Deceleration cutting control method and control device

A technology of control method and control device, which is applied in the direction of program control, general control system, control/adjustment system, etc., can solve the problems of poor pole piece cutting accuracy, influence on stability, influence on cell yield, etc., and improve deceleration efficiency , Shorten the deceleration time, and the effect of cutting control is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

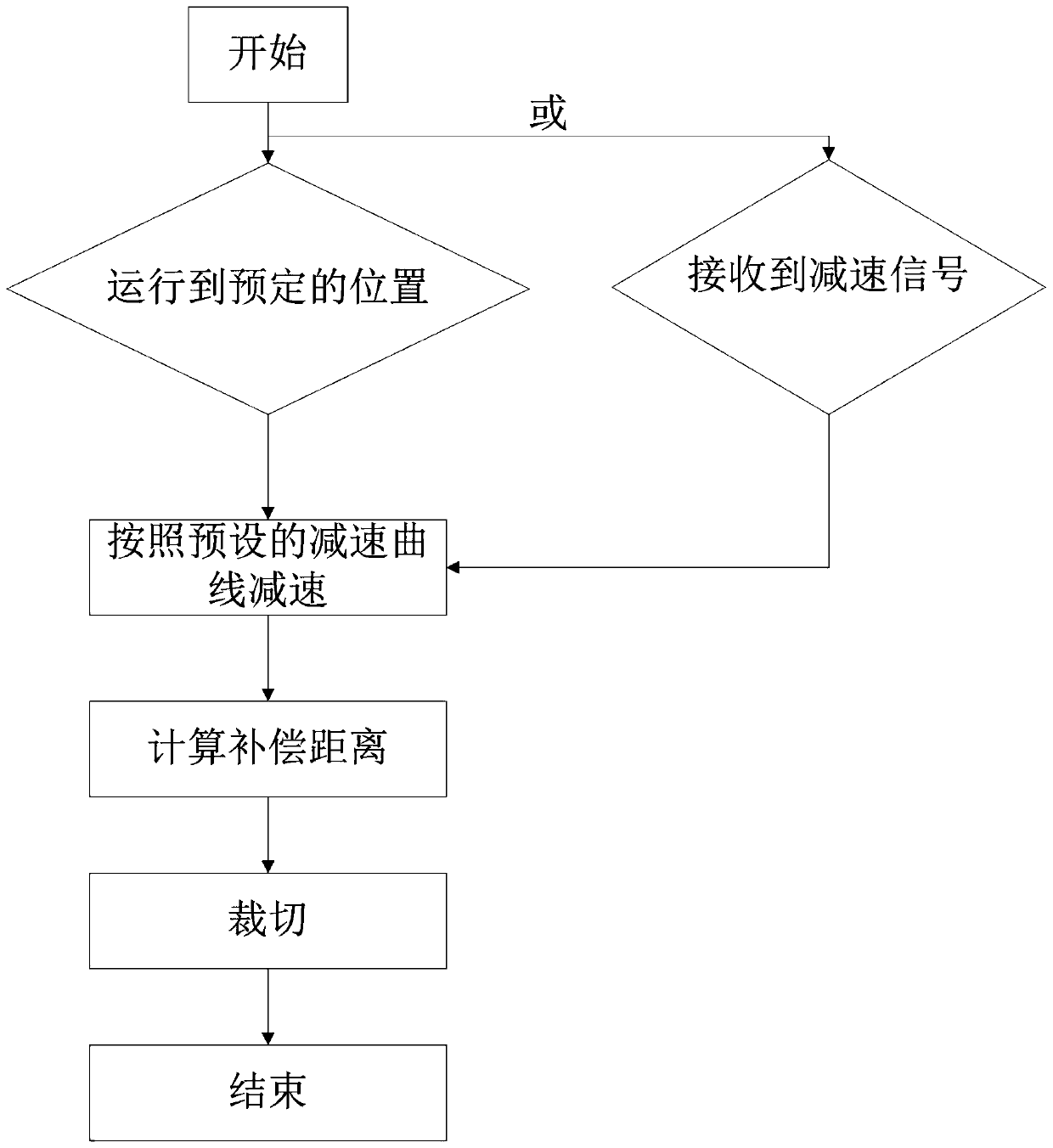

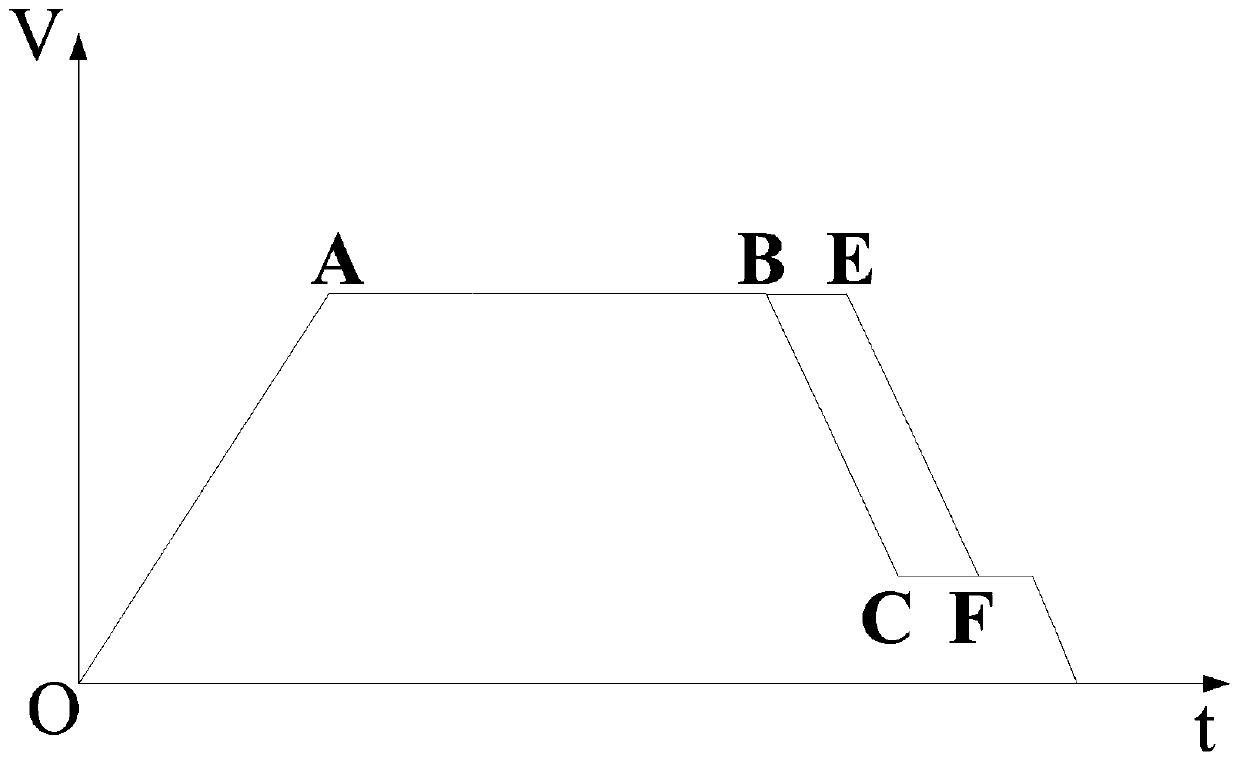

[0029] This embodiment provides a deceleration cutting control method, please refer to figure 1 , which is a flow chart of the deceleration and cutting control method in this embodiment. The deceleration and cutting control method of this embodiment includes: when the product to be cut runs to a predetermined position, or receives a deceleration signal, the product to be cut is decelerated according to a preset deceleration curve; The set deceleration curve completes the deceleration, and the product to be cut is cut. That is to say, when the cutting product moves to the predetermined position and any one of the conditions of receiving the deceleration signal is met, the product to be cut will decelerate according to the preset deceleration curve. For example, when the cutting product moves to the predetermined position but If the deceleration signal is not received, the product to be cut will decelerate according to the preset deceleration curve, or, when the deceleration si...

Embodiment 2

[0036] This embodiment provides a deceleration and cutting control device, which includes a conveying element, a detection element, a sensor, a controller, and a cutting element. The conveying part is used to convey the products to be cut, and the conveying part includes a main drive motor, a winding motor and a plurality of rollers. The detection element is used to detect the running state of the conveying piece. The detection element includes an encoder, which is installed on one of the rollers. The encoder measures the angle or number of turns of the roller, and outputs a pulse signal according to the measured angle or number of turns. The sensor is used to sense the product to be cut and emit a deceleration signal. The sensor can be a deceleration photoelectric sensor. When the sensor detects that the product to be cut enters the sensing range, it emits a deceleration signal.

[0037] The controller judges whether the product to be cut runs to the predetermined position or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com