Method for preparing microelectrolysis filler by using various industrial solid wastes

A solid waste and solid waste technology is applied in the field of preparing micro-electrolytic fillers, which can solve the problems of high cost of sewage treatment, large market demand for iron filings, and high cost of treating sewage with iron filings treatment layer, so as to avoid the oxide film on the surface of the filler. The effect of forming, increasing the rate of electrochemical corrosion, and solving the problem of passivation of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

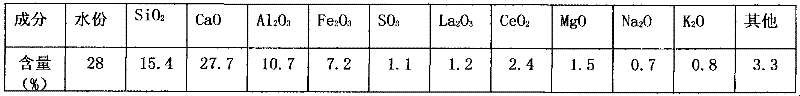

[0027] The converter dust sludge and blast furnace dust sludge of Baotou Steel Group are mixed according to the weight ratio of converter dust sludge:blast furnace sludge = 2:1 to form metallurgical comprehensive iron-containing sludge.

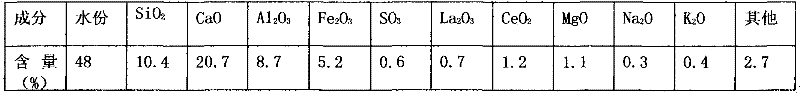

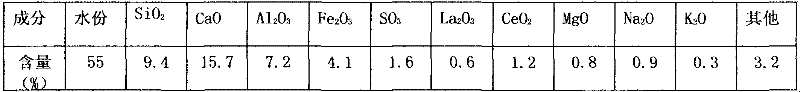

[0028] According to the comprehensive iron-containing dust sludge of Baotou Steel Group: the waste activated carbon of Shandong Xinhua Pharmaceutical Co., Ltd.: the sludge produced by physicochemical treatment of high-concentration organic sewage of Shandong Xinhua Pharmaceutical Co., Ltd.: bentonite: water glass=70wt.%: 15wt. %: 5wt.%: 7wt.%: 3wt.% The ratio is mixed evenly.

[0029] At a pressure of 1.68×10 8 Pa is pressed into an oval spherical shape with a particle size of 15-25mm.

[0030] Then place it in a roasting furnace with a temperature of 1250°C, use waste activated carbon from Shandong Xinhua Pharmaceutical Co., Ltd. as a reducing material, and roast for 5 hours to reduce FeO to metallic iron, so that the metal iron-carbon, met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com