Zero-return-difference involute small-tooth-difference reduction box

A technology with involute and less tooth difference, which is applied in the direction of mechanical equipment, gear transmission, transmission parts, etc., can solve the problems of reduced bearing capacity, increased manufacturing cost, large axial force, etc., and achieves simple manufacturing process and Effects of cost reduction and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

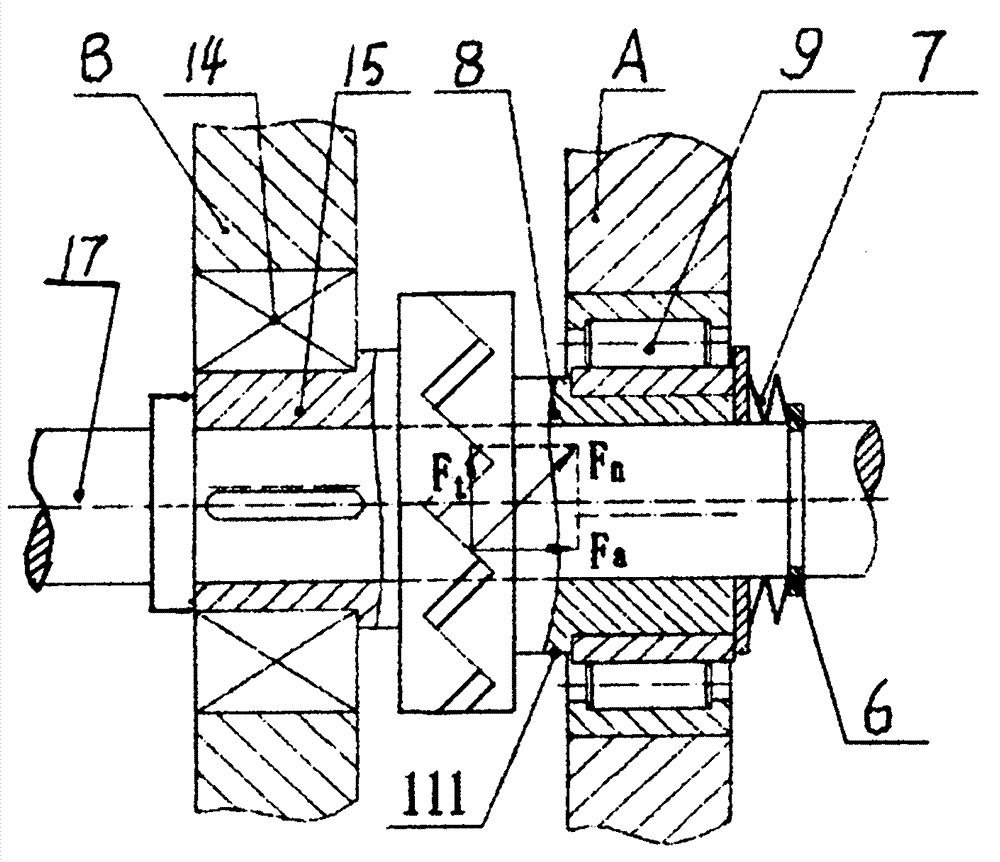

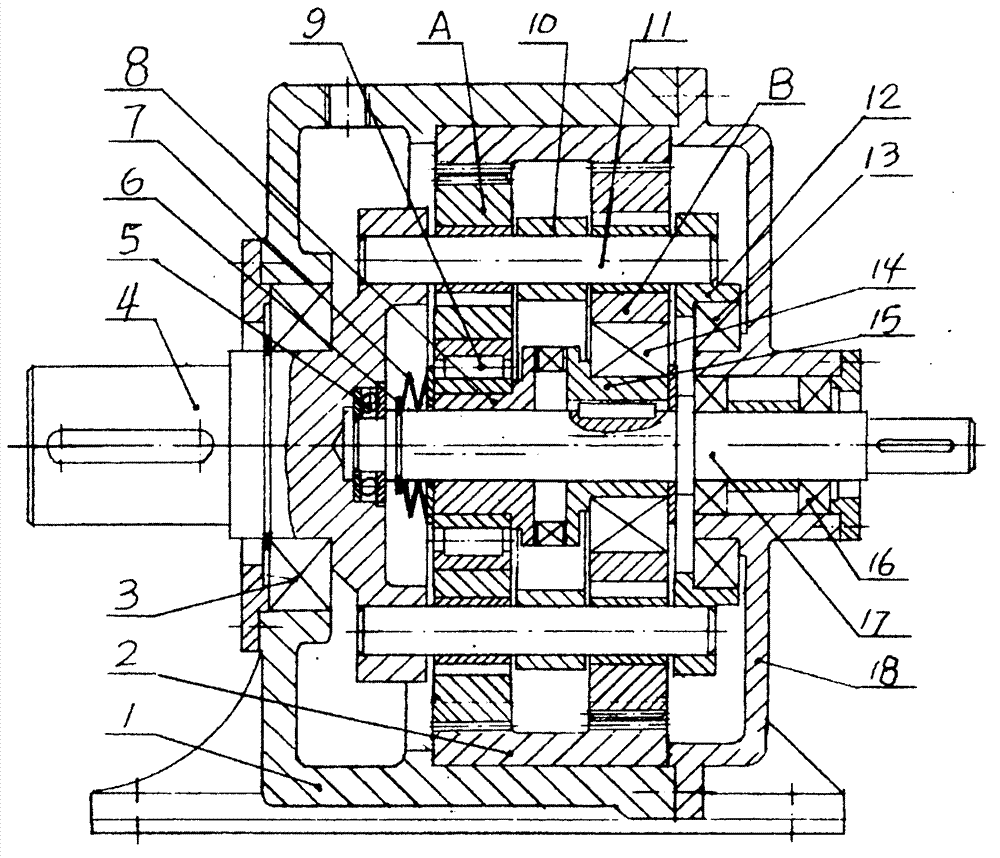

[0028] Such as figure 1 and 2 As shown, a zero-hysteresis involute reducer with less tooth difference includes a machine base 1, two planetary gears A, B, an inner ring gear 2, an input shaft 17, an end cover 18 and a w output mechanism, and the input shaft 17 is supported in the end cover 18 with the first bearing 16, and the end cover 18 is connected to the end surface of the machine base 1. The w output mechanism includes the output shaft 4, the evenly distributed column pins 11 and the first Load sharing ring 10, one end of the column pin 11 is closely matched with the hole on the disc of the output shaft 4, and the other end is slidingly matched with the hole on the second load sharing ring 12, and the output shaft 4 and the second load sharing ring 12 The second and third bearings 3, 13 are respectively supported on the outer circle of the inner hole of the machine base 1 and the inner flange of the end cover 18, which is characterized in that:

[0029] The inner ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com