Preparation method of spherical powder of refractory material

A spherical powder and refractory technology, which is applied in the field of preparation of spherical powder of refractory materials, can solve the problems of low quality of spherical powder, low yield of spherical powder, difficulty in separating unspheroidized powder, etc., and shorten the melting time time, shorten the preparation cycle, and increase the surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment includes the following steps:

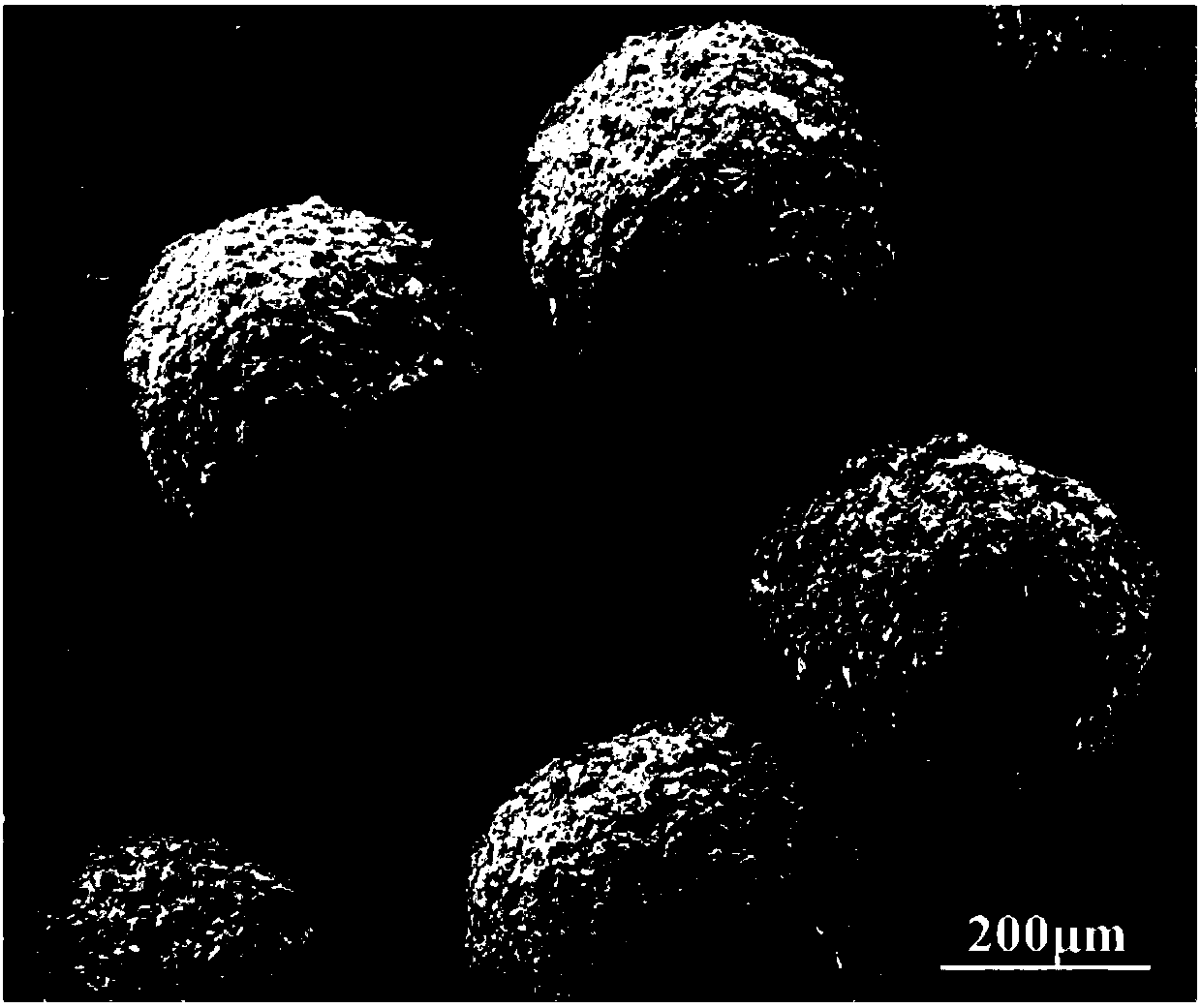

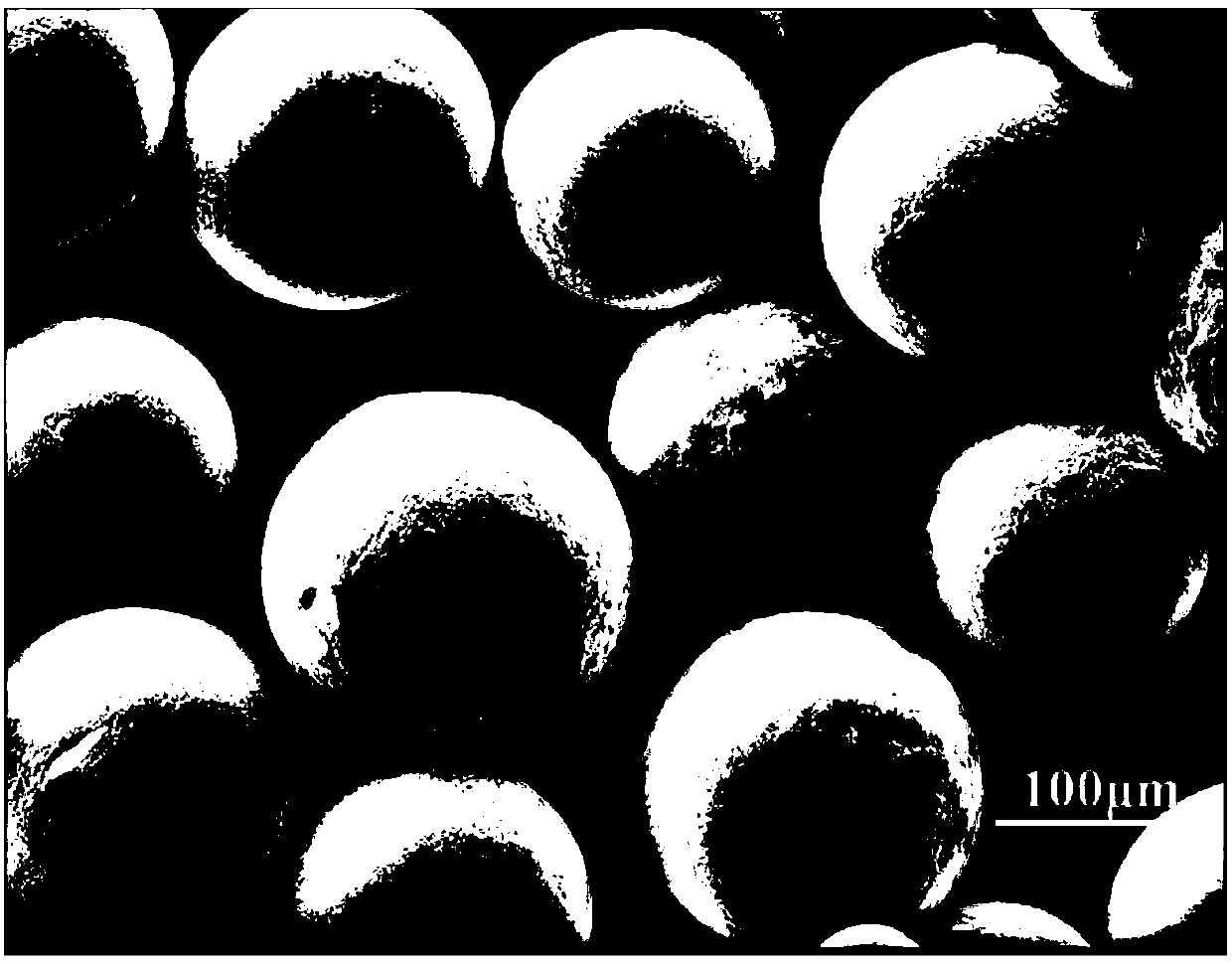

[0036] Step 1. Add 160 g of non-spheroidized tantalum powder and 20 g of polyvinyl alcohol aqueous solution into a mixer and mix for 60 minutes, then spray granulate to obtain spherical tantalum prefabricated pellets; the non-spheroidized tantalum powder The particle size of the polyvinyl alcohol solution is 10 μm, the mass concentration of the polyvinyl alcohol aqueous solution is 4%, the particle size of the prefabricated aggregate is 220 μm, and the porosity is 60%;

[0037] Step 2. Put the tantalum prefabricated pellet obtained in step 1 into a sintering furnace for vacuum sintering to obtain a tantalum prefabricated pellet body; the vacuum degree of the vacuum sintering is 1.0×10 -3 Pa, the heating rate is 2°C / min, the temperature is 1400°C, and the time is 3h;

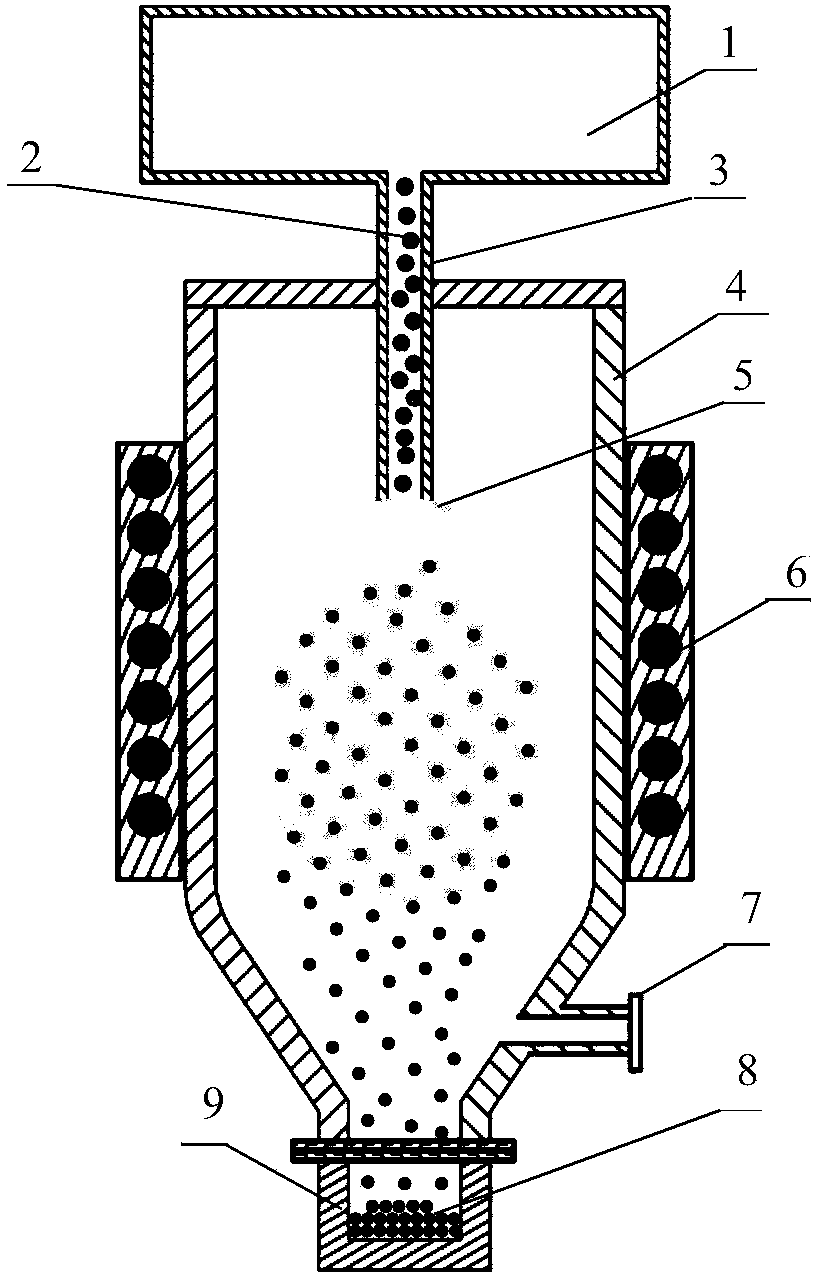

[0038] Step 3, set the power of the plasma equipment to 40kW, put the tantalum prefabricated pellet body obtained in step 2 into the quantitative powder fee...

Embodiment 2

[0044] This embodiment includes the following steps:

[0045] Step 1. Add 240g of non-spheroidized niobium-tungsten-tantalum alloy powder and 20g of polyvinyl alcohol aqueous solution into a mixer and mix for 60 minutes, then spray granulate to obtain spherical niobium-tungsten-tantalum alloy prefabricated pellets; The particle size of the chemically treated niobium-tungsten-tantalum alloy powder is 0.1 μm, the mass concentration of the polyvinyl alcohol aqueous solution is 6%, the particle size of the niobium-tungsten-tantalum alloy prefabricated pellets is 100 μm, and the porosity is 40%;

[0046] Step 2. Put the niobium-tungsten-tantalum alloy prefabricated pellets obtained in step 1 into a sintering furnace for hydrogen atmosphere protective sintering to obtain the niobium-tungsten-tantalum alloy prefabricated pellet body; the hydrogen gas flow rate for the hydrogen atmosphere protective sintering is 5L / min, The heating rate is 10°C / min, the temperature of hydrogen atmosph...

Embodiment 3

[0052] This embodiment includes the following steps:

[0053] Step 1. Add 220g of tungsten carbide alloy powder without spheroidization treatment and 20g of polyvinyl alcohol aqueous solution into a mixer and mix for 30 minutes, then spray granulate to obtain spherical tungsten carbide alloy prefabricated pellets; The particle size of the tungsten carbide alloy powder is 1.8 μm, the mass concentration of the polyvinyl alcohol aqueous solution is 2%, the particle size of the tungsten carbide alloy prefabricated pellets is 50 μm, and the porosity is 20%;

[0054] Step 2. Put the tungsten carbide alloy prefabricated pellets obtained in step 1 into a sintering furnace for hydrogen atmosphere protective sintering to obtain a tungsten carbide alloy prefabricated pellet green body; the hydrogen flow rate for the hydrogen atmosphere protective sintering is 30 L / min, and the heating rate is The temperature is 5°C / min, the temperature of hydrogen atmosphere protection sintering is 1400°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com