Double-metal macromolecule permeable reactive barrier stuffing material and preparation method thereof

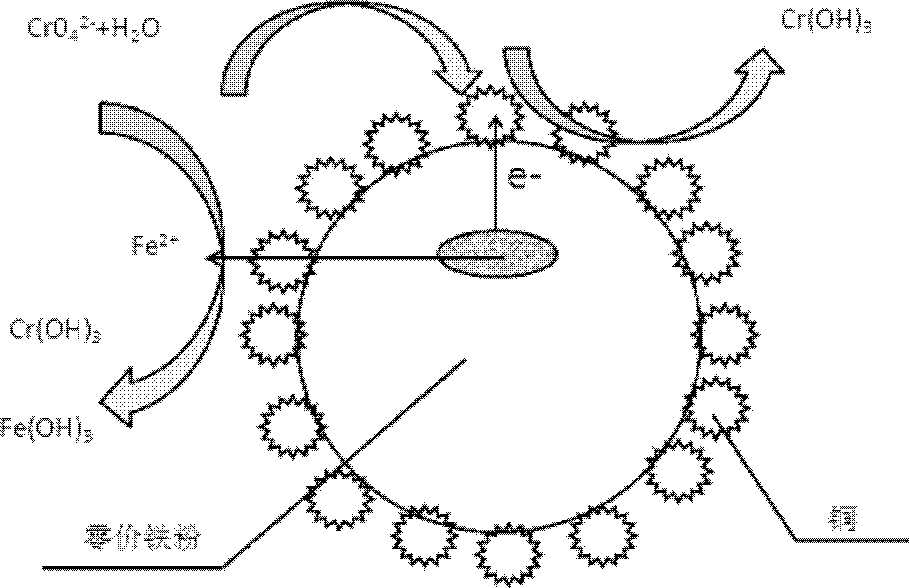

A permeable reaction wall and bimetallic technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the problem of inability to fully utilize the specific surface area of zero-valent iron and the formation of nano-scale bimetallic particles Poor performance, unable to meet the strength requirements of engineering applications, etc., to achieve the effect of extremely high chromium removal efficiency, strong Cr(VI) removal ability, and solve the problem of filler strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

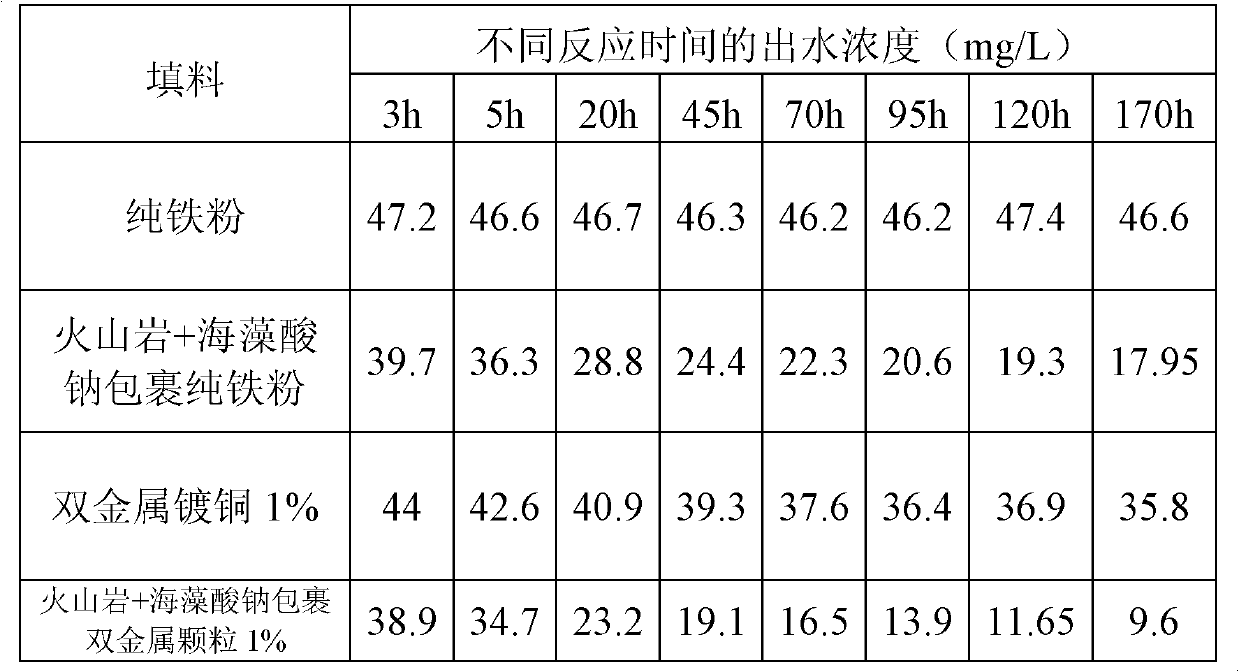

Embodiment 1

[0050] Take 1-3mm volcanic rock and wash it with distilled water for 3 times, then put it in a constant temperature drying box and dry it at 110°C for later use; take 200 mesh zero-valent iron powder with a purity of 98%, wash it with 0.5mol / L hydrochloric acid, and then wash it with water for 3 times until medium After drying, take out the wet iron powder and dry it for later use; put the above iron powder in CuCl 2 Metal Cu with a mass fraction of 1% was plated on the solution through a displacement reaction. After 30 minutes of reaction, the wet bimetal was taken out and placed in a constant temperature drying oven at 40°C for 6 hours. Add to 100mL distilled water, stir well, heat and dissolve at a constant temperature of 85°C, and set aside after the dissolution is complete; weigh 0.505g of bimetallic particles, add them to the prepared sodium alginate solution, and stir at high speed to disperse the bimetallic particles in the solution ;Add volcanic rock to the mixed solu...

Embodiment 2

[0053] The difference from Example 1 is:

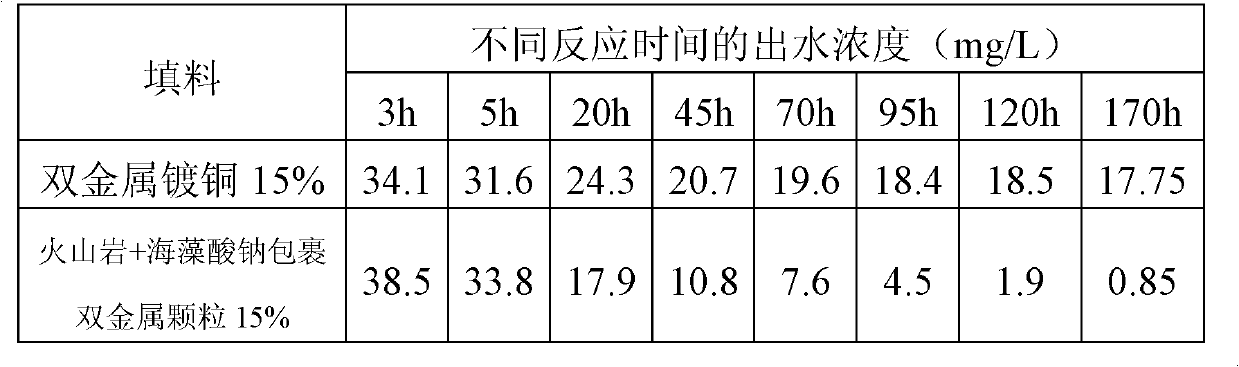

[0054] Place the above iron powder in CuCl 2 Metal Cu with a mass fraction of 15% was plated in the solution through a displacement reaction, and after 30 minutes of reaction, the wet bimetal was taken out and placed in a constant temperature drying oven at 40°C for 6 hours, and 0.588 g of bimetal particles were weighed. Ratio and manufacturing process are identical with embodiment 1.

[0055] The fillers prepared in this example and the fillers used for experimental comparison (15% bimetallic copper plating, 15% volcanic rock+sodium alginate wrapped bimetallic particles) were all added to the Cr(VI ) waste water, the zero-valent iron content in all the above-mentioned fillers is 0.5g, and the experimental results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com