Spray purification device and method

A purification device and spray head technology, applied in the field of air purification, can solve the problems of lack of air purification equipment and expensive dust removal equipment, and achieve the effects of compact structure, small footprint and high speed reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

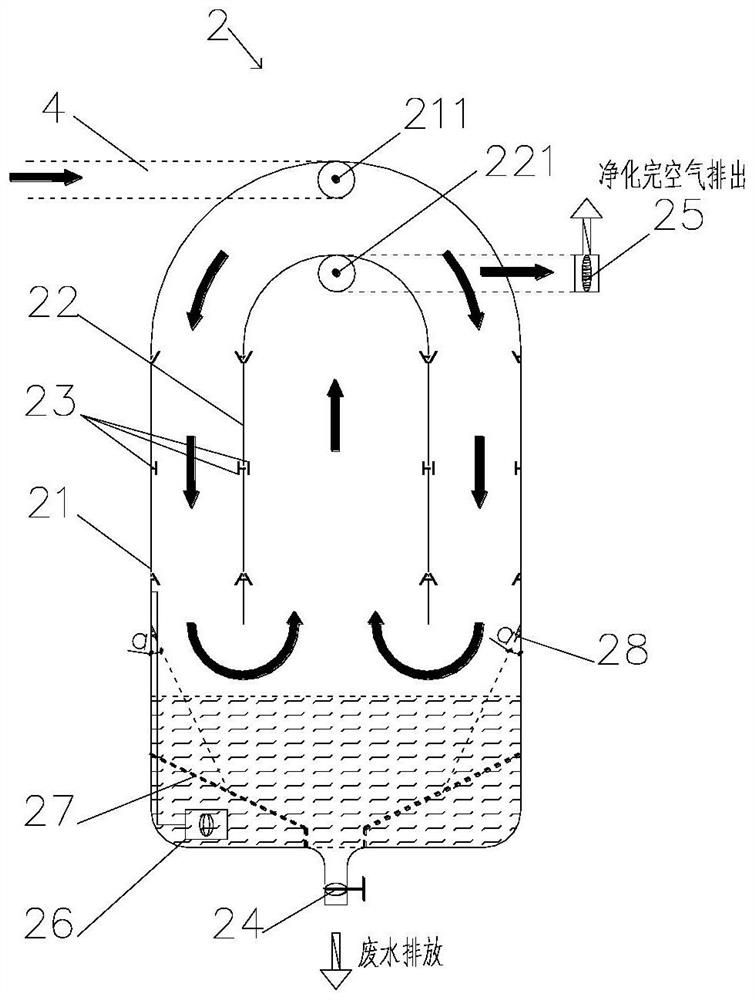

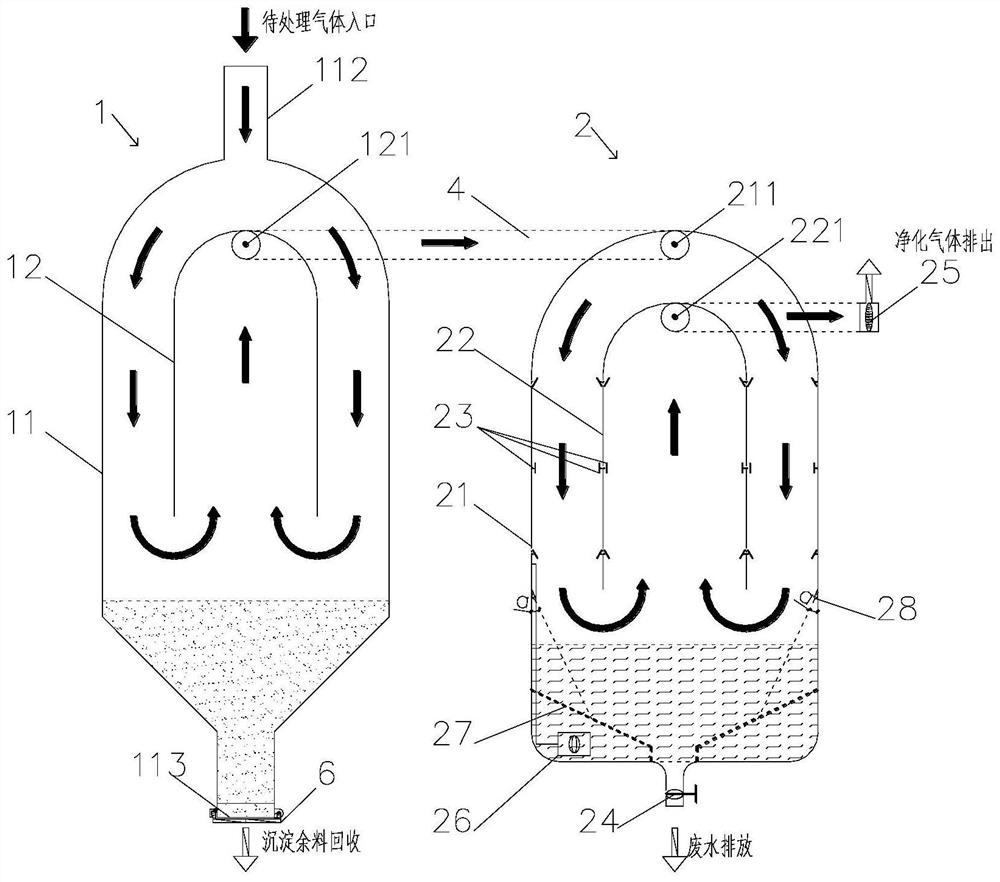

[0040] see figure 1 , the present embodiment provides a spray purification device, including a closed container 21, an inverted container 22 and several pipelines with spray heads 23, the top of the closed container 21 offers an air inlet 211, the closed The bottom of the container 21 is used as a sump, and the bottom of the sump is provided with a first waste water discharge valve 24. The inverted container is an inverted U-shaped structure, and the inverted container 22 is coaxially arranged in the closed container 21. The cross section of the inverted container 22 and the closed container 21 is circular, the top of the inverted container 22 is provided with an exhaust port 221, the bottom of the inverted container 22 is opened, and the gas under pressure with dust is The gas to be treated enters the inside of the closed container 21 through the air inlet 211, passes through the channel between the closed container 21 and the inverted container 22, flows into the inverted co...

Embodiment 3

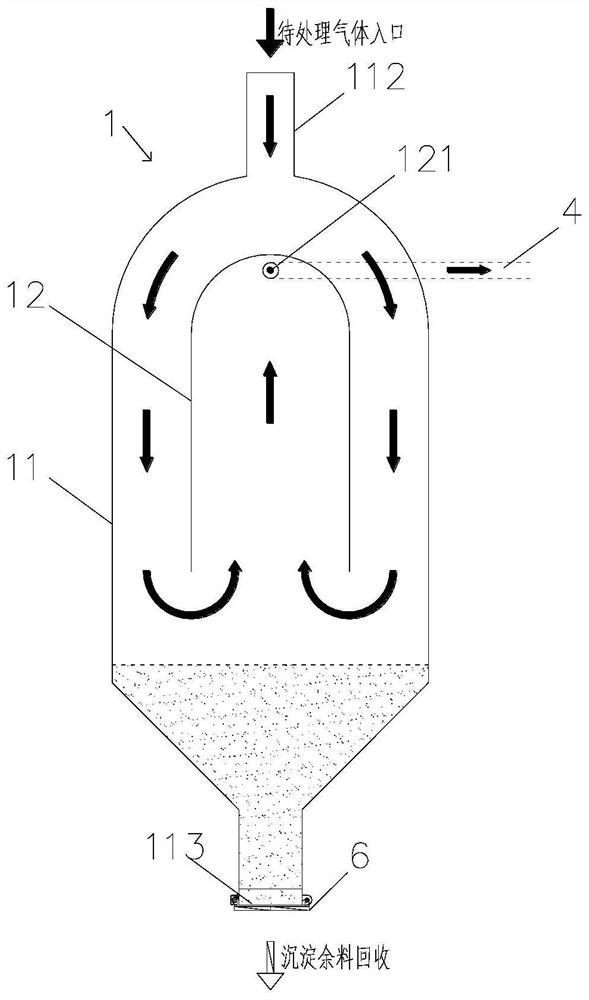

[0054] see Figure 2 to Figure 3 The difference between the pressurized gas purification method provided in the third embodiment and the second embodiment is that, before using the spray purification device 2 to process the dust pressurized gas, that is, the gas to be treated, the gravity sedimentation device 1 is used to expand the volume of the gas to be treated. speed, to precipitate solid particles with a particle size of 10-100 μm in the gas, and the gravity sedimentation device 1 is sealed and connected with the spray purification device 2 through the first pipeline 4 .

[0055] Preferably, in the above-mentioned spray purification device, the gravity sedimentation device 1 includes a first airtight container 11 and a first inverted container 12, the top of the first airtight container 11 has a first air inlet 112, the The bottom of the first airtight container 11 offers the sedimentation residue recovery port 113, and the first inverted container 12 is an inverted U-sha...

Embodiment 4

[0061] see Figure 5 to Figure 9 , and can be combined with Figure 1 to Figure 4 The difference between the present embodiment and the third embodiment is that the gas treated by the spray purification device 2 is also subjected to liquid-gas combination purification treatment through the liquid dust removal and mixing device 3 chamber, so that the solid particles in the gas are further dissolved in the liquid. The spray purification device 2 is in sealing connection with the liquid dust removal and mixing device 3 through the second pipeline 5, that is to say, the exhaust port 221 is not externally connected with the exhaust valve 25 for discharging the purified gas, but passes through the second pipeline 5 It is sealingly connected with the liquid dust removal and mixing device 3 , that is to say, the spray purification device 2 is sealed and connected with the liquid dust removal and mixing device 3 through the second pipeline 5 .

[0062] The liquid dedusting mixing devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com