Coaxial multi-stage gearbox

A gearbox, coaxial technology, applied in the direction of transmission boxes, gear transmissions, components with teeth, etc., can solve the problems of low deceleration efficiency, inconvenient, limited, etc., and achieve the effect of improving service life and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

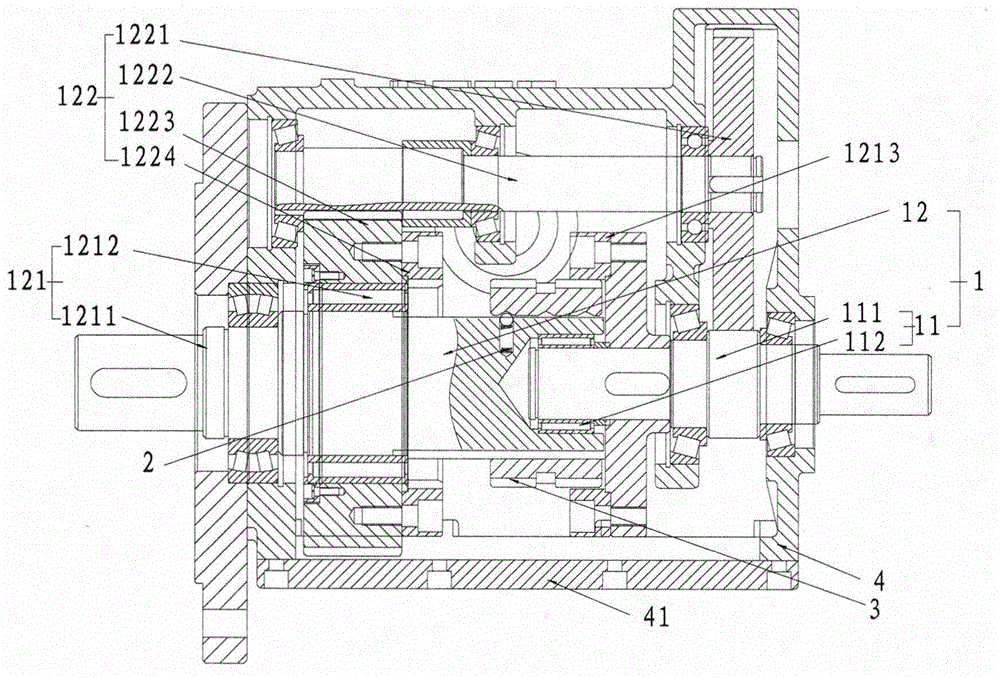

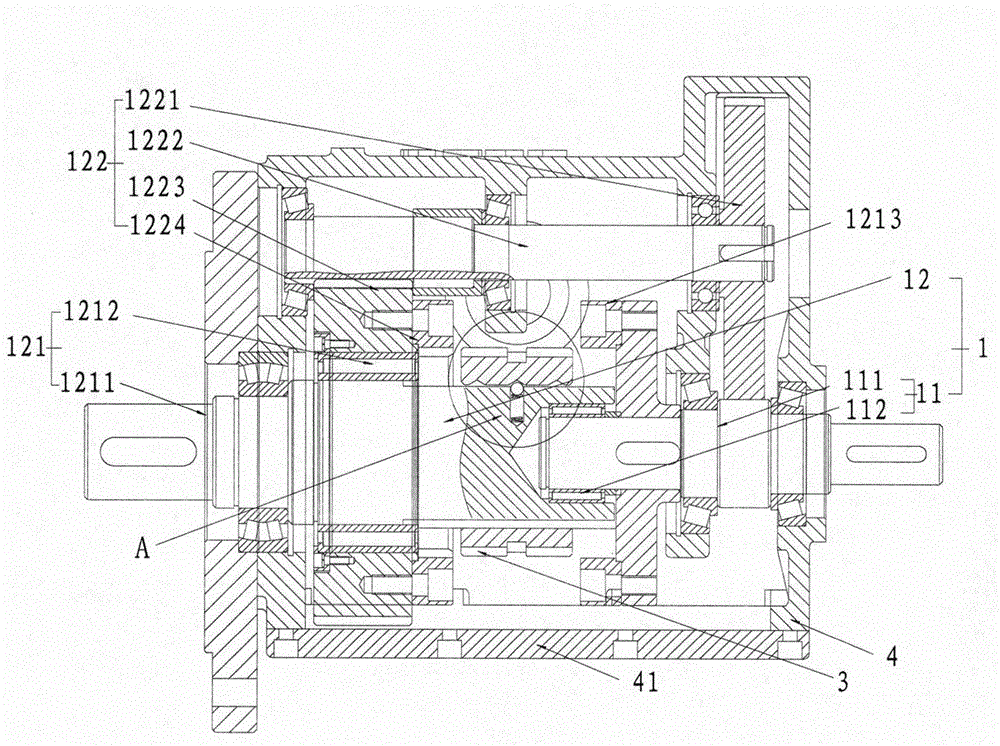

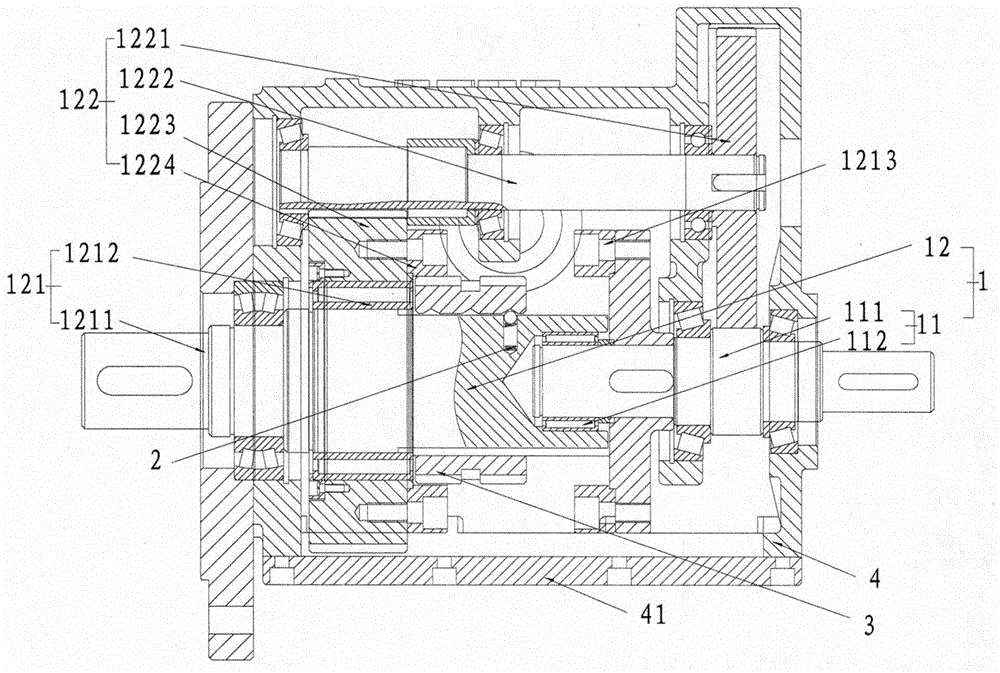

[0030] refer to Figure 1 to Figure 5 The embodiment of the coaxial multi-stage gearbox of the present invention will be further described.

[0031] A coaxial multi-stage gearbox includes a box body 4, and the box body 4 is provided with a driving device 1 and an adjusting transmission device 3 that can be engaged with the driving device 1 so that the driving device 1 outputs various powers.

[0032] The driving device 1 includes an input system 11, the input system 11 includes an input drive pinion 111; and an output system 12, the output system 12 includes an output main shaft 1212, which can be engaged with the input drive pinion 111 to output various powers. The driving output device 121 and the driven output device 122 ; the adjusting transmission device 3 includes a clutch gear meshed with the driving output device 121 and the driven output device 122 , and the output main shaft 1212 runs through the clutch gear.

[0033] The box body 4 includes a first housing 41; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com