Energy-efficient sol combined mullite castable used for blast furnace air supply branch pipe inner liner

A mullite and castable technology, applied in the field of refractory materials, can solve the problems of high surface temperature, low thermal shock stability, reduced wear resistance of lining structure, etc., and achieve excellent physical and chemical properties, good construction performance, and sealing effect. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be described in detail below in conjunction with the examples. Before making the present invention, the applicant has done a lot of investigation and research on the existing problems in the prior art, such as the temperature rise and redness of the surface of the blast furnace air supply branch pipe, and the serious heat dissipation of the tube shell.

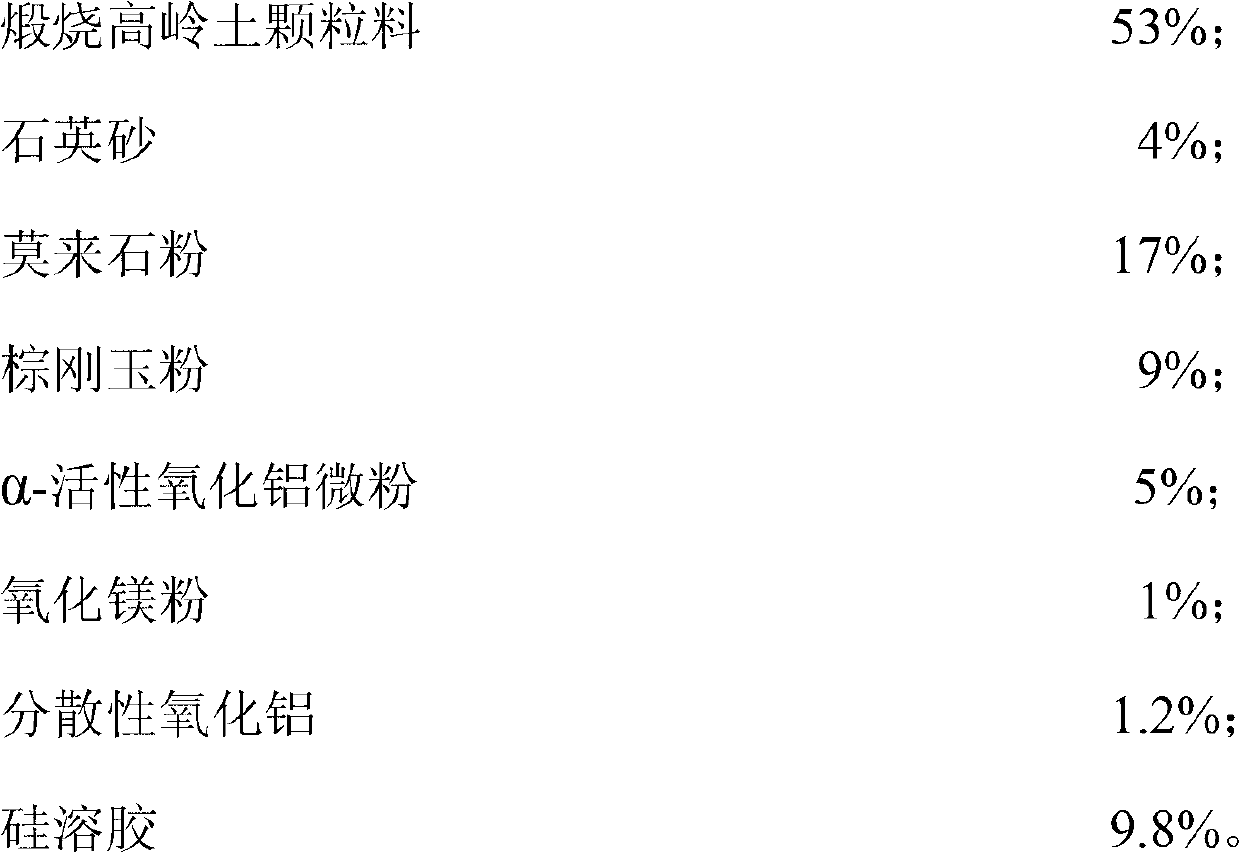

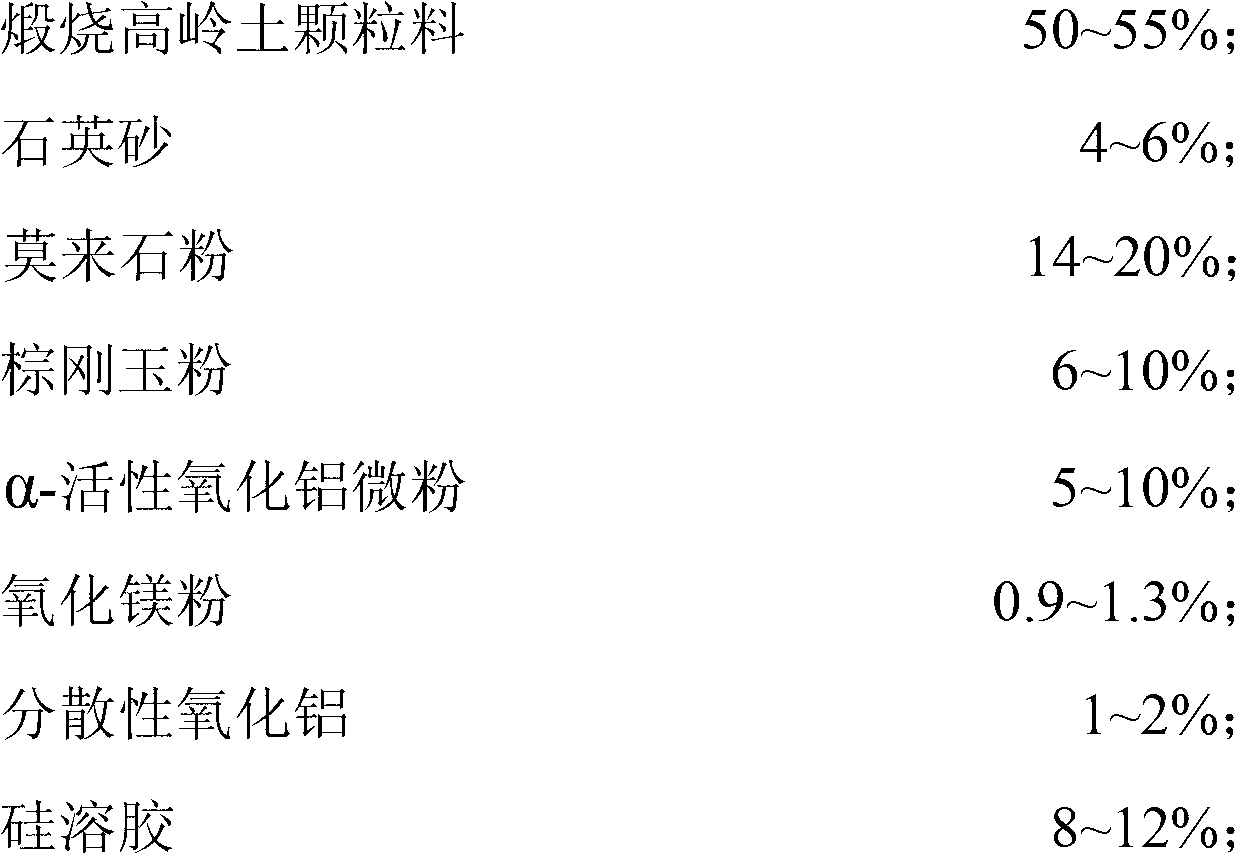

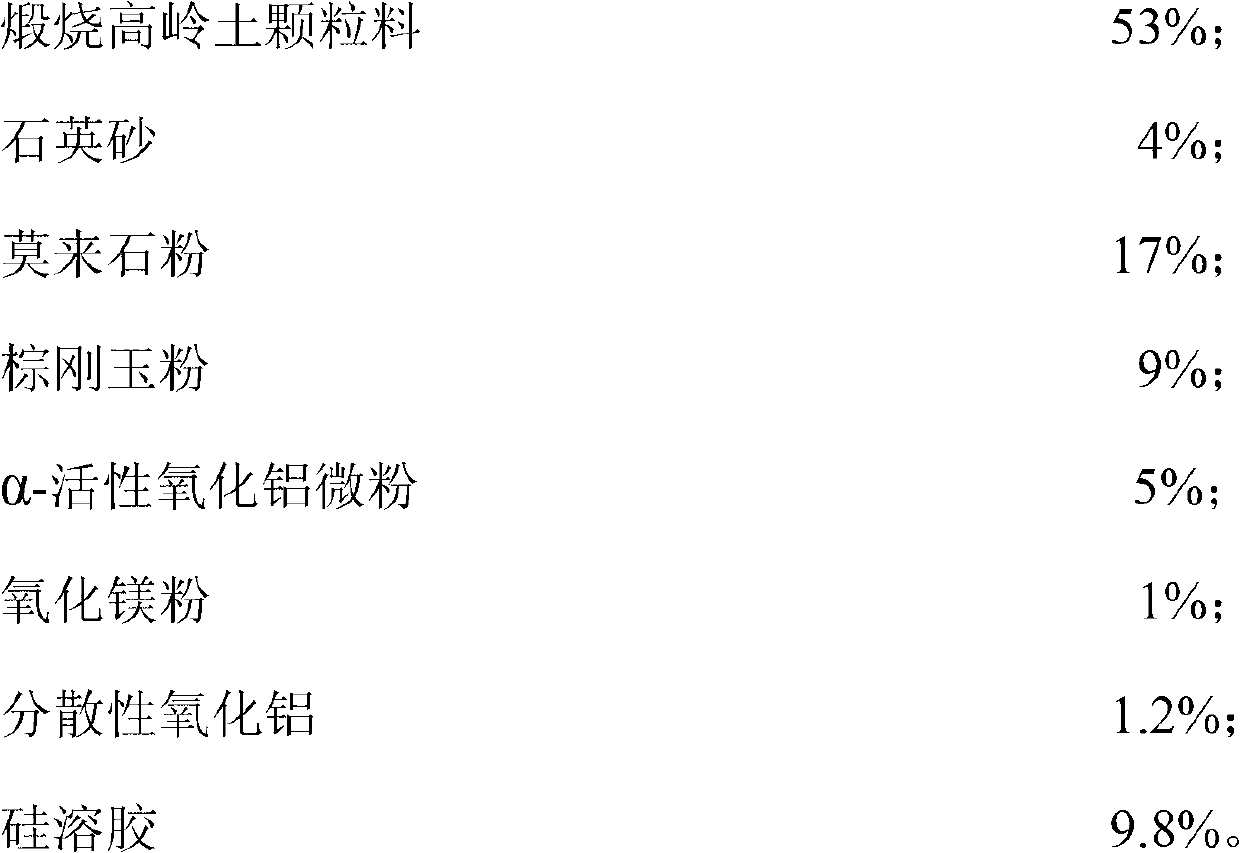

[0030] The following table 1 shows the physical and chemical properties and usage of low-cement castables for the lining of blast furnace air supply branch pipes produced by a certain factory:

[0031] Table 1. Physicochemical properties and usage of low-cement pouring lining of blast furnace air supply branch pipe in a factory

[0032]

[0033]The lining material of the air supply branch pipe in this factory is made of low-cement castables. During the production process, due to the characteristics of the cement binder, it takes 5-8 hours to remove the formwor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com