Anti-scaling device for pipeline

An anti-scaling and pipeline technology, applied in pipeline anti-corrosion/anti-rust protection, pipeline protection, damage protection, etc., to achieve the effect of reducing crystal formation, convenient connection and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

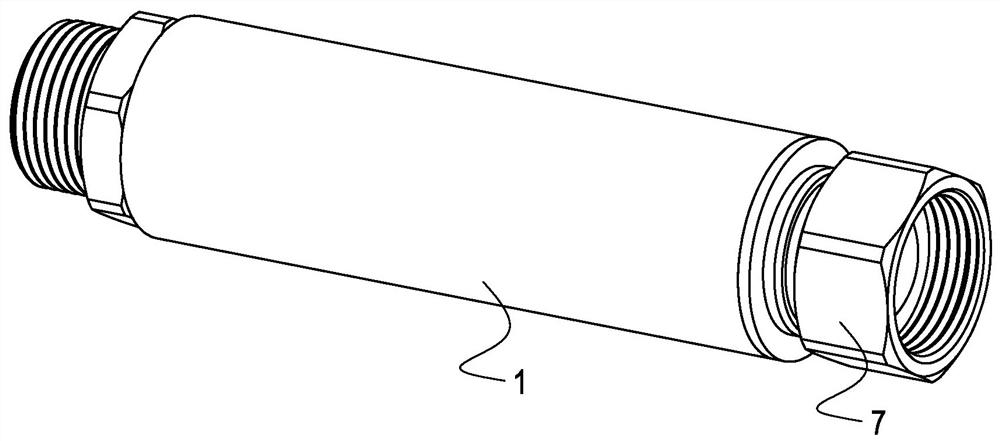

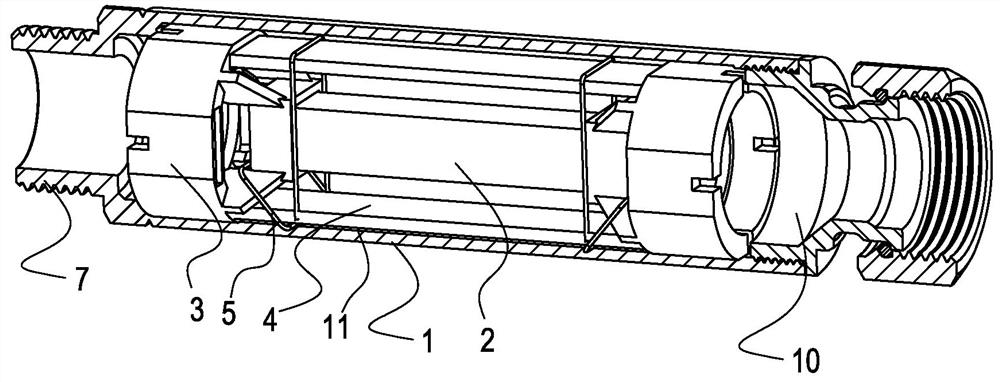

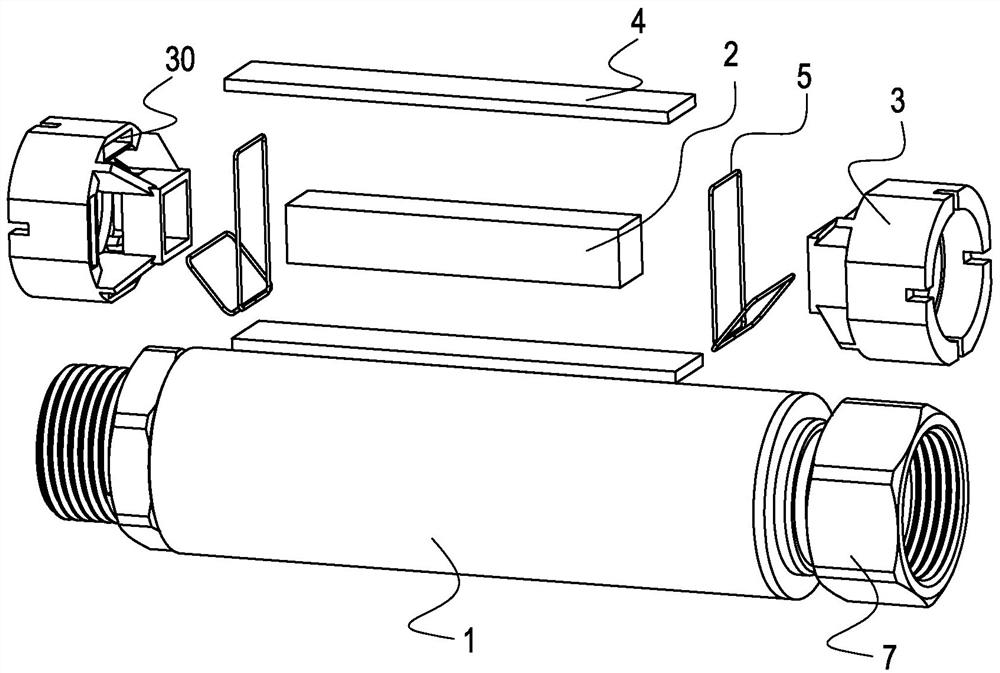

[0026] as attached figure 1 to attach image 3 The preferred embodiment 1 shown is a pipeline anti-scaling device. The main body 1 is in a tubular structure, and the two ends are provided with a pipeline connection structure 7; The two ends are fixed in the tubular inner cavity 10 through the fixing seat 3; the temperature-resistant zinc alloy body 4 is also fixed on the fixing seat 3, and there is a gap distance between the temperature-resistant zinc alloy body 4 and the pipe wall 11 and the magnetic body 2; There is an anode element 5 of the primary battery in contact with the temperature-resistant zinc alloy body 4 .

[0027] The main body 1 has a tubular structure without bending or circuitous flow channels, and has good hydraulic characteristics. It solves the problems of large flow resistance and greatly reduced water pressure cause...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com