Polyurethane coating layer for aircraft organic glass, and preparation method thereof

A polyurethane coating and plexiglass technology, applied in polyurea/polyurethane coatings, coatings, chemical instruments and methods, etc., can solve the problems of inability to meet the needs of use, cracking and peeling of coatings, inability to prevent static electricity, etc. Excellent weather resistance, extended service life, and the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

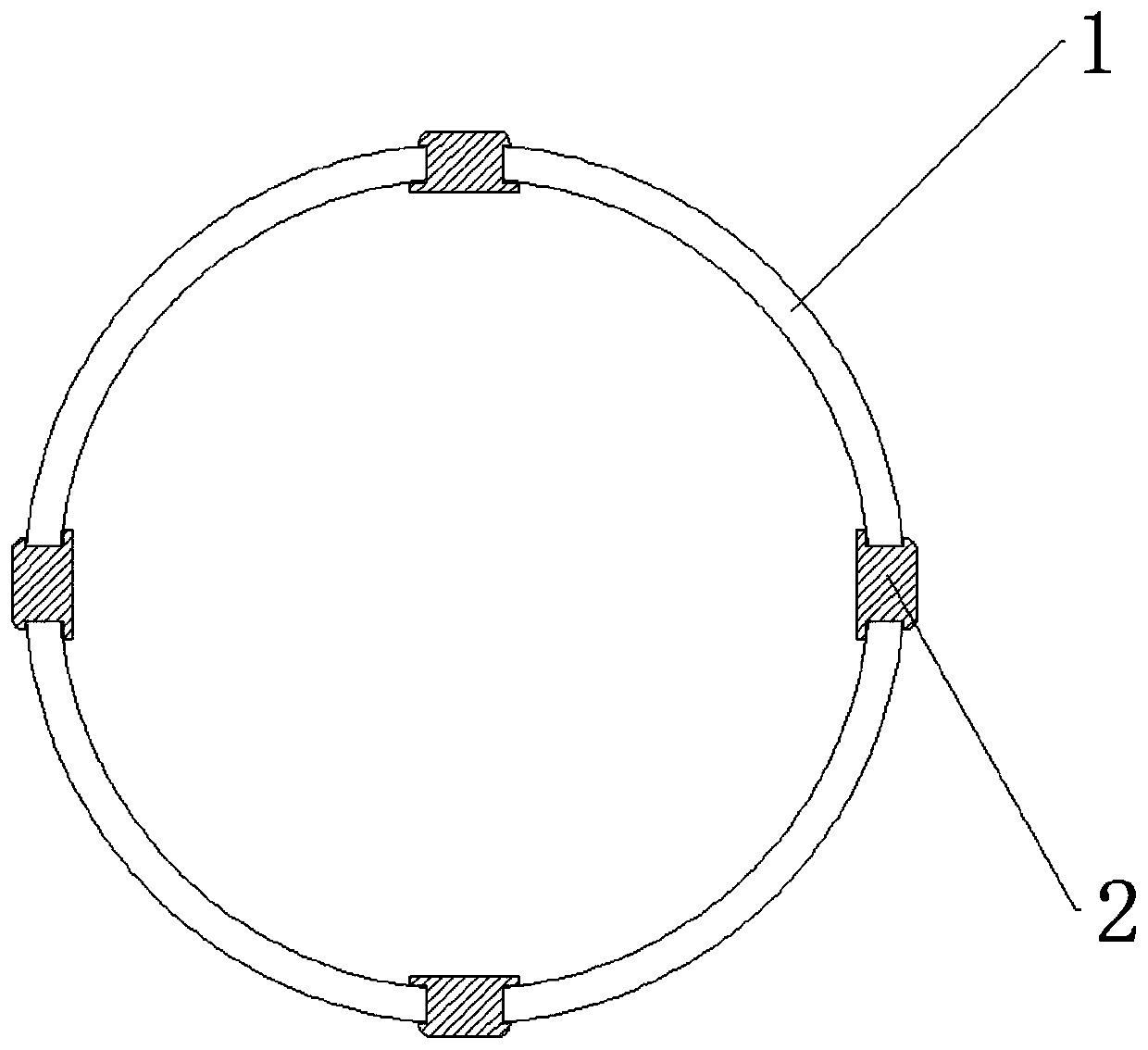

Image

Examples

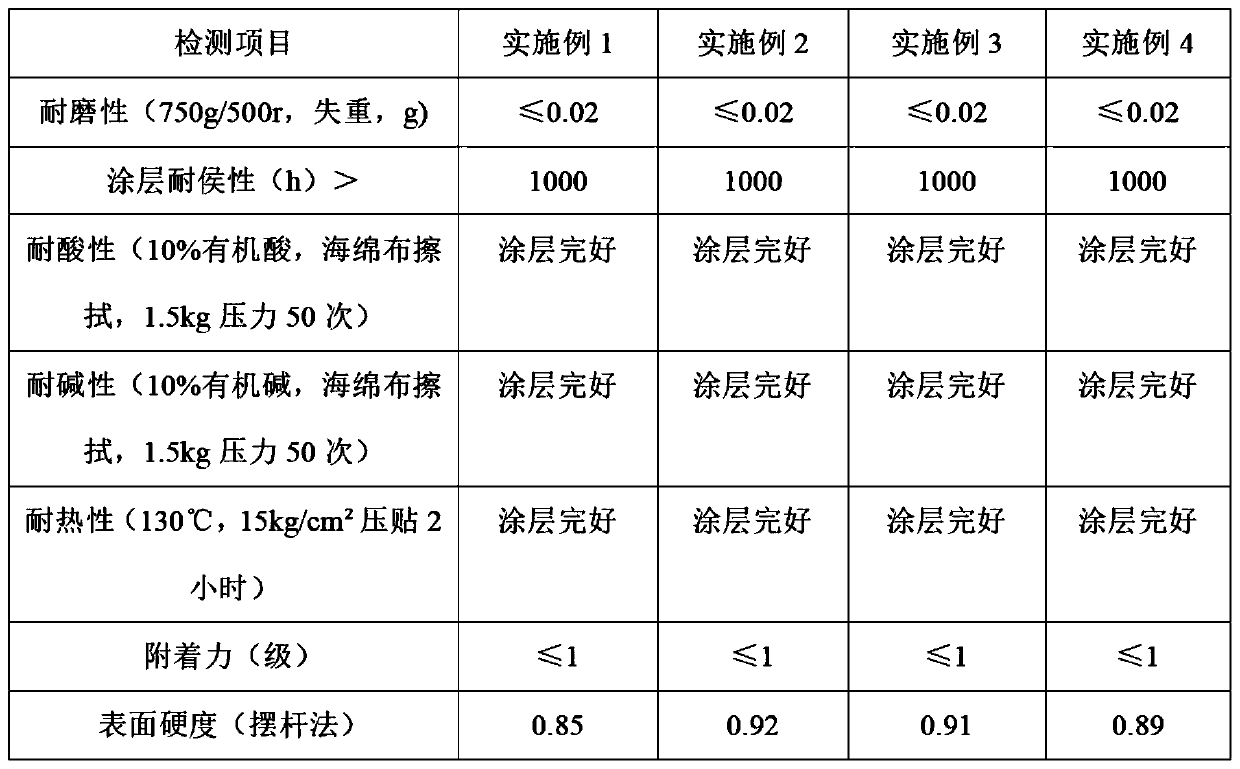

Embodiment 1

[0039] A polyurethane coating for aircraft plexiglass, in percentage by weight, comprising the following components after mixing the raw materials to form a solution, which is made after coating and curing:

[0040] The proportion of the solution is: 10% isocyanate, 5% diol, 15% triol, 0.0005% catalyst, 0.015% antistatic agent, 0.035% surfactant, 0.5% antioxidant, 1% ultraviolet absorber, fluid Leveling agent 0.3%, surplus are organic solvents, and the preparation method of solution comprises the following steps:

[0041] Step 1. Add isocyanate, diol, surfactant, and antistatic agent into the flask, put it in an oil bath, heat and stir, set the temperature at 80°C, until the solution is transparent and clear;

[0042] Step 2: Add trihydric alcohol, leveling agent, UV absorber, and antioxidant into another flask, heat and stir in an oil bath, and put in an appropriate amount of rotary spray balls at the same time, set the temperature at 90°C until all dissolved;

[0043] The ...

Embodiment 2

[0051] A polyurethane coating for aircraft plexiglass, in percentage by weight, comprising the following components after mixing the raw materials to form a solution, which is made after coating and curing:

[0052] The proportion of the solution is: 12% isocyanate, 4% diol, 18% triol, 0.0005% catalyst, 0.015% antistatic agent, 0.035% surfactant, 0.5% antioxidant, 1% ultraviolet absorber, fluid Leveling agent 0.3%, surplus are organic solvents, and the preparation method of solution comprises the following steps:

[0053] Step 1. Add isocyanate, diol, surfactant, and antistatic agent into the flask, put it into an oil bath, heat and stir, set the temperature at 85°C, until the solution is transparent and clear;

[0054] Step 2. Add trihydric alcohol, leveling agent, UV absorber and antioxidant into another flask, heat and stir in an oil bath, and add an appropriate amount of rotary spray ball at the same time, set the temperature at 90°C until all dissolve;

[0055] The rota...

Embodiment 3

[0063] A polyurethane coating for aircraft plexiglass, in percentage by weight, comprising the following components after mixing the raw materials to form a solution, which is made after coating and curing:

[0064] The proportion of the solution is: 15% of isocyanate, 5% of diol, 19% of triol, 0.0005% of catalyst, 0.015% of antistatic agent, 0.035% of surfactant, 0.5% of antioxidant, 1% of ultraviolet absorber, fluid Leveling agent 0.3%, surplus are organic solvents, and the preparation method of solution comprises the following steps:

[0065] Step 1. Add isocyanate, diol, surfactant, and antistatic agent into the flask, put it in an oil bath, heat and stir, set the temperature at 80°C, until the solution is transparent and clear;

[0066] Step 2. Add trihydric alcohol, leveling agent, UV absorber and antioxidant into another flask, heat and stir in an oil bath, and add an appropriate amount of rotary spray ball at the same time, set the temperature at 90°C until all dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com