Tab cutting device and method for soft package lithium battery

A soft-packed lithium battery and tab technology, which is applied in the field of tab cutting devices for soft-packed lithium batteries, can solve the problems of fluctuation in the gap between the upper cutter and the lower cutter, no tab wire drawing prevention mechanism, and increased company costs, etc. Achieve the effect of avoiding the problem of continuous cutting, avoiding the problem of passivation of the cutter, and avoiding the drawing of the tabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0042] A lug cutting device and method for a soft-pack lithium battery designed by the present invention, the cutting device of the present invention has self-adaptive capability, including the self-adaptive welding position of the cutter, the scraper unit to prevent the leftovers, the sharpening unit to grind the cutter and The automatic adjustment of the gap solves the technical problem of tab cutting in the tab cutting process in the lithium battery manufacturing process.

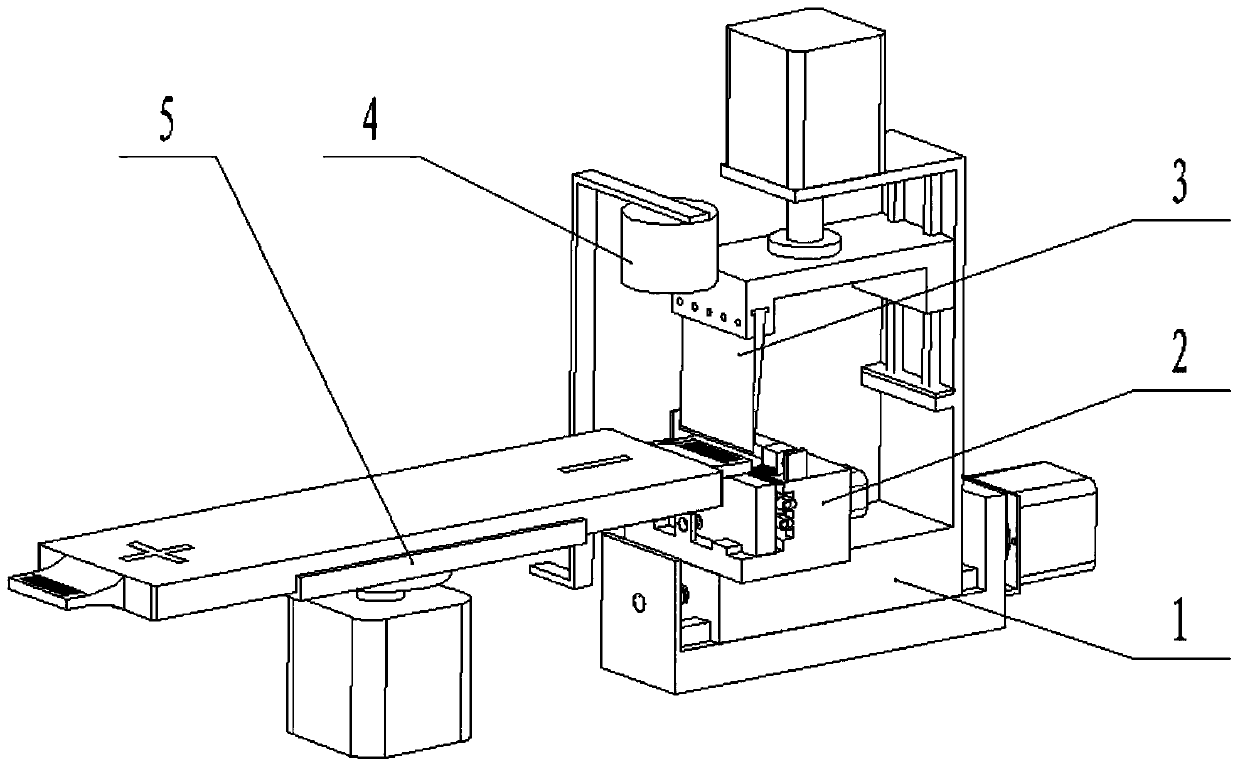

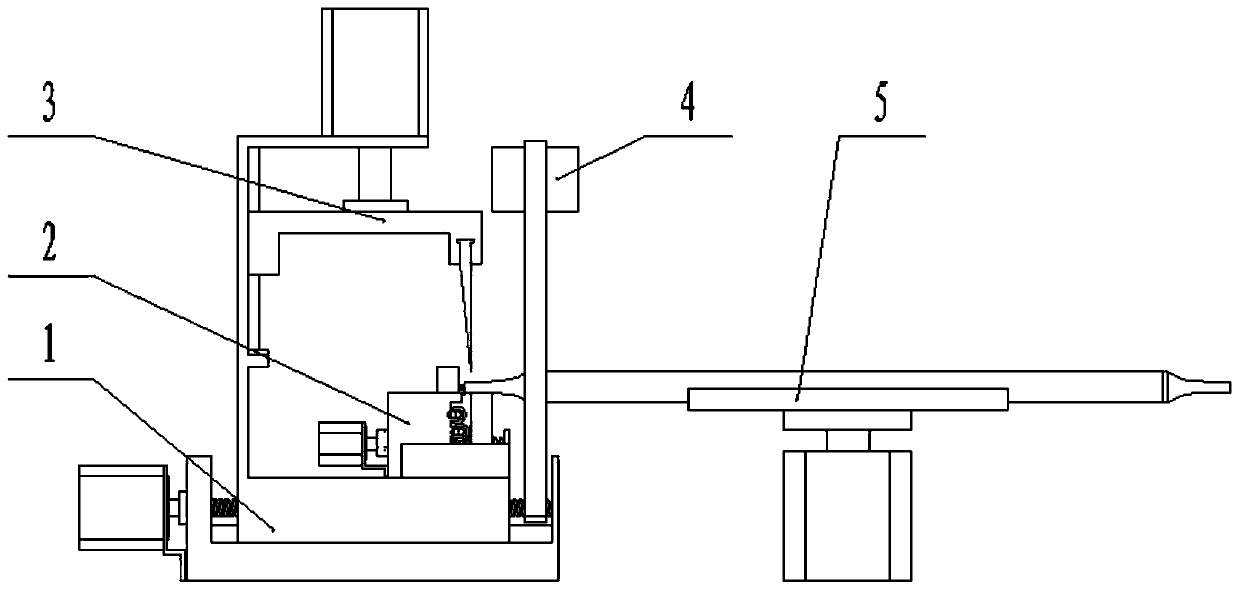

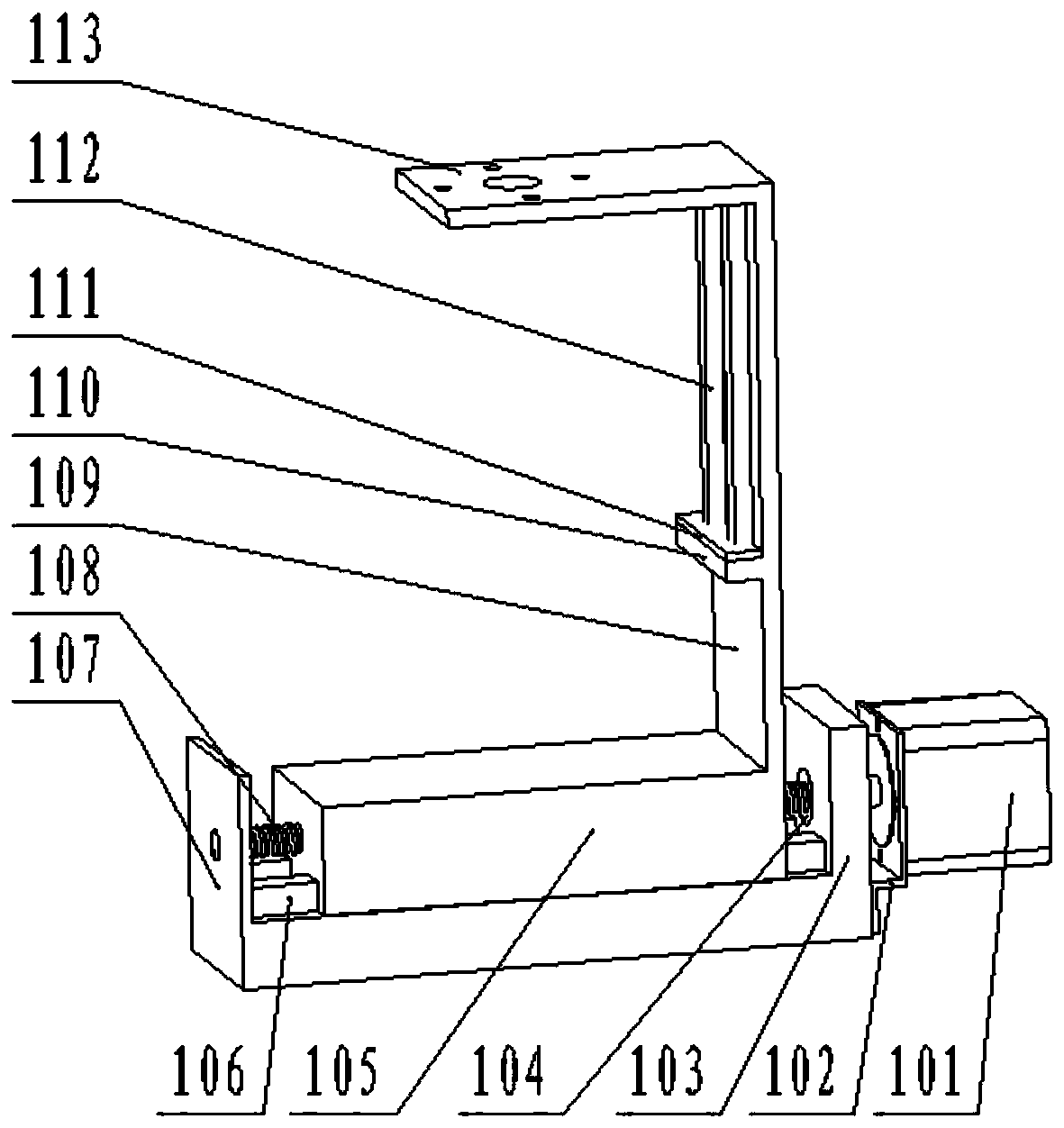

[0043] see Figure 1 to Figure 13 As shown, a tab cutting device for a soft-pack lithium battery is composed of a cutter driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com