Efficient planet gear speed reducer with cooling function

A planetary gear reduction and planetary gear technology, which is applied in the field of planetary gear reducers and high-efficiency planetary gear reducers, can solve the problems of inability to use for a long time, short use time, poor heat dissipation, etc., to facilitate promotion and use, and improve use Good effect of time and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

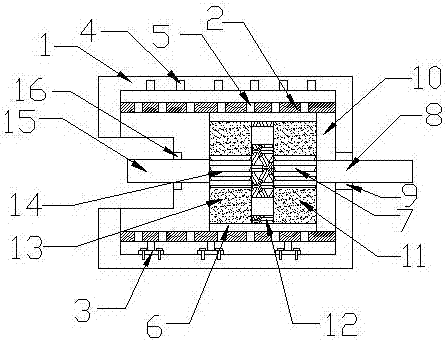

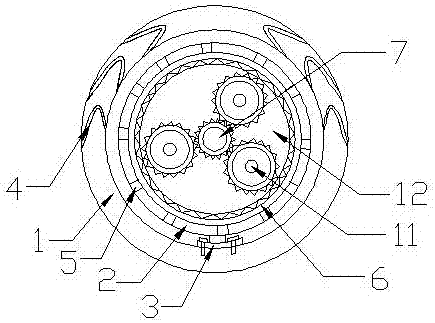

[0019] Such as Figure 1-2 As shown, the present invention provides a high-efficiency planetary gear reducer with heat dissipation function, including the outer shell 1, the inner shell 2, the first sun gear 7 and the first planetary gear 11, and the inner shell 2 is welded by the mounting bracket at the outer bottom end 3 and the connecting bolts are installed and fixed in the outer shell 1. Several heat dissipation holes 5 are provided on the shell wall of the inner shell 2 to dissipate the heat in the inner shell 2. Several arc holes are symmetrically arranged on both sides of the shell wall of the outer shell 1. The arc-shaped heat dissipation pipe 4 is used to discharge the heat emitted by the heat dissipation holes 5, and the center of the arc heat dissipation pipe 4 is bent upwards, which can prevent the water on the wall of the shell 1 from flowing into the interior, and then enter the interior through the heat dissipation holes 5. In the shell 2, damage to the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com