Automatic test equipment

A technology of automated testing and equipment, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of affecting the efficiency of testing, inconvenient movement, large plate volume, etc., to achieve accelerated deceleration efficiency, Reasonable design to reduce the effect of staying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

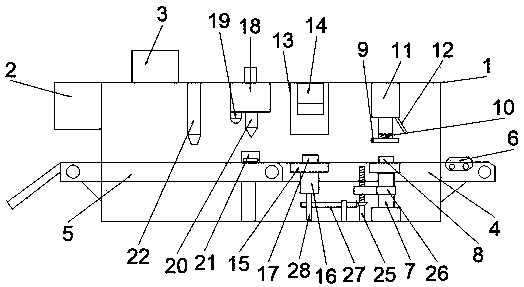

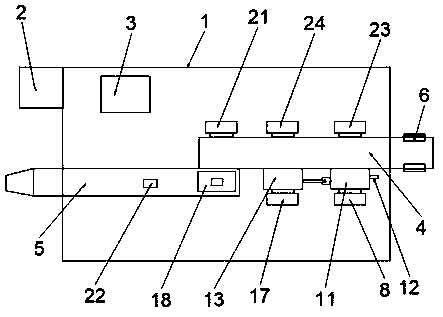

[0020] Such as Figure 1-2 As shown, an automated testing device includes a housing 1, a transmission mechanism and a controller, the controller is fixed on the outside of the housing 1, the transmission mechanism is fixed in the housing 1, and the transmission mechanism includes a first transmission belt 4 and the second conveyor belt 5, the first conveyor belt 4 is parallel to the second conveyor belt 5, and the second conveyor belt 5 is located on the left side of the first conveyor belt 4, and the first conveyor belt 4 is arranged successively according to the transmission direction There is a compression test mechanism and a heat insulation test mechanism. A corrosion resistance test mechanism is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com