Outer rotor plane motor traction machine

A motor traction machine, planar motor technology, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of poor practical functionality, increased axial thickness, waste of axial space, etc., to save thickness space , Reduce the axial thickness and save the axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

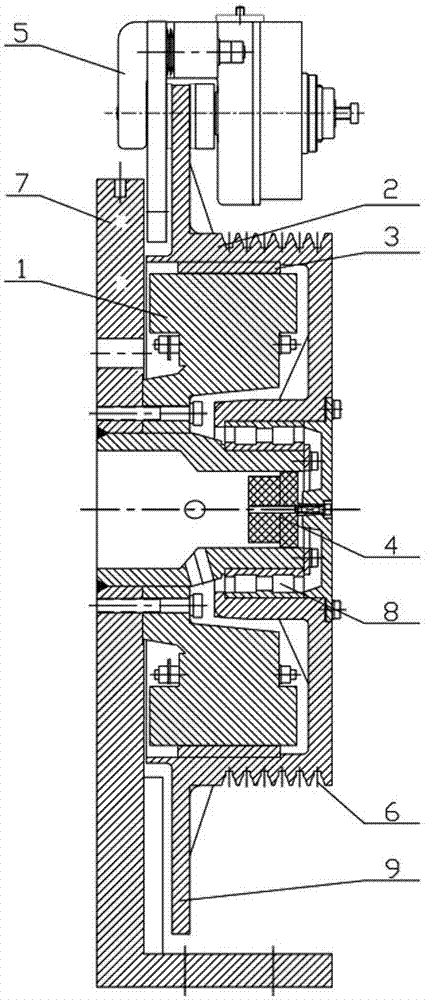

[0014] refer to figure 1 , the specific embodiment adopts the following technical solutions: the outer rotor planar motor traction machine includes a motor stator 1, a traction wheel 2, a permanent magnet 3, an encoder 4 and a disc brake 5, and the outer surface of the traction wheel 2 is arranged There is a wire rope groove 6, and a permanent magnet 3 is pasted on the inner surface of the traction sheave 2. As the rotor of the permanent magnet synchronous motor, one part is used as both the traction sheave and the rotor of the motor, and is also used as a brake disc. , Motor stator 1 is installed inside the motor housing, and a symmetrical three-phase AC coil is wound on the motor stator 1. An encoder 4 is installed in the middle of the hollow sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com