Bridge frame walking driving mechanism of bridge crane

An overhead crane, traveling drive technology, applied in the directions of traveling mechanism, load hanging element, transportation and packaging, can solve the problems of increasing machine cost, reducing wheel life, uneven force on wheels, etc., to protect wheels and rails. , the inertia walking distance is short, the effect of shortening the transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

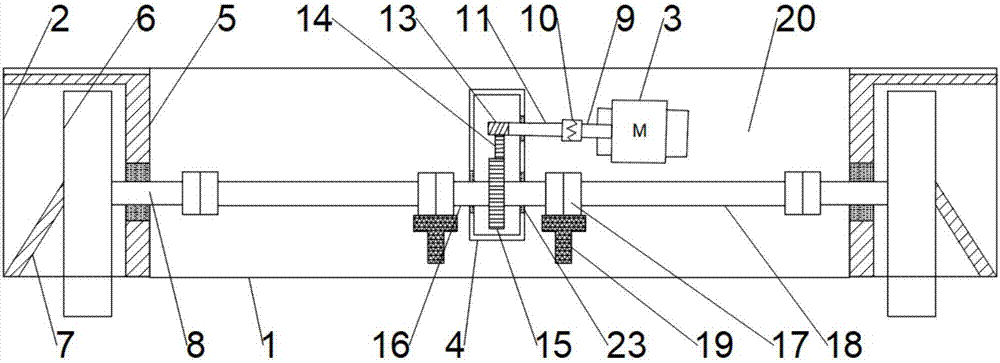

[0027] Such as figure 1 As shown, the present invention provides a traveling driving mechanism for a bridge crane. Connected with the main beam 1, the end beam 2 is equipped with wheels 6 through the angular bearing box 5, and the angular bearing box 5 is installed on the outside of the end beam 2, and the angular bearing box 5 serves to fix the wheels and bear the pressure of the cart , so that the heavy-duty running of the cart is smoother, the angular bearing box 5 includes the angular box 7 and the wheel axle 8, the angular box 7 and the wheel 6 are installed on the outside of the wheel axle 8, the angular box 7 can be well The wheel 6 is limited, and the corner box 7 is provided with several bearing groups for buffering the gravity of the wheel shaft 8.

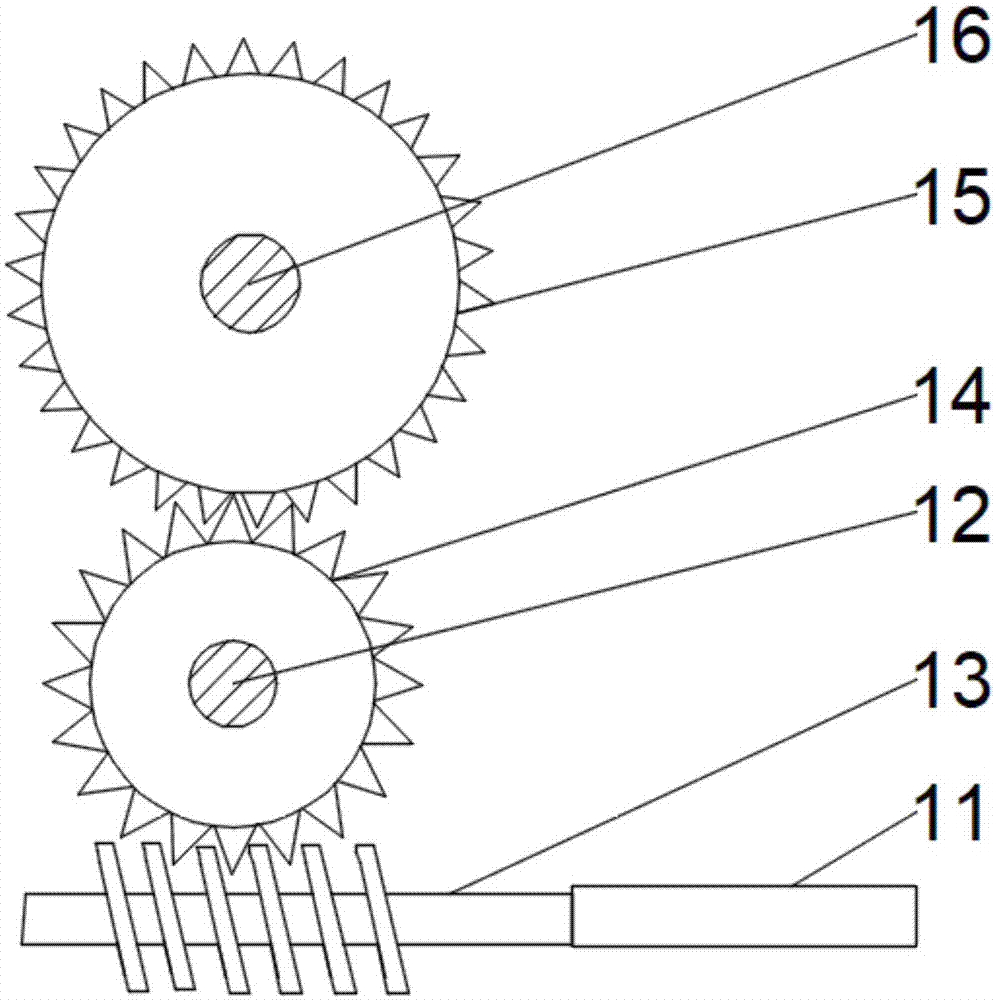

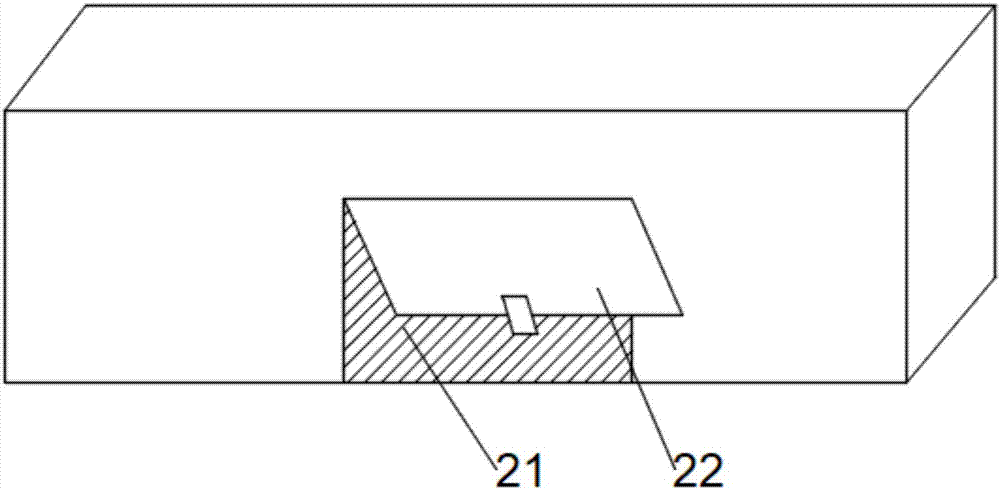

[0028] Such as figure 1 with image 3 As shown, a motor 3 and a reducer 4 are installed in the center of the main beam 1, the main beam 1 has an internal hollow structure, a hollow interlayer 20 is installed in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com