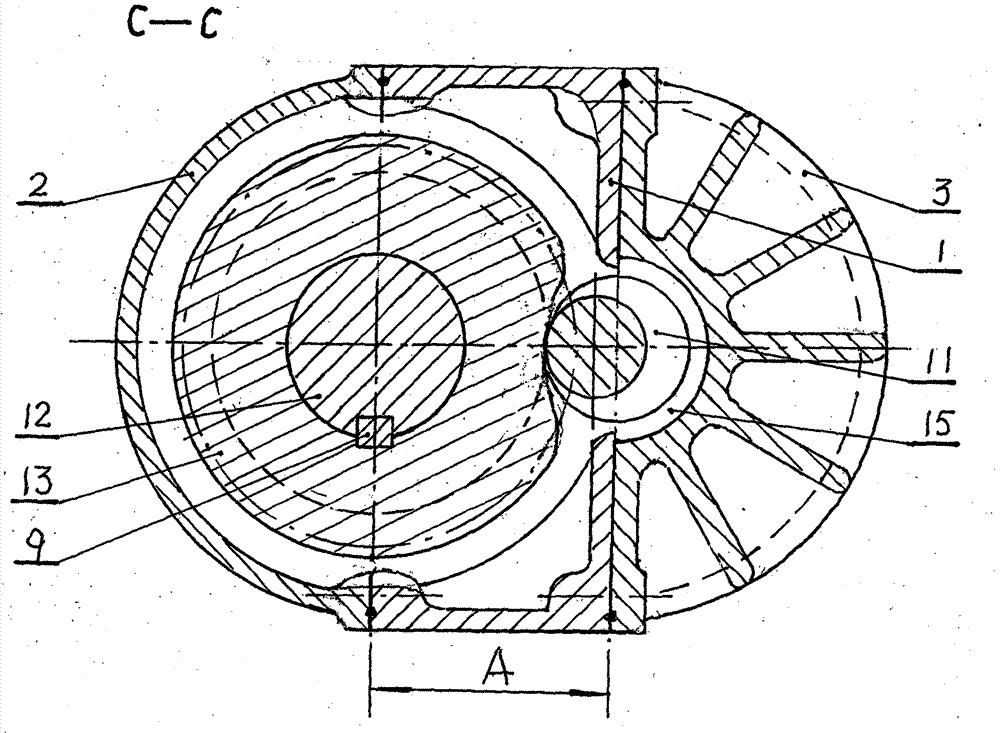

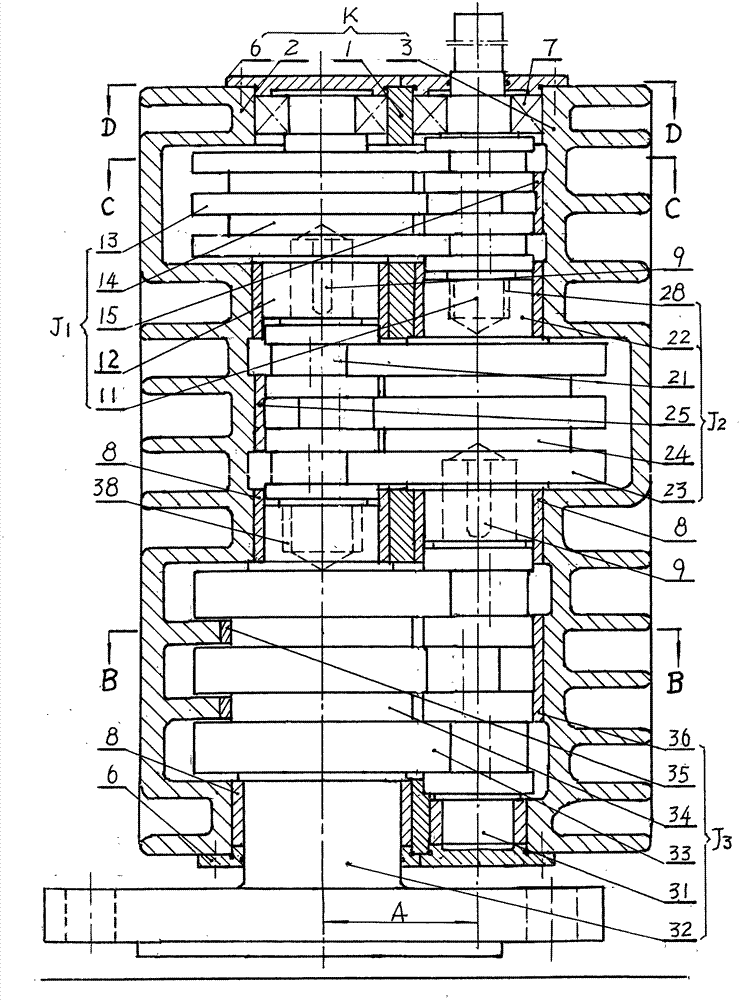

Series cycloidal gear reducer

InactiveCN105276144BReduce slip speedImprove deceleration efficiencyGearing detailsThree levelConnection type

The invention relates to a serial connection type cycloid gear speed reducer, a tubular speed reducer for short. The advantages of cycloid gear engagement pairs are brought into full play. A high-speed shaft rotates by a circle, a low-speed shaft rotates by one tooth, and the speed ratio is low so that a machine body can be small. The three engagement pairs low in speed ratio are connected in series, the overall speed ratio is calculated according to the power three, and the good effect that the speed ratio is large while the size is small is achieved. A machine shell (K) is composed of a middle base (1), a left cover (2) and a right cover (3) which are connected through screws (4) to form the rigid shell. A first-level transmission assembly (J1), a second-level transmission assembly (J2) and a third-level transmission assembly (J3) are included. The tooth profile parameters of three levels of engagement pairs of the serial connection type cycloid gear speed reducer are completely the same, the three levels of engagement pairs are the same in radial size and center distance A, only the axial size is increased according to the stress conditions, and all components are installed in the tubular machine shell (K). The transmission ratio is large, the size is small, the weight is low, noise is avoided, and heating is not likely to happen. Meanwhile, efficiency is very high, ad work is reliable. The serial connection type cycloid gear speed reducer is suitable for being used under the special conditions that installing spaces for robots, mechanical arms and the like are narrow.

Owner:袁正敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com