Carbon nanotube fibrous composite material and preparation method thereof

A carbon nanotube fiber and composite material technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of not preparing carbon nanotube fiber composite materials, difficult single-layer film deep compounding, and mutual interaction Low-level problems, to achieve the effect of obvious interspersed effect, easy molding, and strong interlayer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

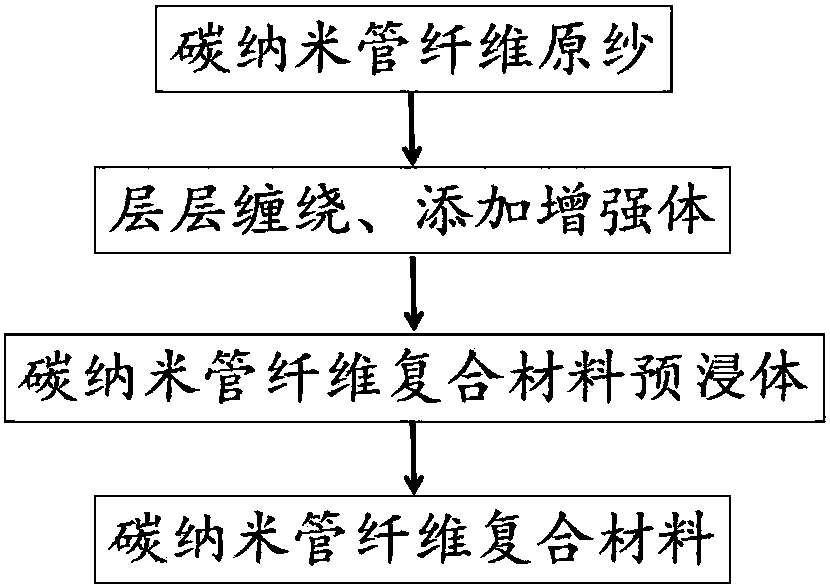

[0033] An aspect of the embodiments of the present invention provides a method for preparing a carbon nanotube fiber composite material, which includes:

[0034] Provide one-dimensional carbon nanotube fibers;

[0035] A layer-by-layer winding method is adopted, and a reinforcement is added during the layer-by-layer winding process, so that the carbon nanotube fibers are stacked and arranged layer by layer to form a carbon nanotube fiber composite material prepreg with a layered composite structure;

[0036] The carbon nanotube fiber composite material prepreg is molded to obtain the carbon nanotube fiber composite material.

[0037] In some typical implementation cases, the carbon nanotube fibers exist in the form of one-dimensional fibers, which can be any one or a combination of two or more of twisted fibers, untwisted fibers, and flat filaments, But not limited to this.

[0038] More preferably, the carbon nanotube fiber is a flat filament, because the flat filament can ...

Embodiment 1

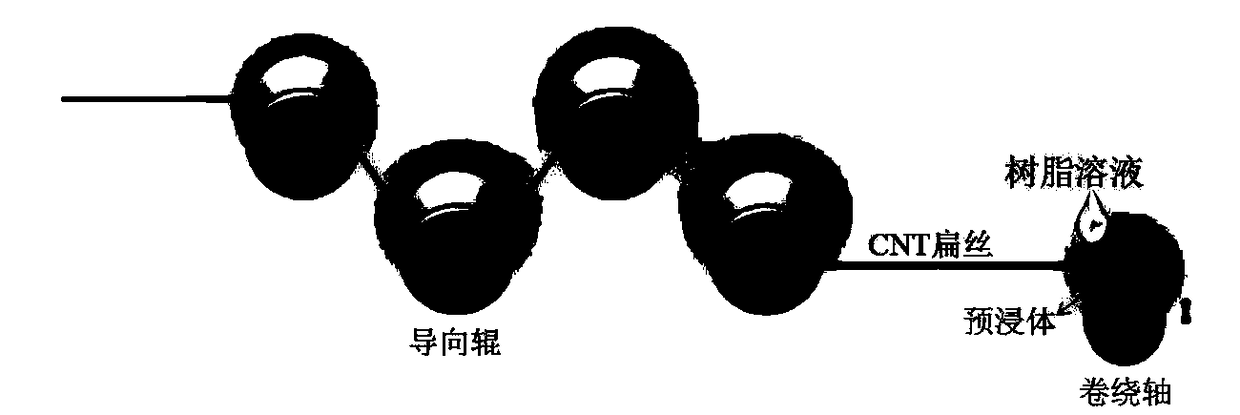

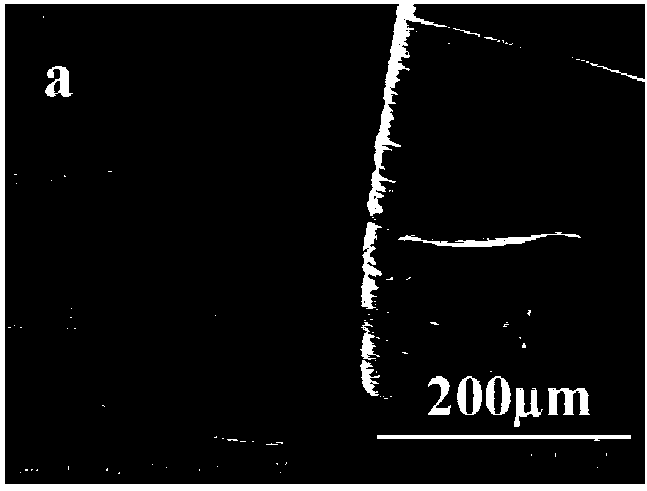

[0083]Take a shaft of carbon nanotube fiber flat filament, the length is about 100 meters, the width is about 200 μm, the thickness is 10 μm, and the tensile breaking load is about 1N. First place the carbon nanotube fiber shaft on the pay-off shaft, draw the carbon nanotube fiber and make it pass through the yarn guide shaft, the number of the yarn guide shaft can be selected according to the tension of the yarn (ie carbon nanotube fiber), and then the carbon nanotube fiber The fiber is wound on the collection shaft, the winding distance between two adjacent coils is set to 100 μm, the winding angle is 30 degrees, the yarn tension is 500-600mN, the winding width is 10cm, the winding speed is 1m / min, and the winding time is 20min, during the winding process, it is infiltrated with epoxy resin / acetone solution with a mass concentration of 5% to form a composite material prepreg, and then it is removed from the collection shaft, and then hot-pressed at 130°C for 1 hour under a pr...

Embodiment 2

[0085] A shaft of flat carbon nanotube fiber is taken, the length is about 100 meters, the width is about 500 μm, the thickness is about 10 μm, and the tensile breaking load is about 3N. First place the carbon nanotube fiber shaft on the pay-off shaft, lead out the fiber to pass through the yarn guide shaft, the number of yarn guide shafts can be selected according to the yarn tension, and then place the yarn on the collection shaft, between two adjacent coils The winding distance is set to 250 μm, the winding angle is 85 degrees, the yarn tension is 1-1.2N, the winding width is 10cm, the winding speed is 2m / min, the winding time is 50min, and the mass concentration is 5 during the winding process. % epoxy resin / acetone solution infiltration to form a composite material prepreg, then removed from the collection shaft, and then hot pressed at 130° C. for 1 hour under a pressure of 7 MPa to form a carbon nanotube fiber composite material. The carbon nanotube fiber composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com