A method and system for welding double symmetrical heat sources based on soft-arc plasma

A technology of plasma welding and welding method, which is applied in the field of ion double symmetrical heat source welding, can solve the problems of continuous development hidden dangers, low-level quality, and product quality fluctuations, and achieve the effect of improving welding quality, improving quality, and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

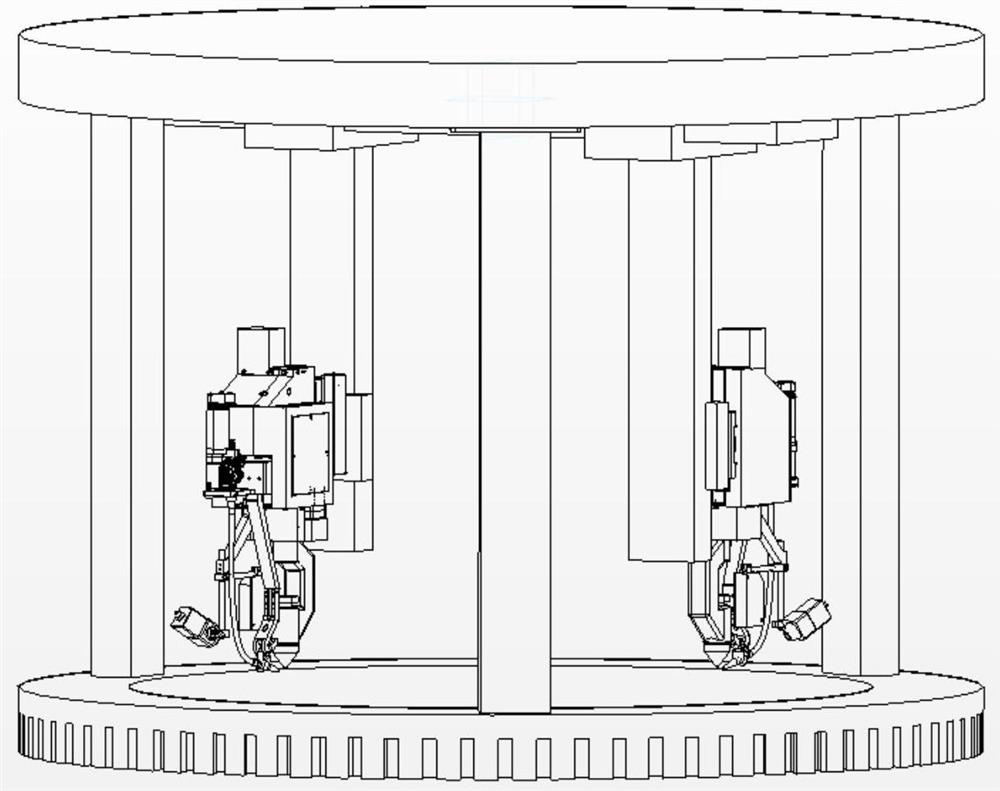

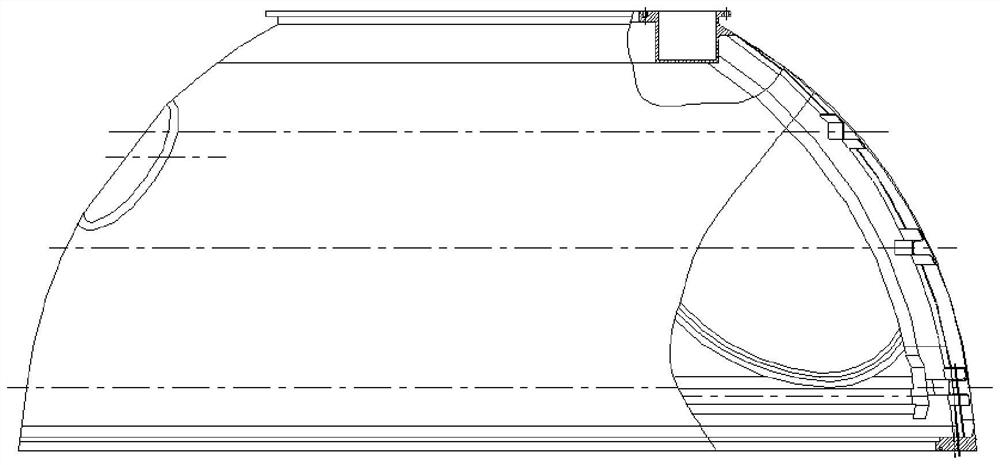

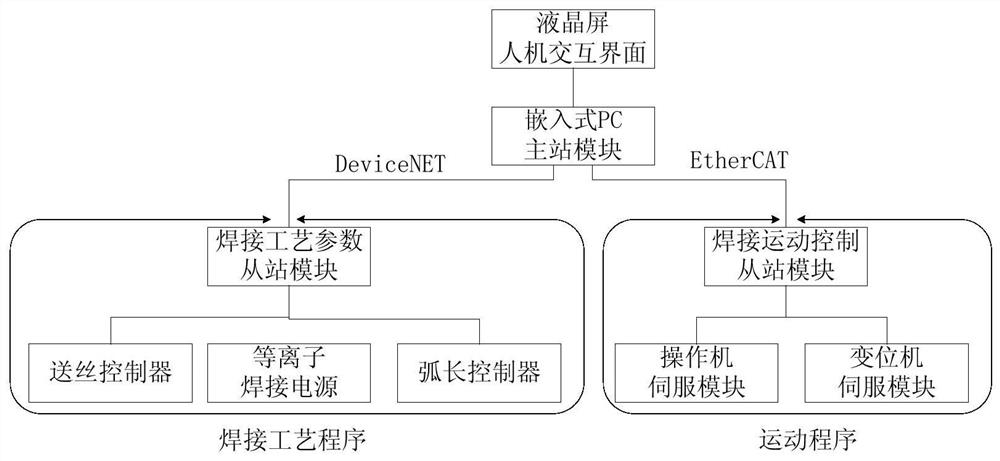

[0028] In view of the deficiencies in the prior art, the present invention proposes a double-symmetrical heat source welding method based on soft-arc plasma, which can effectively reduce post-weld deformation and improve the quality of the weld, especially for the weld between the skin and the flange in the large-scale sealed cabin structure. The welding has unique advantages. The system of the present invention is as figure 1 As shown, two groups of heads are symmetrically arranged and welded at the same time. Each welding torch welds a 180-degree weld ring to reduce welding deformation caused by asymmetrical heat input. Each group of welding heads is centered on a soft-arc plasma welding torch , to further reduce heat input, thereby reducing welding deformation, and automatic welding can significantly improve welding quality compared with manual welding. Therefore, in view of the welding requirements of complex thin-walled airtight cabins in manned follow-up missions, fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com