Planet speed reducer with efficient heat dissipation function

A planetary reducer, high heat dissipation technology, applied in the field of planetary gear reducer, high heat dissipation planetary reducer, can solve the problems of inability to use for a long time, poor heat dissipation effect, short use time, etc., to achieve easy promotion and use, cooling effect Good, improve the effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

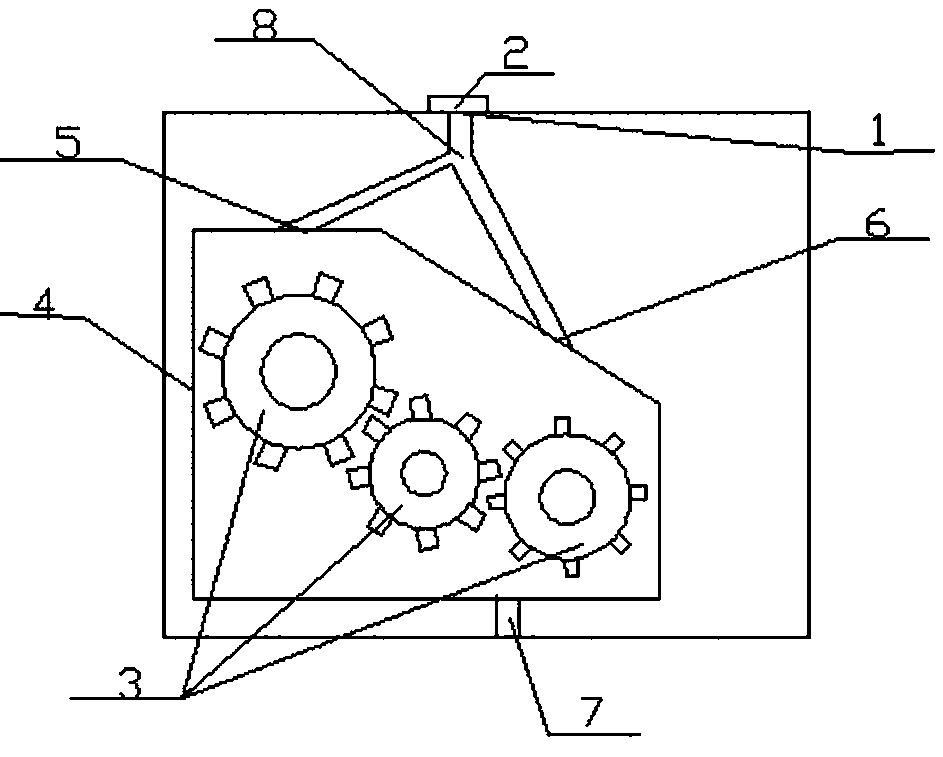

[0018] Such as figure 1 As shown, the present invention provides a high heat dissipation planetary reducer, including the outer shell 1, the inner shell 2, the first sun gear 7 and the first planetary gear 11, the inner shell 2 is welded by the mounting bracket 3 at the outer bottom end and the connecting bolts Installed and fixed in the outer shell 1, the shell wall of the inner shell 2 is provided with a number of cooling holes 5 for dissipating the heat in the inner shell 2, and the shell wall of the outer shell 1 is symmetrically provided with several arc-shaped heat dissipation pipes 4 , used to discharge the heat dissipated from the heat dissipation holes 5, and the center of the arc heat dissipation pipe 4 is bent upwards, which can prevent the water on the shell wall of the outer shell 1 from flowing into the interior, and then enter the inner shell 2 through the heat dissipation holes 5, Damage to the equipment in the inner shell 2 occurs, so that the arc-shaped heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com