Process method for heavy metal wastewater treatment

A technology of wastewater treatment and process method, which is applied in water/sewage treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc. Easy to block and other problems, to solve the plate passivation, reduce the frequency of system maintenance, ensure smooth and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

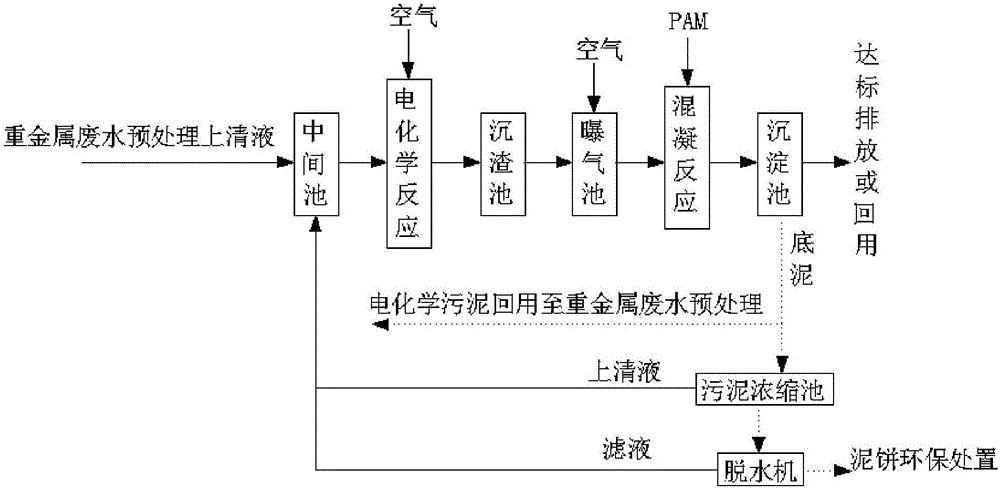

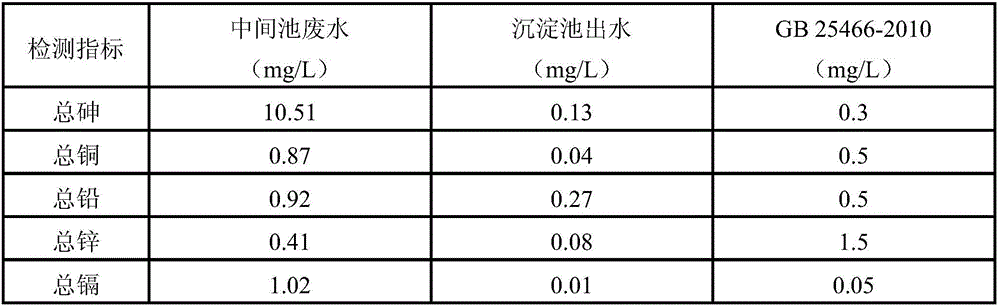

[0040] A process method for heavy metal wastewater treatment of the present invention, such as figure 1 As shown, the heavy metal wastewater used is the pretreated production wastewater of a lead-zinc smelting enterprise, mainly including the acidic heavy metal wastewater clear liquid after lime neutralization and pretreatment. The process method comprises the following steps:

[0041] (1) Send the pretreated heavy metal wastewater supernatant (that is, the heavy metal wastewater pretreatment supernatant) into the intermediate pool, and the intermediate pool clear liquid is 50m 3 The amount of water per hour is discharged into the electrochemical equipment for electrochemical reaction. The SS in the clear liquid is ≤200mg / L, the pH is 7~11, the total amount of heavy metals is ≤100mg / L, and 1.7m 3 / min of air for intermittent aeration, each intermittent aeration air charge is 2 times the amount of wastewater treatment by electrochemical equipment, that is, the volume ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com