Polyaniline/carbon nanotube/cotton fabric composite flexible electrode with high specific capacitance, and preparation and application thereof

A technology of carbon nanotubes and high specific capacitance, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

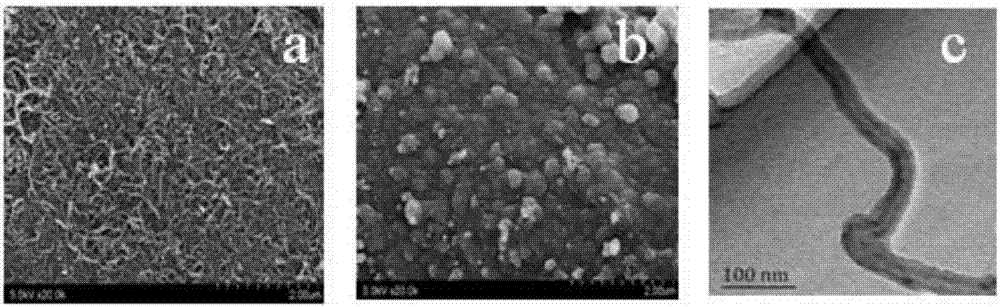

[0032] (1) Preparation of carbon nanotube solution:

[0033] Add carboxylated carbon nanotubes to deionized water, then add sodium dodecylbenzenesulfonate (total ratio of carbon nanotubes is 1:1), stir, ultrasonic 1h, and finally use a homogenizer to disperse, A carbon nanotube dispersion was obtained.

[0034] (2) Preparation of carbon nanotube / cotton composite:

[0035] Immerse the cotton fabric in the prepared carbon nanotube solution (preferably the surface is impregnated) and place it in an infrared proofer for treatment. The treatment condition is 5°C / min to 135°C for 70min; then take it out and place it in an oven at 100°C Tumble dry on medium; finish with water rinse and line dry at room temperature.

[0036] (3) Preparation of polyaniline / carbon nanotube / cotton composite:

[0037] Soak 0.5g carbon nanotube / cotton composite in 200mL mixed solution containing 0.5mol / L hydrochloric acid and 0.25mol / L aniline for 1h, then add 40mL 0.25mol / L ammonium persulfate solution...

Embodiment 2、3

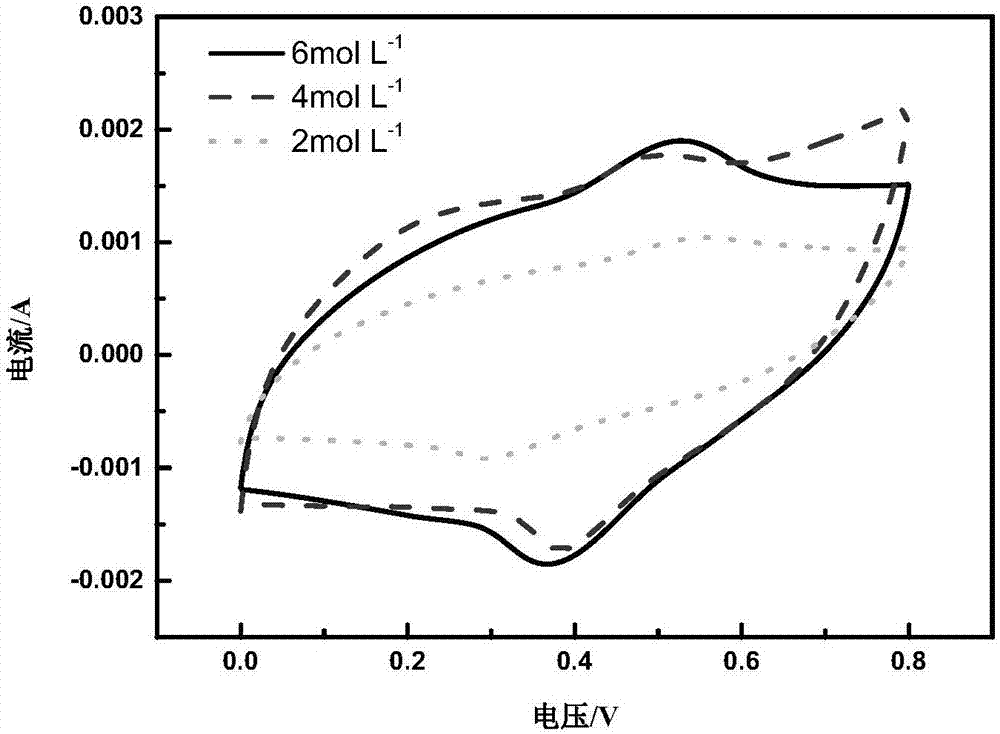

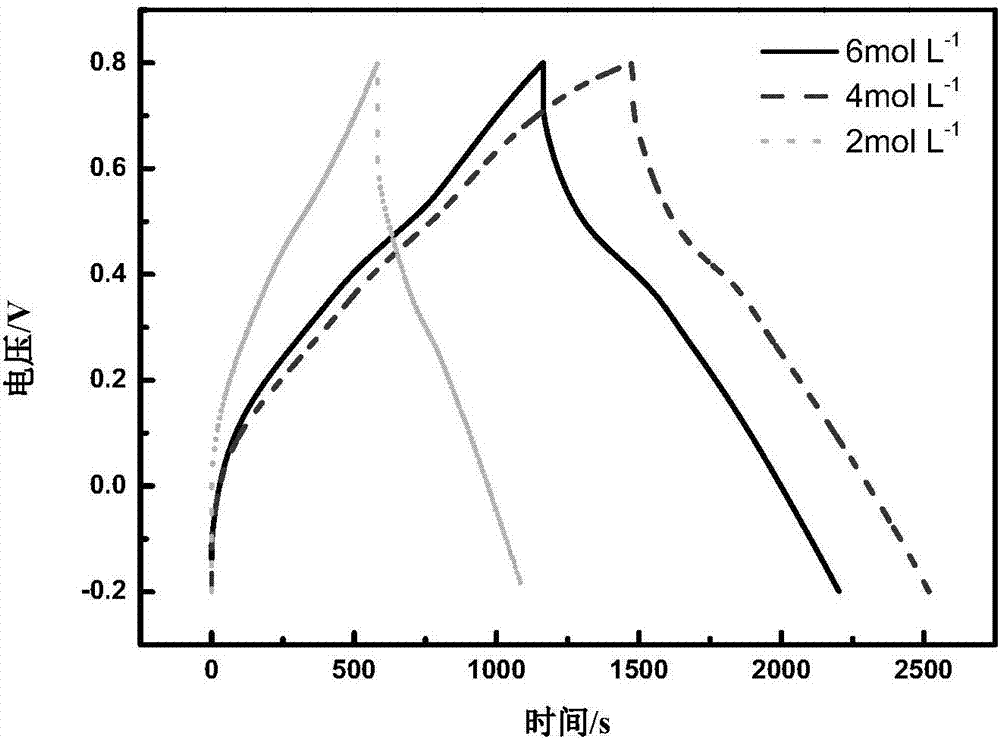

[0043] The operation process is the same as that of Example 1, but the performance of the material under different conditions is discussed, because different electrolyte concentrations will stimulate different energy storage capabilities of the electrode material. The sodium chloride concentration that embodiment 2 adopts is 4mol L -1 , the concentration of the sodium chloride that embodiment 3 adopts is 6mol L -1 .

[0044] In the above examples, carbon nanotubes were purchased from Beijing Boyu Co., Ltd., and the performance parameters are shown in Table 1. All other reagents used were of analytical grade and no further purification was required during use. The infrared proofing machine was purchased from Suzhou Starle Printing and Dyeing Machinery Co., Ltd., the instrument model is DL-6000Plus (Starle-3); use the RTS-9 double electric measuring four-probe tester (Guangzhou Simei Technology Co., Ltd.) to test the square resistance . The electrochemical workstation CHI660...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com